Novel wind ring assembly of automobile engine

A technology of automobile engine and wind protection ring, applied in the direction of engine components, machine/engine, engine cooling, etc., can solve the problems of low production efficiency, cumbersome vulcanization process, low assembly efficiency of wind protection ring assembly, etc. zoom out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

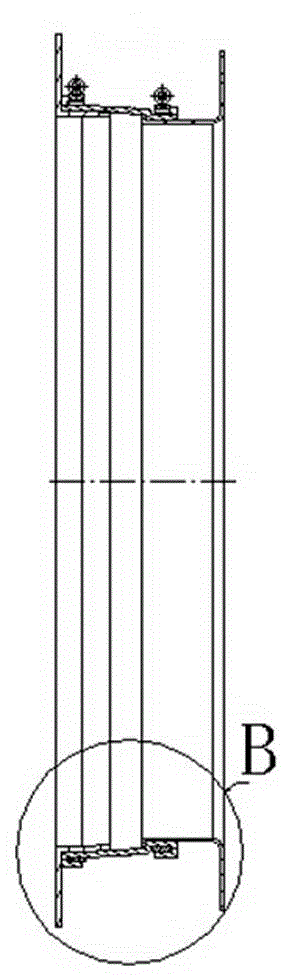

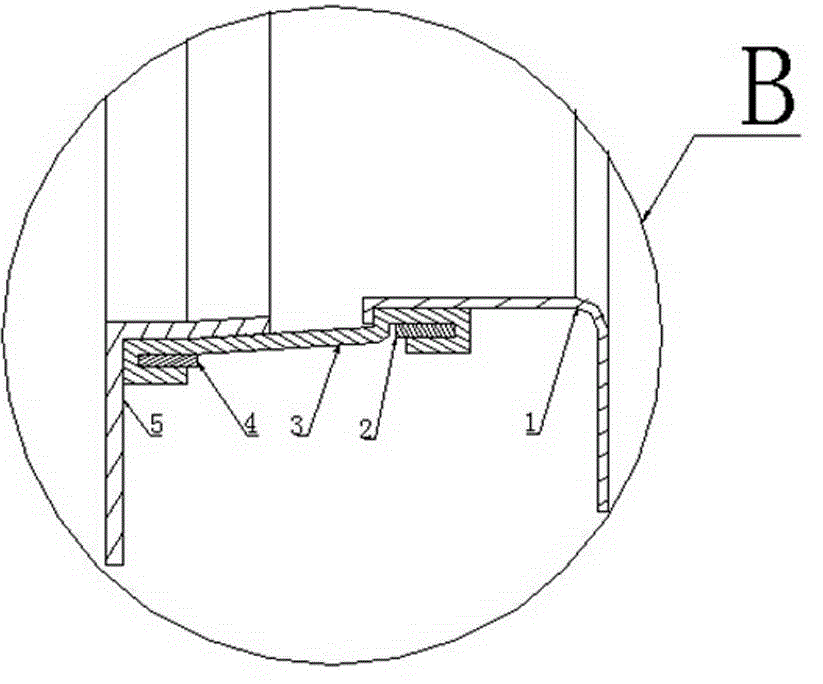

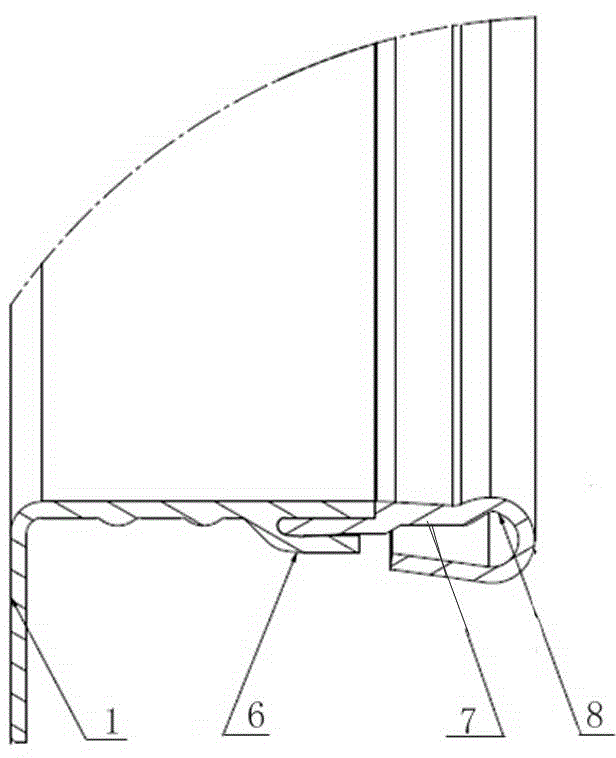

[0017] The present invention as image 3 , 4 , 5, 6, 7, and 8.

[0018] A new windshield assembly for an automobile engine, including a windshield 1, an open-type riveting structure 6 is provided on the journal of the windshield 1, and a rubber ring 7 is put into the open-type riveting structure 6, and pressure is applied to make the opening The opening of the type pressure riveting structure 6 is narrowed and the rubber ring 7 is clamped to form a wind protection ring assembly, wherein the rubber ring 7 is axially extended to form a bell mouth.

[0019] The connecting section between the axial extension of the rubber ring 7 and the windshield 5 is provided with a thickness mutation structure 8, so that the rubber ring 7 can be folded freely.

[0020] The opening angle a of the bell mouth is 10°~50°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com