Permanent magnet synchronous motor for hoisting mechanism of direct-drive crane

A technology of permanent magnet synchronous and hoisting mechanism, applied in synchronous machine, electromechanical device, spring mechanism, etc., can solve the problems of low efficiency, high cost of dragging system, difficult maintenance, etc., to enhance reliability and improve transmission. Efficiency and the effect of reducing maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

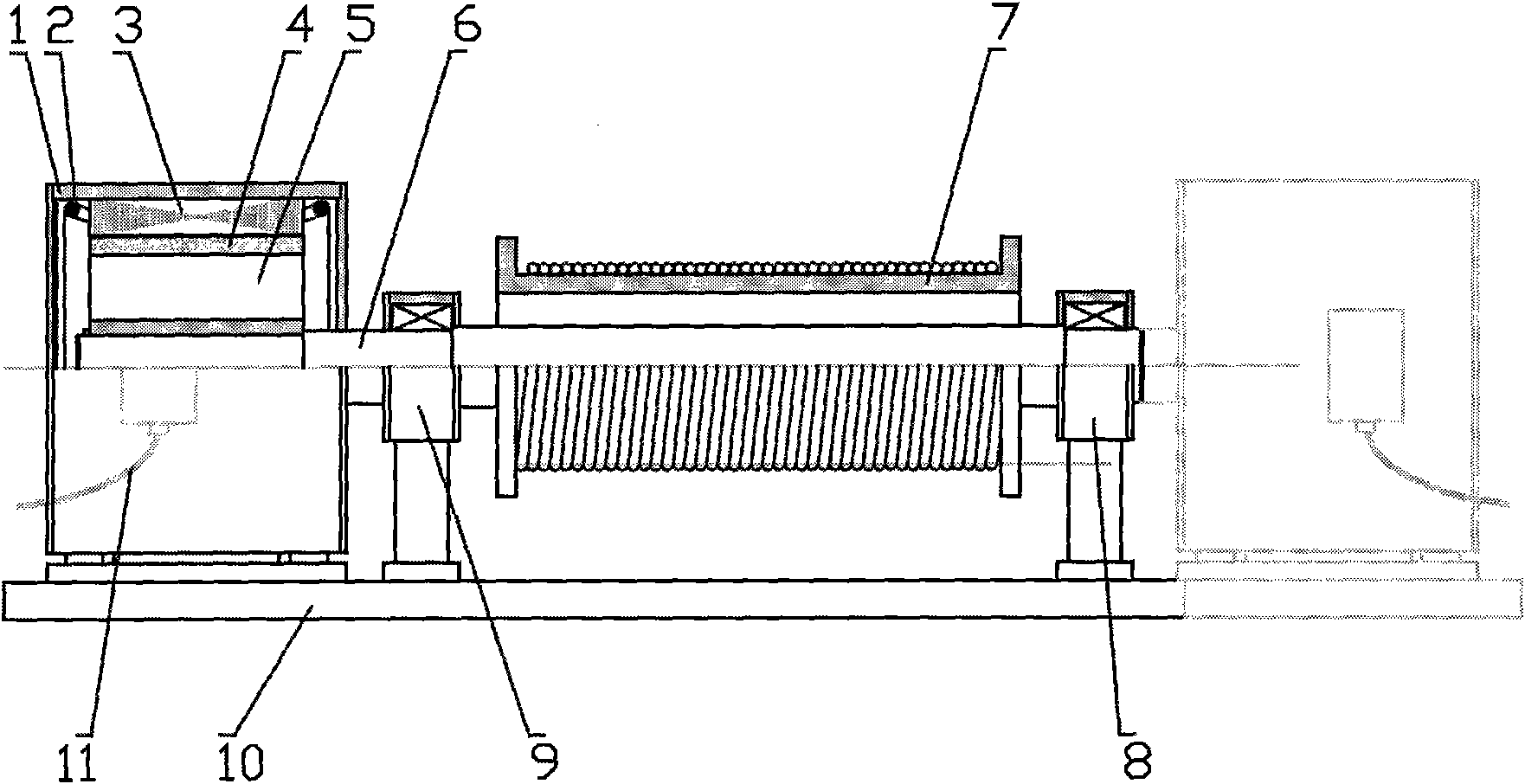

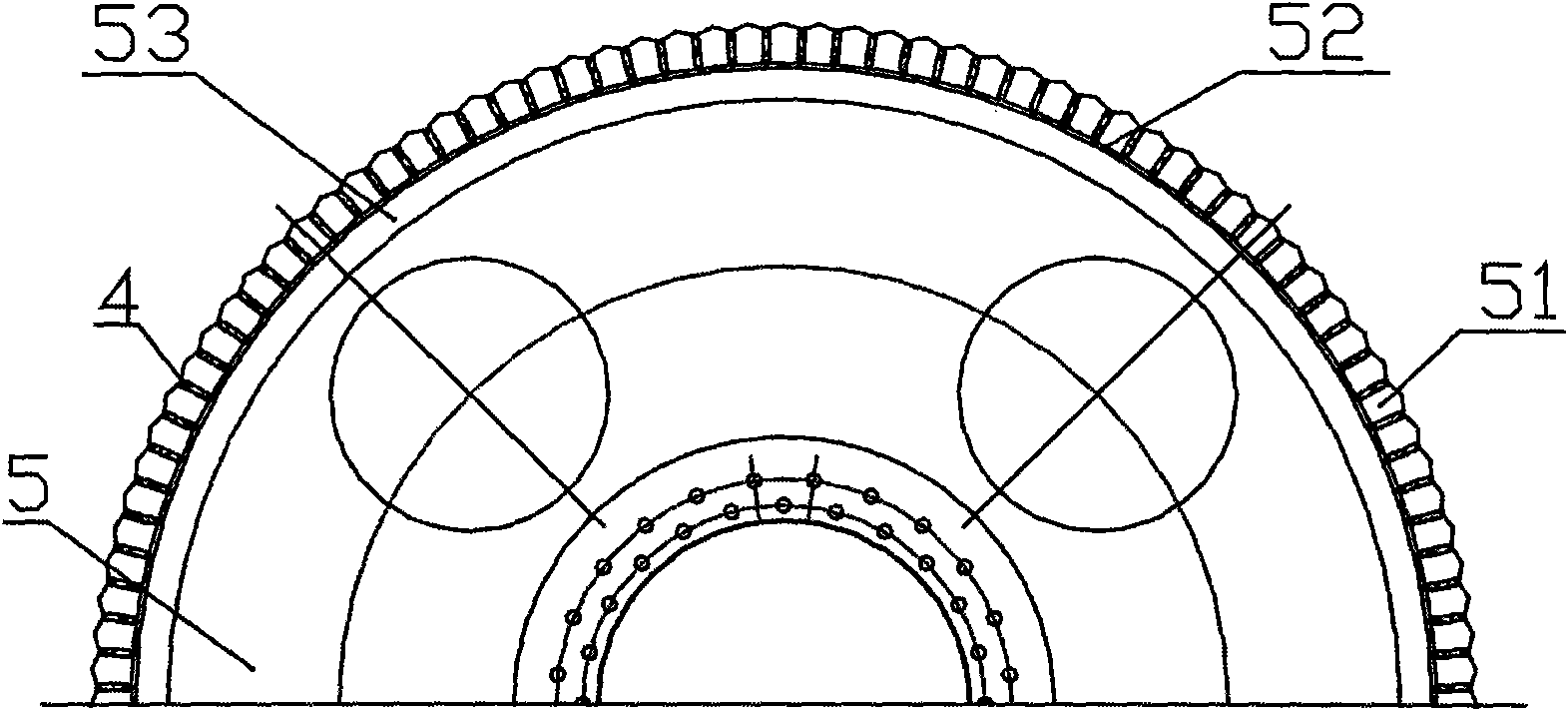

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] Please refer to figure 1 and figure 2 The permanent magnet synchronous motor for the hoisting mechanism of a direct drive crane in this embodiment comprises: a permanent magnet synchronous motor housing 1, a stator winding 2, a stator core 3, a permanent magnet 4, a rotor 5, a rotor pole 51, and a magnetic isolation steel ring 52, rotor support shaft 53, reel rotating shaft 6, reel 7, right bearing 8 for reel, left bearing 9 for reel, machine base 10, inverter power supply lead 11. The permanent magnet synchronous motor housing 1 is fixed on the base 10 of the hoisting mechanism of the crane, the stator core 3 is directly installed on the permanent magnet synchronous motor housing 1 with bolts, the stator winding 2 is distributed on the stator core 3, and the rotor 5 is placed on the On the reel rotating shaft 6, the rotor magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com