A kind of spring end surface grinding device and grinding method thereof

A technology of end faces and mounting seats, which is applied in the direction of grinding drive devices, grinding machines, grinding slides, etc., can solve the problems of affecting the grinding quality, differences, and changes in height and position, so as to improve the grinding quality, improve the grinding effect, reduce the The effect of radial runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

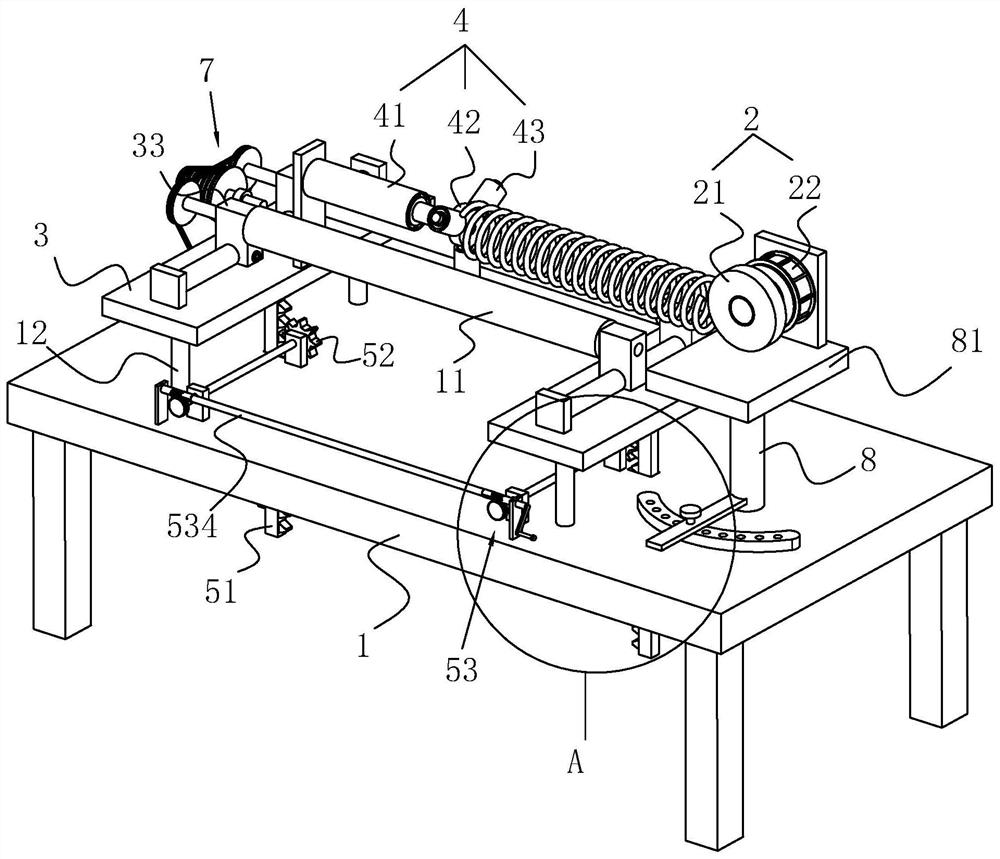

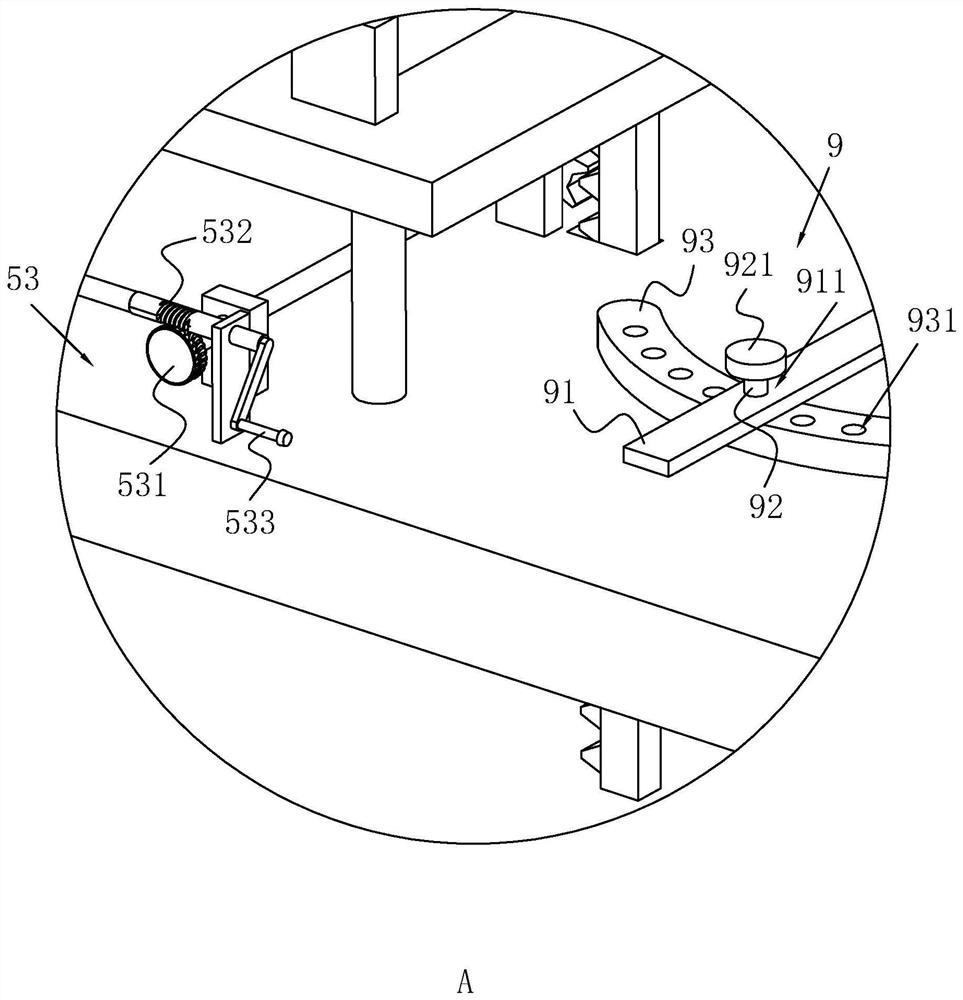

[0045] Such as figure 1 As shown, a spring end face grinding device includes a bottom plate 1 on which a grinding assembly 2 for grinding springs is arranged. The grinding assembly 2 includes a grinding wheel 21 and a rotating motor 22 . The bottom plate 1 is provided with a mounting plate 3, and two mounting plates 3 are arranged in parallel. Two rotating rollers 11 are horizontally arranged on the mounting plate 3 .

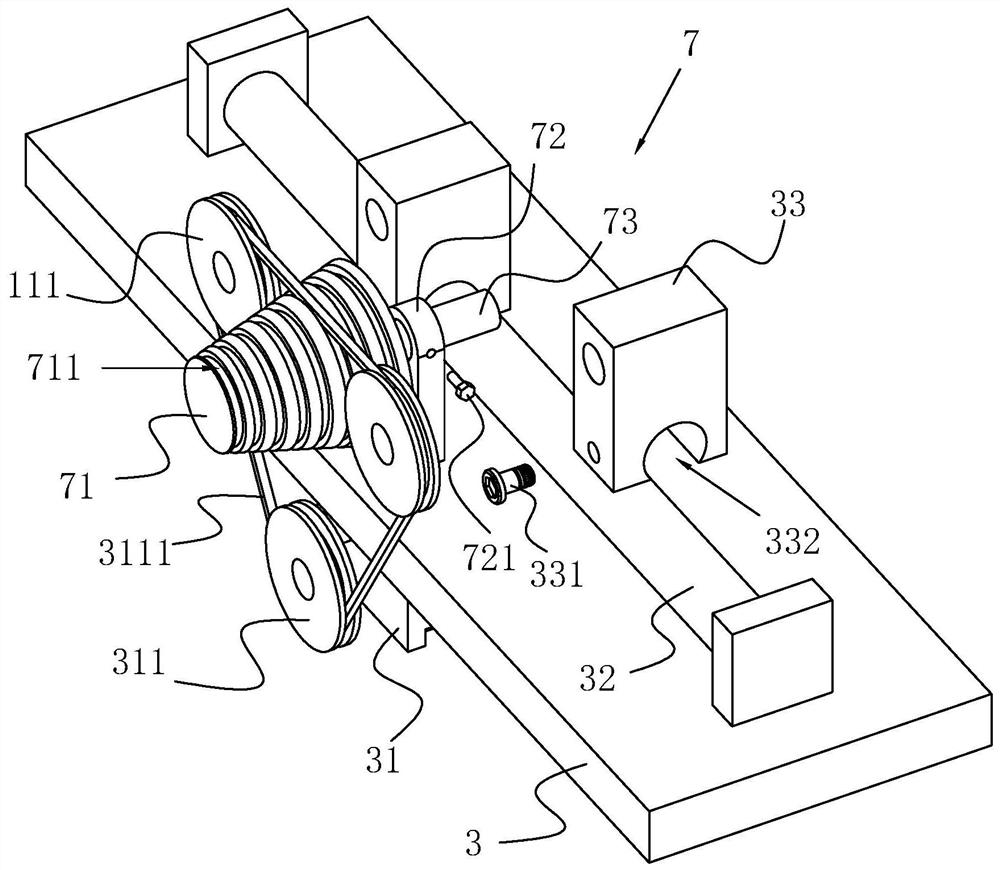

[0046] Such as figure 1 , 3 As shown, guide rail 32 is fixedly arranged on the mounting plate 3 along the radial direction of rotating roller 11, and guide rail 32 is provided with two, and the cross section of guide rail 32 is circular; The bottom wall of the block 33 is provided with a chute 332 adapted to the guide rail 32 ;

[0047] Such as figure 1 , 3 As shown, the rotating roller 11 is rotatably disposed on the mounting block 33, and the mounting block 33 is provided with a limiting member 331 for limiting the position of the mounting block 33; the...

Embodiment 2

[0063] A method for grinding a spring end face, using a spring end face grinding device for grinding, comprising the following steps:

[0064] S1, place the spring to be polished on the two rotating rollers 11;

[0065] S2, rotate the mounting seat 81, adjust the position of the mounting seat 81, so that the spring contacts the edge of the end face of the grinding wheel 21, and then fix the position of the mounting seat 81 through the fixing assembly 9;

[0066] S3, pressing against the spring through the pressing assembly 4, and applying a certain preload to the spring;

[0067] S4, start the driving source, drive the rotating roller 11 to rotate, so that the spring rotates, then start the rotating motor 22, and the rotating motor 22 drives the emery wheel 21 to rotate, and then the spring is polished;

[0068] S5. After finishing the grinding, stop the motor 22 and the driving source, then loosen the clamping assembly 4 and take off the spring.

[0069] When grinding the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com