Roll mill

A roller mill and frame technology, applied in the field of roller mills, can solve the problems of complicated and time-consuming disassembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

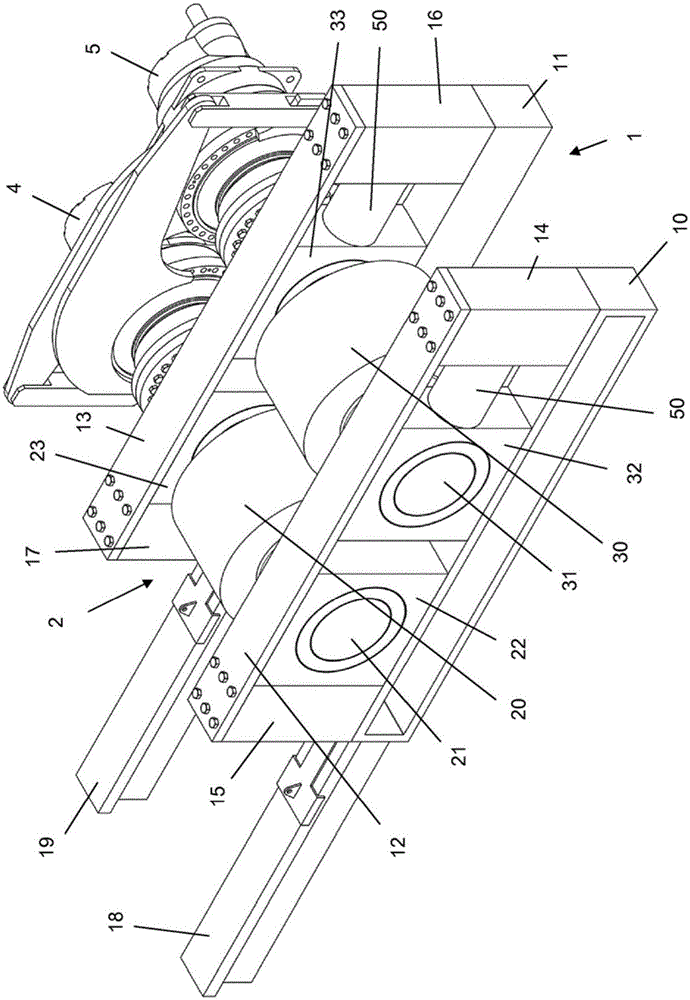

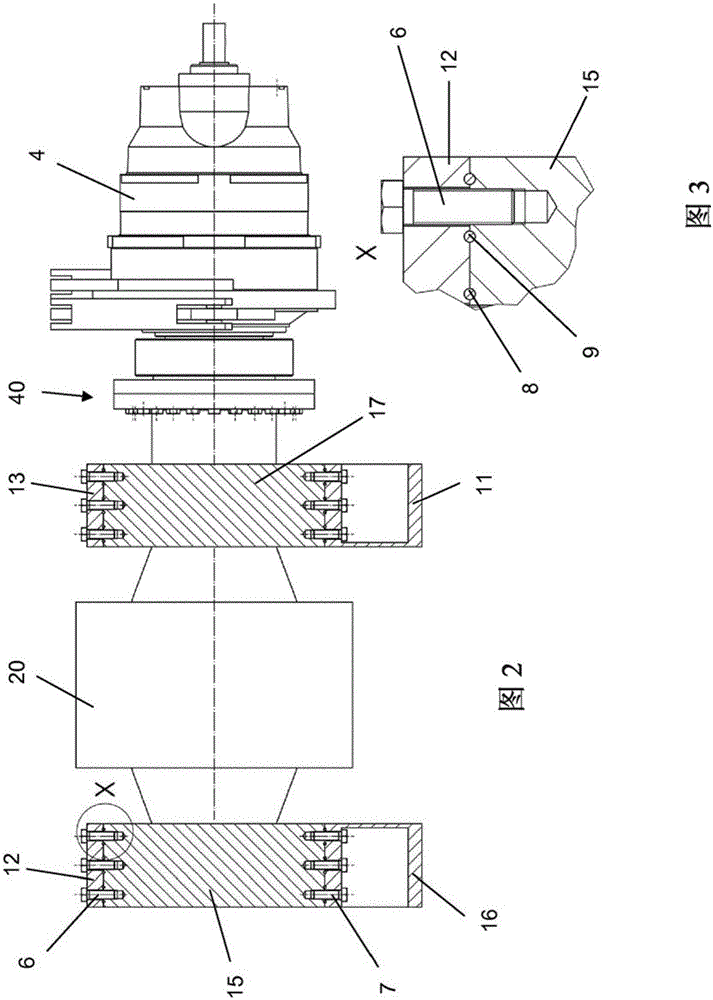

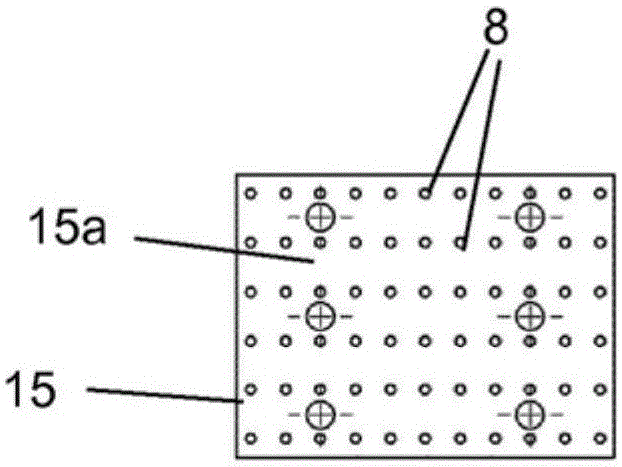

[0029] figure 1 The roller mill shown is a roller press or a material bed type roller mill. The roller mill has, for example, two roller units 2, 3, which are arranged in the frame 1 and in each type In each case, there is a grinding roller 20 or 30, wherein the grinding rollers are arranged opposite to each other, and in each case the grinding rollers are connected to driving devices 4, 5 for driving the grinding rollers in mutually opposite rotations. The frame is composed of two lower frame parts 10 and 11, two upper frame parts 12 and 13, and four compression beams 14-17. The grinding rollers 20, 30 are installed through the respective short shafts 21 or 31 in the respective jewel bearings 22, 23 or 32, 33, wherein the jewel bearings on the lower frame parts 10, 11 and the upper frame parts 12, 13 are slid And can be guided in a displaceable way.

[0030] In the illustrated exemplary embodiment, the roller unit 2 is installed as a fixed roller in the frame 1 and is supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com