Improved dual-support oil wedge-shaped dynamic pressure spindle assembly for conical roller coreless grinding machine

A centerless grinding machine and tapered roller technology, which is applied in the direction of grinding machines, machine tools designed for grinding the rotating surface of workpieces, and parts of grinding machine tools. It can solve the problems of low rotation accuracy, small surface roughness of product processing, and small grinding force And other problems, to achieve the effect of high rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

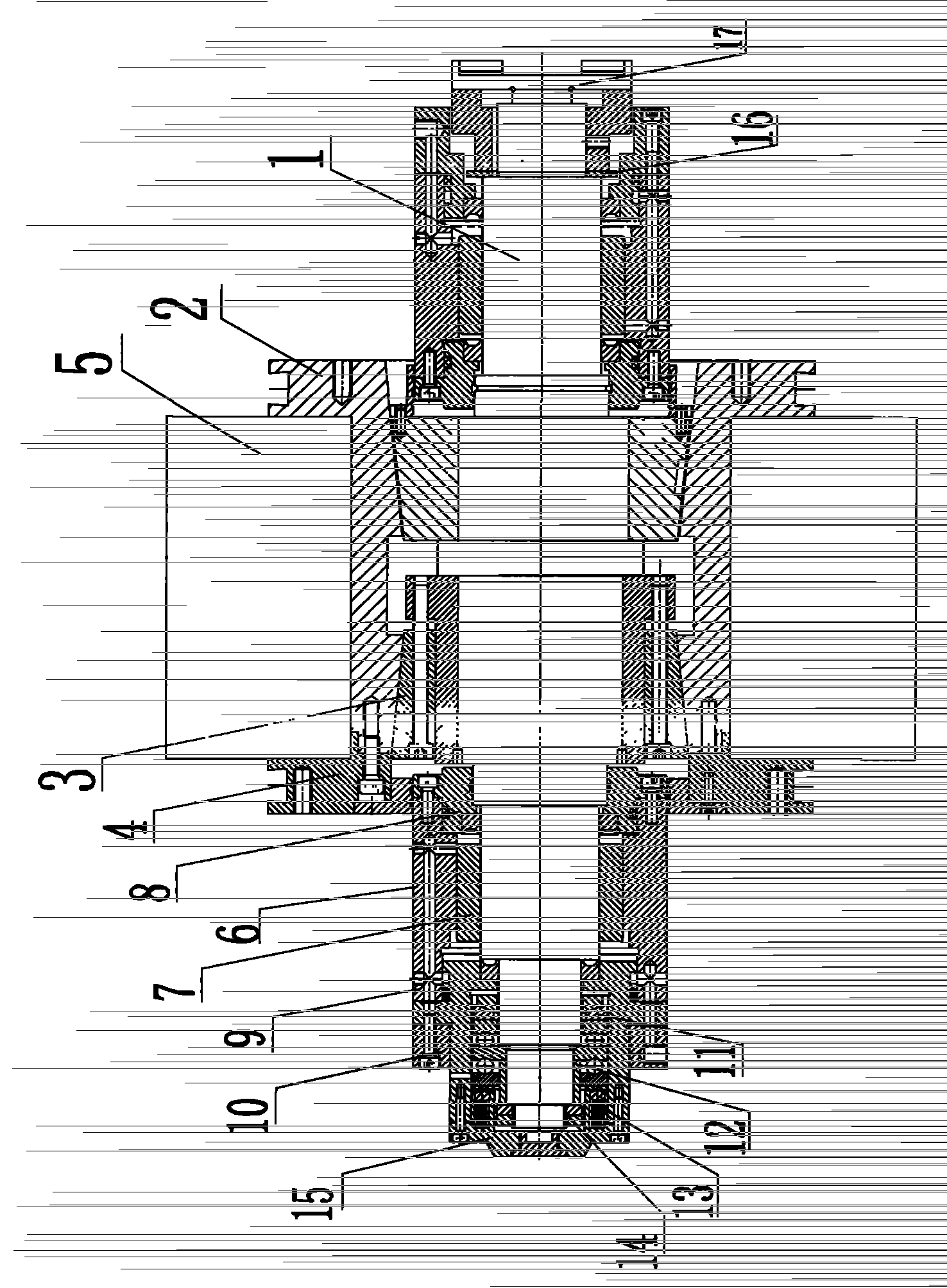

[0015] Such as figure 1 As shown, the improved double-supported oil wedge-shaped hydrodynamic spindle assembly includes a main shaft 1, a grinding wheel assembly, and a shoe sleeve assembly. The grinding wheel assembly is located in the middle of the main shaft 1. The grinding wheel assembly includes a grinding wheel chuck 2 and a spindle taper sleeve 3 , the grinding wheel chuck end cover 4 and the grinding wheel 5, and the grinding wheel 5 is fastened on the grinding wheel chuck 2 through the main shaft 1, the grinding wheel chuck 2, the main shaft taper sleeve 3 and the grinding wheel chuck end cover 4; the two ends of the main shaft 1 Each is equipped with a bushing combination, and the bushing combination includes a bushing 6, a bearing bush 7, a bushing cover 8, a bushing end cover 9, and an end cover connecting plate 10. The bushing 6 is equipped with four hemispherical screws for support Type oil wedge bearing bush 7, bushing 6 both ends are equipped with bushing gland...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com