Coated abrasive tool and preparation method and application method thereof

A technology of coated abrasives and abrasives, applied in the direction of coating, abrasives, manufacturing tools, etc., can solve the problem of low grinding efficiency of coated abrasives, achieve contact angle optimization, improve grinding efficiency, and improve grinding angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

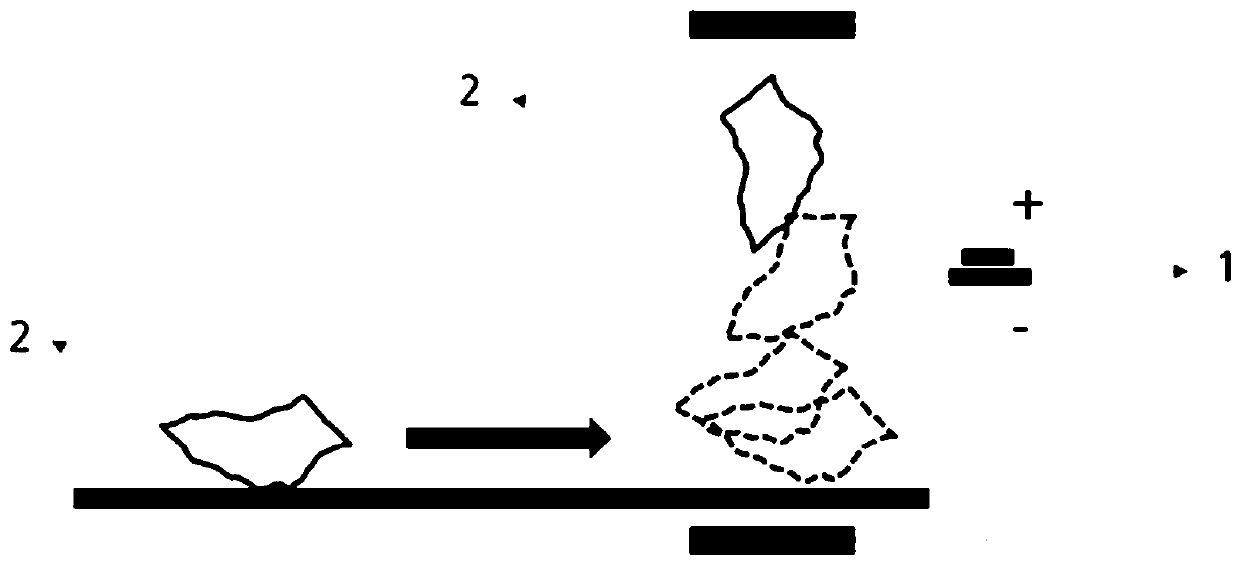

Problems solved by technology

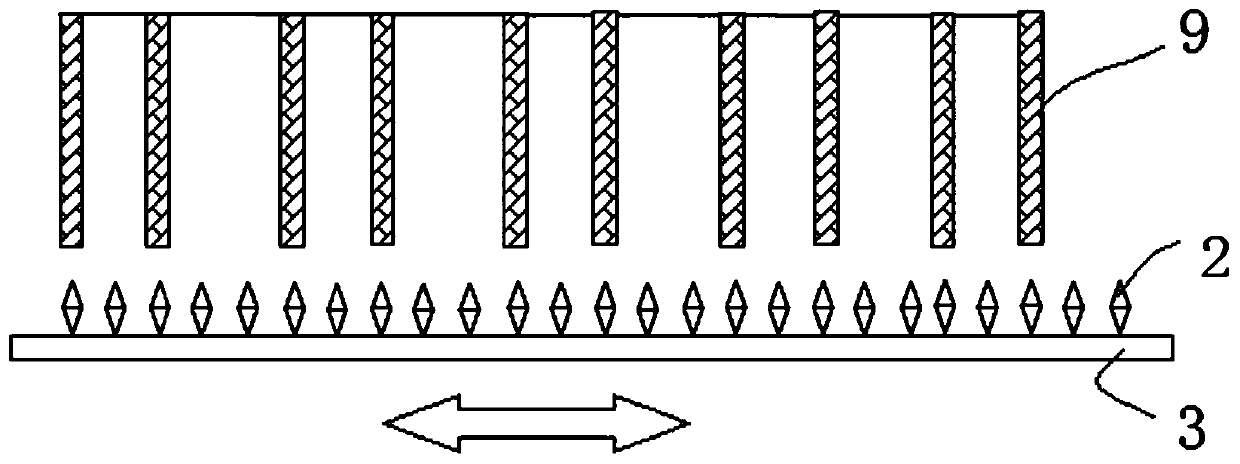

Method used

Image

Examples

Embodiment 1

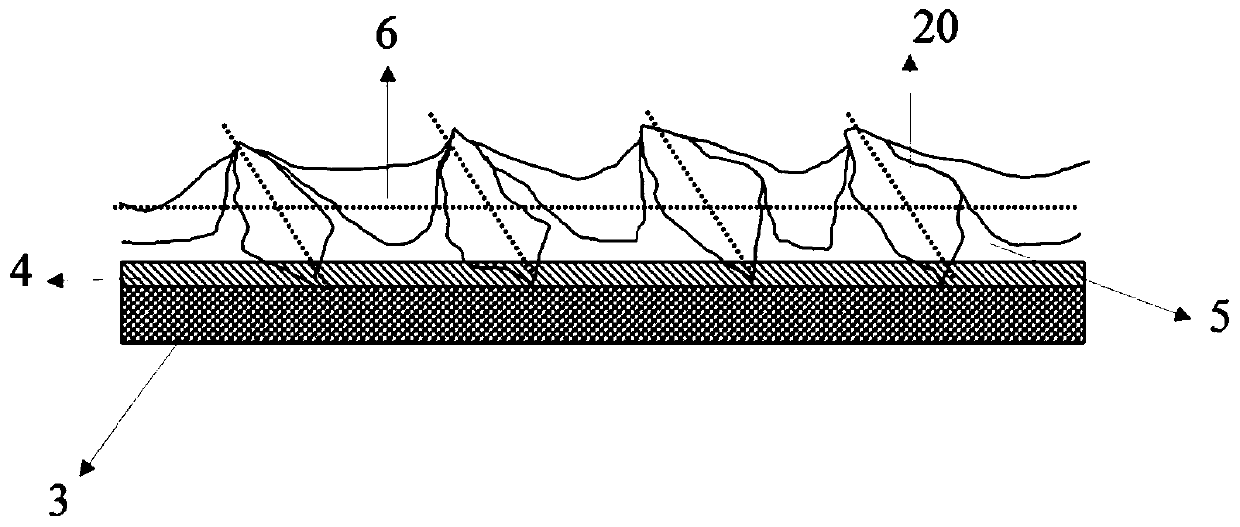

[0047] The coated abrasive of the present embodiment, such as figure 2 As shown, it includes a base material 3 and an abrasive layer, the abrasive layer includes a primer layer 4, abrasives embedded in the primer layer, a size coat 5 coated on the abrasive material and the primer layer 4, and a size layer coated on the primer layer The supercoating layer 6 on the glue layer 5, the abrasive grains (inclined abrasive 20) on the primer layer with sand planting angle α=70° account for 40±5% of all abrasive grains, and the sand planting angle α of the remaining abrasive grains 90°; sand planting density is 700g / m 2 .

[0048] The base material 3 is a polyester cloth with a thickness of 0.3 mm.

[0049] The primer layer 4 is made of the following raw materials in parts by weight: 48 parts of phenolic resin, 50 parts of calcium carbonate, 1 part of polyoxypropylene glyceryl ether defoamer, and 1 part of fatty amine salt surfactant; the thickness of the primer layer is 180 μm.

...

Embodiment 2

[0054] The coated abrasive of this embodiment is basically the same in structure as the coated abrasive embodiment 1, the only difference being:

[0055] Abrasive grains with a sand planting angle of α=60° on the primer layer accounted for 40±5% of all abrasive grains.

[0056] The primer layer is made of the following raw materials in parts by weight: 35 parts of phenolic resin, 30 parts of calcium carbonate, 2 parts of polyoxypropylene glyceryl ether defoamer, and 1 part of fatty amine salt surfactant; the thickness of the primer layer is 180 μm .

[0057] The adhesive layer is made of the following raw materials in parts by weight: 45 parts of phenolic resin, 30 parts of wollastonite powder, 1 part of pigment, 2 parts of polyoxypropylene glyceryl ether defoamer, 2 parts of fatty amine salt surfactant, acrylic acid copolymer 2 parts of thickener; the thickness of the glue layer is 200μm.

[0058] The supercoat is made of the following raw materials in parts by weight: 30 p...

Embodiment 3

[0060] The coated abrasive of this embodiment is basically the same in structure as the coated abrasive embodiment 1, the only difference being:

[0061] Abrasive grains with a sand planting angle of α=50° on the primer layer accounted for 40±5% of all abrasive grains.

[0062] The primer layer is made of the following raw materials in parts by weight: 40 parts of phenolic resin, 25 parts of calcium carbonate, 1 part of polyoxypropylene glyceryl ether defoamer, and 2 parts of fatty amine salt surfactant; the thickness of the primer layer is 180 μm .

[0063] The adhesive layer is made of the following raw materials in parts by weight: 30 parts of phenolic resin, 20 parts of wollastonite powder, 1 part of pigment, 1 part of polyoxypropylene glyceryl ether defoamer, 2 parts of fatty amine salt surfactant, acrylic acid copolymer 1 part thickener; the thickness of the glue layer is 200 μm.

[0064] The supercoat is made of the following raw materials in parts by weight: 20 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com