Non-woven fabric brush wheel as well as production system and method thereof

A technology of production system and production method, which is applied in the direction of wheels, abrasives, metal processing equipment, etc. of the working part with flexibility, can solve the problems of poor grinding uniformity, low grinding and cutting force, and low production efficiency, and achieve improved grinding force, improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

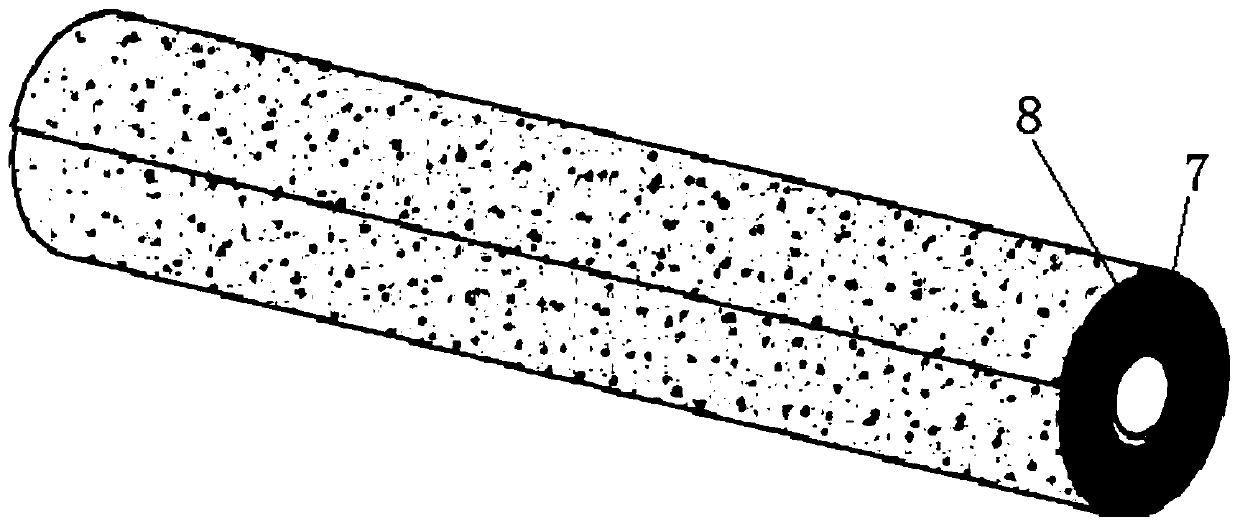

[0024] Embodiment 1: as figure 2 As shown, a non-woven brush wheel includes an axis 7 and a non-woven layer 8 wound on the axis and composed of multiple layers of non-woven fabrics. It is characterized in that the non-woven layer 8 is wound on the Obtained on axis 7.

[0025] In this embodiment, the axis 7 is a phenolic paper-based bakelite tube, the non-woven fabric is a non-woven fabric containing abrasives, so that the non-woven fabric brush wheel has better friction, and the glue is composed of resin glue: acetic acid Ethyl ester: formulated with a surfactant; the resin glue is phenolic resin glue, water-based polyurethane resin, or one of other epoxy resins, PU foaming resins, acrylic resins, and melamine resins , or a combination of the above-mentioned various resin glues; the surfactant is one of anionic surfactants, cationic surfactants or nonionic surfactants.

Embodiment 2

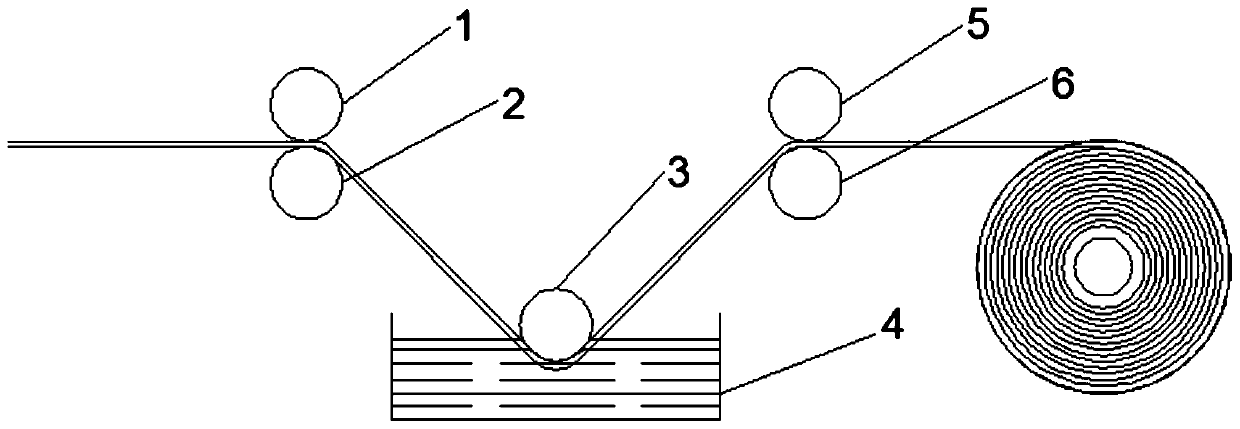

[0026] Embodiment 2: as figure 1 As shown, a production system for non-woven brush wheels, including a feeding unit for inputting non-woven fabrics, a dipping unit for dipping non-woven fabrics and a non-woven fabric for winding the dipped non-woven fabrics into dense non-woven fabrics arranged in sequence Winding unit for rolls.

[0027] In this embodiment, the feeding unit includes a first upper roller 1 and a first lower roller 2 arranged up and down, and between the first upper roller 1 and the second upper roller 2 is a supply The non-woven fabric passes through the gap, and the two sides of the surface of the non-woven fabric rub against the upper and lower rollers to move forward, thus completing the feeding of the non-woven fabric. In this embodiment, the feeding unit is not limited to the above-mentioned scheme, and a conveyor belt can also be used and a roller is arranged above the conveyor belt. There is a gap for the non-woven fabric to pass between the conveyor b...

Embodiment 3

[0031] Embodiment 3: a kind of production method of non-woven cloth brush wheel, it adopts a kind of production system of non-woven cloth brush wheel to implement, and its steps are:

[0032] 1) Start the winding machine to rotate the winding roller, and the non-woven fabric enters the feeding unit, which is smoothed by the feeding unit and transported to the dipping unit;

[0033] 2) The non-woven fabric enters the dipping tank and is placed under the pressure roller. Under the pressure exerted by the pressure roller, the non-woven fabric is completely submerged in the prepared glue;

[0034] 3) The dipped non-woven fabric enters the extrusion unit, and the excess glue is squeezed out under the pressure exerted by the second upper roller and the second lower roller;

[0035] 4) The non-woven fabric is wound on the upper axis layer by layer through the rotation of the winding roller to form a non-woven fabric brush wheel;

[0036] 5) Shake the glue with the rolled brush wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com