Method for manufacturing electroplating diamond grinding wheel

A technology of electroplating diamonds and manufacturing methods, which is applied in the direction of electrolytic coatings, coatings, etc., can solve the problems of poor clamping of diamonds, peeling off of coatings, and reduced wear resistance, and achieve strong clamping force, improved bonding force, Effect of increasing grinding force and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

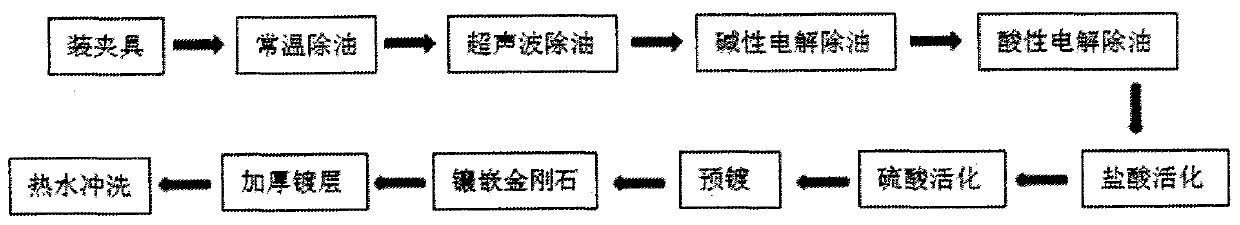

[0041] Such as Figure 1~6 Shown, a kind of manufacturing method of electroplated diamond grinding wheel comprises the steps:

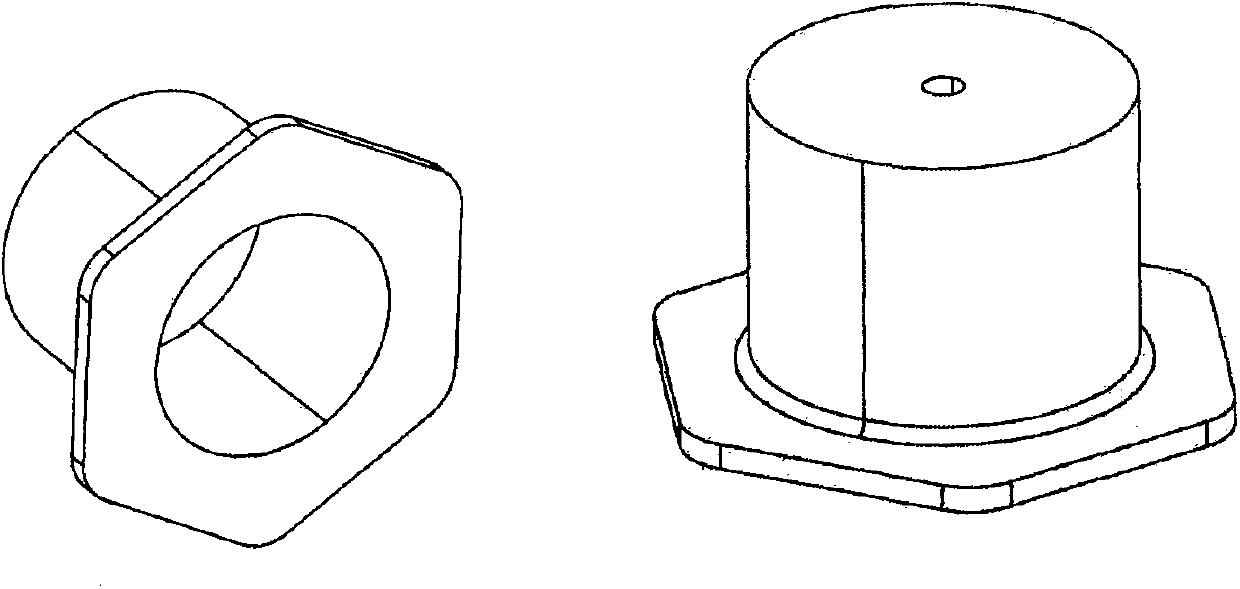

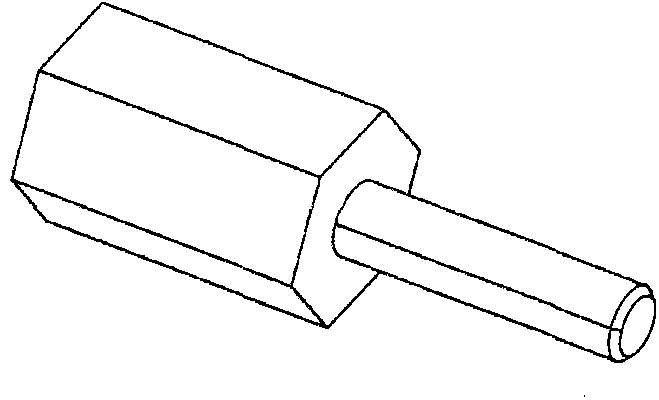

[0042] 1) Install the fixture: put the fixture on both ends of the main shaft of the grinding wheel that has been ground with a grinding machine. The two ends of the main shaft are provided with holes with internal threads, and then fix the fixture with the fixture head with a screw so that the two ends of the grinding wheel Side seal protection. Before the grinding wheel is plated, the outer circle must be ground with a grinder to expose a fresh surface that has not been oxidized, rusted, or corroded. Clamps are used to protect the spindle at both ends of the grinding wheel and the bearings on the spindle. The bottom edge of the jig is hexagonal, which is convenient for turning six sides when setting diamonds. The jig head is embedded in a hexagonal prism made of corrosion-resistant PVC material with a part of the copper screw, and the jig head wi...

Embodiment 2

[0062] Such as Figure 1~6 Shown, a kind of manufacturing method of electroplated diamond grinding wheel comprises the steps:

[0063] 1) Install the fixture: put the fixture on both ends of the main shaft of the grinding wheel that has been ground with a grinding machine. The two ends of the main shaft are provided with holes with internal threads, and then fix the fixture with the fixture head with a screw so that the two ends of the grinding wheel Side seal protection. Before the grinding wheel is plated, the outer circle must be ground with a grinder to expose a fresh surface that has not been oxidized, rusted, or corroded. Clamps are used to protect the spindle at both ends of the grinding wheel and the bearings on the spindle. The bottom edge of the jig is hexagonal, which is convenient for turning six sides when setting diamonds. The jig head is embedded in a hexagonal prism made of corrosion-resistant PVC material with a part of the copper screw, and the jig head wi...

Embodiment 3

[0083] Such as Figure 1~6 Shown, a kind of manufacturing method of electroplated diamond grinding wheel comprises the steps:

[0084] 1) Install the fixture: put the fixture on both ends of the main shaft of the grinding wheel that has been ground with a grinding machine. The two ends of the main shaft are provided with holes with internal threads, and then fix the fixture with the fixture head with a screw so that the two ends of the grinding wheel Side seal protection. Before the grinding wheel is plated, the outer circle must be ground with a grinder to expose a fresh surface that has not been oxidized, rusted, or corroded. Clamps are used to protect the spindle at both ends of the grinding wheel and the bearings on the spindle. The bottom edge of the jig is hexagonal, which is convenient for turning six sides when setting diamonds. The jig head is embedded in a hexagonal prism made of corrosion-resistant PVC material with a part of the copper screw, and the jig head wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com