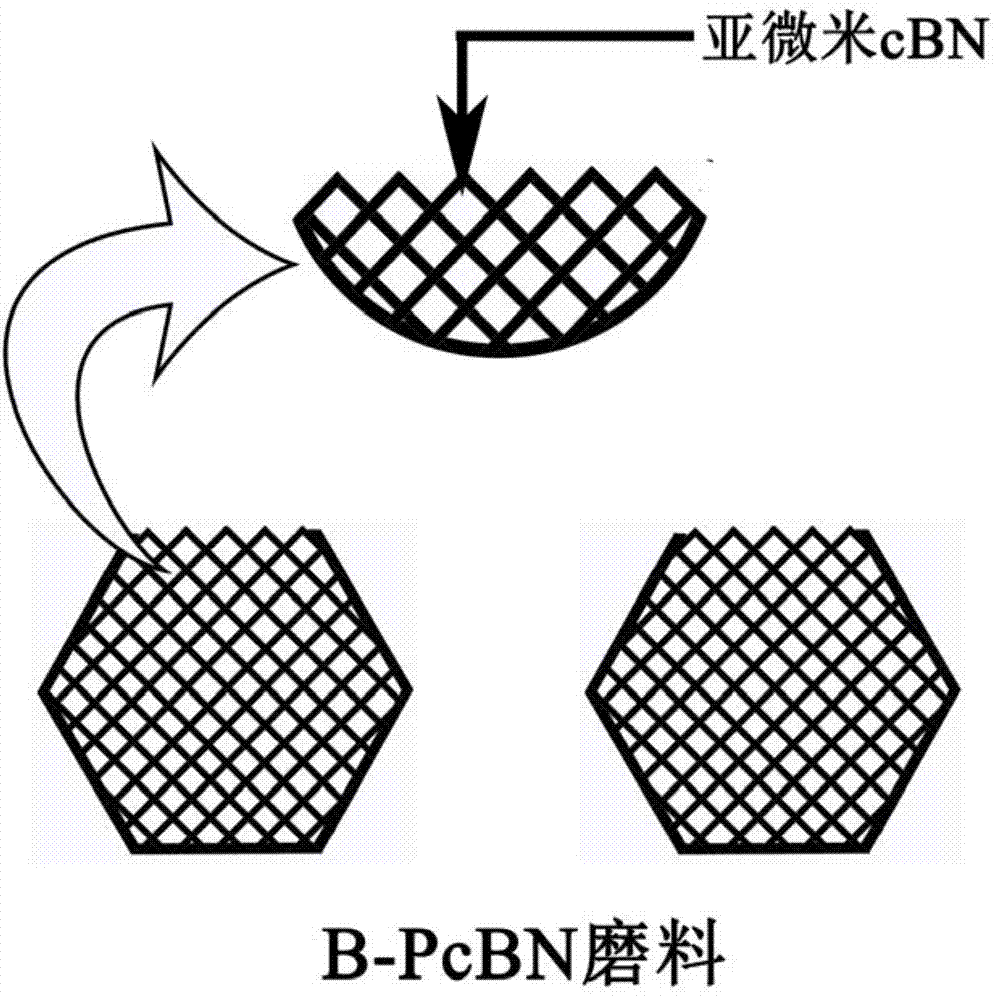

Binder-free polycrystalline cubic boron nitride abrasive and preparation method thereof

A polycrystalline cubic, binder-free technology, applied in chemical instruments and methods, inorganic chemistry, nitrogen compounds, etc., can solve the problem of affecting the hardness, wear resistance and thermal conductivity of PcBN abrasives, which cannot meet the requirements of high-efficiency and high-precision grinding, Reduce the problems of abrasive performance and service life, achieve outstanding self-sharpening and isotropy, avoid sharp increases in grinding force and grinding temperature, and achieve high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The polycrystalline cubic boron nitride abrasive without binding agent of the present embodiment is prepared by the following method:

[0038] 1) After filling the hexagonal boron nitride (hBN) powder with a particle size of 0.1-1 μm into the mold, place it in a vacuum hot-pressing sintering furnace at a vacuum degree of 6.6×10 -2 Pa, the molding temperature is 800°C under the molding condition for 0.5h, and then the pressure is applied for preforming, and the loading pressure is 100MPa to obtain a preform;

[0039] 2) Put the preform obtained in step 1) into a rubber glove, perform cold isostatic pressing after vacuuming, the pressure is 150MPa, and the holding time is 2h, to obtain a dense hexagonal boron nitride block; the dense hexagonal boron nitride The oxygen impurity content of the boron nitride block is ≤0.05%, and the bulk density is 1.7g / cm 3 .

[0040] 3) Put the hexagonal boron nitride block obtained in step 2) into a tantalum cup, and form an assembly bl...

Embodiment 2

[0045] The polycrystalline cubic boron nitride abrasive without binding agent of the present embodiment is prepared by the following method:

[0046] 1) After filling the hexagonal boron nitride (hBN) powder with a particle size of 0.5-3 μm into the mold, place it in a vacuum hot-pressing sintering furnace at a vacuum degree of 6.6×10 -2 Pa, the molding temperature is 1000°C under the molding conditions for 1.5h, and then the pressure is applied for preforming, and the loading pressure is 50MPa to obtain a preform;

[0047] 2) Put the preform obtained in step 1) into a rubber glove, perform cold isostatic pressing after vacuuming, the pressure is 200MPa, and the holding time is 5h, to obtain a dense hexagonal boron nitride block; the dense hexagonal boron nitride The oxygen impurity content of the boron nitride block is ≤0.05%, and the bulk density is 2.2g / cm 3 .

[0048] 3) Put the hexagonal boron nitride block obtained in step 2) into a tantalum cup, and form an assembly b...

Embodiment 3

[0053] The polycrystalline cubic boron nitride abrasive without binding agent of the present embodiment is prepared by the following method:

[0054] 1) Put the hexagonal boron nitride (hBN) powder with a particle size of 1 to 5 μm into the mold, and place it in a vacuum hot-pressing sintering furnace at a vacuum degree of 6.6×10 -2 Pa, the molding temperature is 1600°C under the molding conditions for 1.5h, and then the pressure is applied for preforming, and the loading pressure is 75MPa to obtain a preform;

[0055] 2) Put the preform obtained in step 1) into a rubber glove, perform cold isostatic pressing after vacuuming, the pressure is 200MPa, and the holding time is 5h, to obtain a dense hexagonal boron nitride block; the dense hexagonal boron nitride The oxygen impurity content of the boron nitride block is ≤0.05%, and the bulk density is 2.1g / cm 3 .

[0056] 3) Put the hexagonal boron nitride block obtained in step 2) into a tantalum cup, and form an assembly block ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com