Electric spark mechanical composite grinding method and machine for non-conductive superhard material

A superhard material and EDM technology, applied in the field of mechanical processing, can solve problems that have not yet been developed, and achieve the effect of avoiding poor processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

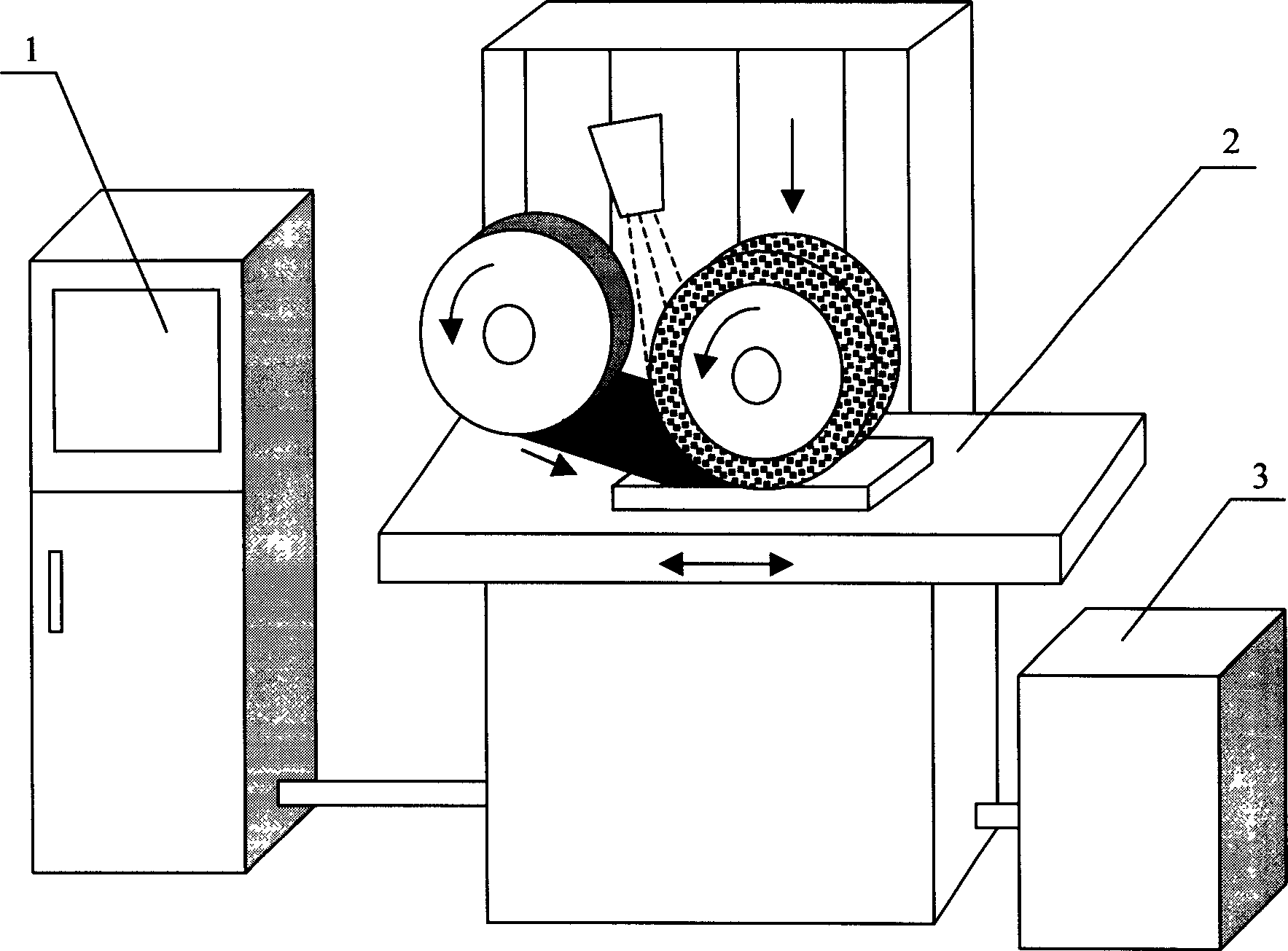

[0016] see figure 1 . The non-conductive superhard material electro-spark mechanical compound grinding machine tool of the present invention is mainly composed of three parts. 1 is the control electric cabinet, which includes computer, control circuit, pulse power supply, operation panel, etc. The computer realizes the control and management of the machine tool through the control circuit; 2 is the processing host; The process provides circulating working fluid.

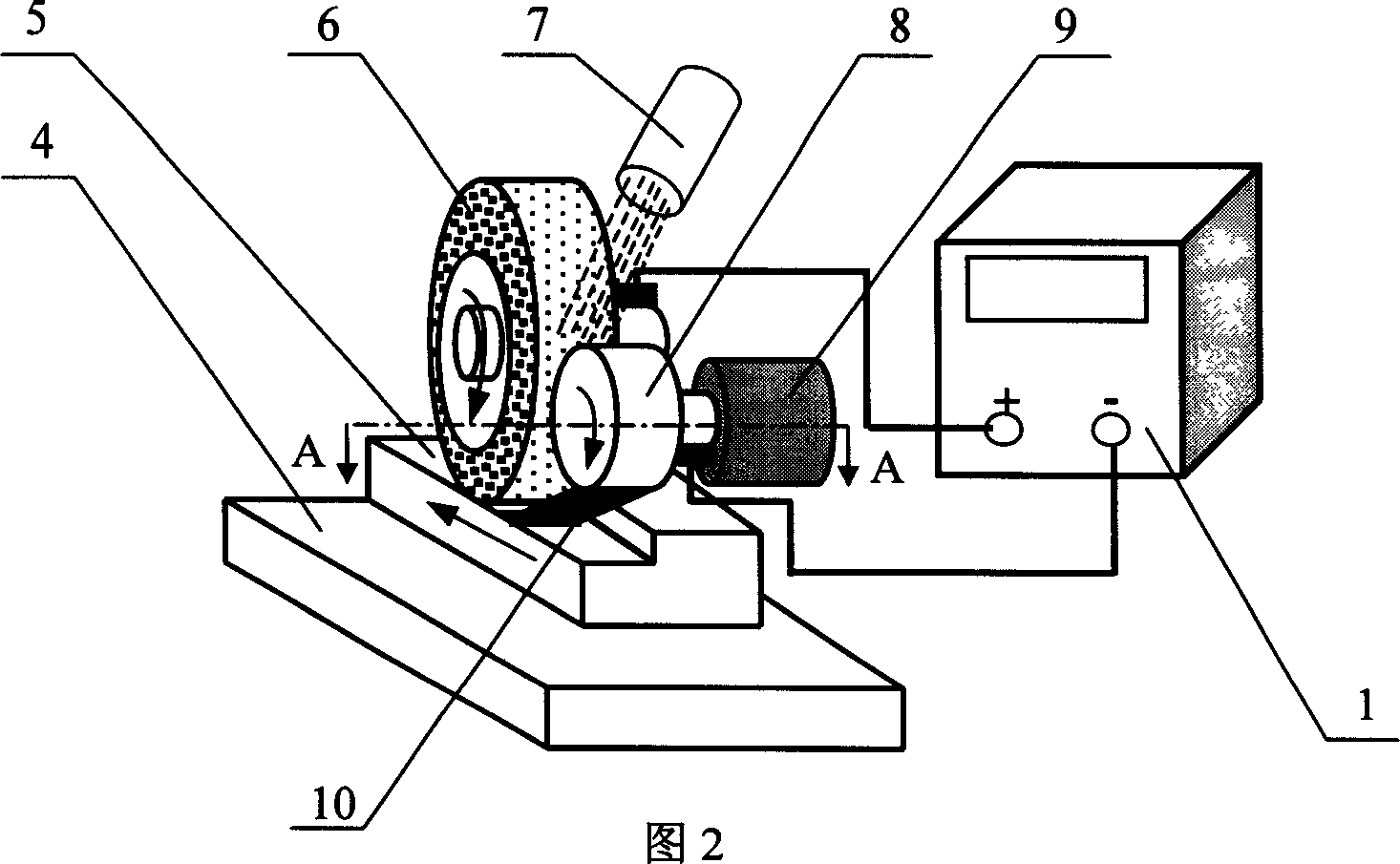

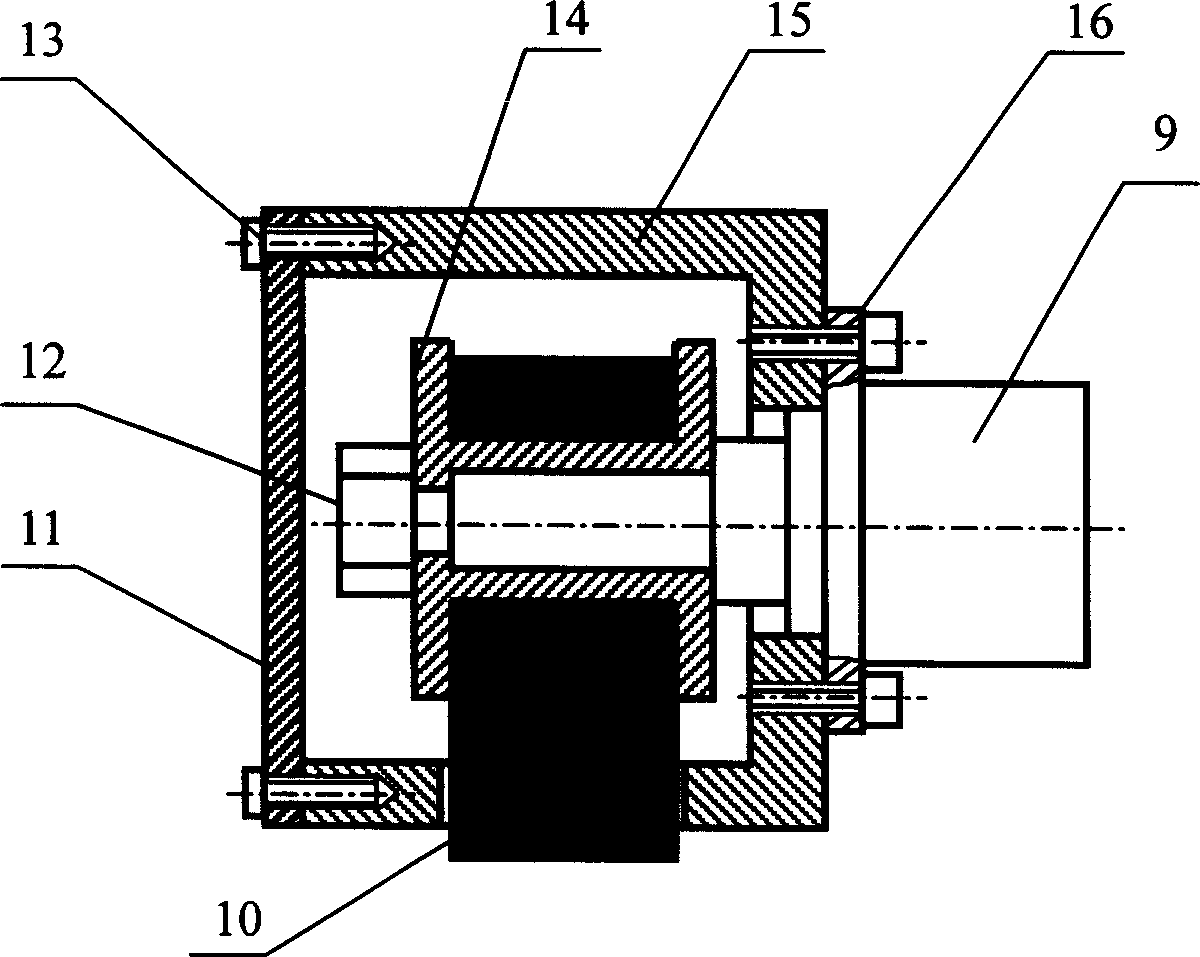

[0017] See Figure 2. The processing mechanism of the machine tool of the present invention comprises a workbench 4, which drives the workpiece to perform feeding and processing motion; the workpiece to be processed 5; the conductive grinding wheel 6, which can be a conductive grinding wheel or other conductive wheels; the nozzle 7, which injects working fluid into the processing area; Mechanism 8; DC servo motor 9 controls the feeding of the sheet electrode to maintain the continuous EDM process; the sheet electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com