Diamond grinding pad for processing super-hard ceramics and preparation method for diamond grinding pad

A diamond and grinding pad technology, which is applied in the field of research and development of ceramic processing devices, can solve the problems of difficult to meet product dimensional accuracy, poor product surface quality, and difficult to meet dimensional accuracy, etc., to achieve heat dissipation and chip removal, consistent size, Good stability of grinding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

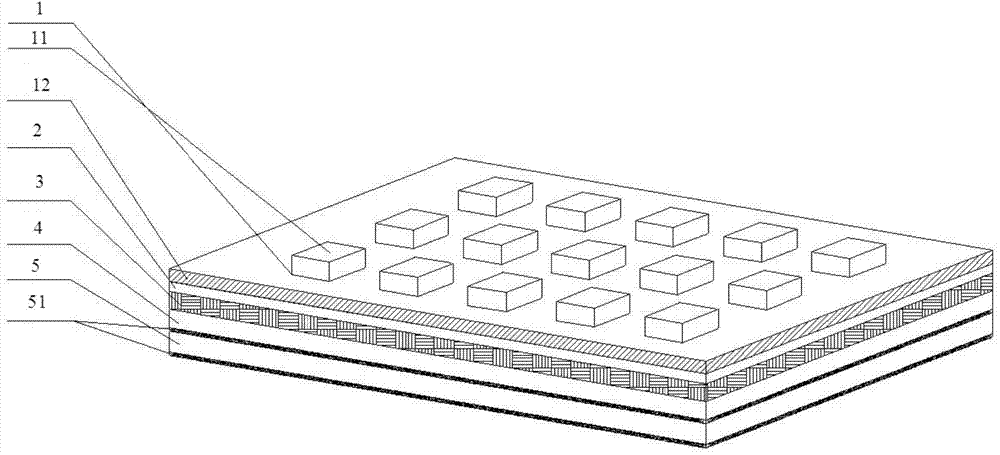

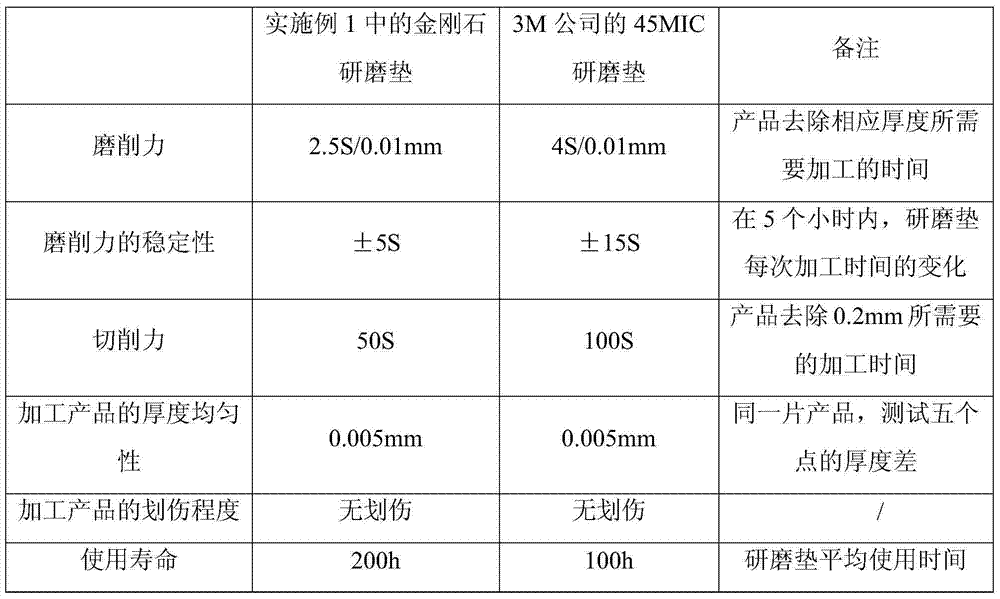

[0042] Such as figure 1 As shown, the present invention provides a diamond grinding pad for processing superhard ceramics, the grinding pad includes a diamond material layer 1 , and the diamond material layer 1 includes a square grinding block layer 11 and a flat layer 12 . From one side to the other side of the diamond grinding pad, it includes: square grinding block layer 11, flat layer 12, non-woven fabric layer 2, adhesive layer 3, PET film layer 4, PC with double-sided adhesive Ply 5. figure 1 Among them, 51 is the double-sided adhesive layer on the PC board layer with double-sided adhesive. The diamond material layer is made of the following raw materials by mass percentage, 35% of resin binder, 10% of diamond, 50% of wollastonite, 3% of molybdenum disulfide, and 2% of fumed silicon dioxide.

[0043] The above-mentioned preparation method for processing the diamond grinding pad of superhard ceramics comprises the following steps:

[0044] Step 1: Mixing: Weigh each ra...

Embodiment 2

[0056] The structure of the diamond grinding pad in embodiment 2 is the same as in embodiment 1, but the composition of preparing the diamond material layer is: resin binder 25%, diamond 20%, wollastonite 40%, molybdenum disulfide 10%, gas phase Silica 5%.

Embodiment 3

[0058] The structure of the diamond grinding pad in embodiment 3 is the same as in embodiment 1, but the composition of preparing the diamond material layer is: resin binder 50%, diamond 5%, wollastonite 43.5%, molybdenum disulfide 1%, gas phase Silica 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com