Pneumatic grinding wheel-based robot finish-machining system

A pneumatic grinding wheel and finishing technology, which is used in metal processing equipment, manipulators, manufacturing tools, etc., can solve the problems of low rotation speed and small grinding force, and achieve the effect of improving effect and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

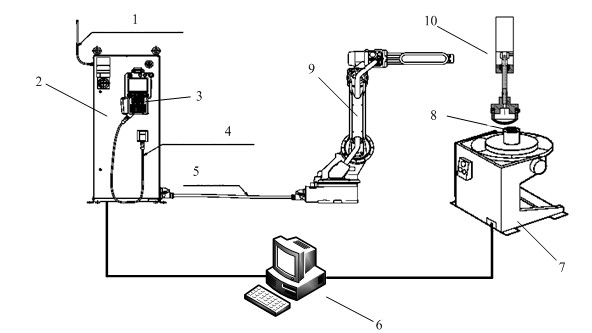

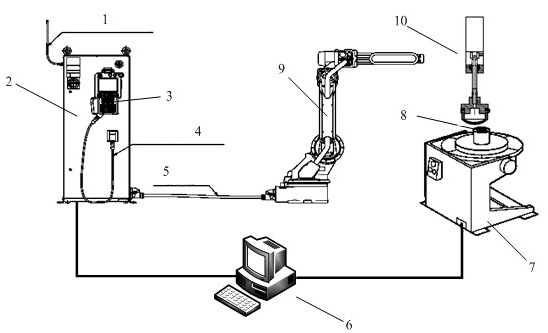

[0021] refer to figure 1 , figure 2 , a pneumatic grinding wheel based robot finishing system, comprising a pneumatic grinding wheel finishing tool 10, the pneumatic grinding wheel finishing tool 10 is installed above the workbench 7, and contacts with the workpiece 8 on the workbench 7; The pneumatic grinding wheel finishing tool 10 is connected to the robot 9 that controls its movement and rotation; The computer control and processing module 6 and the teaching programmer 3 for manually controlling the movement of the robot 9, the workbench 7 is connected with the computer control and processing module 6 that controls the number of revolutions of the rotating shaft on the workbench 7;

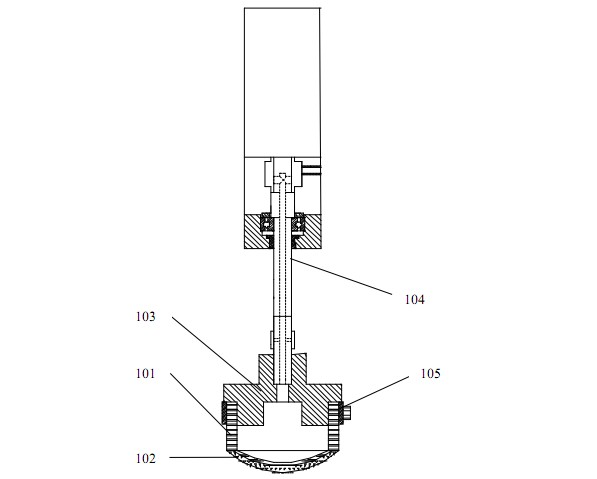

[0022] The pneumatic grinding wheel finishing tool 10 includes a first module and a second module, the first module includes a rubber air bag 101 and abrasive materials 102 bonded to the rubber air bag 101, and the rubber air bag 101 is installed on the air bag holder 103; the airbag holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com