One-step forming wire drawing and water milling machine

A water mill, one-off technology, applied in grinding machines, mechanical equipment, sugarcane machining and other directions, can solve the problems of wasting labor, wasting time, reducing work efficiency, etc., to save labor, reduce production costs, and increase work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

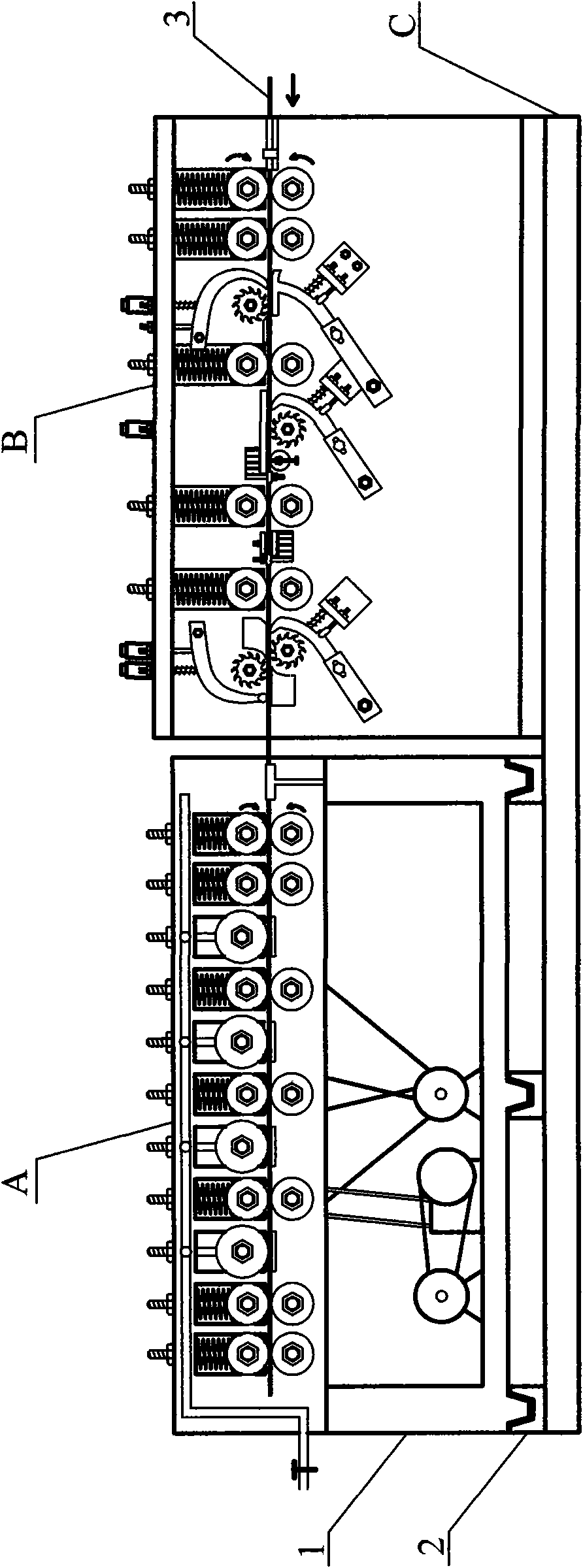

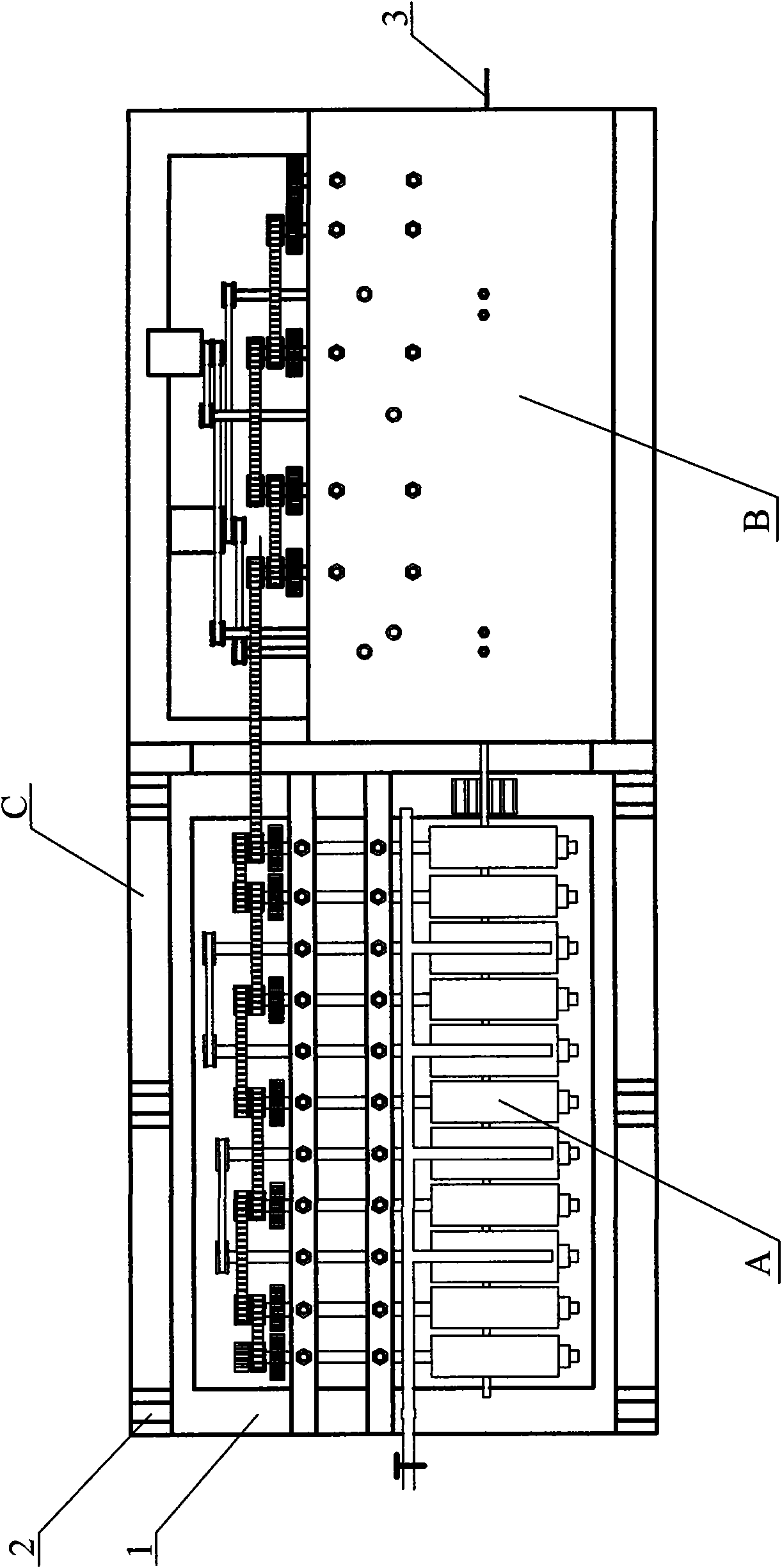

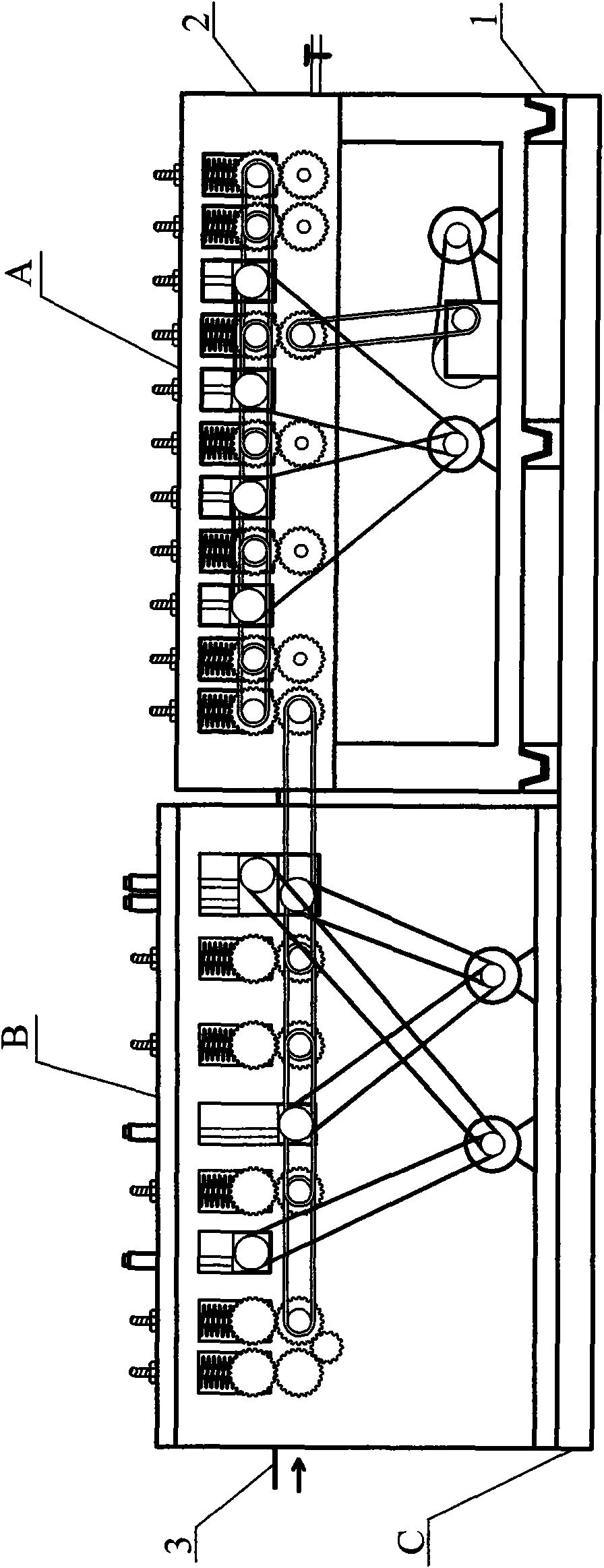

[0016] The disposable water mill for wire drawing is composed of a water mill A, a wire drawing machine B and a base C. The feed inlet is corresponding, and the working planes of water mill A and wire drawing machine B are kept at the same level.

[0017] The water mill A is composed of a fuselage 1 and a guide rail 2, the fuselage 1 is installed on the guide rail 2, and the fuselage 1 and the guide rail 2 are flexibly connected; the fuselage 1 is composed of a base a, a driving part b, a transmission part c. The water supply part d and the grinding part e are composed, the driving part b is fixedly installed on the base a, and the transmission part c connects the driving part b and the grinding part e.

[0018] The wire drawing machine B is composed of a frame f, a pressing device g, a clamping and limiting device h, a gear cutter i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com