Rotary type flat plate magnetic separator and system

A magnetic separator, rotary technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problem that the iron removal effect of the magnetic separator is not very good, and achieve a good iron removal effect and sufficient mineral tumbling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

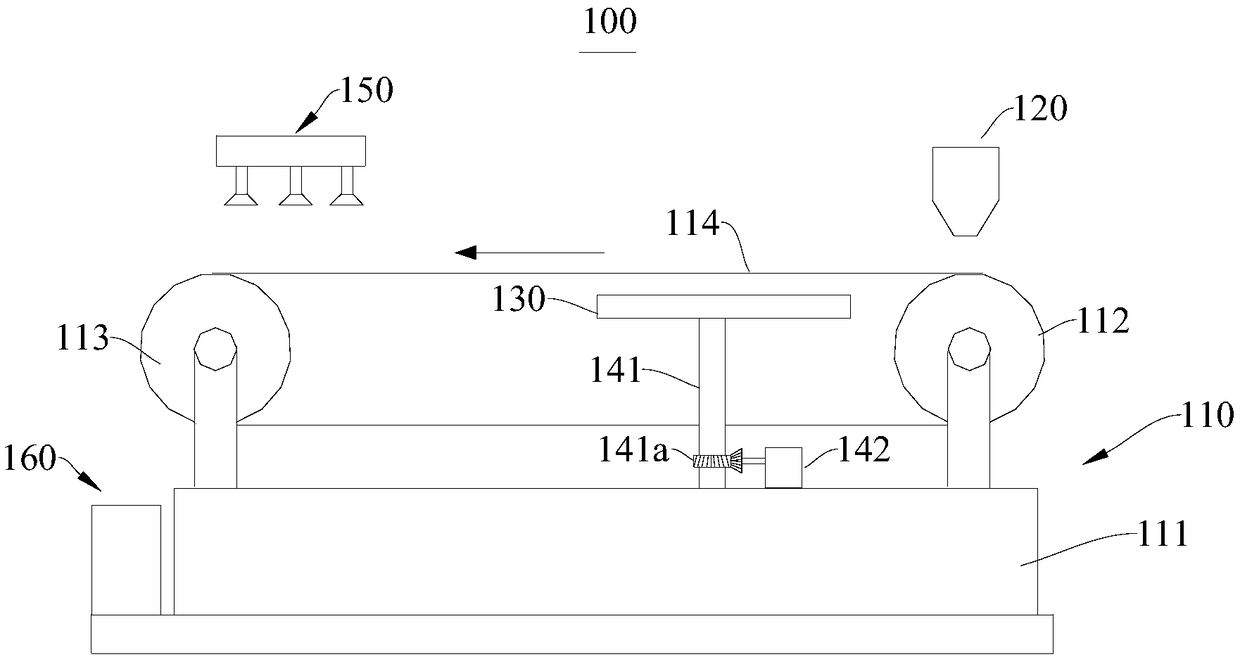

[0041] This embodiment provides a rotary flat magnetic separator 100, please refer to figure 1 . The rotary flat magnetic separator 100 has a good iron removal effect.

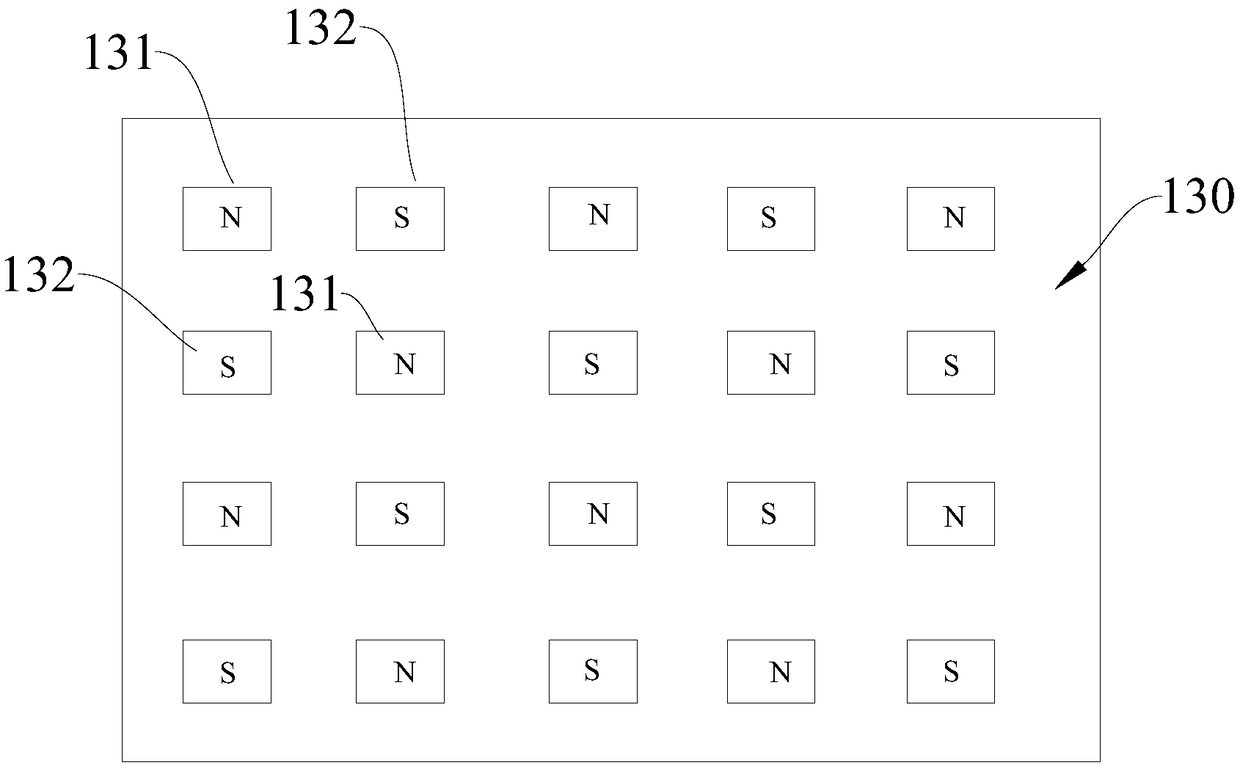

[0042] Specifically, the rotary flat magnetic separator 100 includes a conveying device 110, a feeding device 120, a magnetic plate 130 and a spray device 150.

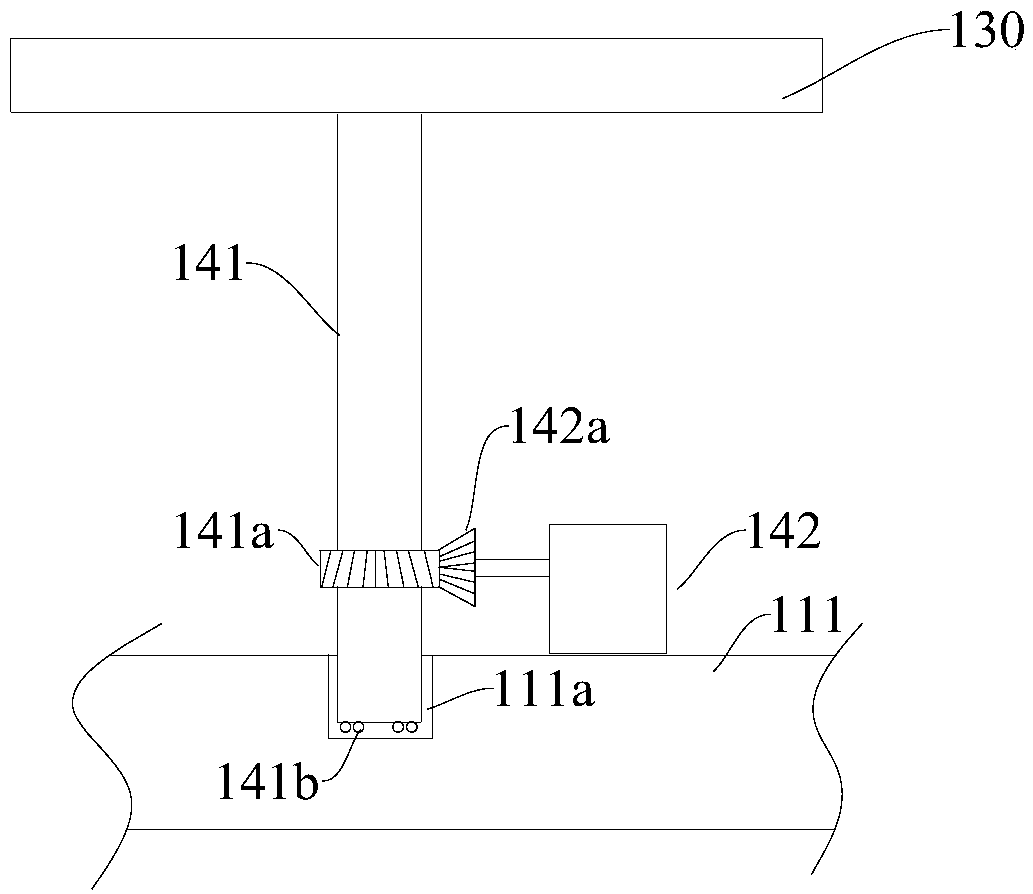

[0043] The conveying device 110 includes a frame 111, a driving wheel 112 and a driven wheel 113 rotatably supported on the frame 111, a driving mechanism (not shown in the figure) that can drive the driving wheel 112 to rotate, and a conveyor belt 114. The driving shaft of the driving wheel 112 is rotatably supported on the frame 111, and the driven shaft of the driven wheel 113 is rotatably supported on the frame 111, such as figure 1 As shown, in this embodiment, the driving wheel 112 is arranged on the right side, and the driven wheel 113 is arranged on the left side. The conveyor belt 114 is wound around the driving wheel 112 and the driven wheel 113...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com