Resource utilization method for industrial iron-containing acid solution

An acidic solution and resource recovery technology, applied in chemical instruments and methods, compounds of elements in group 5/15 of the periodic table, organic chemistry, etc., can solve the problems of difficult filtration and separation of precipitated products, low purity of products, loss of components, etc. problems, to achieve the effect of easy automatic production and popularization, high purity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

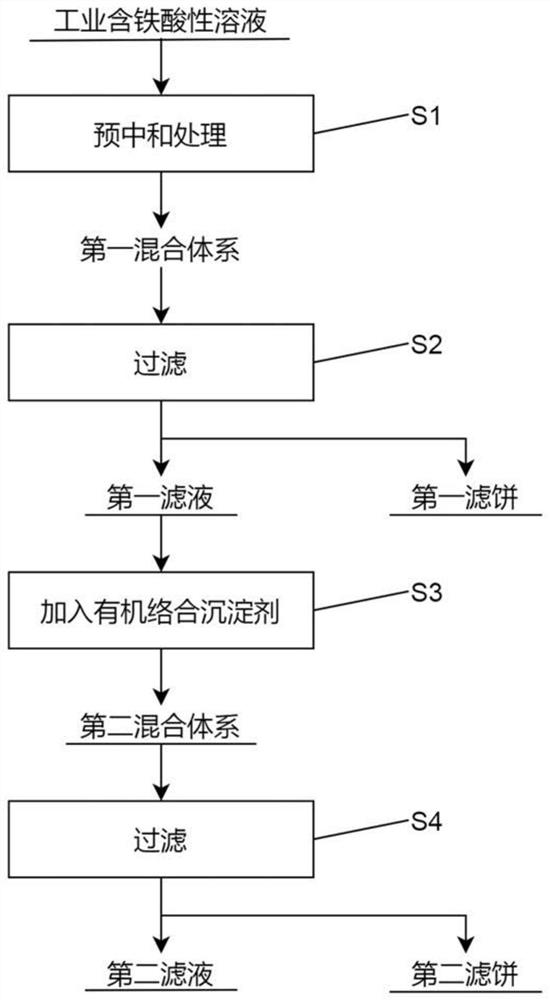

[0048] In this example, the resource utilization method of the industrial iron-containing acidic solution includes the following steps:

[0049] S1. Remove impurities, crush and grind the limestone raw material to obtain limestone powder with a particle size of less than 150 μm (-100 mesh), and use the acidic production waste liquid with pH=0.24 generated during the wet resource utilization of asbestos tailings Place in a reactor equipped with a stirring device and slowly add limestone powder while stirring, adjust the pH of the system to 1.0, stir and react at 10°C for 60 minutes at a stirring speed of 300r / min, and let it stand for 10 minutes after the reaction.

[0050] S2, using a belt-type suction filtration-washing all-in-one machine to carry out suction filtration dehydration and rinsing for 3 times to obtain the first filtrate and the first filter cake, the iron ion content of the first filtrate is 1.55g / L, store for later use, the first filter cake Dry under natural c...

example 2

[0054] In this example, the resource utilization method of the industrial iron-containing acidic solution includes the following steps:

[0055] S1. Put the acidic production waste liquid with pH=1.0 produced during the wet resource utilization of asbestos tailings in a reactor with a stirring device and slowly add limestone powder while stirring to adjust the pH of the system to 1.5. The mixture was stirred and reacted for 60 minutes at a stirring speed of 300 r / min, and aged for 10 minutes after the reaction was completed. The particle size of the limestone powder is less than 150 μm (-100 mesh), and can be obtained by removing impurities, crushing and grinding limestone raw materials.

[0056] S2, using a belt-type suction filtration-washing all-in-one machine to carry out suction filtration dehydration and rinsing for 3 times to obtain the first filtrate and the first filter cake, the iron ion content of the first filtrate is 1.55g / L, store for later use, the first filter ...

example 3

[0060] In this example, the resource utilization method of the industrial iron-containing acidic solution includes the following steps:

[0061] S1. Put the acidic production waste liquid with pH=0.7 produced during the wet resource utilization of asbestos tailings in a reactor with a stirring device and slowly add limestone powder while stirring to adjust the pH of the system to 1.0. The mixture was stirred and reacted for 60 minutes at a stirring speed of 300 r / min, and aged for 10 minutes after the reaction was completed.

[0062] S2, using a belt-type suction filtration-washing all-in-one machine to carry out suction filtration dehydration and rinsing for 3 times to obtain the first filtrate and the first filter cake, the iron ion content of the first filtrate is 1.55g / L, store for later use, the first filter cake Dry under natural conditions of ventilation or sunlight until the moisture content of free water is less than or equal to 3%, to obtain gypsum products.

[0063...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com