Dry magnetic separator

A magnetic separator, dry technology, applied in the direction of high gradient magnetic separator, etc., can solve the problems of inability to exert equipment separation performance, difficulty in upgrading concentrates, complicated magnetic separator equipment, etc., and achieves obvious iron removal effect. The scheme is simple and practical, and the effect of improving the effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

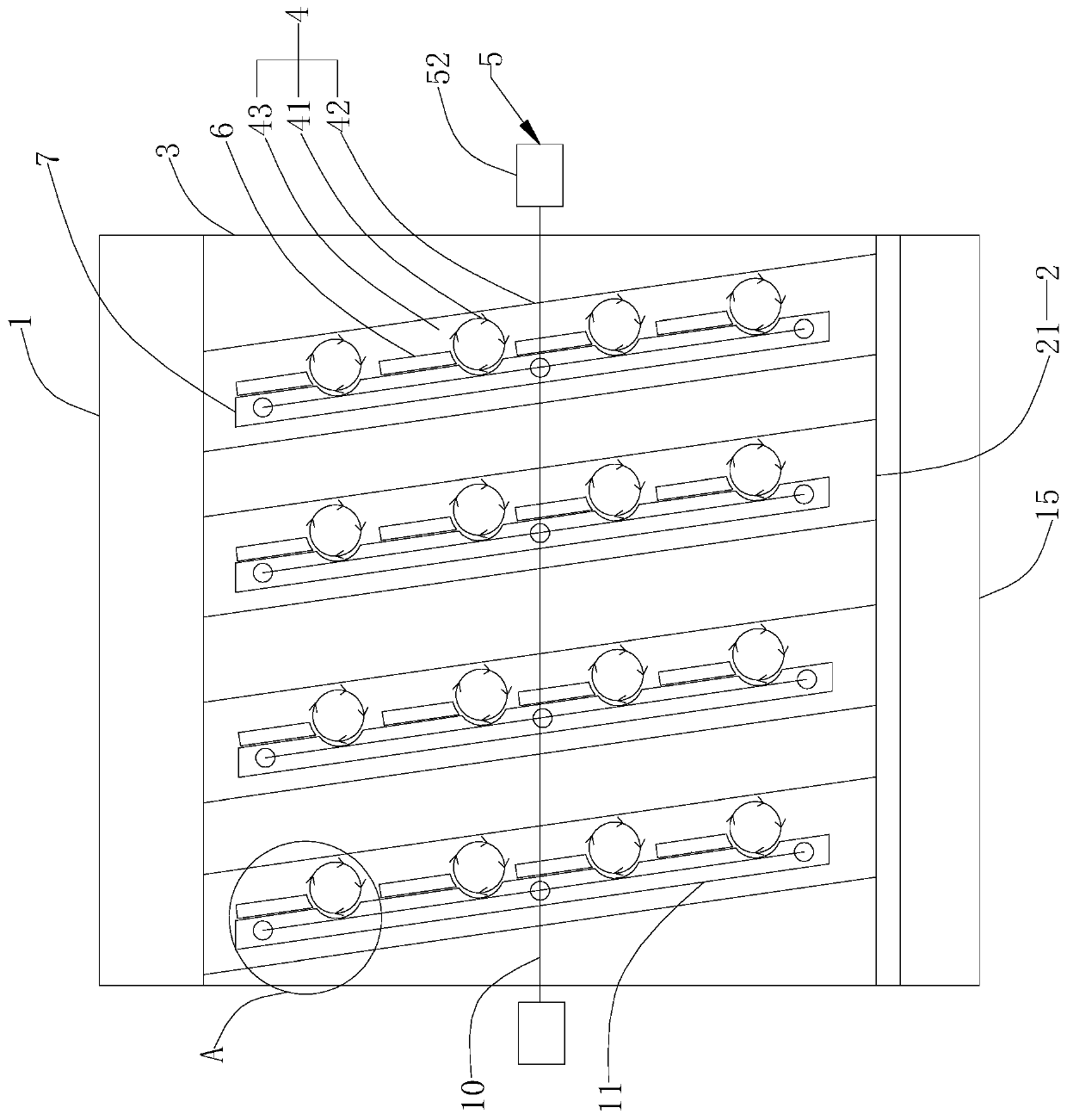

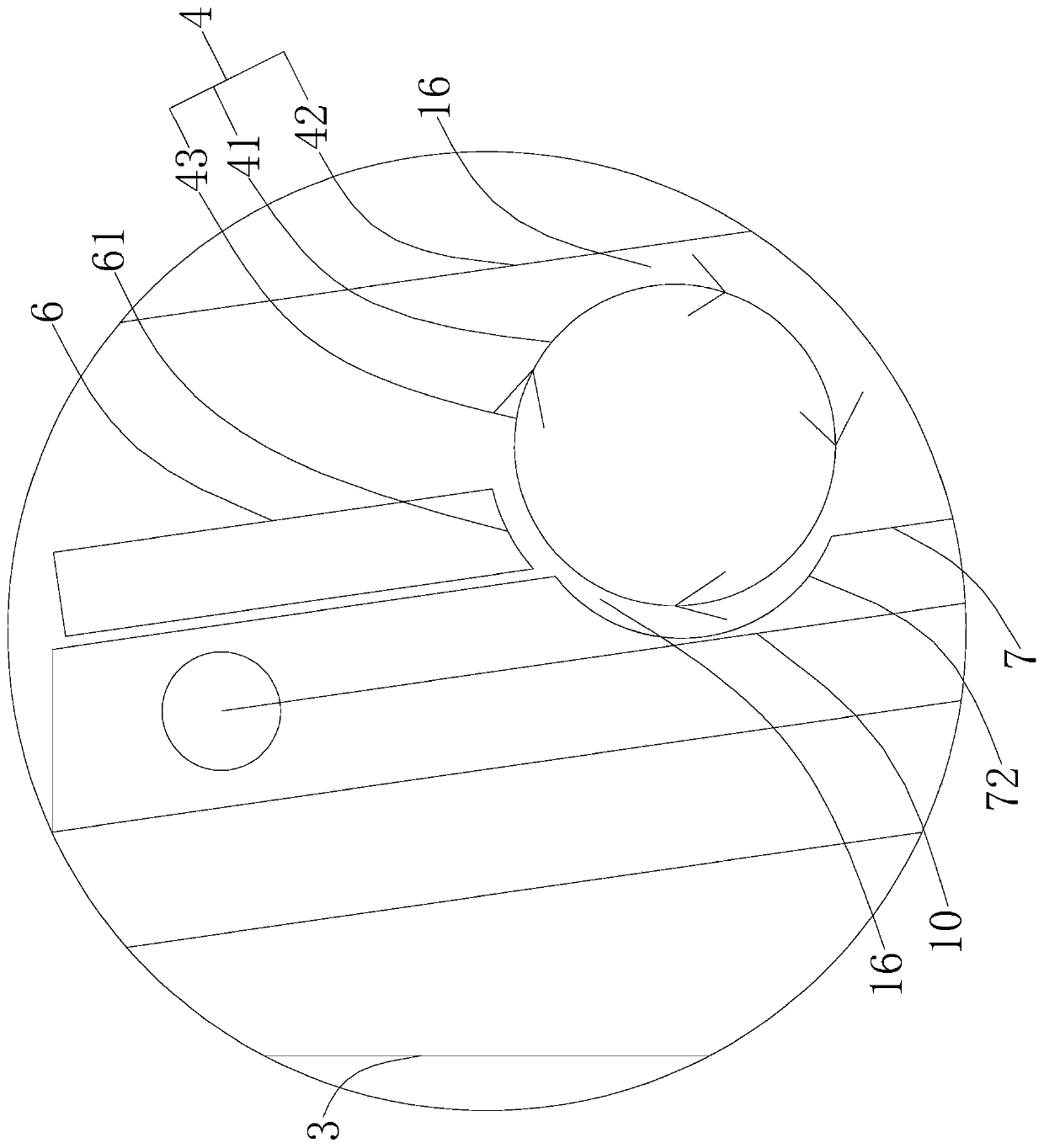

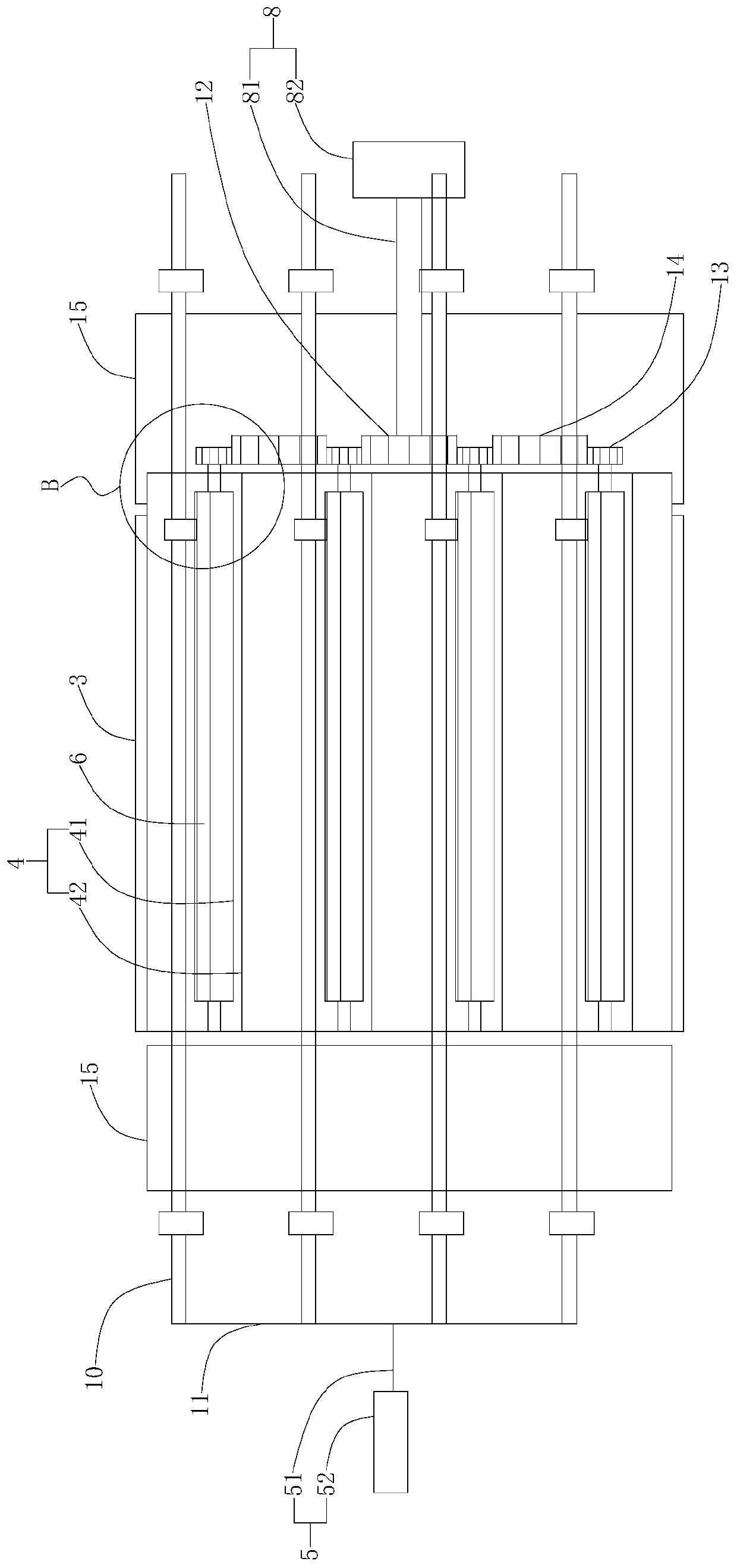

[0037] Embodiment: a kind of dry type magnetic separator, as Figure 1 to Figure 5 As shown, the main frame 3 is included, and the main frame 3 is provided with a feed port 1 and a discharge port 2; the main frame 3 is provided with a magnetic separation assembly 4; the magnetic separation assembly 4 includes a feeding channel 43 and a magnetic Part 41, the feeding channel 43 communicates with the feed port 1 and the feeding port 2, and the magnetic part 41 extends into the feeding channel 43 and can rotate relative to the feeding channel 43; when the magnetic part 41 rotates relative to the feeding channel 43 , the circumferential side wall of the magnetic part 41 reciprocates into and out of the feeding channel 43; the first scraping part 6 and the second scraping part 7 are arranged outside the feeding channel 43; the first scraping part 6 moves along the magnetic part 41 Arranged in the direction of rotation and scratches the circumferential surface of the magnetic piece 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com