Method for removing iron from sodium aluminate solution

A sodium aluminate and sodium ferroaluminate technology, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, can solve the problems of complex operation, high cost of iron removal methods, and limited iron removal effect, and achieves Low process cost, good iron removal effect, and great promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

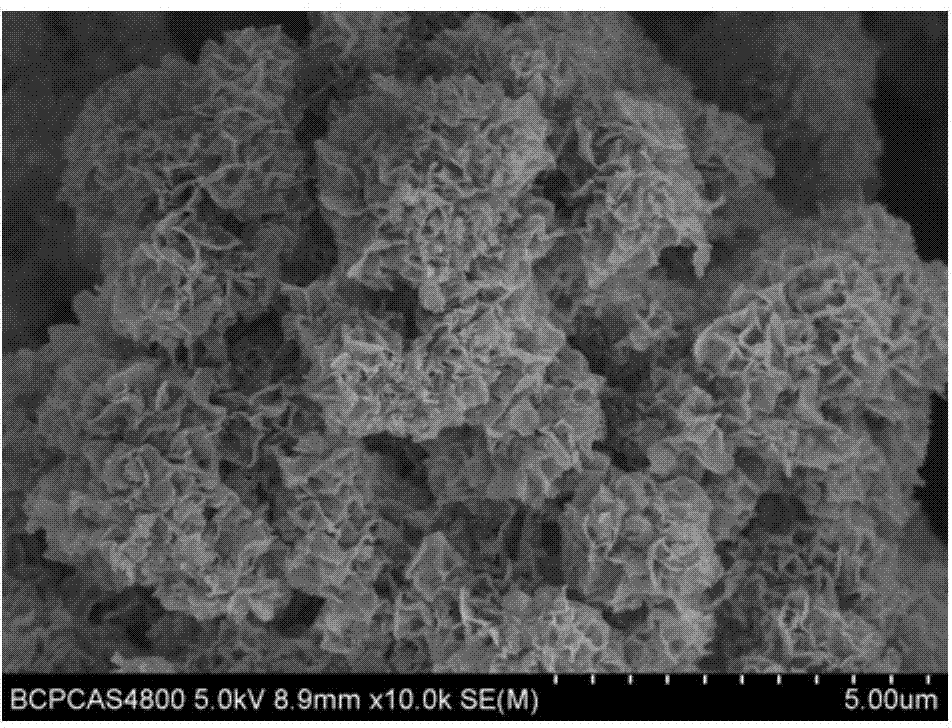

[0022] Take 100 grams of high-aluminum fly ash (48% alumina content and 40% silica content), add 20 grams of sodium hydroxide solution with a mass percentage of 20% to it, mix well, and place the mixture inside In a reactor lined with polytetrafluoroethylene, the desiliconization reaction is carried out at 90°C, the reactant is taken out after 4 hours of reaction, and filtered to obtain a desiliconization solution and filter residue. Add lime milk to the desiliconization solution, stir at room temperature for 1 hour, filter, dealkalize, wash, and dry to obtain active calcium silicate. The scanning electron microscope image is as follows figure 1 Shown. The results show that the active calcium silicate is spherical, with many wrinkles on the surface, mainly honeycomb, layered, and curled layered. The internal and surface pores of the particles are developed. The particle size is 20-40μm, and the pore size is 2-45nm. , The specific surface area can reach 160m 2 / g.

[0023] Take ...

Embodiment 2

[0025] Take 1L industrial sintering sodium aluminate solution (Al 2 O 3 The content is 96.83g / L, Fe 2 O 3 The content is 0.0152g / L, the causticity ratio is α k 1.2), put it in a temperature-controllable laboratory decomposition tank, then add 10 grams of active calcium silicate prepared in Example 1, and stir at a constant speed for 120 minutes at a rotation speed of 300r / min and a temperature of 90°C, and the stirring is complete Afterwards, it was taken out and separated by filtration to obtain a solution of sodium dealoaluminate. After chemical analysis, the Al in the deferrified sodium aluminate solution 2 O 3 The content is 96.21g / L, Fe 2 O 3 The content is 0.0015g / L, and the iron removal rate is 90.13%.

Embodiment 3

[0027] Take 1L industrial sintering sodium aluminate solution (Al 2 O 3 The content is 105.24g / L, Fe 2 O 3 The content is 0.0101g / L, causticity ratio α k 1.2), put it in a temperature-controllable laboratory decomposition tank, then add 15 grams of active calcium silicate prepared in Example 1, and stir at a constant speed for 60 minutes at a speed of 100r / min and 60°C, and the stirring is complete Afterwards, it was taken out and separated by filtration to obtain a solution of sodium dealoaluminate. After chemical analysis, the Al in the deferrified sodium aluminate solution 2 O 3 The concentration is 104.92g / L, Fe 2 O 3 The concentration is 0.0019g / L, and the iron removal rate is 81.19%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com