Method for improving iron removal effect of glass-phase coal-series waste by adopting microwave pretreatment

A pretreatment and glass phase technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of large stockpiles, unbalanced development of comprehensive utilization areas, and low added value of products, and achieve simple and convenient operation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

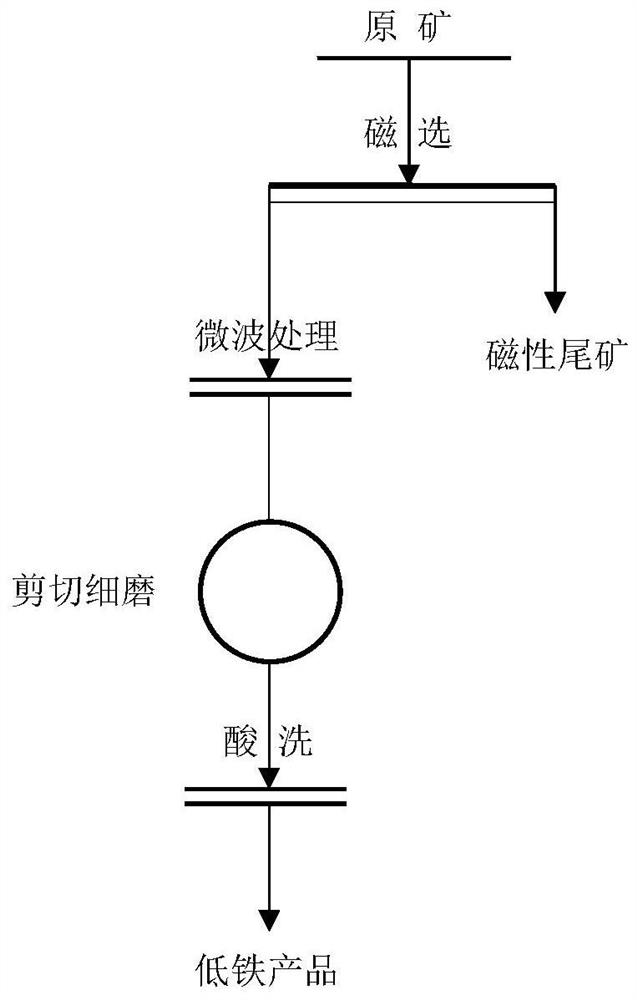

[0031] A method for improving the iron removal effect of glass-phase coal-measure waste by using microwave pretreatment, comprising the following steps:

[0032] (1) The glass-phase coal waste is removed by a magnetic separator, and the magnetic separation operation adopts a periodic pulsating high-gradient magnetic separator with a magnetic field strength of 6000Gs to obtain non-magnetic products;

[0033] (2) Microwave pretreatment is performed on the non-magnetic products after magnetic separation using a microwave oven. Microwave oven pretreatment: heating to a temperature of 100°C, a processing time of 10 minutes, and a microwave power of 1000W;

[0034] (3) The microwave-treated product is finely ground, and the fine grinding method adopts shear force crushing. The equipment is a grinder, and the grinding time is 18 minutes. The finely ground product is pickled, and finally the product after pickling is washed and filtered to obtain the whole Low iron products with less ...

Embodiment 2

[0037] A method for improving the iron removal effect of glass-phase coal-measure waste by using microwave pretreatment, comprising the following steps:

[0038] (1) The glass-phase coal waste is removed by a magnetic separator, and the magnetic separation operation adopts a periodic pulsating high-gradient magnetic separator with a magnetic field strength of 10000Gs to obtain non-magnetic products;

[0039] (2) Microwave pretreatment is performed on the non-magnetic products after magnetic separation using a microwave oven. Microwave oven pretreatment: heating to a temperature of 500°C, a processing time of 5 minutes, and a microwave power of 700W;

[0040] (3) The microwave-treated product is finely ground, and the fine grinding method adopts shear force crushing. The equipment is a grinder, and the grinding time is 24 minutes. Low iron products with less than 0.2% iron.

[0041] In step (3), hydrochloric acid solution with a molar concentration of 0.5 mol / L is used for pic...

Embodiment 3

[0043] A method for improving the iron removal effect of glass-phase coal-measure waste by using microwave pretreatment, comprising the following steps:

[0044] (1) The glass-phase coal-based waste is passed through a magnetic separator to remove magnetic substances. The magnetic separation operation adopts a dry-type induction roller strong magnetic separator with a magnetic field strength of 15000Gs to obtain non-magnetic products;

[0045](2) Microwave pretreatment is performed on the non-magnetic products after magnetic separation using a microwave oven. Microwave oven pretreatment: heating to a temperature of 400°C, a processing time of 8 minutes, and a microwave power of 800W;

[0046] (3) The microwave-treated product is finely ground, and the fine grinding method adopts shear force crushing. The equipment is a grinder, and the grinding time is 24 minutes. Low iron products with less than 0.2% iron.

[0047] In step (3), hydrochloric acid solution with a molar concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com