Roof bed separation water and coal-measure gas collaborative draining method

A roof detachment and coal-measure gas technology, which is applied in drainage, gas discharge, earthwork drilling and mining, etc., can solve the problems of difficult prevention and control of detachment water hazards, large instantaneous water inflow, and inability to take into account other issues of mine safety and production, etc., to achieve The Effect of Preventing Water Damage Accidents of Secondary Roof Detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

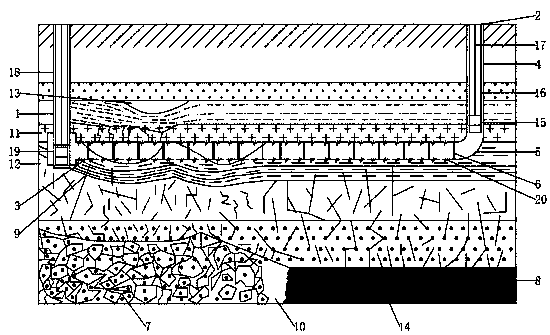

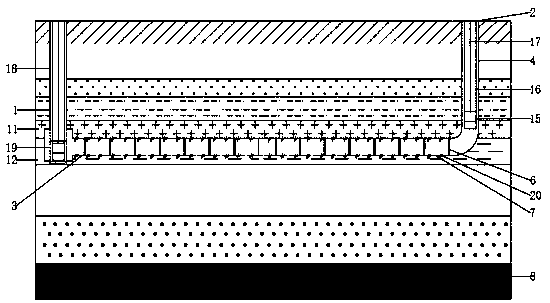

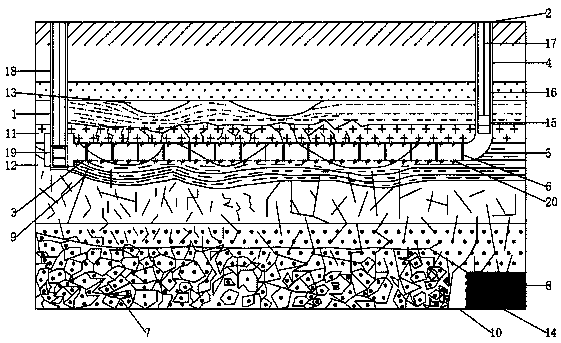

[0018] like figure 1 As shown, in the present invention, the work of drainage and gas production is divided into three stages, including: 1. the stage of single mining of coalbed methane; figure 1 : In the stage of single mining of coalbed methane, before coal recovery, conventional casing 18 directional perforation and staged hydraulic fracturing are performed on the horizontal section 3 of the horizontal well of the U-shaped well. The perforation direction is vertically downward, and vertical well 1 is mainly used for drainage Operation, horizontal well 2 gas production, fracturing fractures to extract the coal-measure gas in the coal seam 8 and the coal seam roof, the extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com