Design method for azimuthal angle of trajectory of commingled producing well of coal measure production group by considering transitional zones

A design method and transition zone technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve problems such as inability to perform accurate simulation, and achieve the effect of saving raw materials, high efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

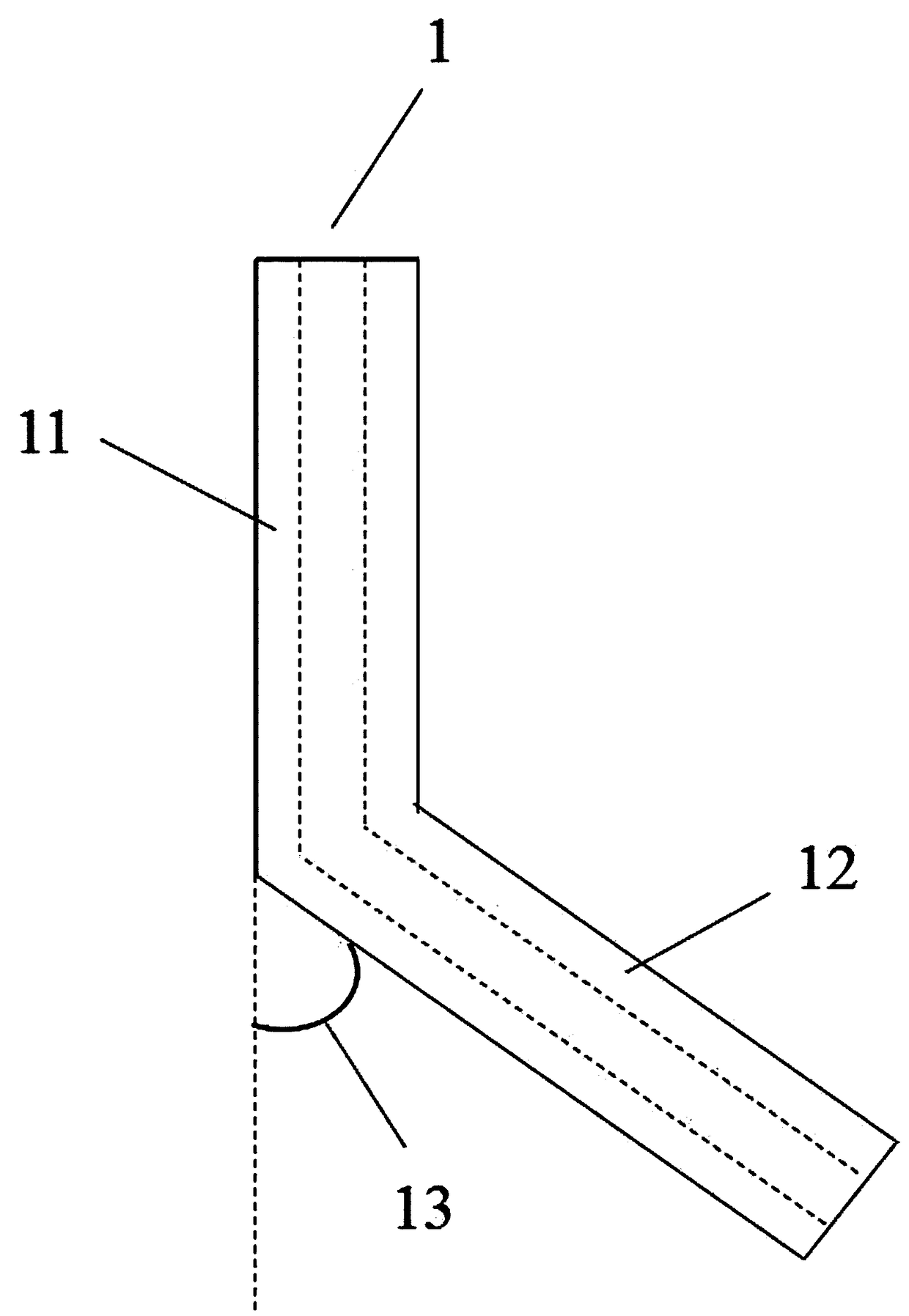

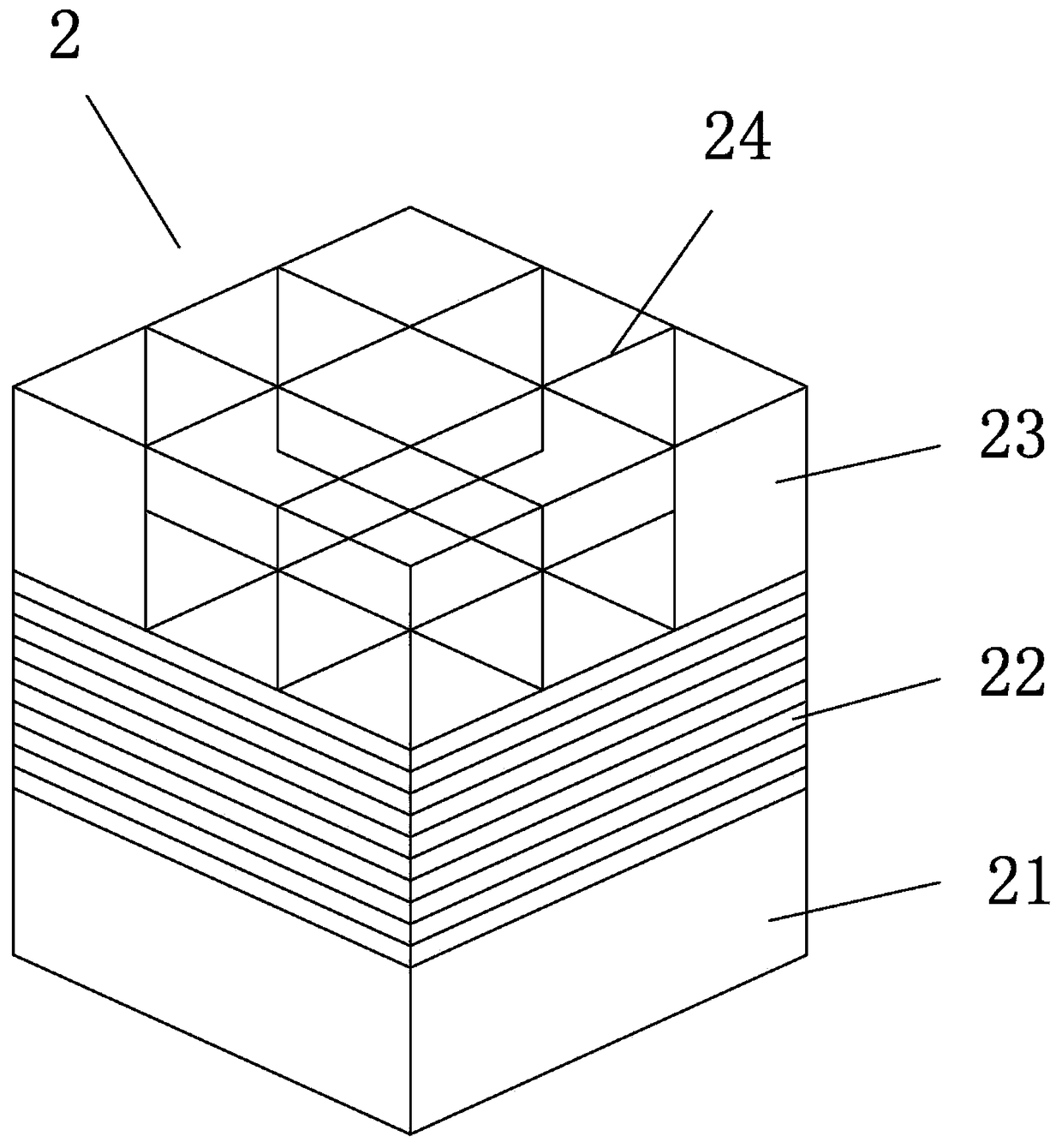

[0043] Such as Figure 1-2 As shown, according to an embodiment of the design method of the azimuth angle of the production well trajectory of the coal-measure production layer combination considering the transition zone of the present invention, it comprises the following steps in order:

[0044] Step 1: Statistically analyze the wellbore structure of the simulated block, determine the inclination angle range of the directional well in the block; process the simulated wellbore 1 with a certain inclination angle 13;

[0045] Step 2: Place the sample mold on the horizontal plane, and open a round hole in the center of the bottom surface of the sample mold; take the line passing through the hole and perpendicular to the bottom surface of the sample mold as the reference line, and simulate the wellbore according to a certain azimuth. 1, the wellbore head is placed downwards in the round hole;

[0046] Step 3: mix cement and quartz sand evenly according to a certain ratio, add wa...

Embodiment 2

[0064] According to another embodiment of the preparation method of the fracturing model sample of the coal-measure production layer group considering the transition zone of the present invention, its specific steps, preparation principle, beneficial effect, etc. are all the same as the first embodiment, the difference is:

[0065] The particle size of described quartz sand is 120 orders;

[0066] In Step 1, the simulated wellbore has an outer diameter of 20 mm and an inner diameter of 15 mm. The length of the vertical section is 40mm, the length of the directional section is 150mm, and the inclination angle is 30°.

[0067] In step 2, the azimuth angle is 60º.

[0068] In step 3, the mass of water added to the cement slurry is 25% of the total mass of cement and quartz sand. The pouring height of the cement slurry in the sample mold is 50 mm.

[0069] In step 4, the volume ratios of cement, quartz sand and coal powder in the ten parts of coal-containing slurry are 1:1:0.15...

Embodiment 3

[0073] According to another embodiment of the preparation method of the fracturing model sample of the coal-measure production layer group considering the transition zone of the present invention, its specific steps, preparation principle, beneficial effect, etc. are all the same as the first embodiment, the difference is:

[0074] The particle size of described quartz sand is 100 orders;

[0075] In step 1, the outer diameter of the simulated wellbore is 18 mm, and the inner diameter is 13 mm. The length of the vertical section is 60 mm, the length of the directional section is 110 mm, and the inclination angle is 60°.

[0076] In step 2, the azimuth angle is 45°.

[0077] In step 3, the mass of water added to the cement slurry is 20% of the total mass of cement and quartz sand. The pouring height of the cement slurry in the sample mold is 80 mm.

[0078] In step 4, the volume ratios of cement, quartz sand, and coal powder in ten parts of coal-containing slurry are 1:1:0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com