Sludge low-temperature drying process and sludge low-temperature dryer

A drying process and dryer technology, used in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of time-consuming, labor-intensive, low-efficiency, etc., and achieve the effects of high efficiency, preventing a large amount of volatilization, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

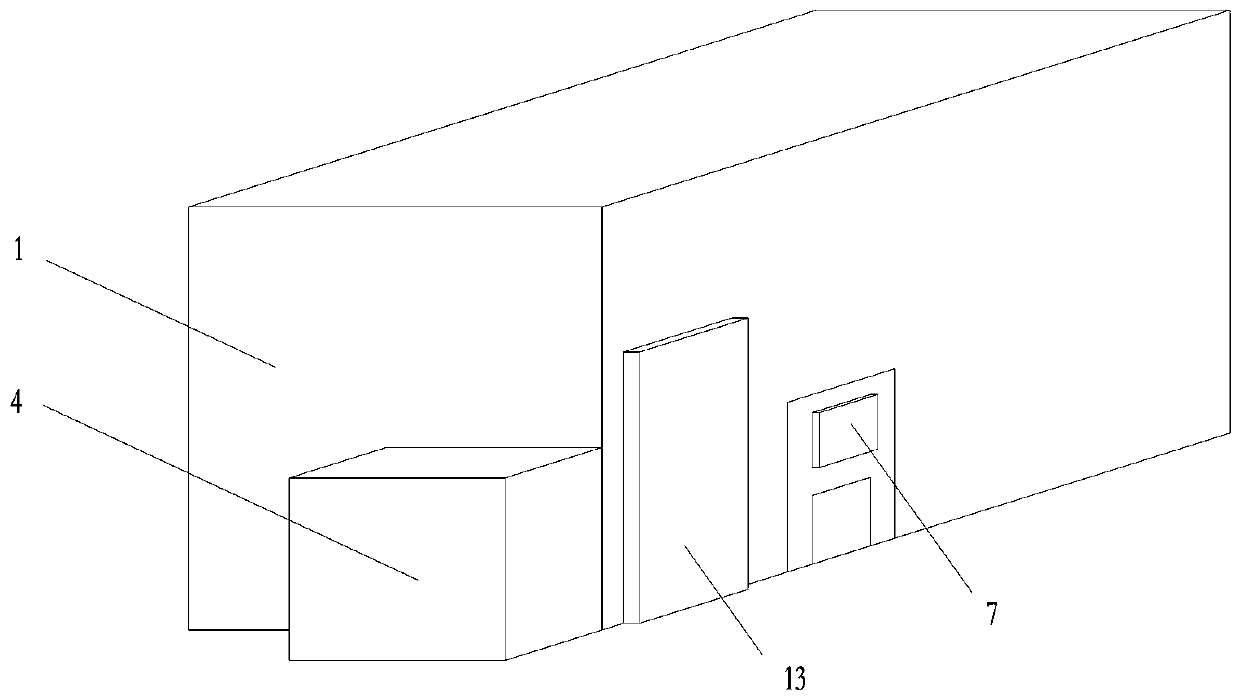

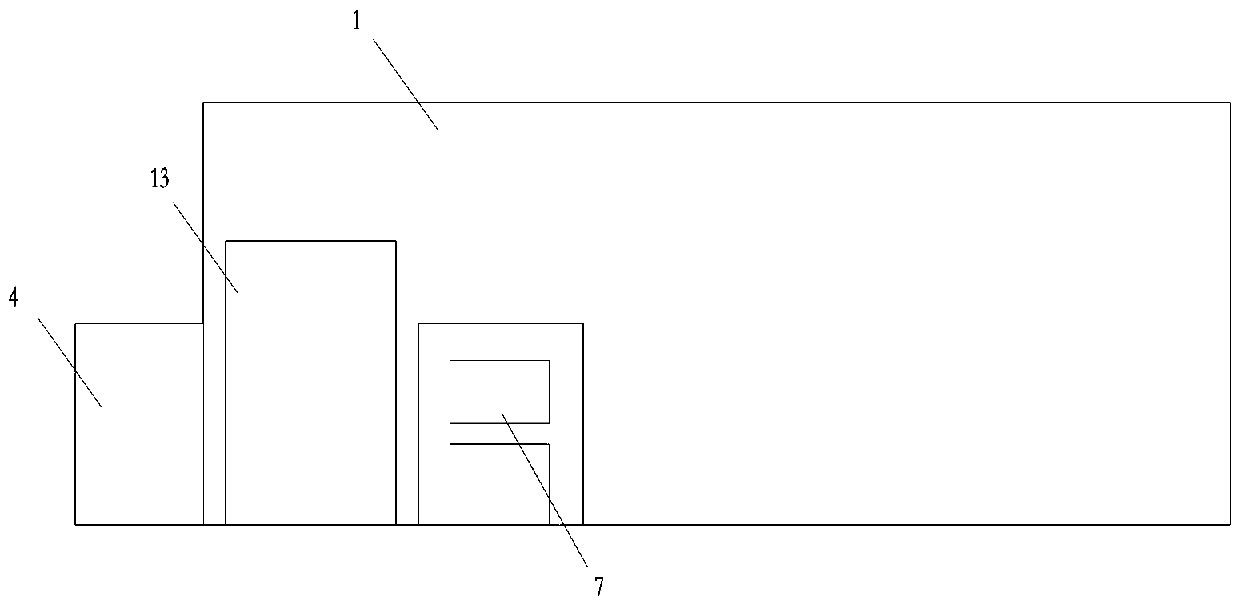

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

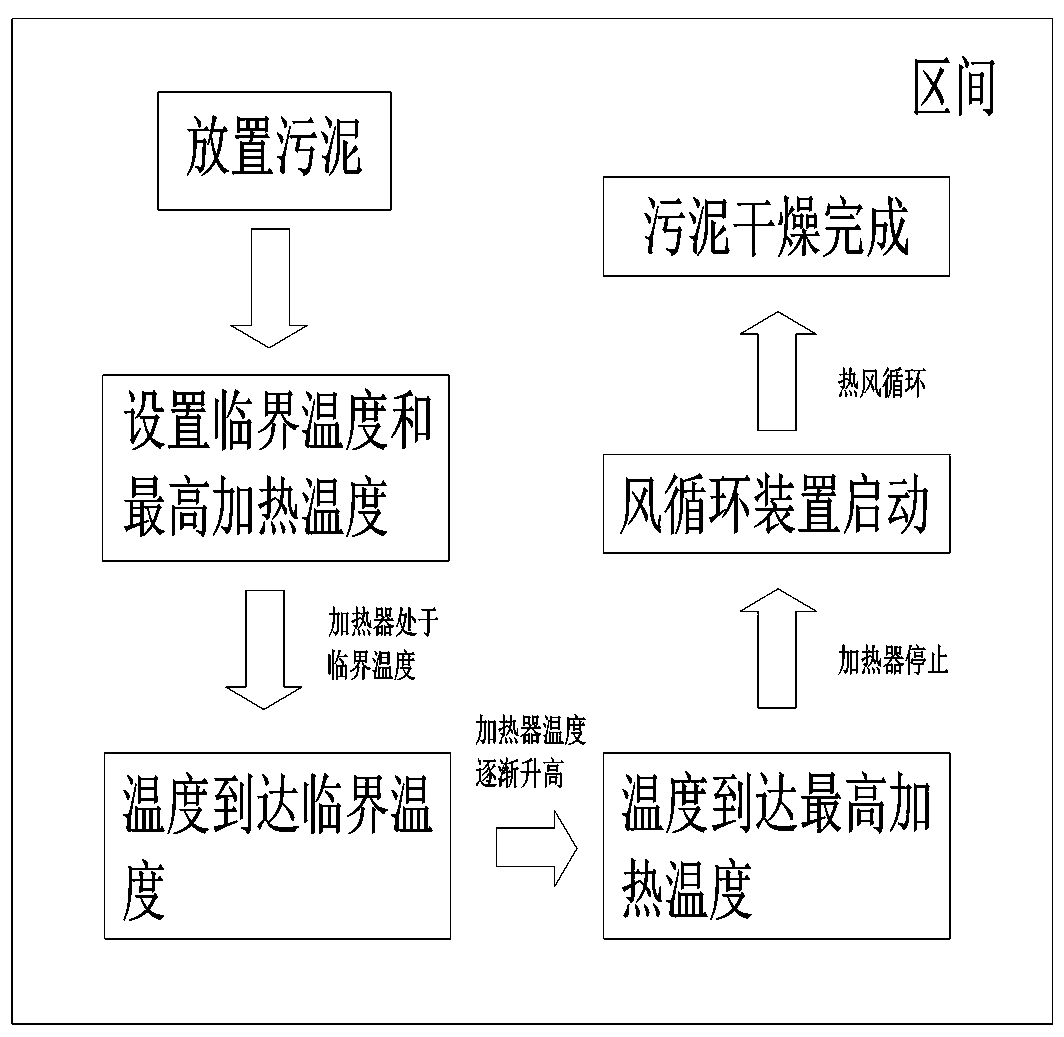

[0030] A sludge low-temperature drying process, characterized in that the steps are as follows:

[0031] 1) At least one section 31 for placing sludge is provided, and a temperature sensor, a heating device and an air circulation device 5 are provided in the section 31, and a critical temperature and a maximum heating temperature are provided in the heating device.

[0032] 2) Place the sludge to be dried in section 31, start the heating device and air circulation device 5, and heat the sludge in section 31. At this time, the temperature of the heating device is set at the critical temperature.

[0033] 3) When the temperature sensor monitors that the temperature in section 31 reaches the critical temperature, the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com