Method for improving tobacco shred making quality of reconstituted tobacco

A technology for reconstituted tobacco leaves and shredded tobacco, applied in tobacco, tobacco preparation, application, etc., to achieve the effects of timeliness and flexibility, convenient operation, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

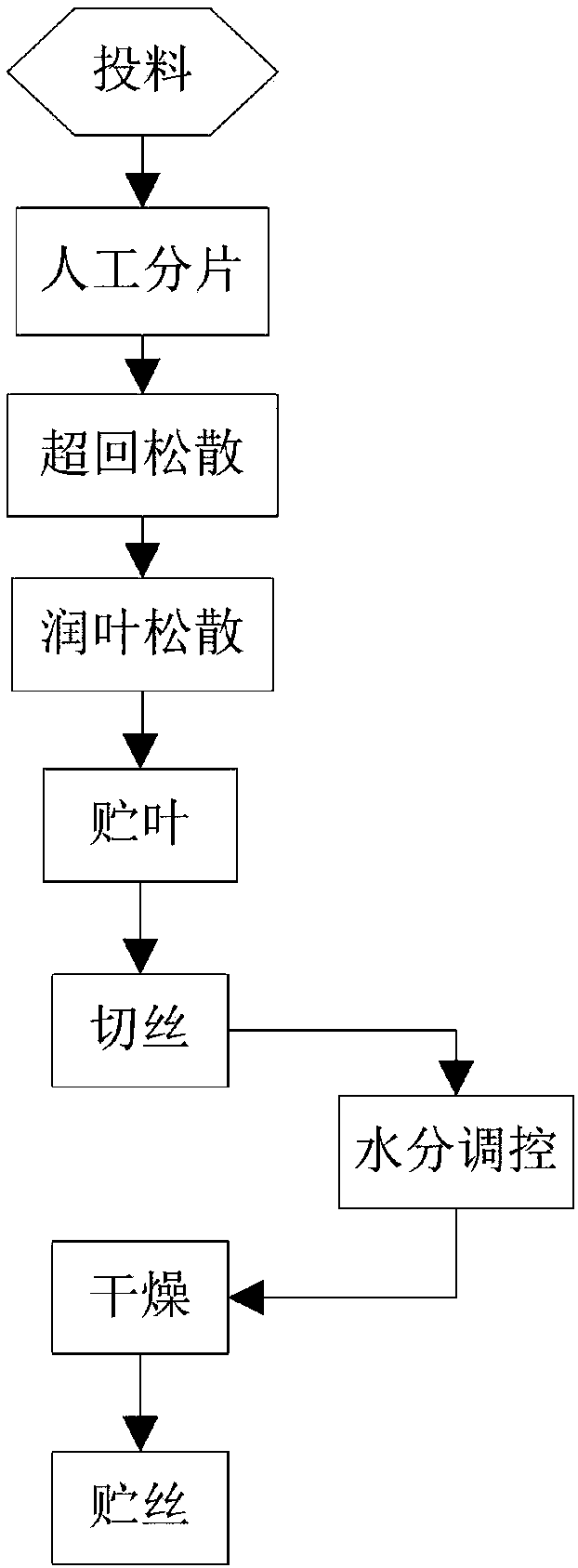

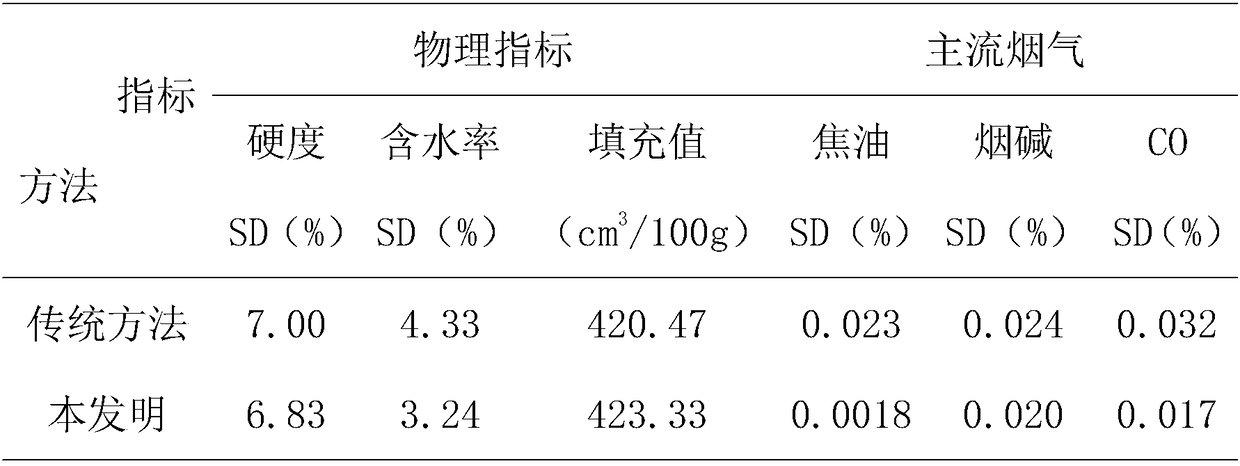

[0038] A method for improving the quality of shredded reconstituted tobacco leaves made of a certain brand of reconstituted tobacco leaves through water regulation includes the following steps:

[0039] (1) After the reconstituted tobacco leaves are fed, they are fed through ultra-loose and quantitative feeding to the step of moisturizing the leaves. After the leaves are stored, they are sent to the shredder for shredding. Process before drying silk.

[0040] (2) After cutting the reconstituted tobacco leaves, use moisture control to complete the moisture control of the material before drying, and add moisture control equipment on the production line between the shredded leaf feeding and the temperature increasing and humidifying equipment to realize the reconstituted tobacco leaves at the entrance of the shredded tobacco Humidification or drying can moderately increase or decrease the moisture content of the material, improve the physical processing resistance of the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com