A spraying device and spraying method of PTC heating material for toilet seat

A technology for heating materials and spraying devices, which is applied in the direction of spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc. It can solve the problems of uneven heating temperature of toilet seat, low spraying efficiency, and easy to be sprayed out of bounds, etc., to achieve Avoid incomplete drying and improve spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings to make those skilled in the art with reference to the specification.

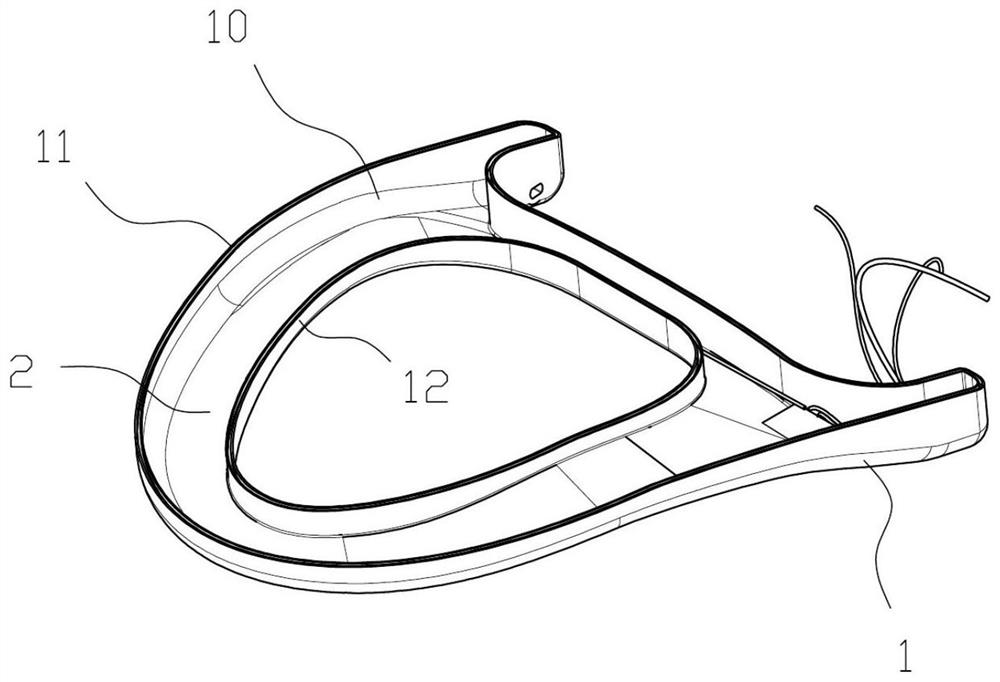

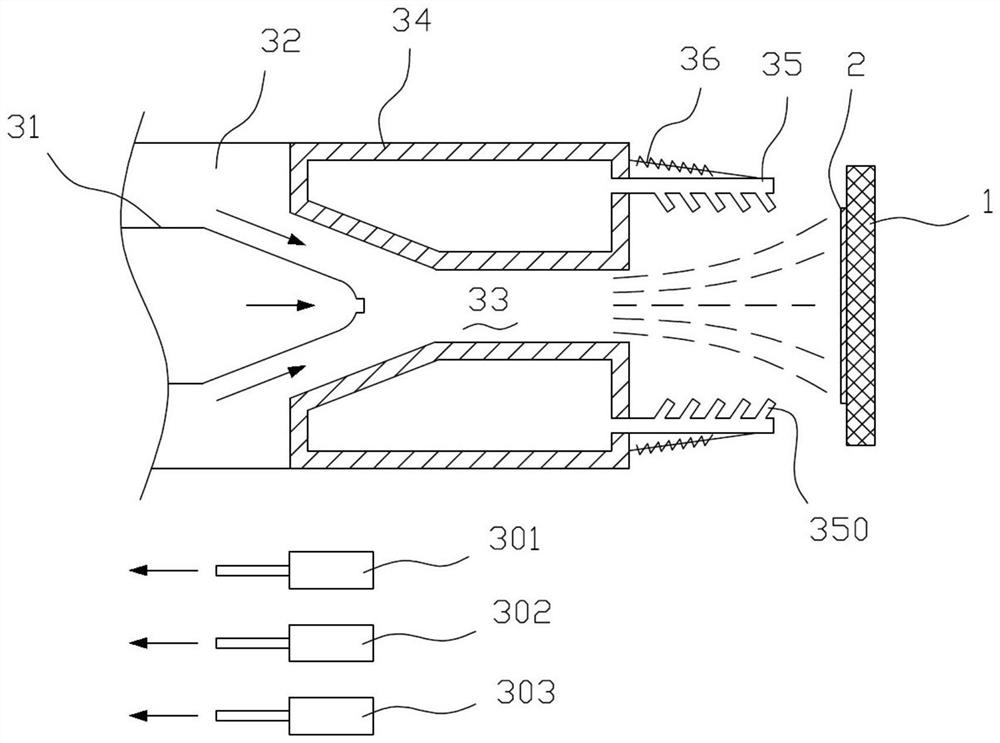

[0029] Such as figure 1 with figure 2 As shown, the present invention provides a spray apparatus for a PTC heating material for a toilet ring, including:

[0030] The material supply unit 31 is used to store and export PTC heating materials;

[0031] The material blowing portion is disposed on the side of the material supply portion 31 for blowing the PTC heating material to the toilet ring 1 to form a PTC heating layer 2;

[0032] The spray guide portion 35 is provided at a side portion at the outlet of the material blowing portion for guiding the PTC heating material blown from the material blowing portion to avoid the PTC heating material is sprayed out of the predetermined range and used for Dry the PTC heating layer 2;

[0033] Heating element (not shown in Figure);

[0034] Wherein the spray guide p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com