Automatic weighing and batching system for carbon black powder

An automatic weighing and batching system technology, applied in mixer accessories, mixed material pretreatment, mixers, etc., can solve problems such as loss of manufacturers and end users, material scrap, quality accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

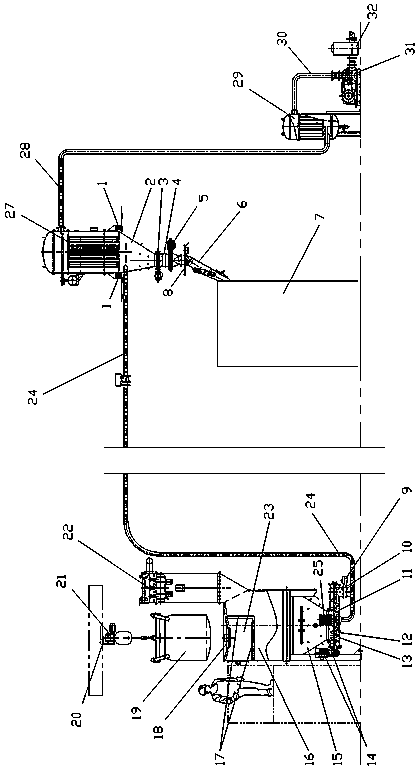

[0013] Such as figure 1 Shown: the automatic weighing and batching system for carbon black powder of the present invention includes an upper hopper 16, a hopper cover 18 is arranged on the upper side of the upper hopper 16, and the inner side of the upper hopper 16 is located at the upper entrance (that is, the hopper cover 18) A pneumatic screen 17 connected with the pneumatic device is provided. The upper part of the upper hopper 16 is connected with a dust recovery device 22, and the dust recovery device 22 is a filter bag type dust collector.

[0014] The lower side of the upper hopper 16 is connected with the lower hopper 15, and the outlet of the lower end of the lower hopper 15 is connected with a horizontally arranged feeding cylinder 13, and the inner side of the feeding cylinder 13 is supported by a rotating shaft 12, and the rotating shaft 12 is provided with a pushing blade 11 , forming a Jiaolong conveying mechanism. One end of the rotating shaft 12 protrudes fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com