Method for temporarily bonding and debonding slice applied to semiconductor manufacturing process

A temporary bonding and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high temperature and environment requirements, silicon wafer pollution in process steps, high process complexity, etc., and achieve low requirements, The effect of strong operation and practicability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

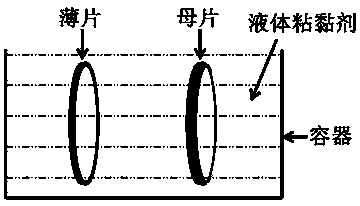

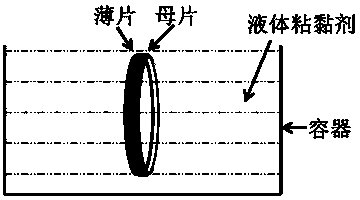

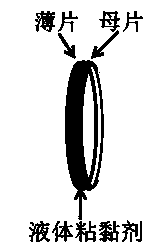

[0023] A method for temporary bonding and debonding of wafers used in semiconductor manufacturing process Step 1: Place semiconductor wafers and mother wafers to be bonded into a container filled with liquid adhesive. The depth of the liquid in the container needs to be greater than that of the wafer and mother wafer The diameter of the sheet, the semiconductor flakes are single crystals, polycrystals and non-wafers of group IV materials and III-V materials; the semiconductor mother sheet is a single crystal of the same material with the same size and shape as the semiconductor sheet, Polycrystalline and non-wafer; the thickness of the sheet is 50 μm to 200 μm; the thickness of the mother sheet is 150 μm to 1000 μm; Step 2: In a container containing a liquid adhesive, place the sheet and the mother sheet in parallel Gradually approach and contact alignment, so that the two are sticky and adsorbed together, and the edges of the two are aligned. When the sheet and the mother shee...

Embodiment 2

[0025]A method for temporary bonding and debonding of sheets used in semiconductor manufacturing processes, step 1: placing semiconductor sheets and mother sheets to be bonded in a container filled with a liquid adhesive, the liquid adhesive being deionized water or ethanol. The container holding the liquid adhesive is a liquid pool or a liquid tank. The depth of the liquid in the container needs to be greater than the diameter of the sheet and the mother sheet. The semiconductor sheet is a single crystal, polycrystalline and Non-wafer, group IV materials such as Ge, group III-V materials such as InP, etc.; the semiconductor mother sheet is single crystal, polycrystal and non-wafer of the same material with the same size and shape as the semiconductor sheet; the thickness of the sheet 200 μm; the thickness of the mother sheet is 1000 μm; Step 2: In a container containing a liquid adhesive, gradually move the thin sheet and the mother sheet closer together in a parallel manner ...

Embodiment 3

[0027] A method for temporary bonding and debonding of sheets used in semiconductor manufacturing processes, step 1: placing semiconductor sheets and mother sheets to be bonded in a container filled with a liquid adhesive, the liquid adhesive being deionized water or ethanol. The container holding the liquid adhesive is a liquid pool or a liquid tank. The depth of the liquid in the container needs to be greater than the diameter of the sheet and the mother sheet. The semiconductor sheet is a single crystal, polycrystalline and Non-wafer, group IV materials such as Si, group III-V materials such as GaAs; the semiconductor mother sheet is single crystal, polycrystal and non-wafer of the same material with the same size and shape as the semiconductor sheet; the thickness of the sheet is 50 μm; the thickness of the mother sheet is 150 μm; step 2: in a container containing a liquid adhesive, gradually move the thin sheet and the mother sheet closer together in a parallel manner and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com