Device for machining metal mirror by laser ablation

A technology of laser ablation and metal, which is applied in the field of mold manufacturing, can solve problems such as difficult to ensure dimensional accuracy, pollute the environment, and low processing efficiency, and achieve the effect of free control of roughness, no pollution, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

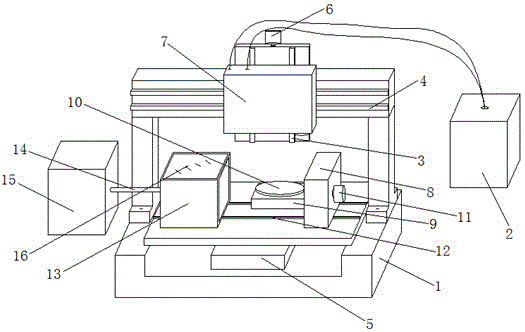

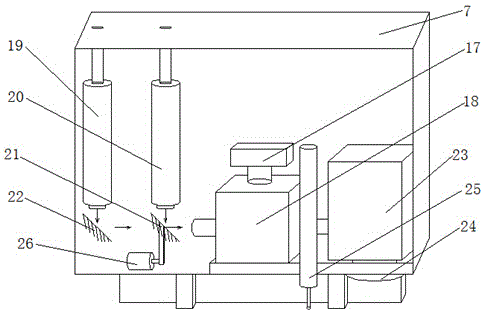

[0017] Attached below figure 1 with 2 The present invention is further described. figure 1 with figure 2 Schematically shows a device of the present invention that uses laser ablation to process metal mirrors, such as figure 1 As shown, it includes an operation platform 1 and a laser 2. The operation platform 1 is provided with a five-axis linkage structure of Z-axis 3, X-axis 4, Y-axis 5, A-axis and C-axis. The Z-axis 3 is provided with The Z-axis motor 6 and the cavity 7, the Z-axis 3, the Z-axis motor 6 and the cavity 7 are all arranged on the X-axis 4, as figure 2 As shown, the cavity 7 is provided with a camera 17, an automatic focusing device 18, a high-power laser output head 19, a low-power laser output head 20, an optical path switching mirror 21 and a total reflection mirror 22. Next to the camera 17 A scanning vibrating mirror 23 is also connected, and a flat-field lens 24 is arranged below the scanning vibrating mirror 23 . The Y-axis 5 is provided with an A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com