Connection method of cathode steel rod and cathode soft bus in aluminium electrolytic bath

A technology of cathode soft busbar and cathode steel rod, which is applied in the field of connection between cathode soft busbar and cathode steel rod, can solve the problem of affecting the stability of cathode current distribution in electrolytic cells, improve the power consumption and production cost of aluminum per ton of aluminum production, and the cathode steel rod Problems such as rough crimping surface, to improve the quality of crimping, reliable work, and reduce the effect of voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

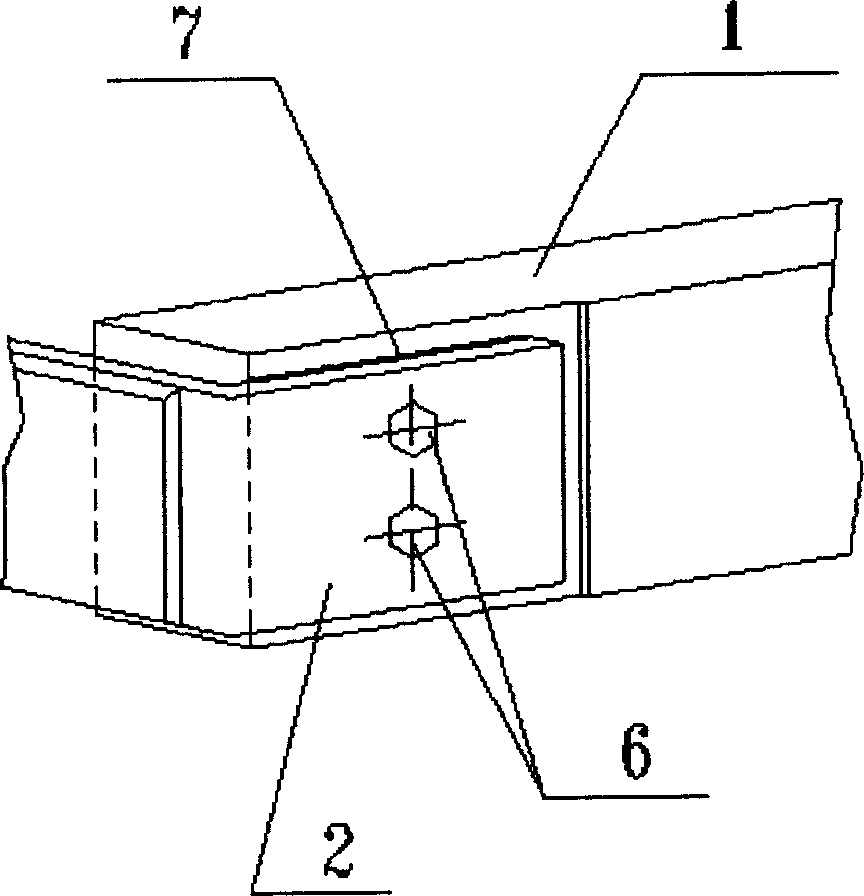

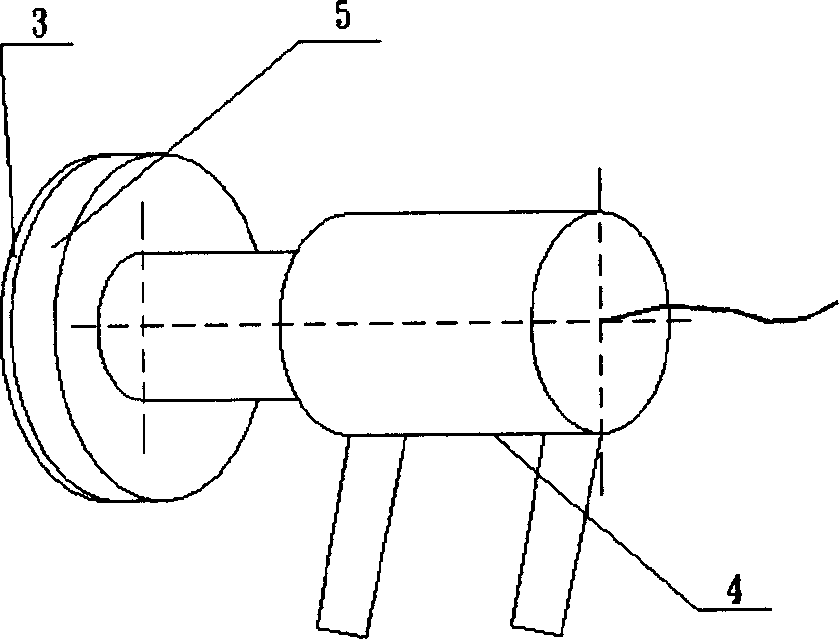

[0008] Embodiment of the present invention: earlier make 2~4 bolt connection holes on the crimping surface of the cathode steel bar (1) that has just built furnace, the flat disk of the hand-held grinder (4) that sells on the market The grinding wheel on (5) is removed, and then the sandpaper (3) for grinding is fixed on the circumference of the flat plate (5) of the hand-held grinder (4) by bonding, and the hand-held grinding wheel is held by hand The handle of the grinder (4), so that the sandpaper (3) mounted on the flat plate (5) of the hand-held grinder (4) can grind the crimping surface of the cathode steel rod (1) back and forth, and grind the crimping surface After the light is bright, place the crimping block (2) on the crimping surface after the cathode steel rod (1) is polished, and make the crimping block (2) tightly crimp on the cathode steel rod (1) through the bolt (6). ) on the crimping surface after polishing; in order to prevent the crimping surface from rust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com