Patents

Literature

132results about How to "Improve crimping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

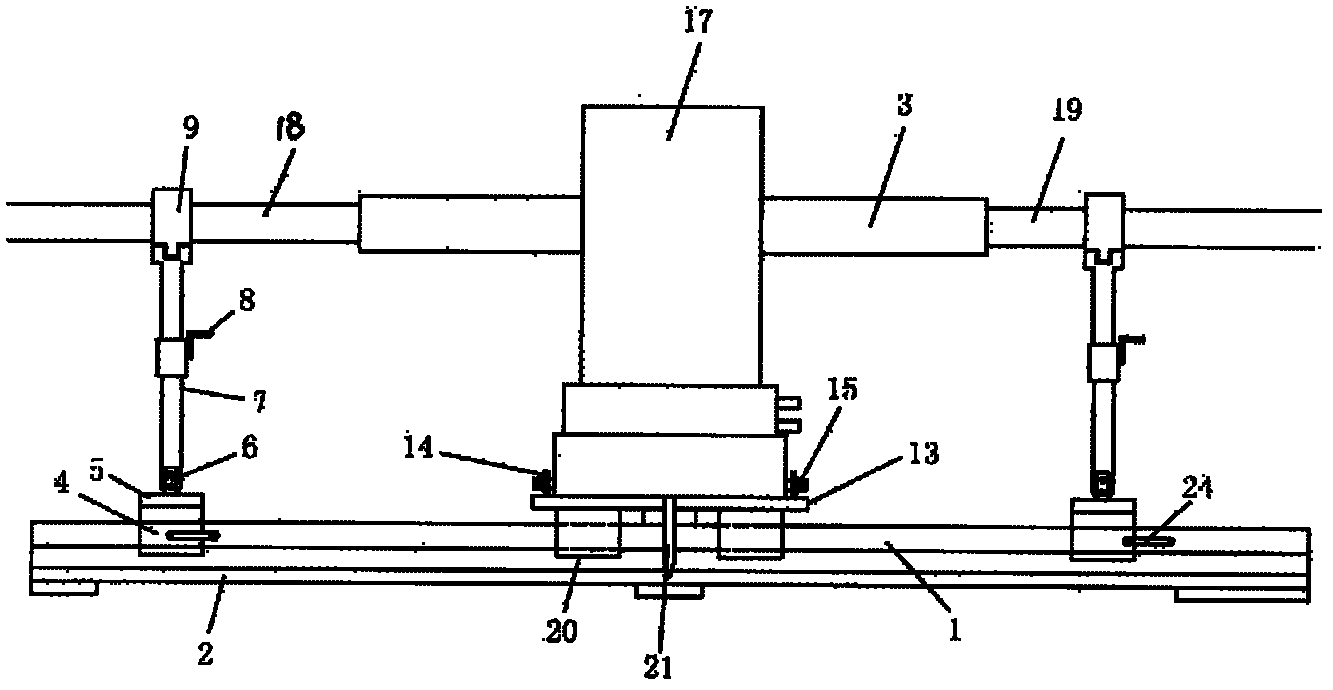

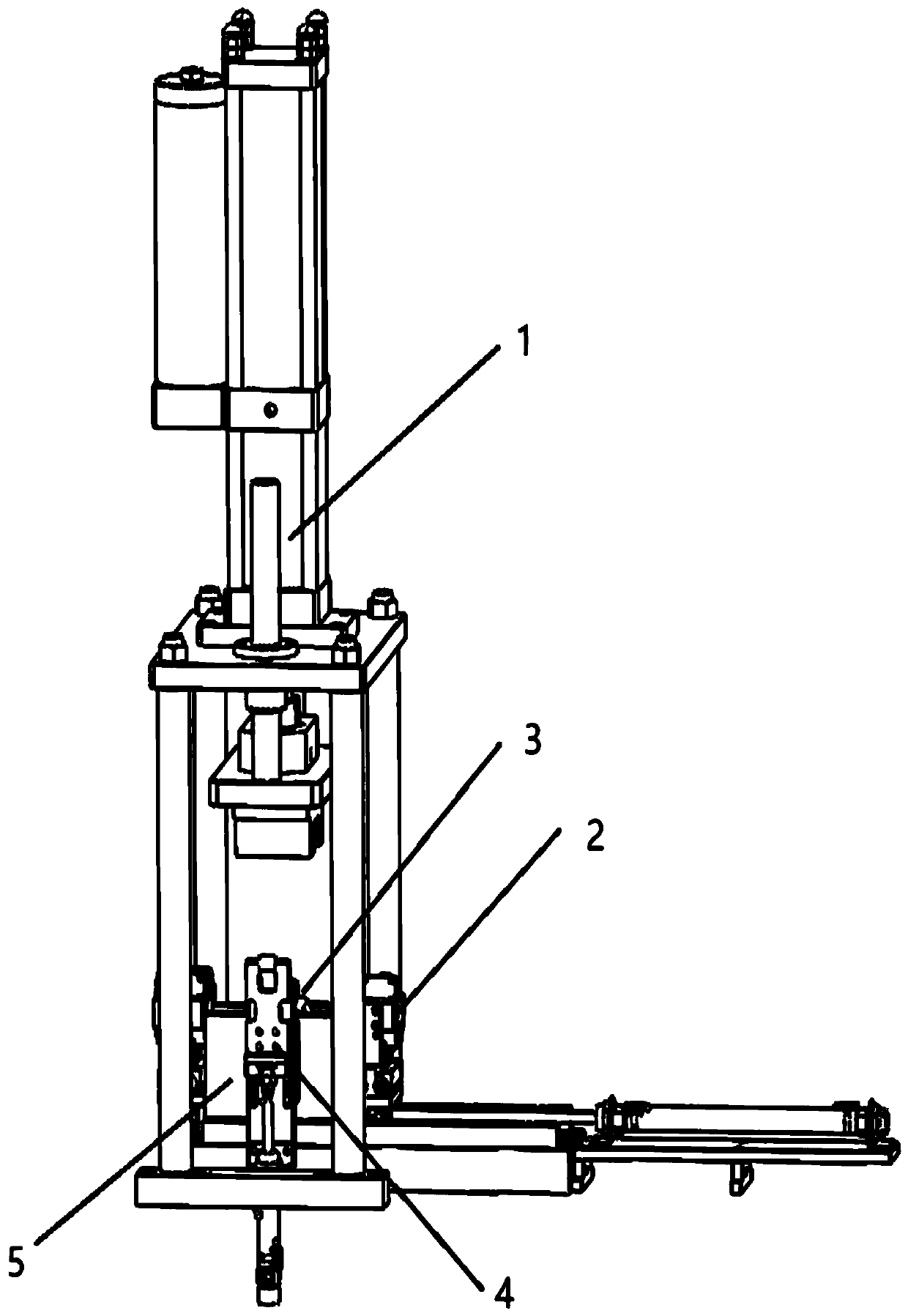

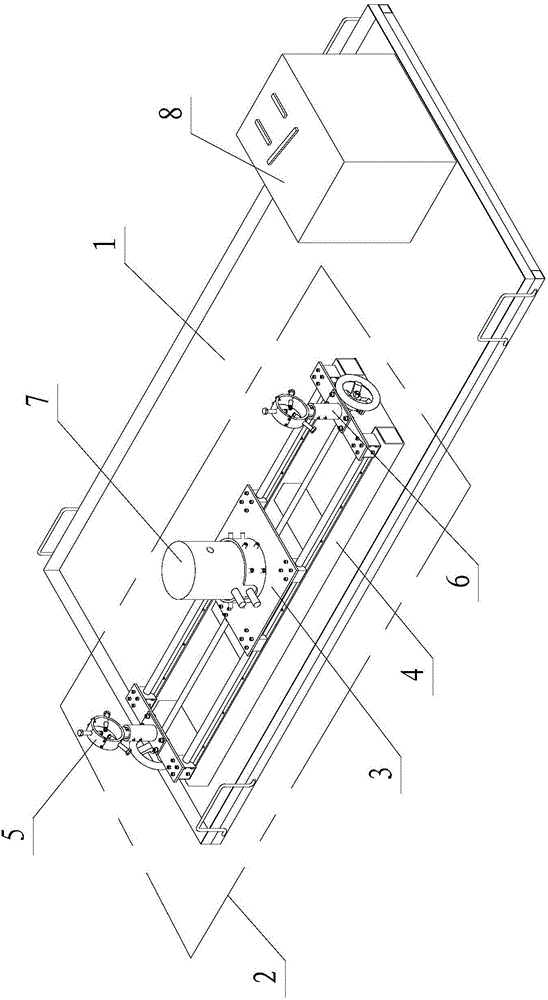

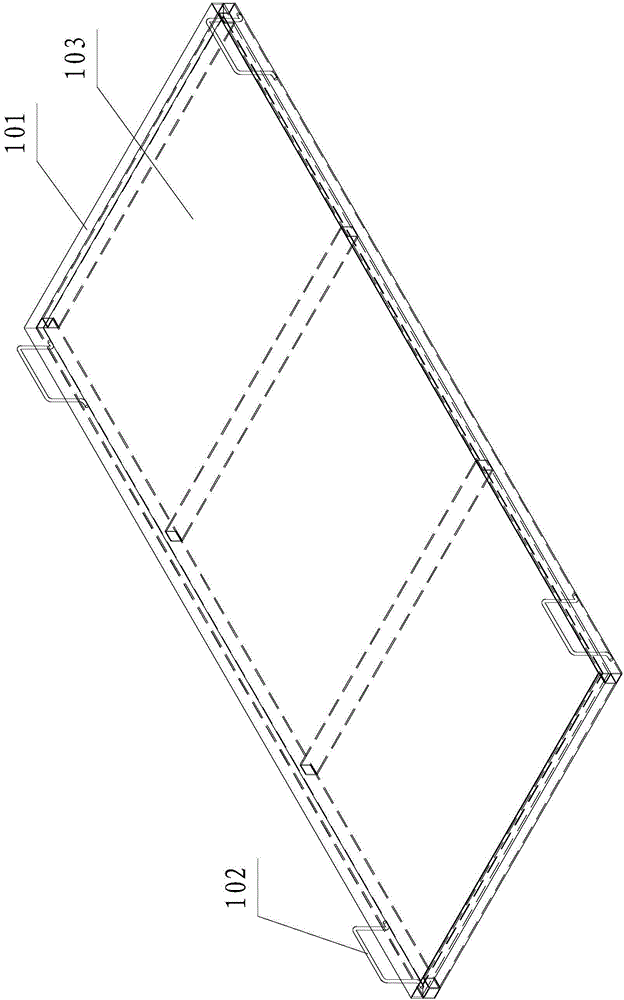

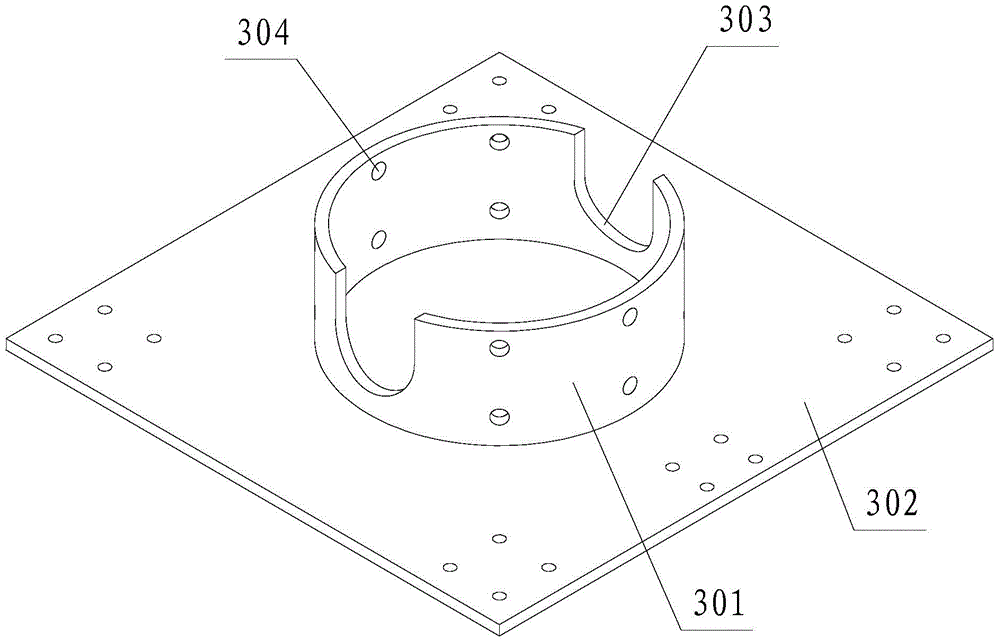

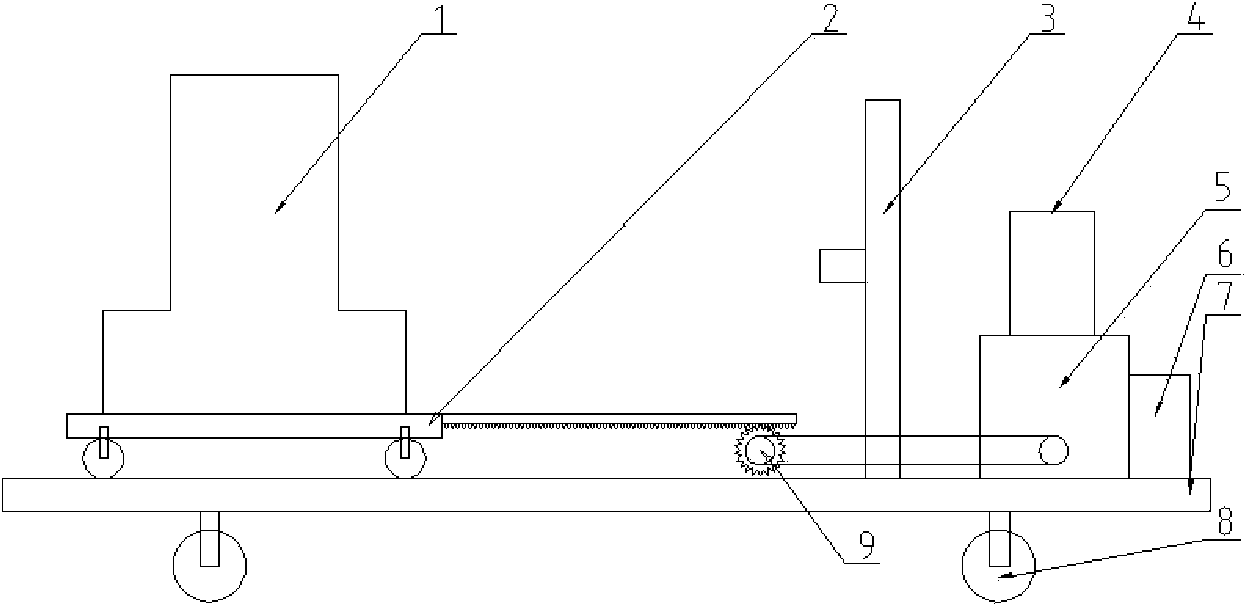

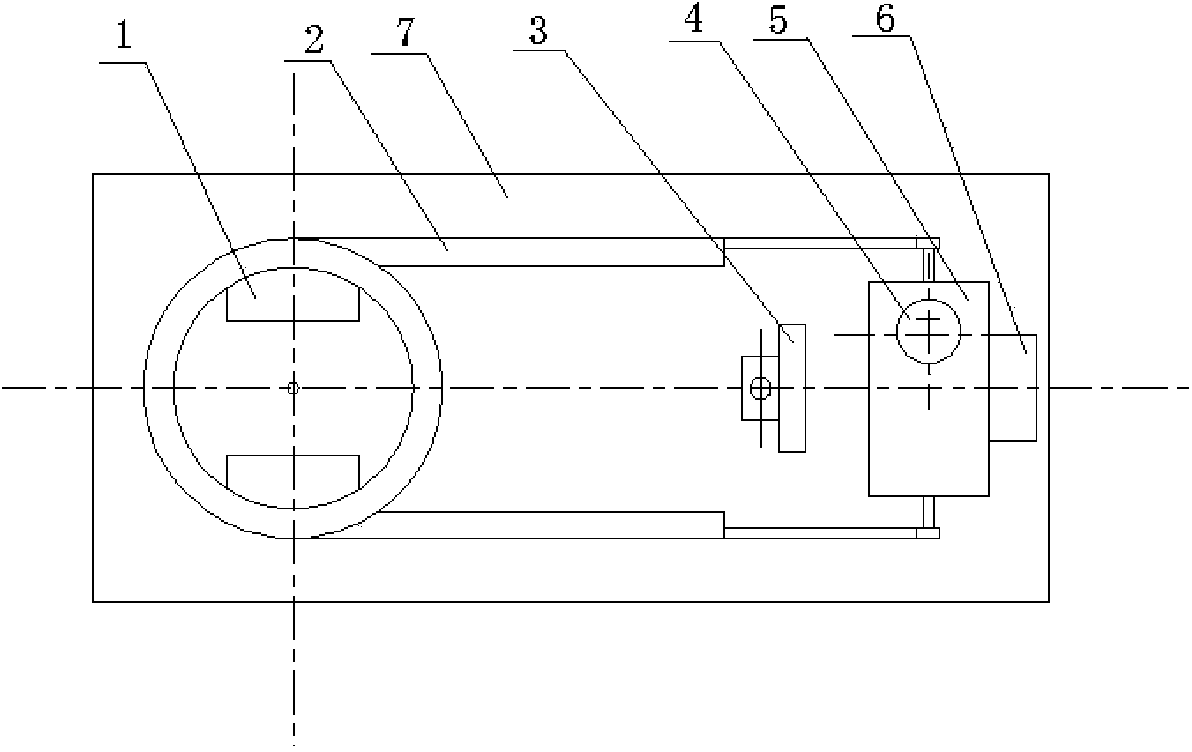

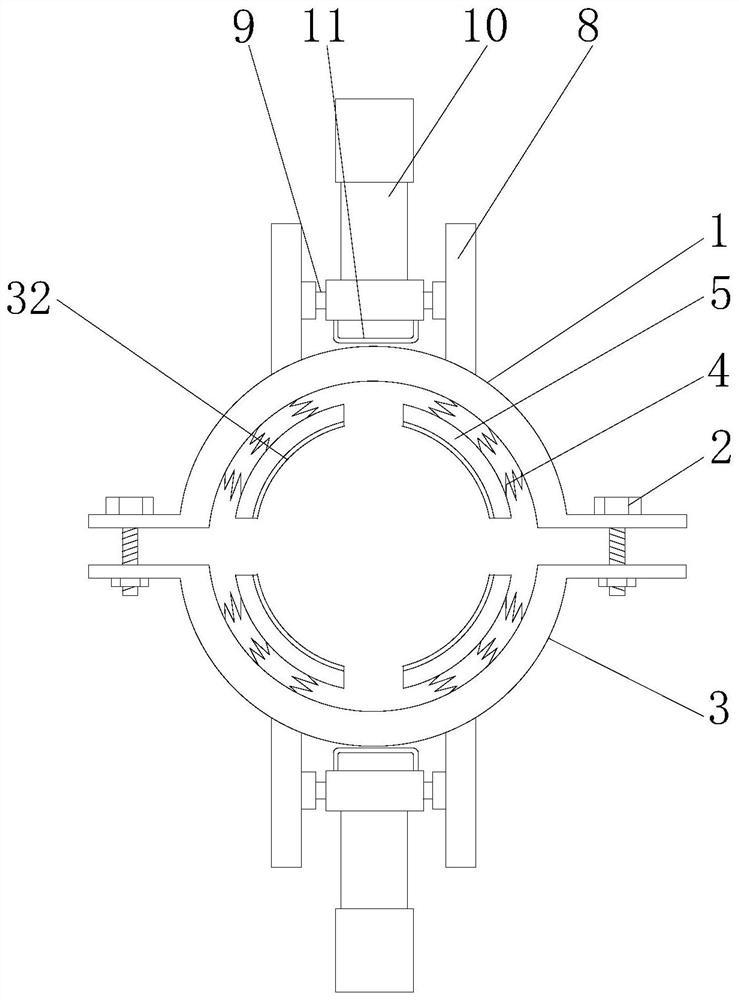

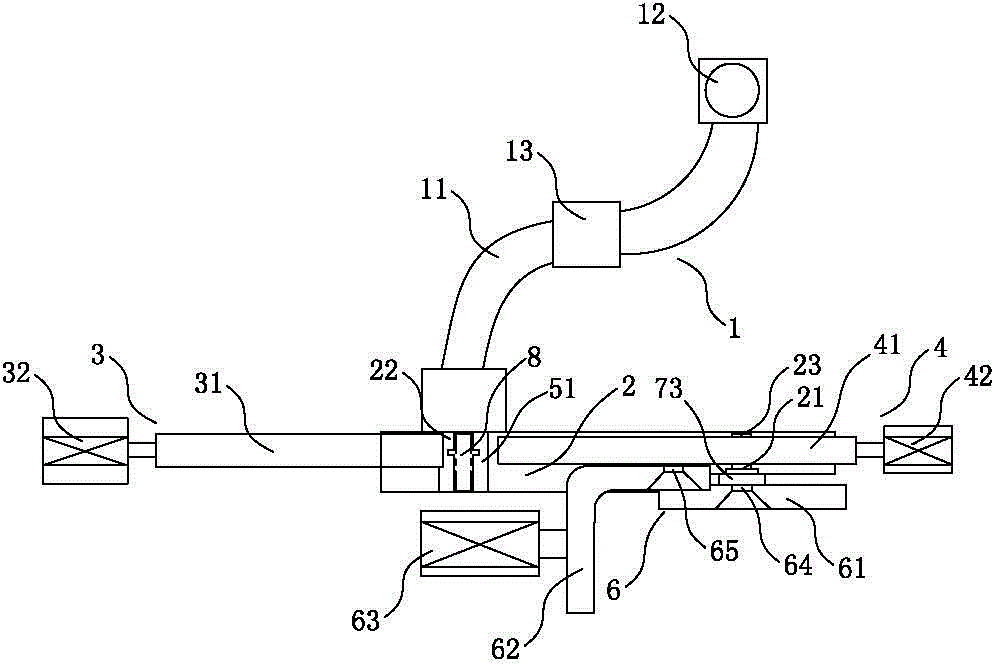

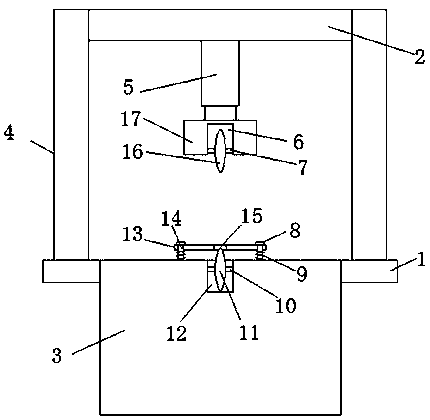

Hydraulic connection operating platform of grounding wires

The invention relates to a hydraulic connection operating platform of grounding wires, belonging to a machine tool for carrying out hydraulic connection on two electric grounding wires by using a crimping pipe. Two rails are erected on a platform base in parallel; two grounding wire support bases are arranged at the left side and the right side of the two rails by sliding blocks; a pair of hydraulic pliers are fixed in a fixed ring through a plurality of fastening bolts; the fixed ring is welded on a mounting plate; the mounting plate is arranged on the two rails through four sliding blocks arranged the lower part of the mounting plate; a stepping motor is arranged on the platform base; a ball screw is connected with the stepping motor through a shaft; the ball screw is arranged below the platform base through two sliding rail supports and spirally connected to a screw nut; and the screw nut is fixed on the bottom surface of the mounting plate. The hydraulic connection operating platform disclosed by the invention has the characteristics of simple structure, safety and reliability, controllable lapping length of the two grounding wires and high crimping efficiency.

Owner:SICHUAN POWER TRANSMISSION & TRANSFORMATION CONSTR +1

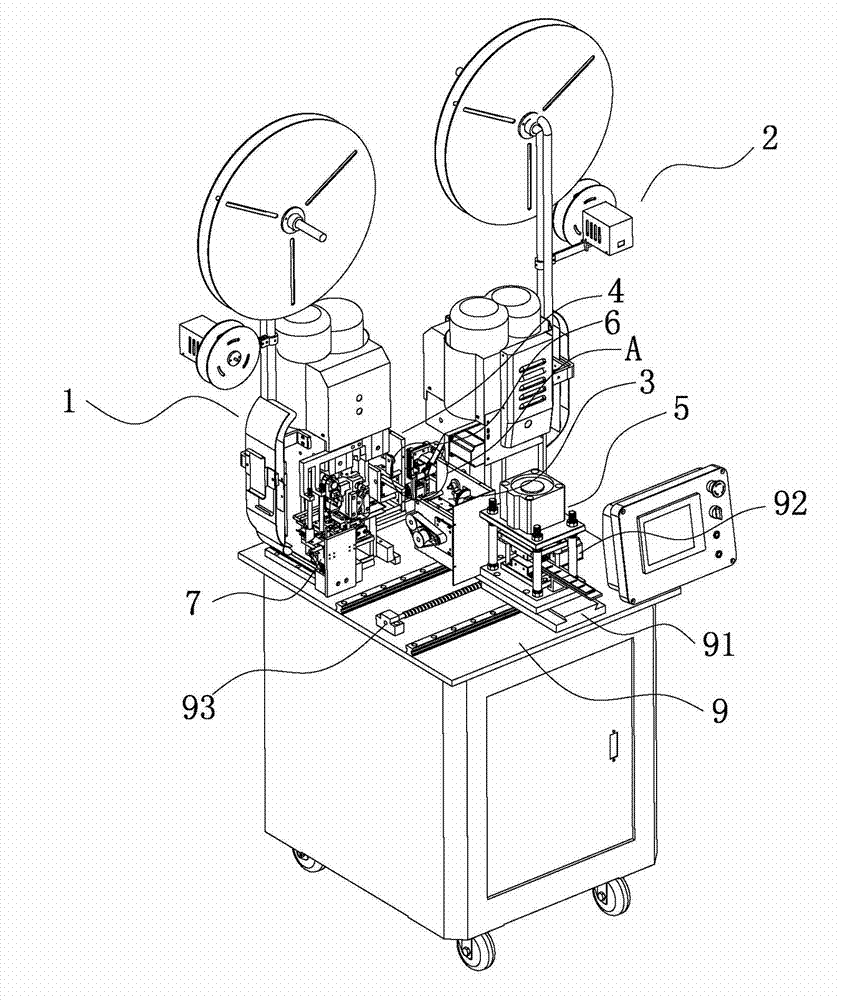

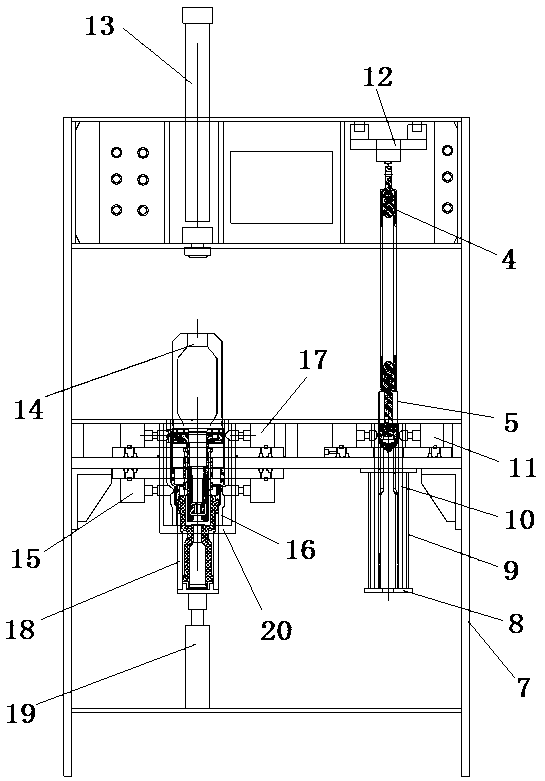

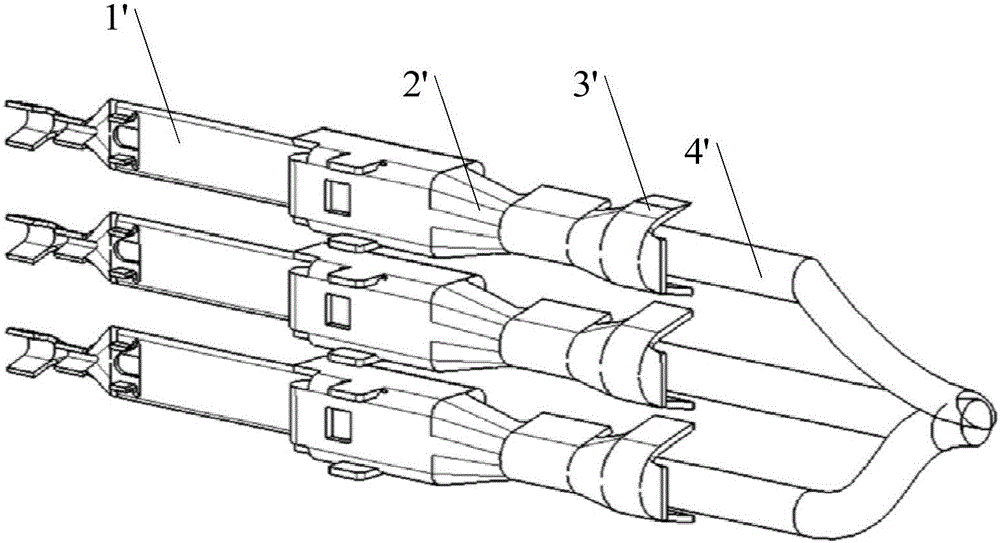

Cable terminal crimping machine

InactiveCN102761044AImprove crimping efficiencyHands-freeConnection formation by deformationComputer engineeringSingle lead

The invention discloses a cable terminal crimping machine, comprising a rack, a cable feeding device arranged on the rack, a cable stripping device and a terminal crimping device, wherein the rack is provided with a cable dispersing device capable of dispersing cables; and the terminal crimping device is provided with a cable drawing device capable of drawing out the dispersed cables one by one. The cables are dispersed by the cable dispersing device, then are fed by the cable feeding device, then are stripping by the cable stripping device, and fiannly are conveyed to the terminal crimping device; in a terminal crimping process, the cable drawing device is used for sequentially separating the dispersed cables one by one, and the terminal crimping operation of single lead is carried out by the terminal crimping device so as to finish the terminal crimping of the whole cable; the whole terminal crimping process is automatically finished by the machine and does not need manual operation, and the terminal crimping efficiency is high; and the cable terminal crimping machine disclosed by the invention can be improved on the basis of the conventional terminal crimping machine, so that the generality of parts is high, the manufacturing cost is low, and the maintenance is very convenient.

Owner:ZHONGSHAN JINSHENG AUTOMATION MACHINERY

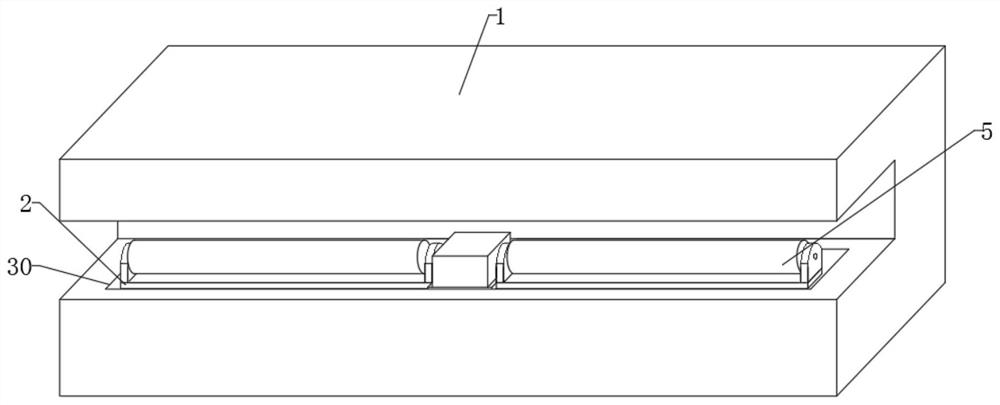

Full-automatic terminal crimping device convenient for cable positioning

ActiveCN110829138AImprove crimp qualityPrecise positioningLine/current collector detailsEngineeringStructural engineering

The invention discloses a full-automatic terminal crimping device convenient for cable positioning. The device comprises an upper pressing die crimping mechanism, a cable positioning mechanism, an ejection mechanism, a terminal pushing sliding block mechanism and a terminal clamping mechanism, wherein the terminal pushing sliding block mechanism is arranged under the upper pressing die pressing mechanism, a lower pressing die base is arranged on the terminal pushing sliding block mechanism, the terminal clamping mechanism and the ejection mechanism are arranged on a left side and a right sideof the lower pressing die base respectively, and a front end and a rear end of the lower pressing die base are respectively provided with a cable positioning mechanism. The device is advantaged in that multiple mechanisms cooperate with each other, coordinate and orderly complete a crimping function, crimping efficiency and the automation degree are improved, a clamping jaw assembly in the cable positioning mechanism is adopted to complete the effect of accurate cable positioning, the terminal clamping mechanism is adopted to improve the terminal crimping quality, the structure is simple, theuse is convenient, the service life is long, safety and reliability are high, and the crimping device is suitable for large, medium and small cable production enterprises and can be applied to crimping of various cable product terminals.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD +1

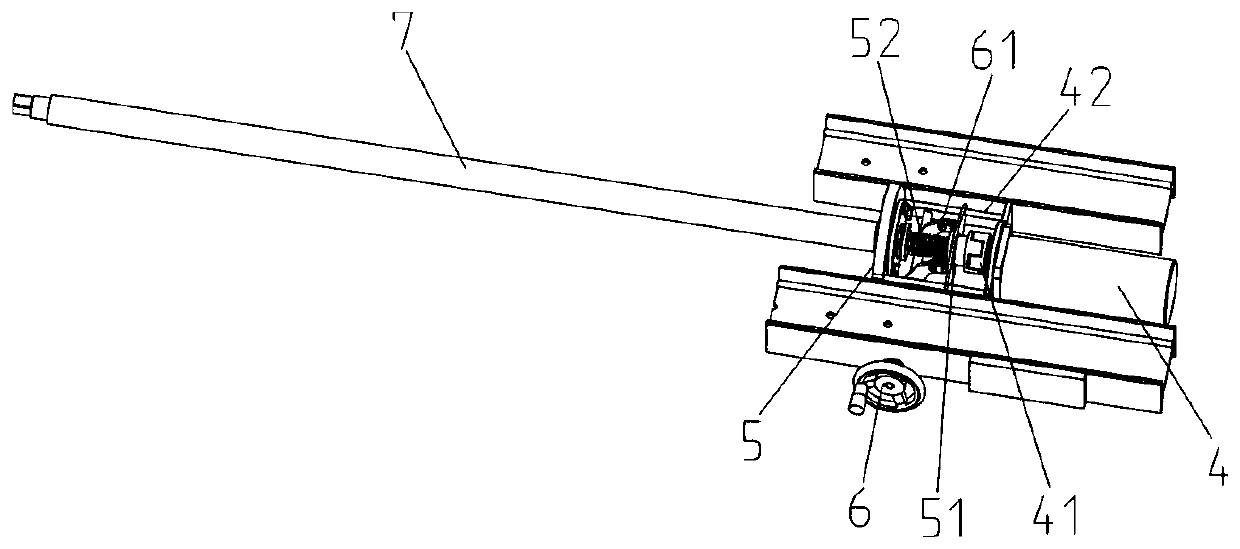

Crimping pipe bending automatic controller

InactiveCN106159628AImprove crimp qualityPrevent slidingLine/current collector detailsBall screwEngineering

The invention relates to wire crimping equipment in the construction of power transmission and transformation lines, in particular to an automatic controller for crimping pipe bending, including a base and an anti-bending controller installed on the base, and the anti-bending controller includes a crimping machine support Frame, crimping machine mobile platform, wire fixed chuck and chuck support, crimping machine mobile platform is installed on the base, including frame body and ball screw pair, crimping machine bracket is connected with ball screw pair to realize pressing The reciprocating movement of the connecting machine; both ends of the frame body are equipped with wire fixing clips, and the wire fixing clips are respectively installed on the frame body through height-adjustable clip supports, and the wire fixing clips at both ends are maintained by the clip supports. The center is in line with the center of the mold on the crimping machine, and each wire fixing chuck clamps the wire to be crimped, and the crimping of the wire is realized by the reciprocating crimping machine. The crimping machine of the present invention can move back and forth, and the bending and twisting of the crimping tube will not occur when conducting wire crimping, which greatly improves the crimping quality.

Owner:LIAONING POWER TRANSMISSION & TRANSFORMATION PROJECT +4

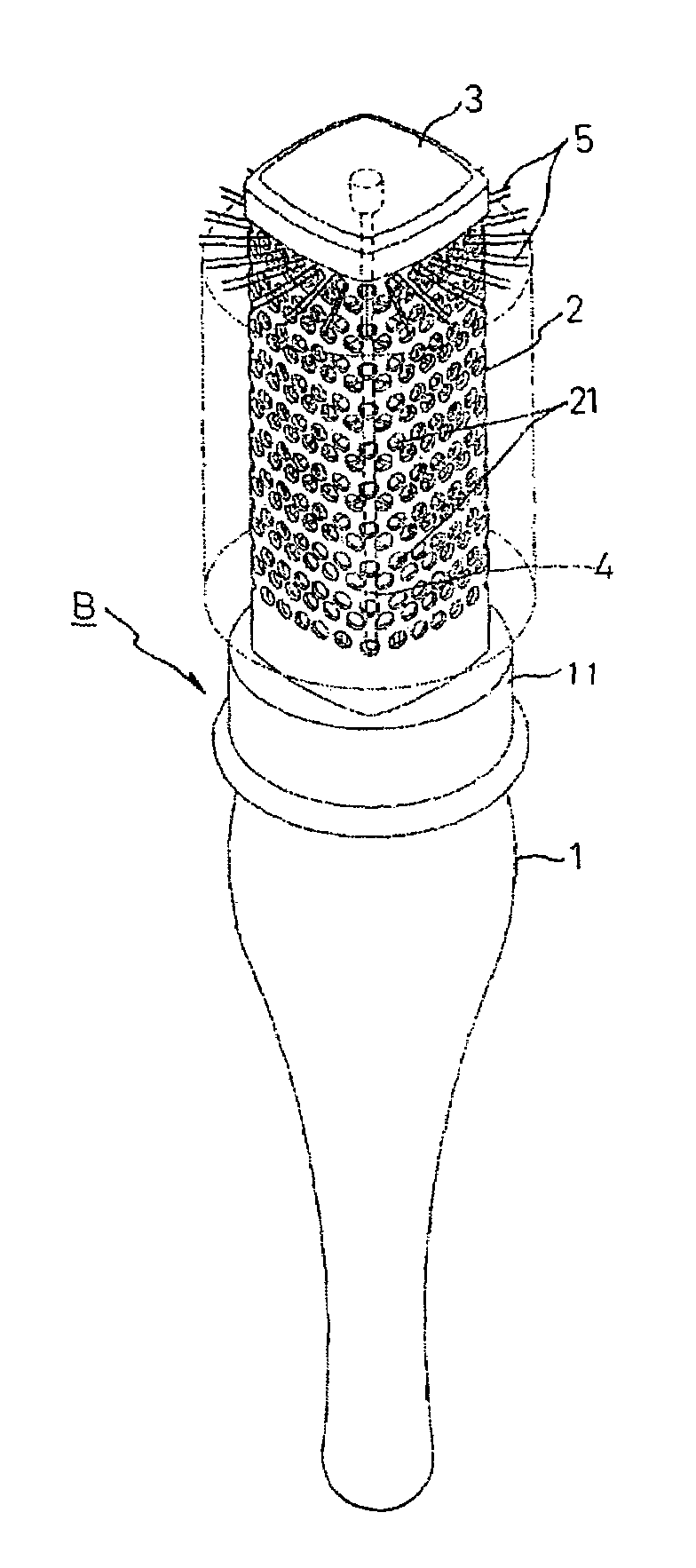

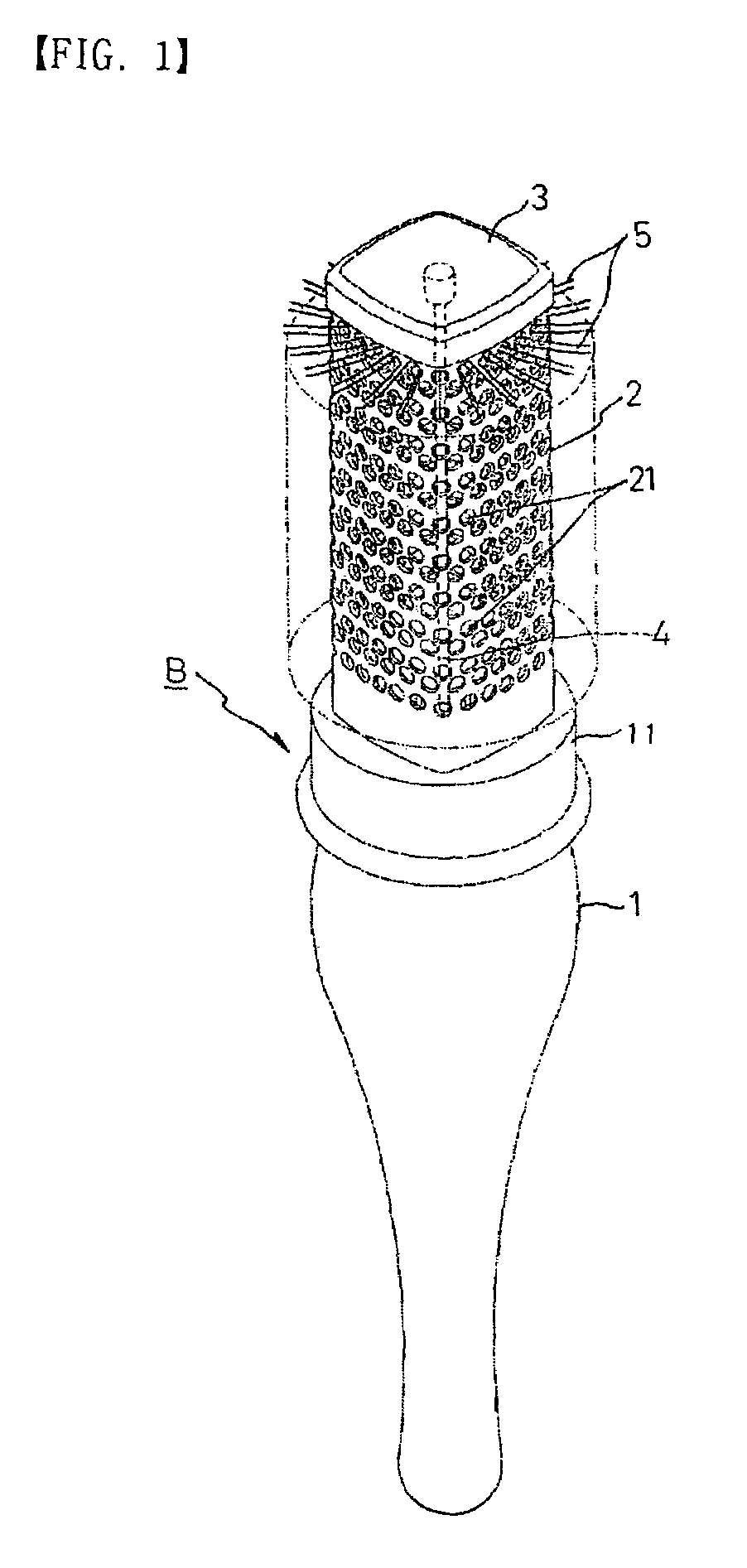

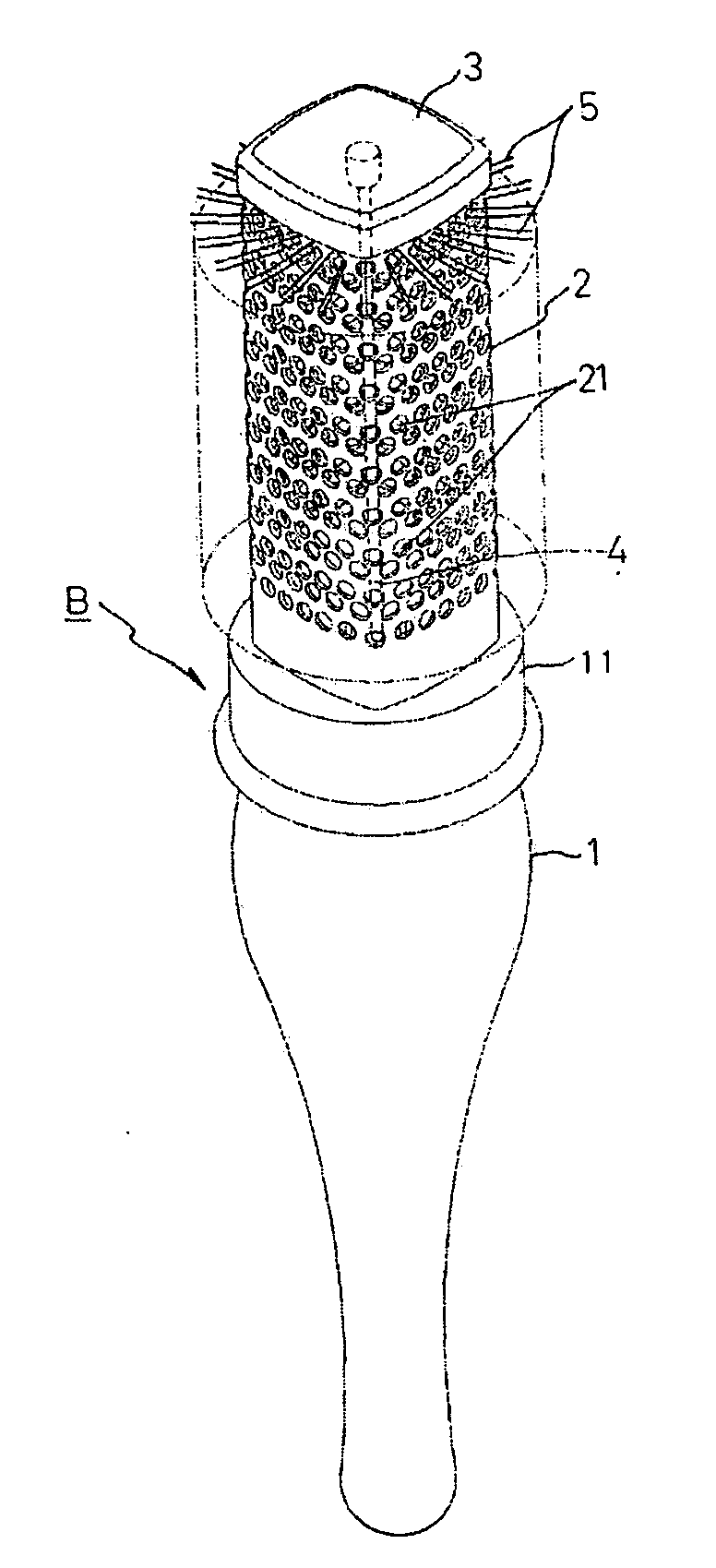

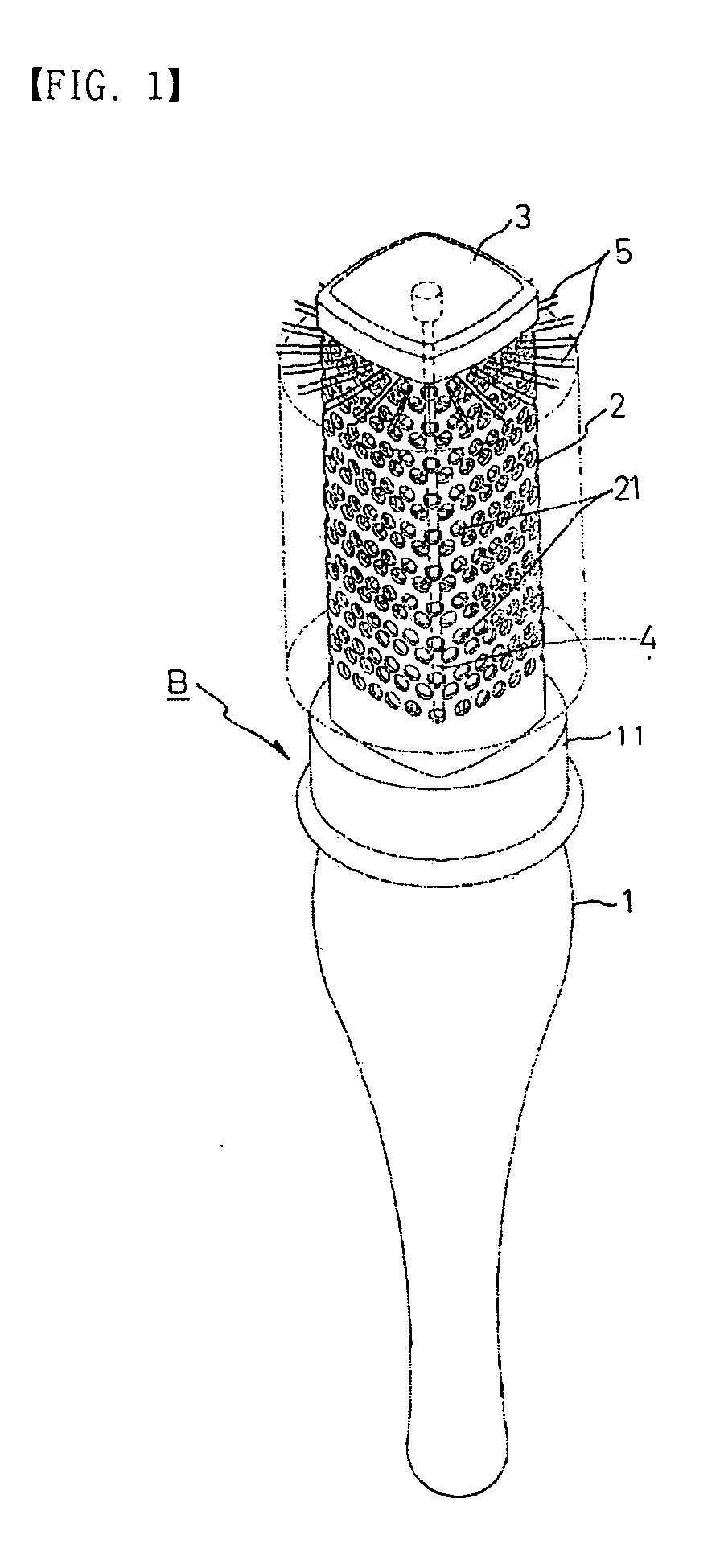

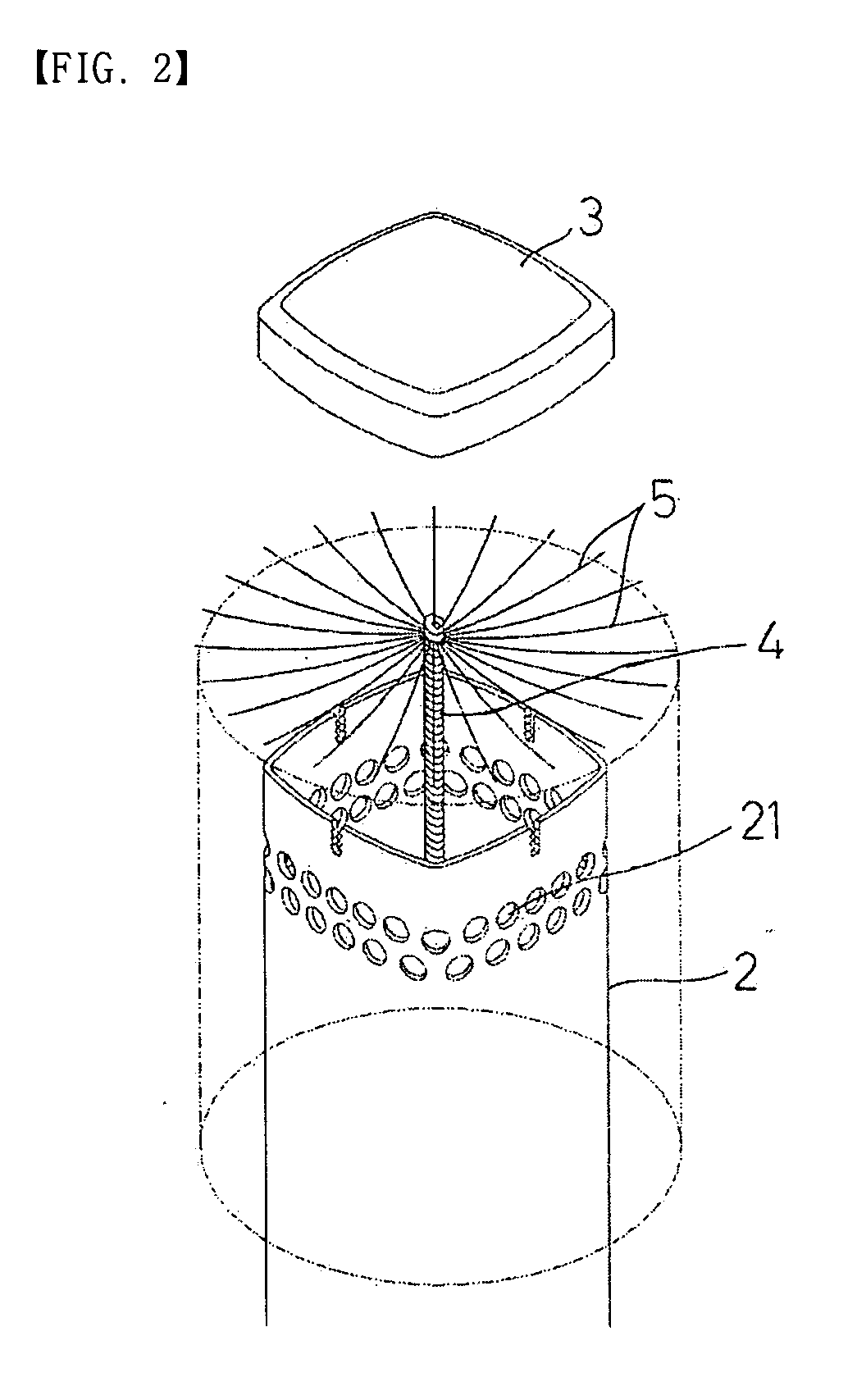

Hair brush for hot curling

A hairbrush for hot curling. A brush body constituting a hairbrush is formed to have a substantially quadrangular sectional shape with rounded corners to thereby shorten a hair drying time and improve hair curling efficiency. A slippage prevention part is formed on the outer surface of each steel wire constituting a core element to increase frictional force between bristles and the steel wire, maintain the firmly fastened state of the bristles for an extended period of time and lengthen the lifetime of the hairbrush. A rounded part is formed on each end of each bristle through grinding to prevent damage to the skin of the head, ensure smooth combing of hair and increase the value of the hairbrush.

Owner:SANG SHIN INDAL

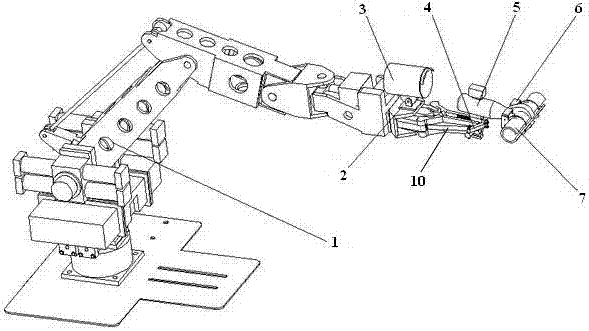

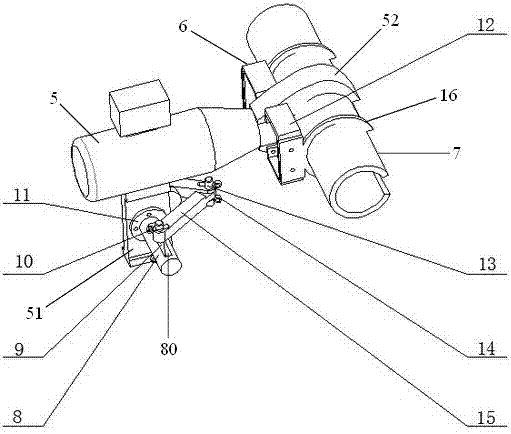

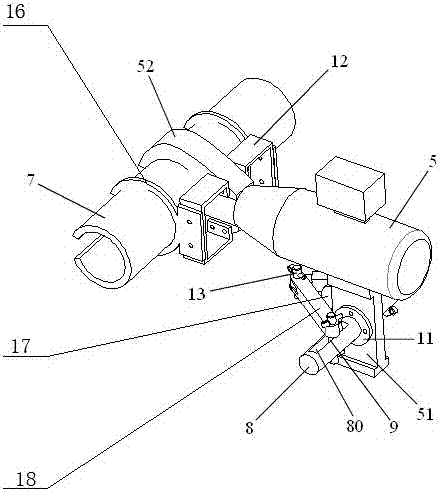

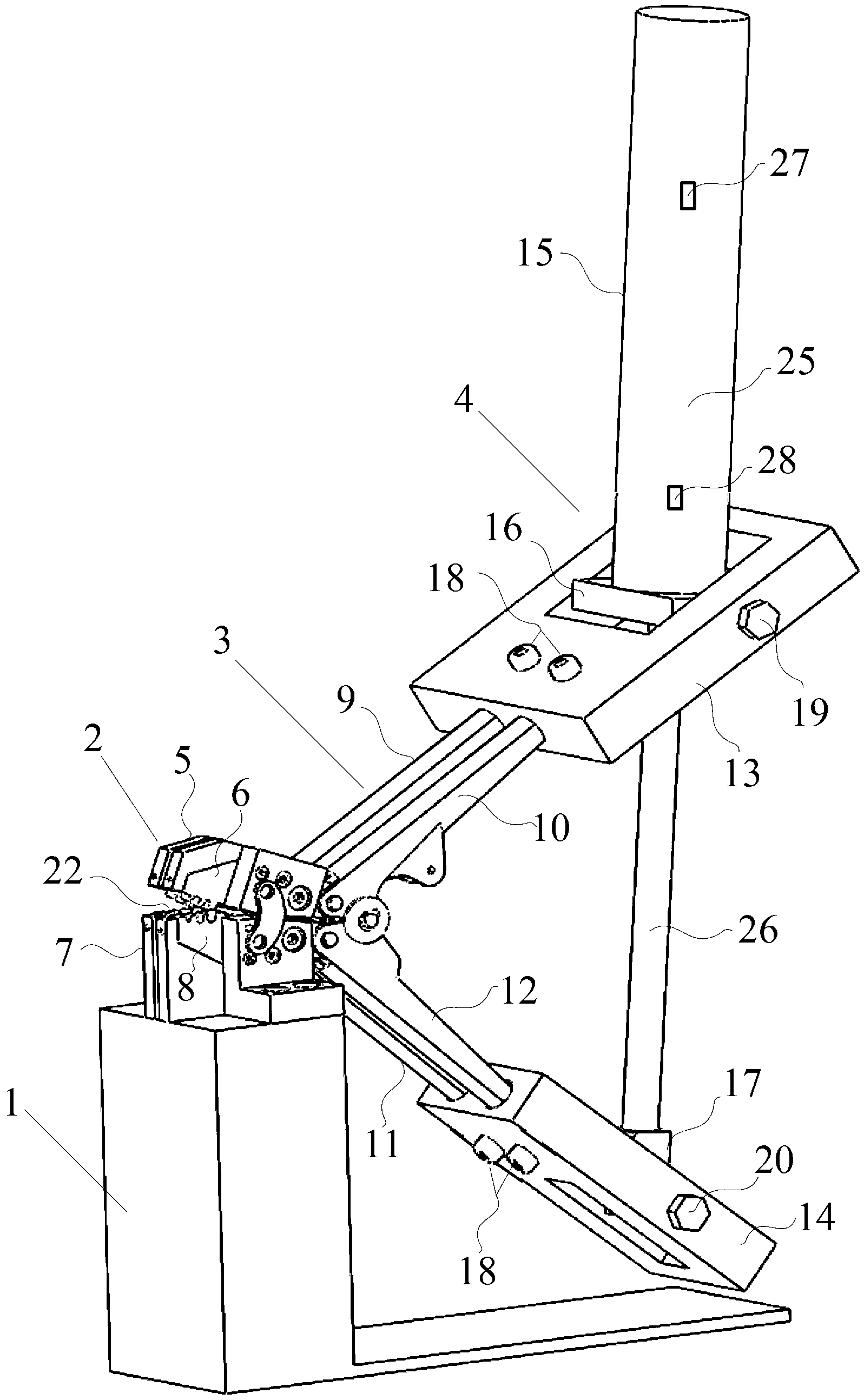

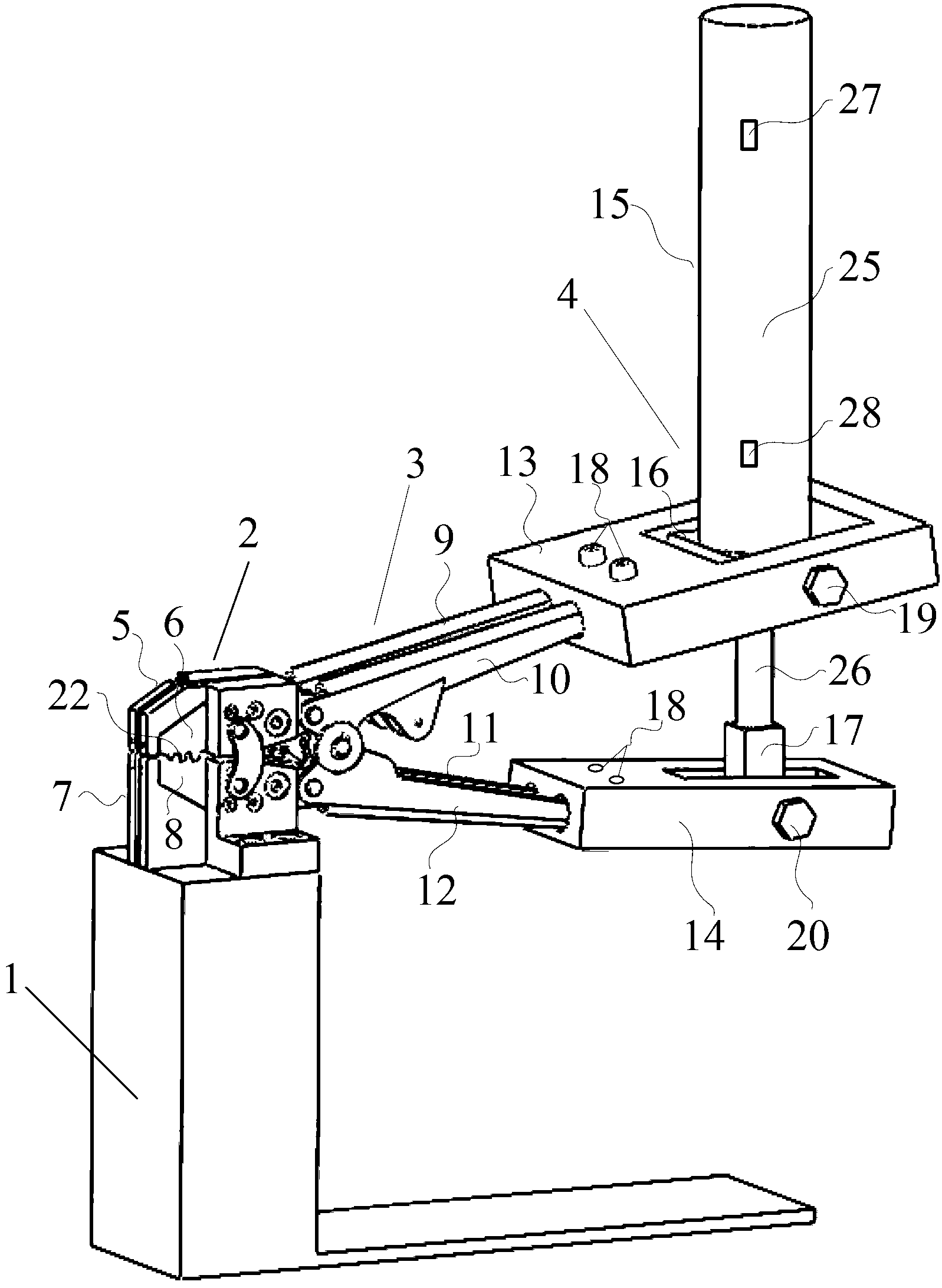

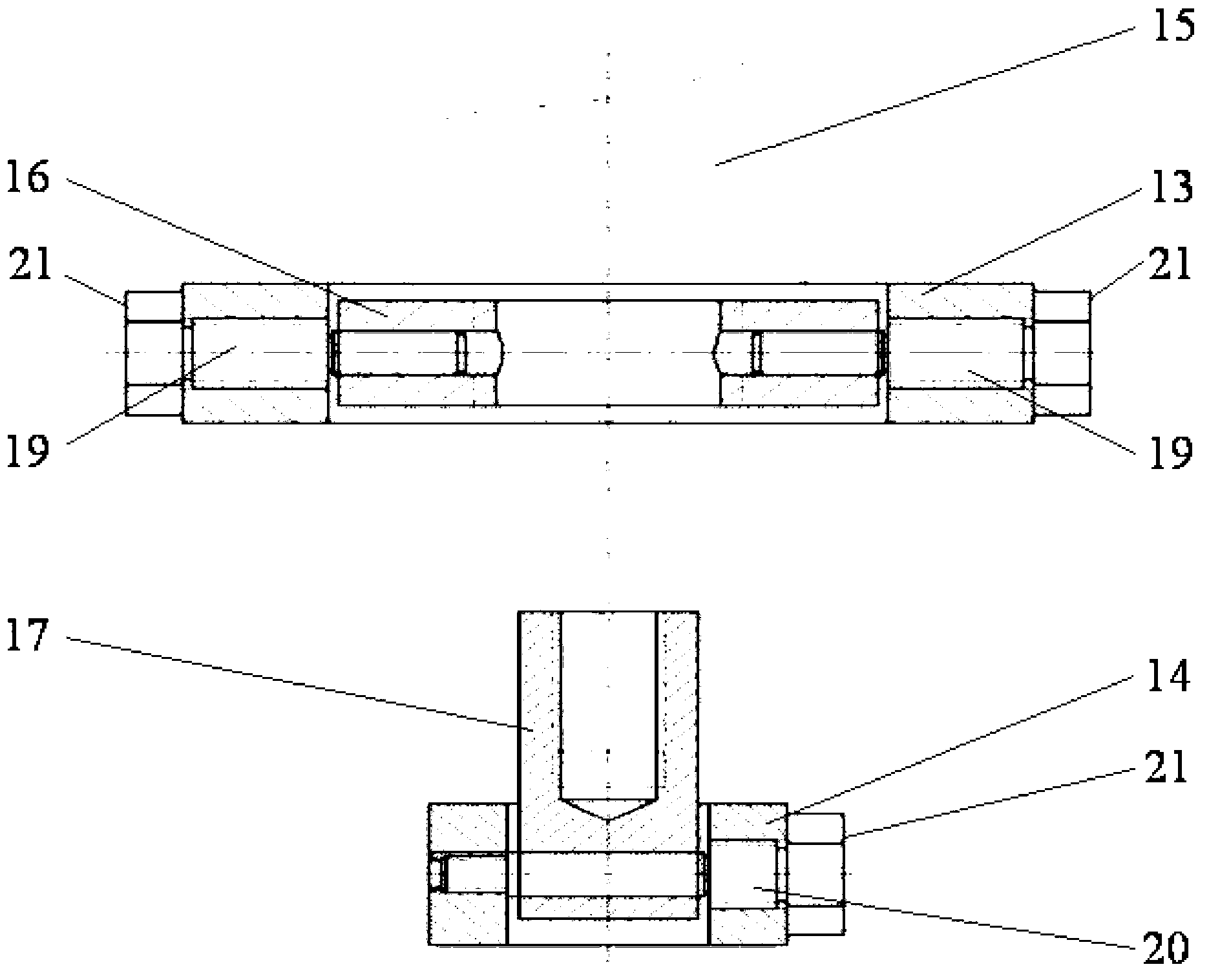

Wire crimping repair device and method of substation

ActiveCN106953274AHigh degree of automationEnsure job safetyApparatus for joining/termination cablesOperation modeEngineering

The invention provides a wire crimping repair device and method of a substation. The wire crimping repair device of the substation comprises a wire repair tube, hydraulic crimping pliers, a clamping execution unit and a mechanical arm, wherein the hydraulic crimping pliers comprise a handle of a crimping switch and a crimping part, the clamping execution unit comprises a clamping shaft, a left clamping support arm and a right clamping support arm, the clamping shaft penetrates through the handle and is fixed at two sides of the handle, one end of the left clamping support arm and one end of the right clamping support arm are connected by a support arm connection shaft, the other ends of the left clamping support arm and the right clamping support arm are connected with a clamping adjustment shaft arranged in a groove, and the mechanical arm is used for moving the hydraulic crimping pliers to a wire position to be repaired and controlling the clamping adjustment shaft to move in the groove so that the support arm connection shaft is driven to move towards the crimping switch and trigger the crimping switch. By the wire crimping repair device, the requirement of wire crimping in the substation is met, the operation safety of an operator is ensured, the working strength of manual operation can be effectively reduced, the crimping efficiency and the automatic level are improved, and a positive change effect is generated for a wire crimping repair operation mode of the substation in China.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

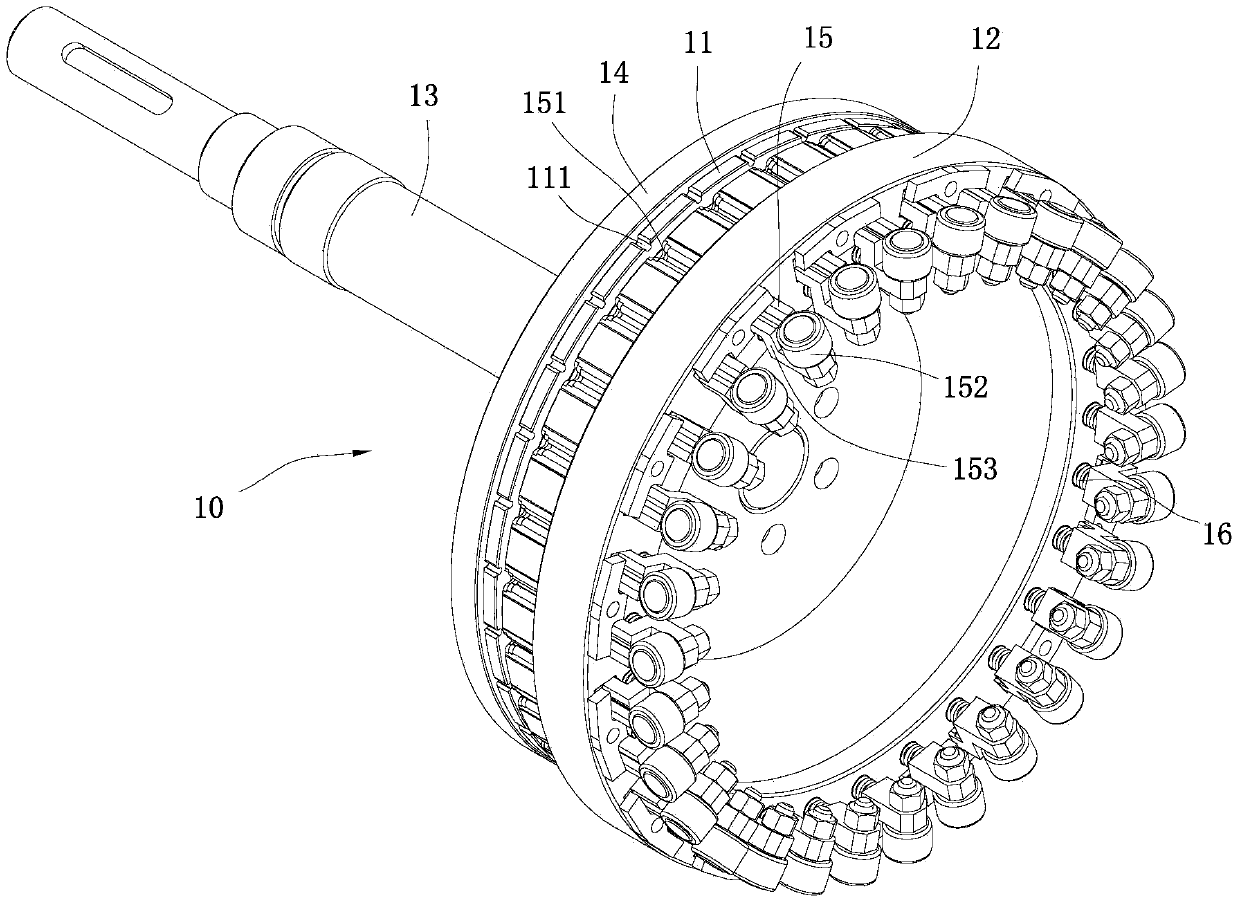

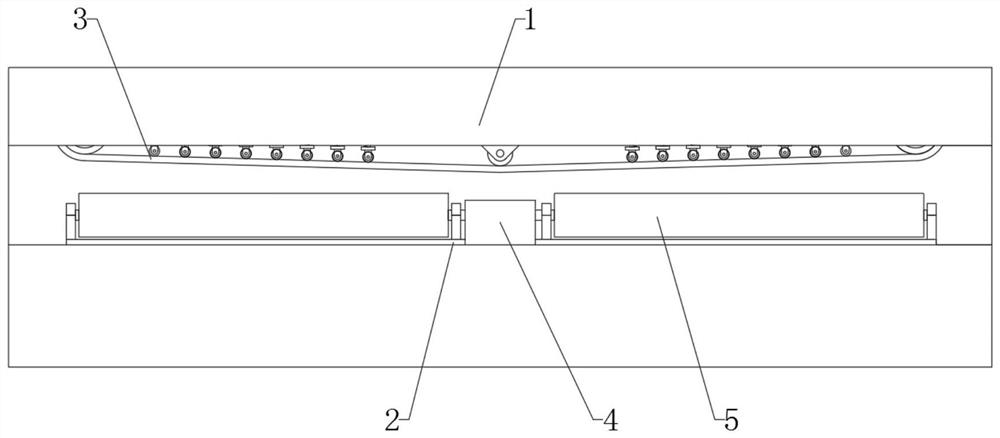

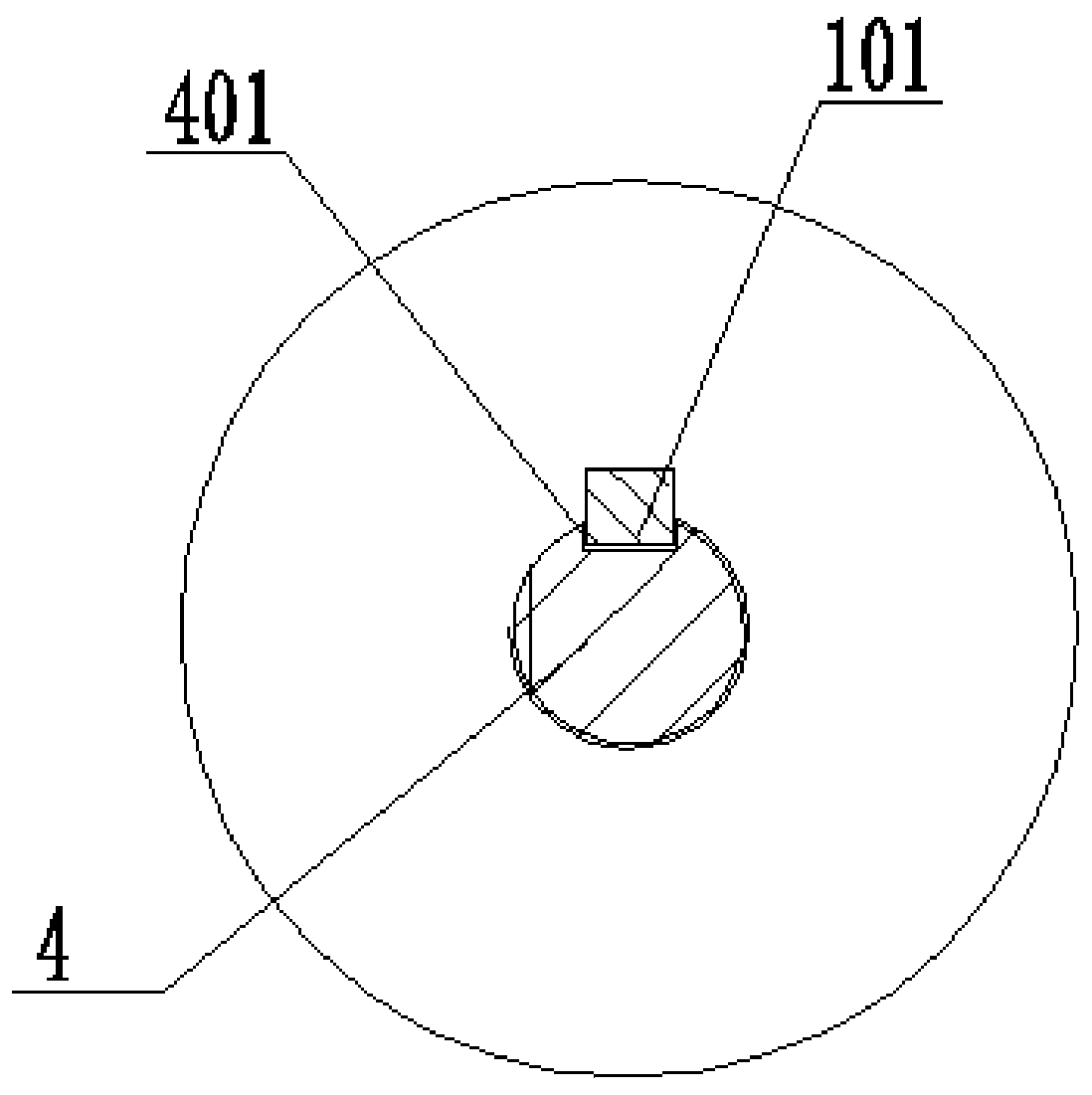

High-speed automatic crimping machine for optical fiber insertion core

The invention discloses a high-speed automatic crimping machine for an optical fiber insertion core. The high-speed automatic crimping machine is used for crimping a metal tail handle and a ceramic insertion core and comprises a support base, a turntable body, a driving device and a material supplying mechanism; multiple containing slots for placing the ceramic insertion cores are arrayed at the outer circle end surface of the turntable body along the circumferential direction at intervals; sliders parallel with the containing slots are arranged at the outer circle end surface of the turntable body; a containing slot port for placing the metal tail handle is arranged at one end of each slider; a floating ejecting block is arranged at the outer edge end surface of one side, provided with the sliders, of the turntable body on the support base; the turntable body adopts a horizontal turntable structure; when the turntable body rotates, the other end of each slider sequentially passes and touches the floating ejecting block to be pushed so as to move towards the direction of the ceramic insertion core, so the ceramic insertion core is pressed into the metal tail handle to form the optical fiber insertion core, fast and continuous crimping is realized, the crimpling efficiency is high, the whole crimping machine is compact in structure, easy to control and lower in manufacturing cost.

Owner:深圳市雅合科技有限公司

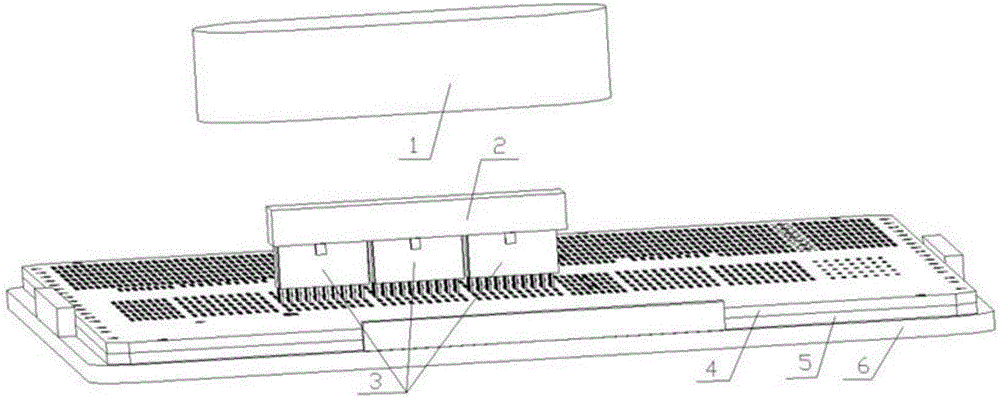

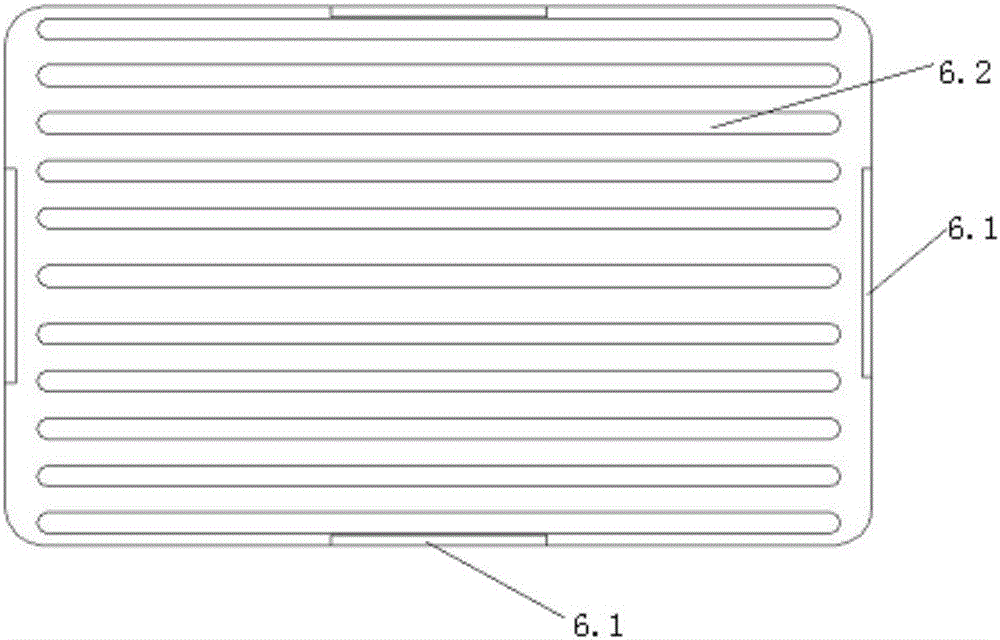

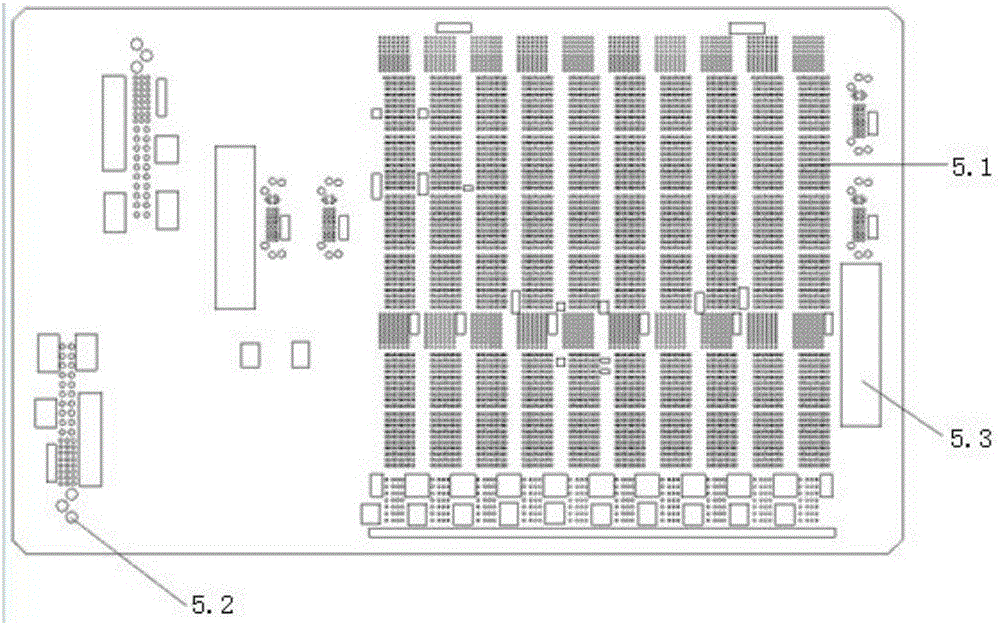

Crimping method of welding-free high-airtight connector

ActiveCN106785802AAutomatic and accurate alignmentSave the process of manual alignmentContact member assembly/disassemblyMechanical engineeringEngineering

The invention discloses a crimping method of a welding-free high-airtight connector. The crimping method is characterized in the design of tooling clamps; each tooling clamp comprises a containing groove (6), a lower press die (5) and an upper press die (2); the tooling clamps are applied to the crimping of the connector to form the crimping method of the welding-free high-airtight connector. The crimping method has the advantages that the welding-free high-airtight connector can be quickly and accurately crimped; a plurality of welding-free high-airtight connectors can be crimped by one crimping process.

Owner:武汉数字工程研究所

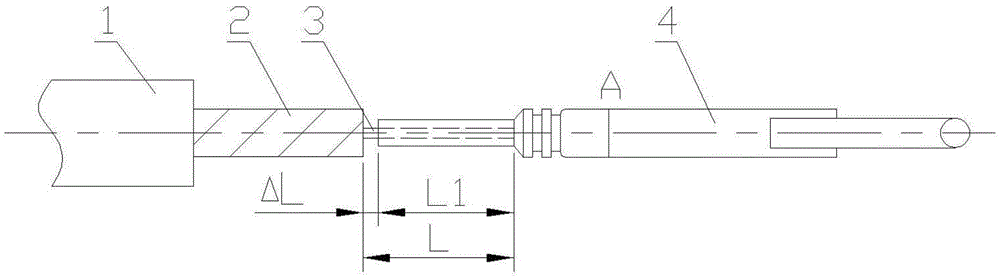

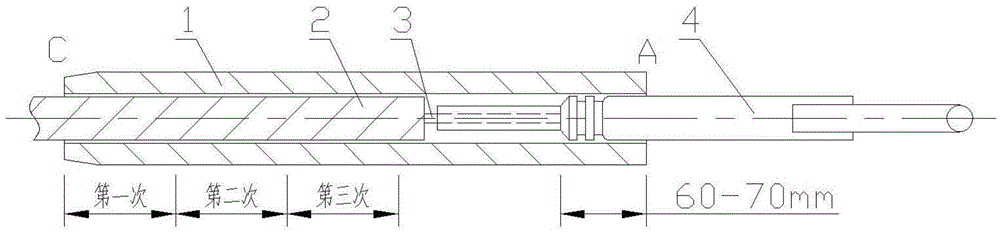

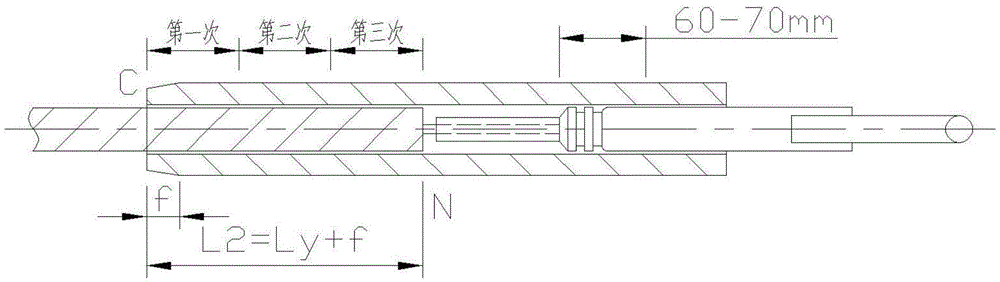

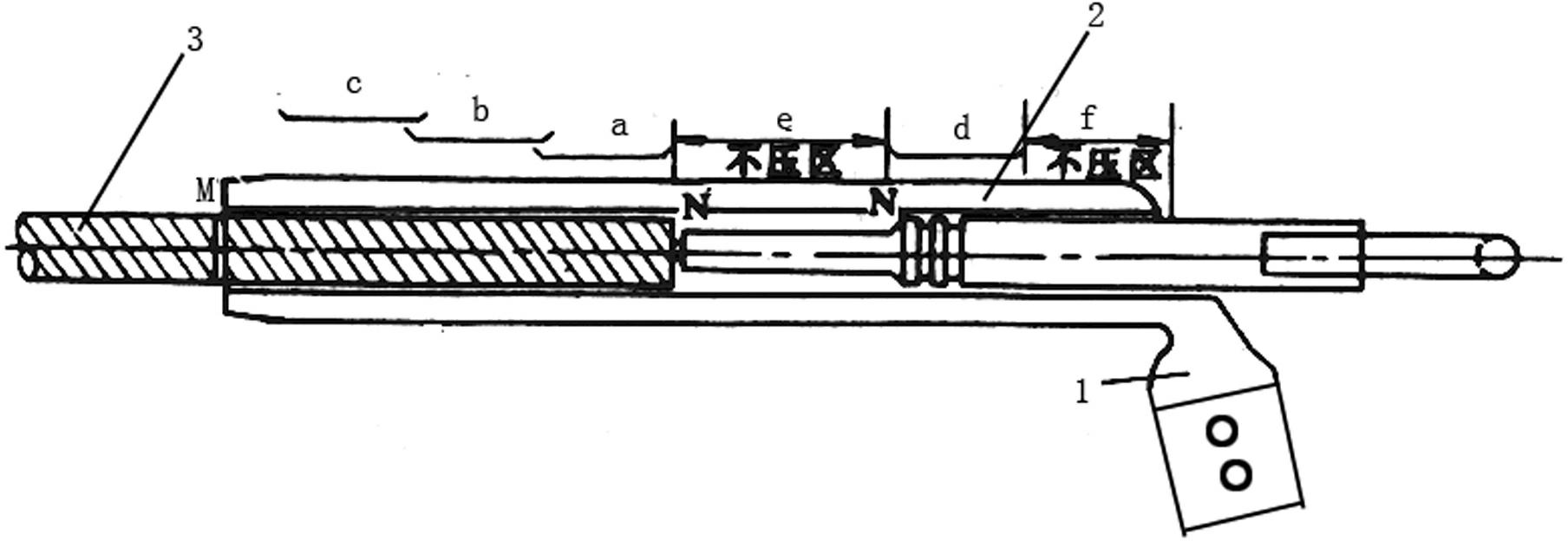

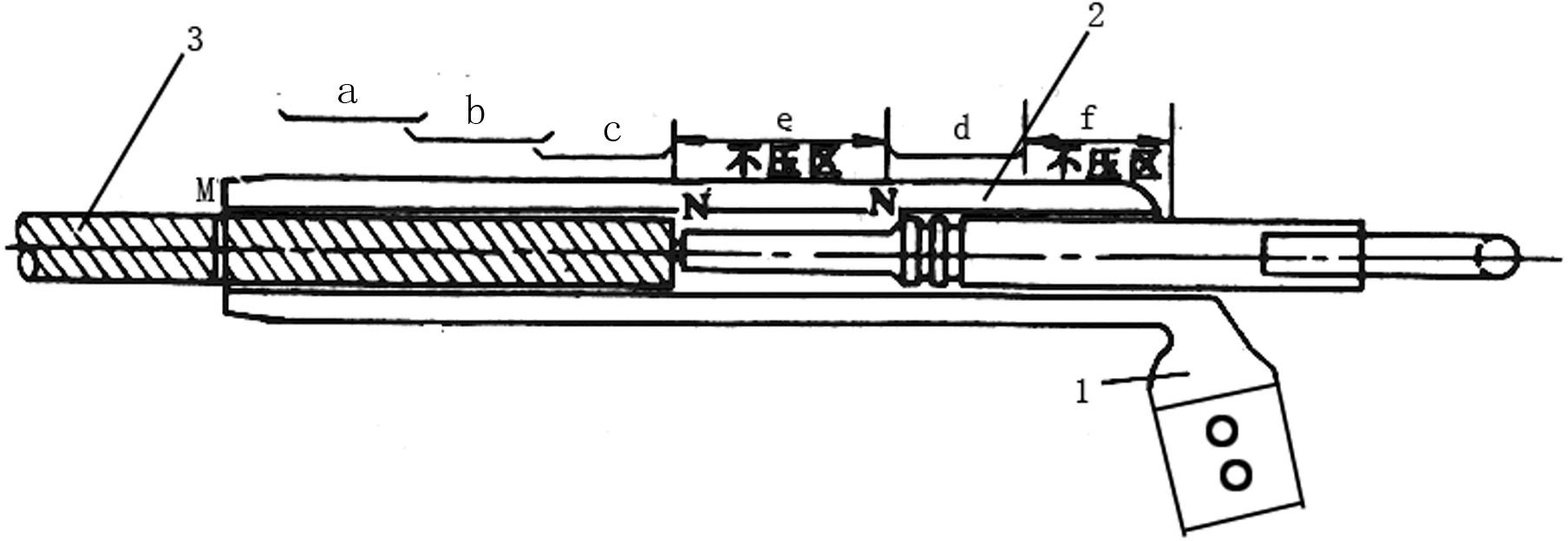

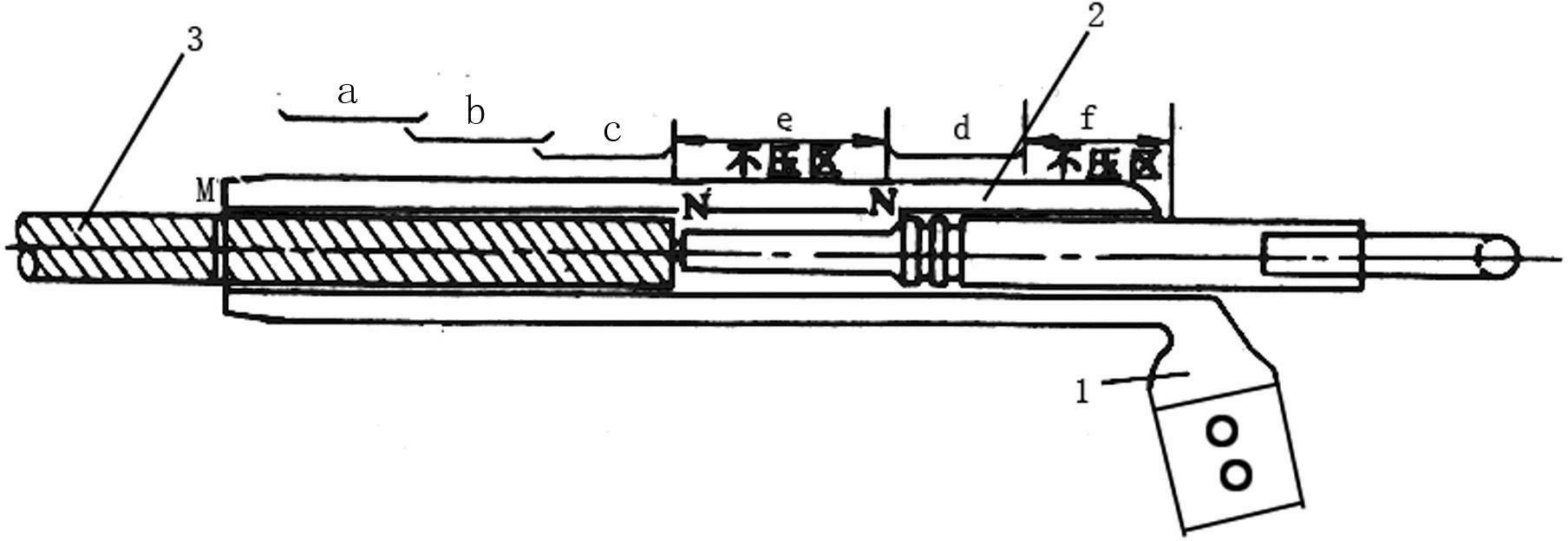

Hydraulic crimping technology forstrain clamp for steel-cored aluminum stranded wire

InactiveCN105490130AGood crimping effectImprove crimping efficiencyConnection formation by deformationAluminiumEnkianthus

The invention provides a hydraulic crimping technology for a strain clamp for a steel-cored aluminum stranded wire. The technology comprises the following steps: peeling off the aluminum stranded wire outside a steel-cored aluminum stranded wire; sleeving an aluminum tube from one end of the steel-cored aluminum stranded wire, and inserting an exposed steel core into an inserting hole from a steel anchor port; pressing and fixing the front part of a steel anchor and the steel core of the steel-cored aluminum stranded wire; marking the position which is 20-30mm to the rear end of the steel anchor from the edge of a final annular groove of the steel anchor asa positioning mark A, and making a positioning mark C on the steel-cored aluminum stranded wire; pushing the aluminum tube to the side of the steel anchor; carrying out crimping by a hydraulic machine, continuously exerting pressure from left to right from the left end of the aluminum tube corresponding to the mark C for at least three times; not crimping an inserting segment, corresponding to the steel core and the steel anchor, of the aluminum tube, and finally exerting pressure once towards the right from the annular groove of the steel anchor. The hydraulic crimping technology has the beneficial effects that the 'Chinese enkianthus' phenomenon at the side of the crimped wire can be avoided by the crimping technology; the wire crimping effect is good; the crimping efficiency is high; and the conductive effect and the born tension after crimping can be ensured.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

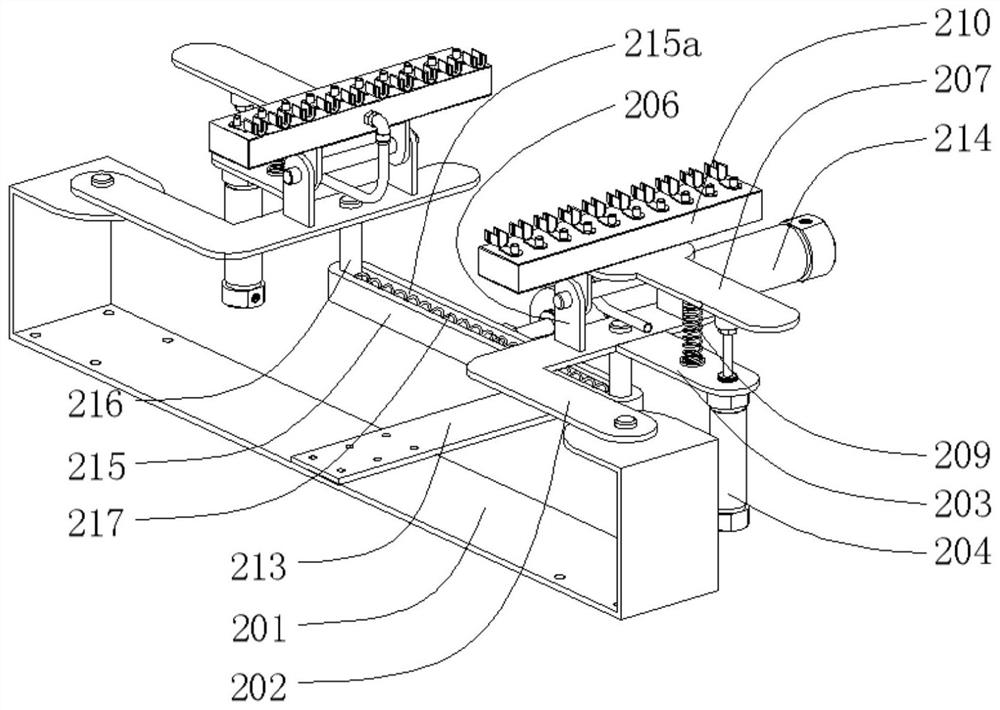

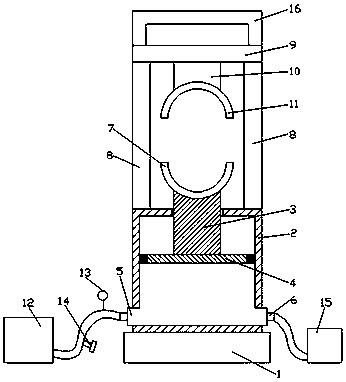

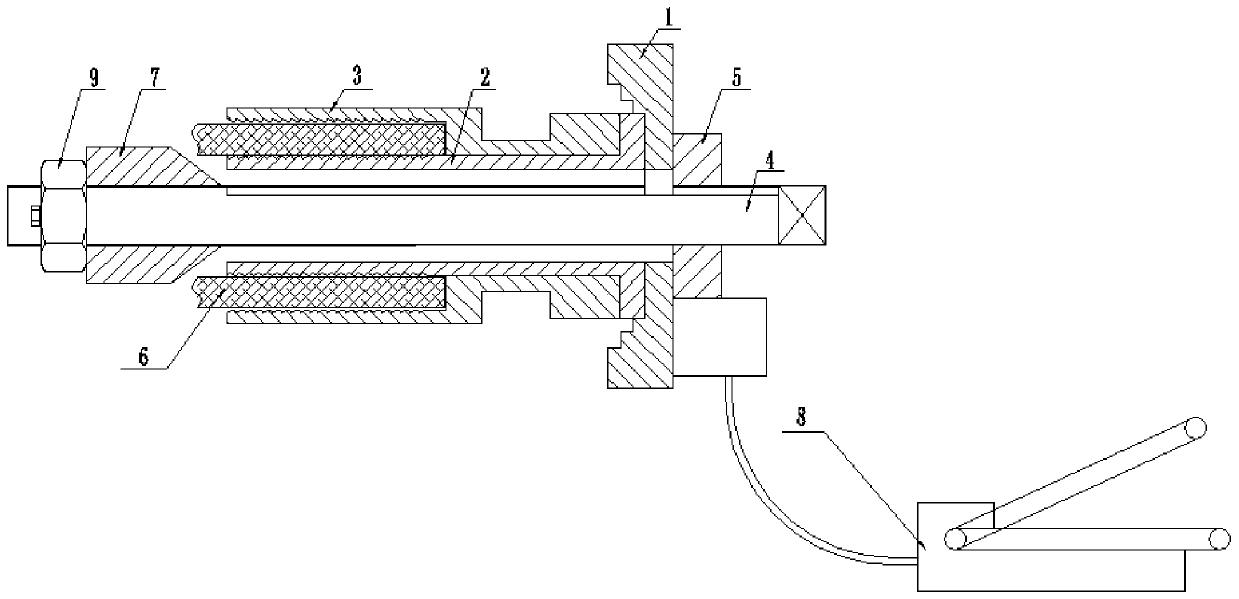

Automatic compression joint device for wires

ActiveCN103986090AMature processing technologyGuarantee processing qualityLine/current collector detailsApparatus for overhead lines/cablesHydraulic pumpUltimate tensile strength

The invention provides an automatic compression joint device for wires. The automatic compression joint device comprises a compression joint mechanism, a fixing mechanism, a motor and a hydraulic pump, wherein the compression joint mechanism, the fixing mechanism, the motor and the hydraulic pump are sequentially and vertically arranged on a support plate in the same axis direction, and the compression joint mechanism is connected with the hydraulic pump through a pipeline. The automatic compression joint device is characterized in that a conveying bracket is arranged between the compression joint mechanism and the support plate, a directed wheel and a flat tooth rail are sequentially arranged at the bottom of the conveying bracket in the arraying direction of the compression joint mechanism and the motor, the flat tooth rail is provided with a transmission gear meshed with the flat tooth rail, and the transmission gear is connected with the motor. Compared with the prior art, the automatic compression joint mode of the hydraulic and mechanical combination is adopted for the automatic compression joint device, the length and the step pitch of compression joint are controlled strictly, compression joint errors are reduced, labor intensity is relieved, compression joint efficiency is improved, and compression joint quality is ensured.

Owner:STATE GRID CORP OF CHINA +1

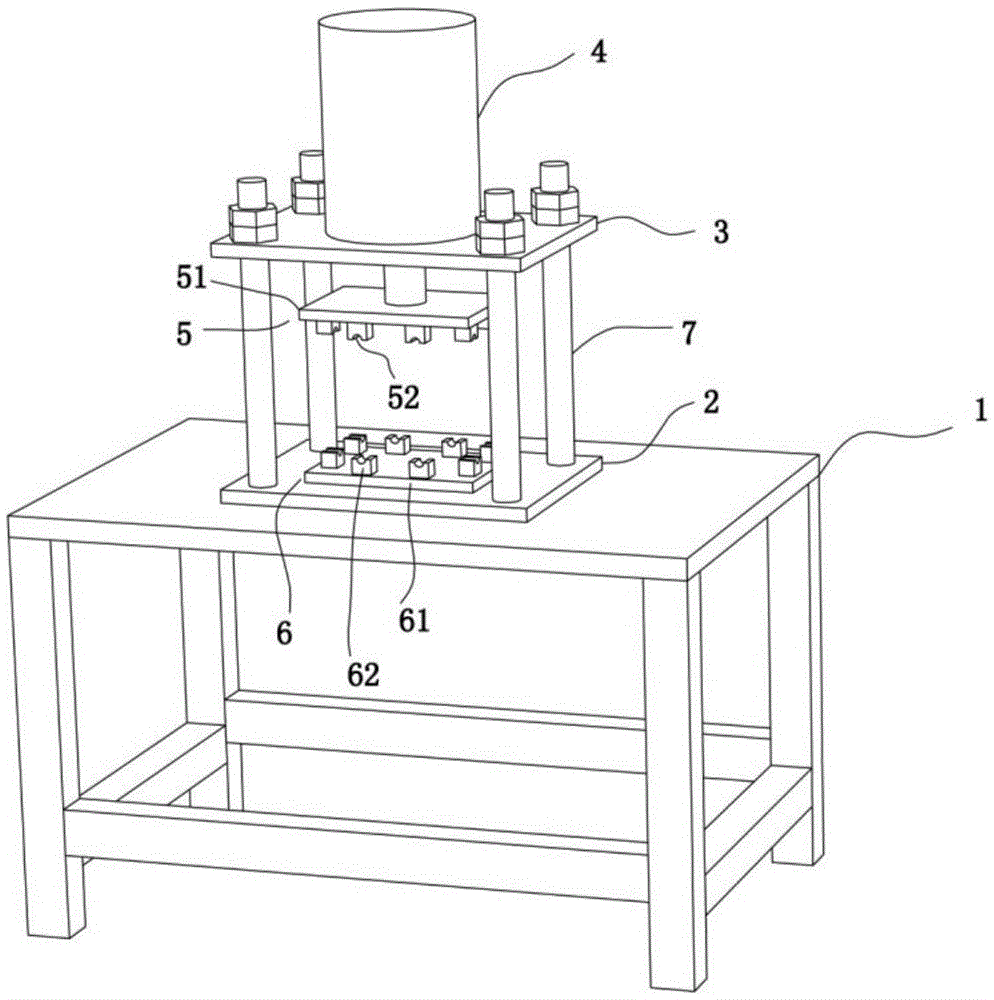

Terminal wire pressing apparatus

InactiveCN105490129ARealize automatic crimpingReduce the labor cost of crimpingLine/current collector detailsEngineeringMechanical engineering

The invention discloses a terminal wire pressing apparatus, which comprises a wire pressing machine stand, a wire pressing lower die holder, an oil cylinder fixing plate, a wire pressing oil cylinder, a wire pressing upper die, and a wire pressing lower die. The wire pressing lower die holder is fixedly disposed on the table top of the pressing machine stand. The oil cylinder fixing plate is fixedly connected to the wire pressing lower die holder and positioned above the wire pressing lower die holder. The body of the wire pressing oil cylinder is fixedly disposed on the oil cylinder fixing plate. A piston rod of the wire pressing oil cylinder is fixedly connected to the wire pressing upper die. The wire pressing upper die is disposed below the oil cylinder fixing plate. The wire pressing lower die is fixedly disposed on the wire pressing lower die holder and positioned below the wire pressing upper die. The wire pressing oil cylinder drives the wire pressing upper die to move downwards, and a wire pressing upper die head of the wire pressing upper die and a wire pressing lower die head of the wire pressing lower die are utilized to conduct wire pressing on a terminal so that wire pressing processing is achieved. Automatic wire pressing of the terminal can be realized. The advantages of the apparatus are that the wire pressing efficiency is high, the quality is high, the labor cost of terminal wire pressing is reduced, and the labor intensity of wire pressing is reduced.

Owner:GUANGDONG HENGNUO GENERAL ELECTRIC CO LTD

Pneumatically-driven double-end automatic crimping device

InactiveCN103296560ADouble-ended automatic crimpingSimple structureLine/current collector detailsCoordinate changeButt joint

The invention belongs to the field of electrical tools, and relates to a pneumatically-driven double-end automatic crimping device which aims at threading leads into two ends of a butt joint terminal to perform crimping to enable the butt joint terminal to be reliably connected with the lead. In order to realize double-end crimping automation, the pneumatically-driven double-end automatic crimping device comprises a pressing pliers assembly, a pliers arm assembly and a pneumatic device, pliers arms are connected with a cylinder in a hinged manner by the aid of pin connection, coordinated changing between a forced direction and a movement direction is realized, the problem of interference of the forced direction and the movement direction in a fixed connection manner is solved effectively, and opening and closing of a pressing pliers jaw are achieved accurately by arrangement of magnetic switches. The pneumatically-driven double-end automatic crimping device is simple in structure and low in cost, a manual crimping mode is substituted, automation of double-end crimping is realized, and crimping efficiency is improved greatly.

Owner:BEIJING UNIV OF TECH

Terminal installation device for hard wire harness

PendingCN113644516AImprove placement efficiencyImprove crimping efficiencyLine/current collector detailsHydraulic cylinderMechanical engineering

The invention discloses a terminal installation device for a hard wire harness, and relates to the technical field of wire harness processing. The terminal installation device comprises a workbench, a terminal carrying and placing mechanism, a terminal crimping mechanism and a wire harness carrying and placing mechanism, wherein the terminal carrying and placing mechanism comprises a fixed strip, a first telescopic air cylinder, a turnover strip, a carrying and placing strip, a second telescopic air cylinder and a linkage strip, the terminal carrying and placing mechanism is used for placing a plurality of terminals at the same time so as to improve the placing efficiency of the terminals, the wire harness carrying and placing mechanism comprises a second hydraulic cylinder, a lifting plate, a positioning strip, a carrying and placing plate, a placing strip and a material blocking strip, the wire harness carrying and placing mechanism is used for achieving simultaneous placement of multiple wire harnesses so as to improve the placement efficiency of the wire harnesses, and the terminal crimping mechanism comprises a supporting plate, a supporting rod, a first hydraulic cylinder and a crimping strip, and is used for crimping terminals at the end portions of a plurality of wire harnesses at the same time so as to improve the crimping efficiency of the terminals. The terminal installation device for the hard wire harness has the advantages of being reasonable in design, ingenious in structure, convenient to use and high in working efficiency.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Crimping device for steel-cored aluminum stranded wire

InactiveCN111969386AGuaranteed uniformityReduce technical difficultyLine/current collector detailsStructural engineeringBar pressing

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO

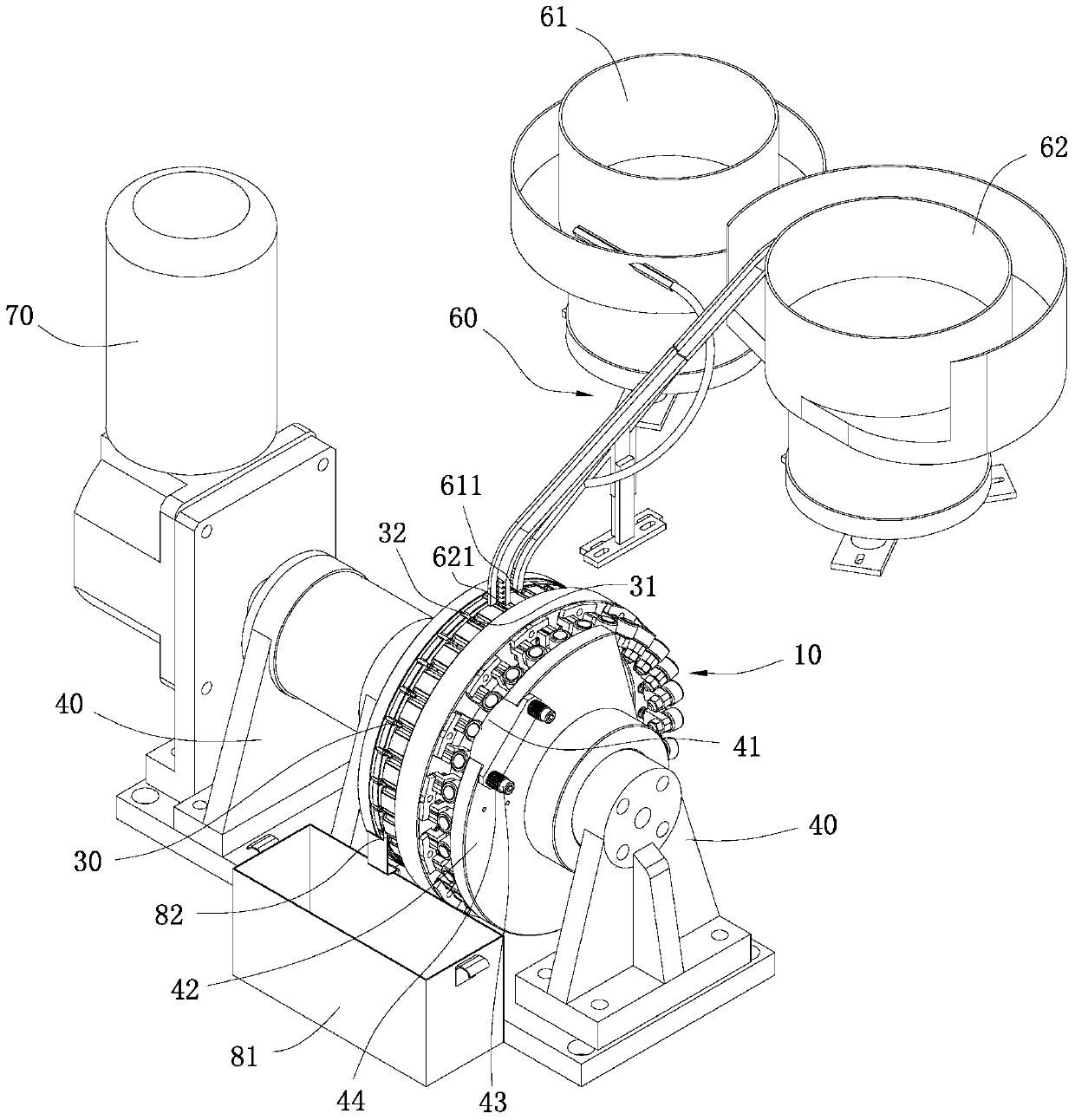

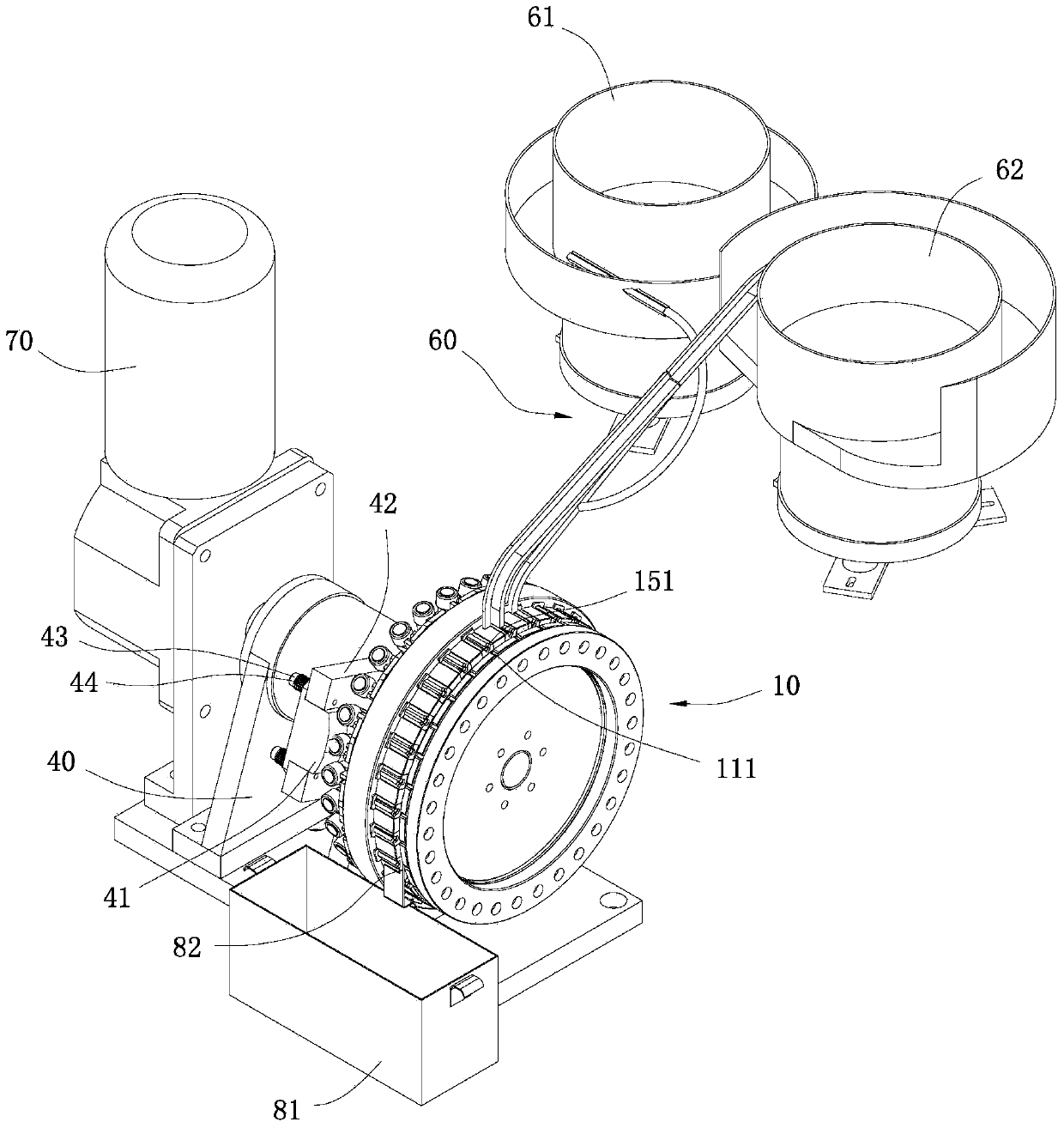

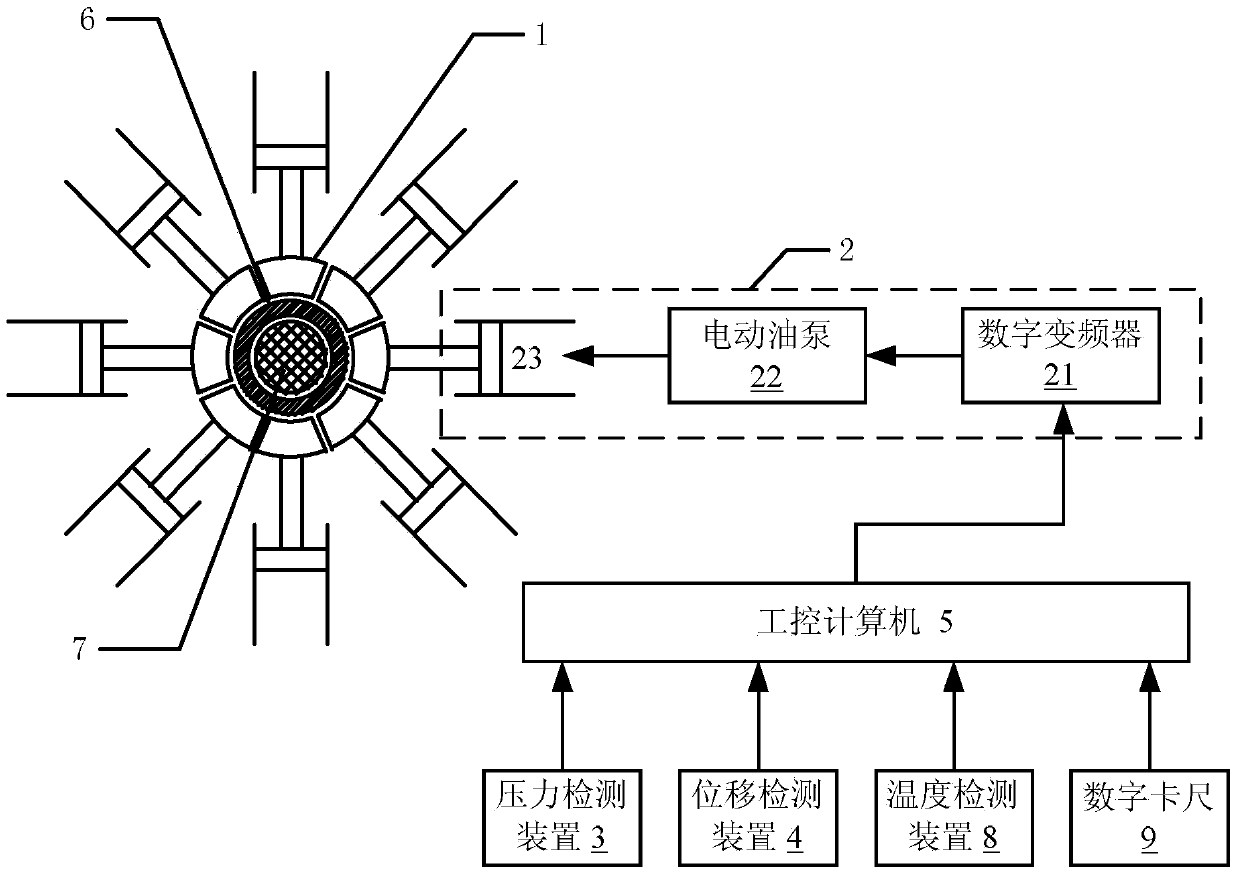

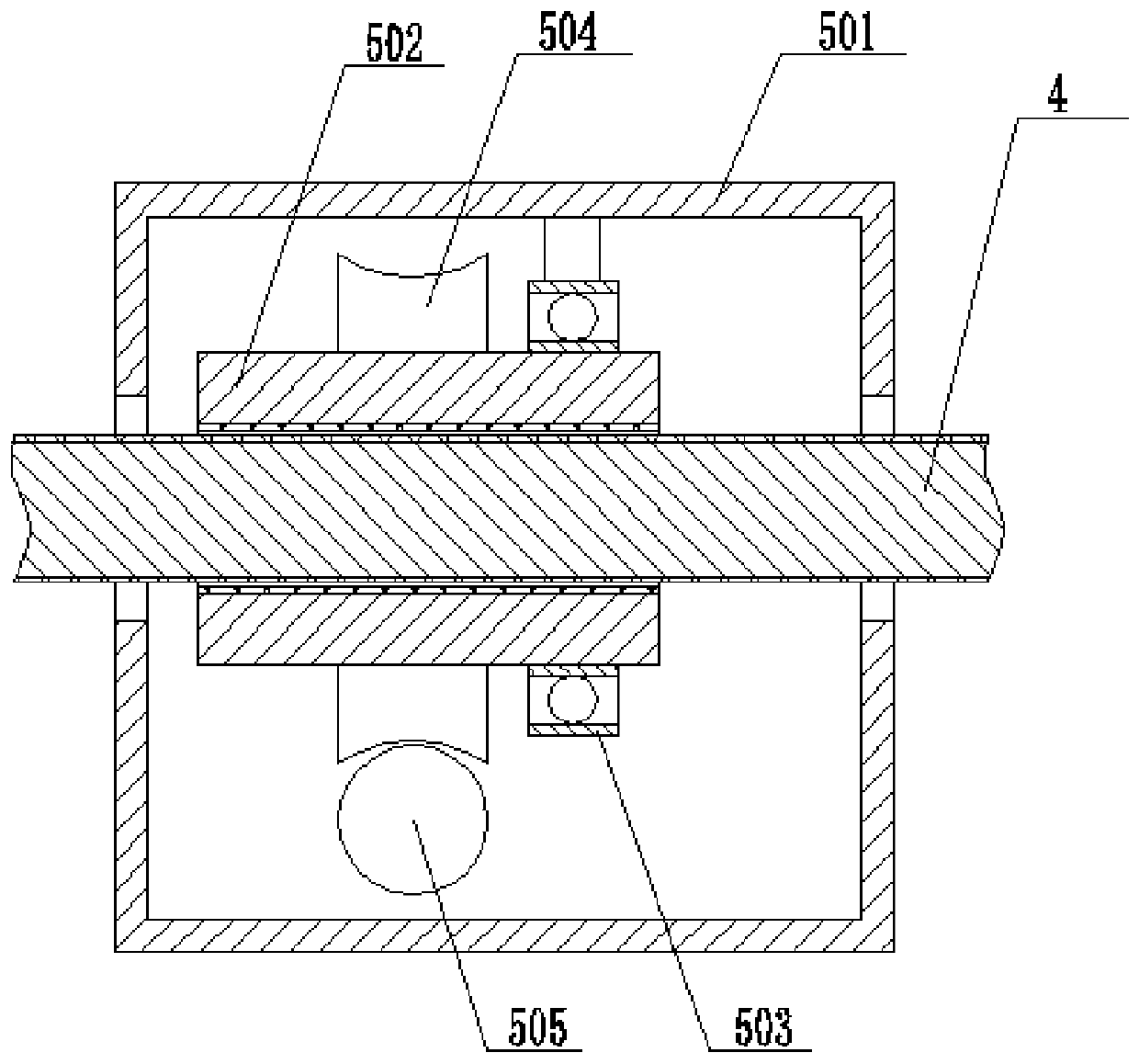

Pressure joint system

ActiveCN104200939AMeet the installation requirementsImprove crimping efficiencyInsulatorsPersonal computerEngineering

The invention discloses a pressure joint system used for pressure joint of insulator core rods and hardware fittings. The pressure joint system comprises a plurality of pressing dies, a pressing die driving device, a displacement detection device and an industrial personal computer. The plurality of pressing dies are arranged around a center of a circle and used for radially moving to extrude the hardware fittings; the pressing die driving device is used for driving the pressing dies to move radially; the pressure detection device is connected with the pressing die driving device and used for detecting pressure applied by the pressing dies; the displacement detection device is used for detecting radial displacement of the pressing dies; the industrial personal computer is respectively connected with the pressing die driving device, the pressure detection device and the displacement detection device and used for controlling the pressing die driving device according to the pressing die radial displacement acquired by the displacement detection device to extrude the hardware fittings by a preset displacement step by step until the pressure detection device detects that pressure stress applied by the pressing dies reaches a preset threshold. The pressure joint system has the advantages that the fact that pressure for pressure joint meets mounting requirements can be guaranteed, and pressure joint efficiency is improved.

Owner:BEIJING RAILWAY INST OF MECHANICAL & ELECTRICAL ENG

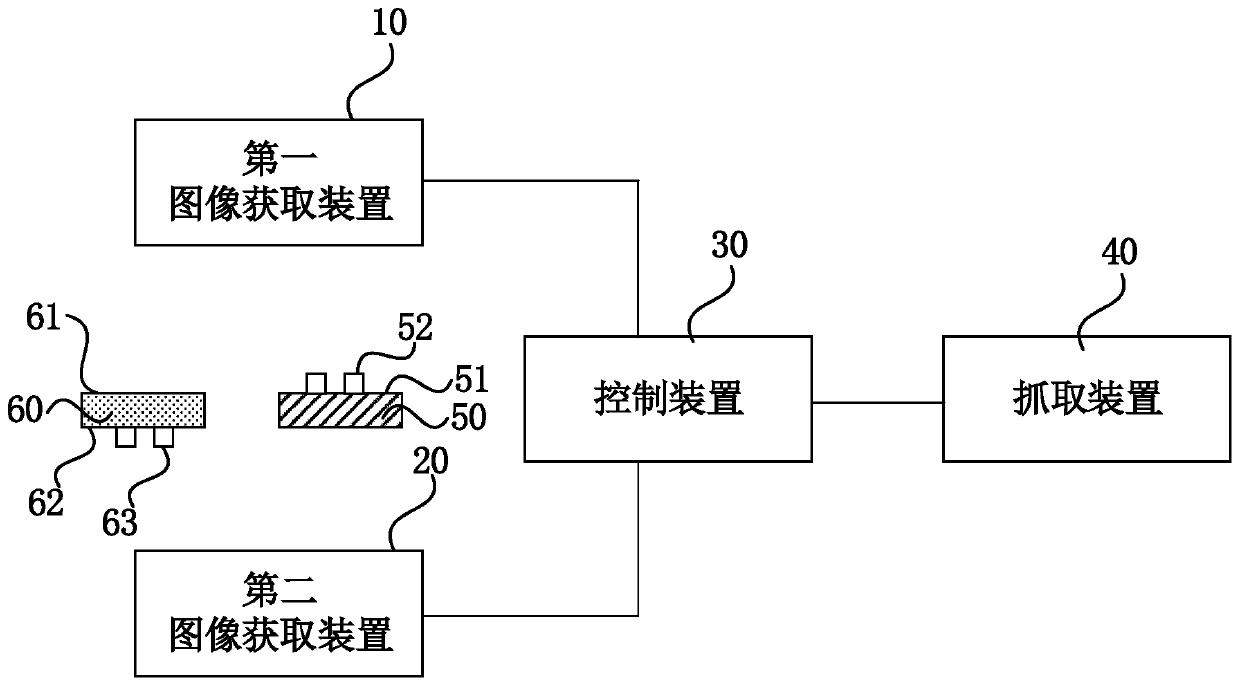

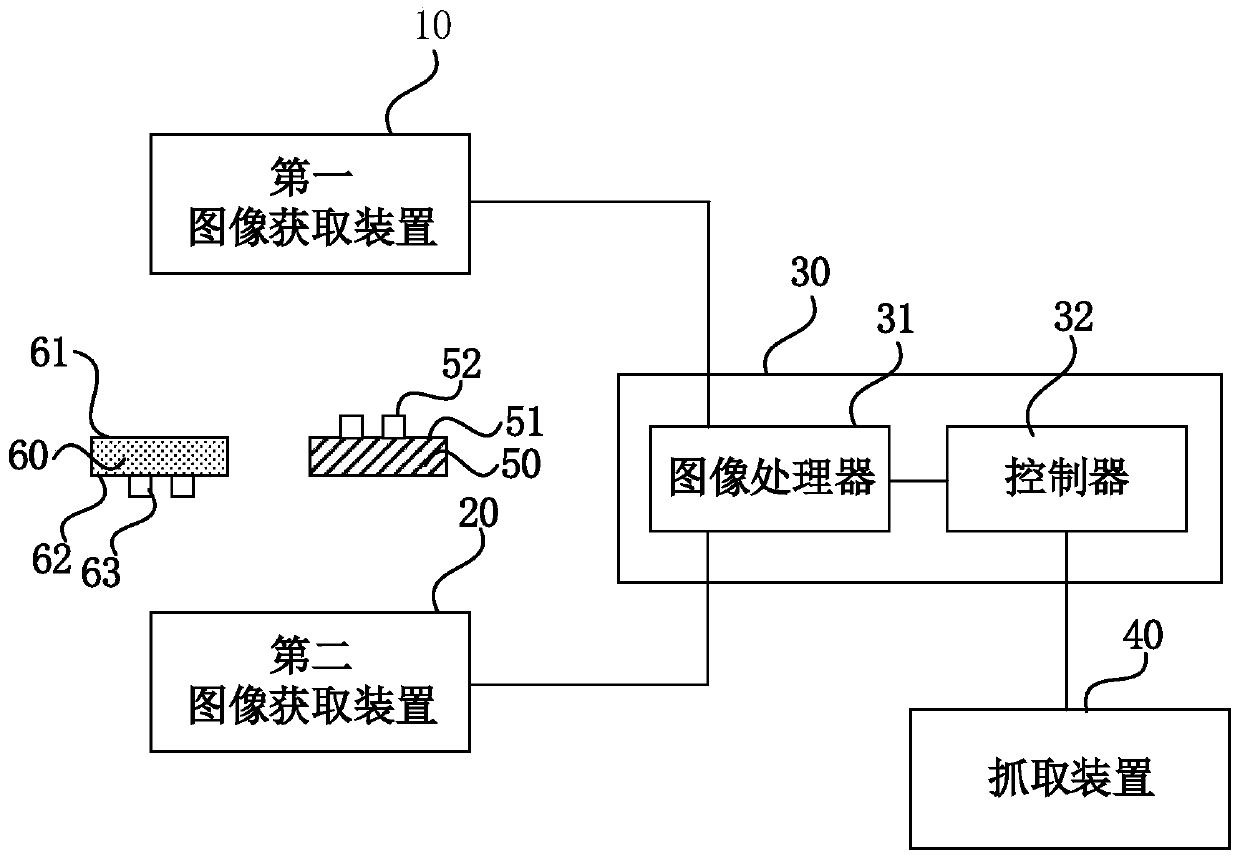

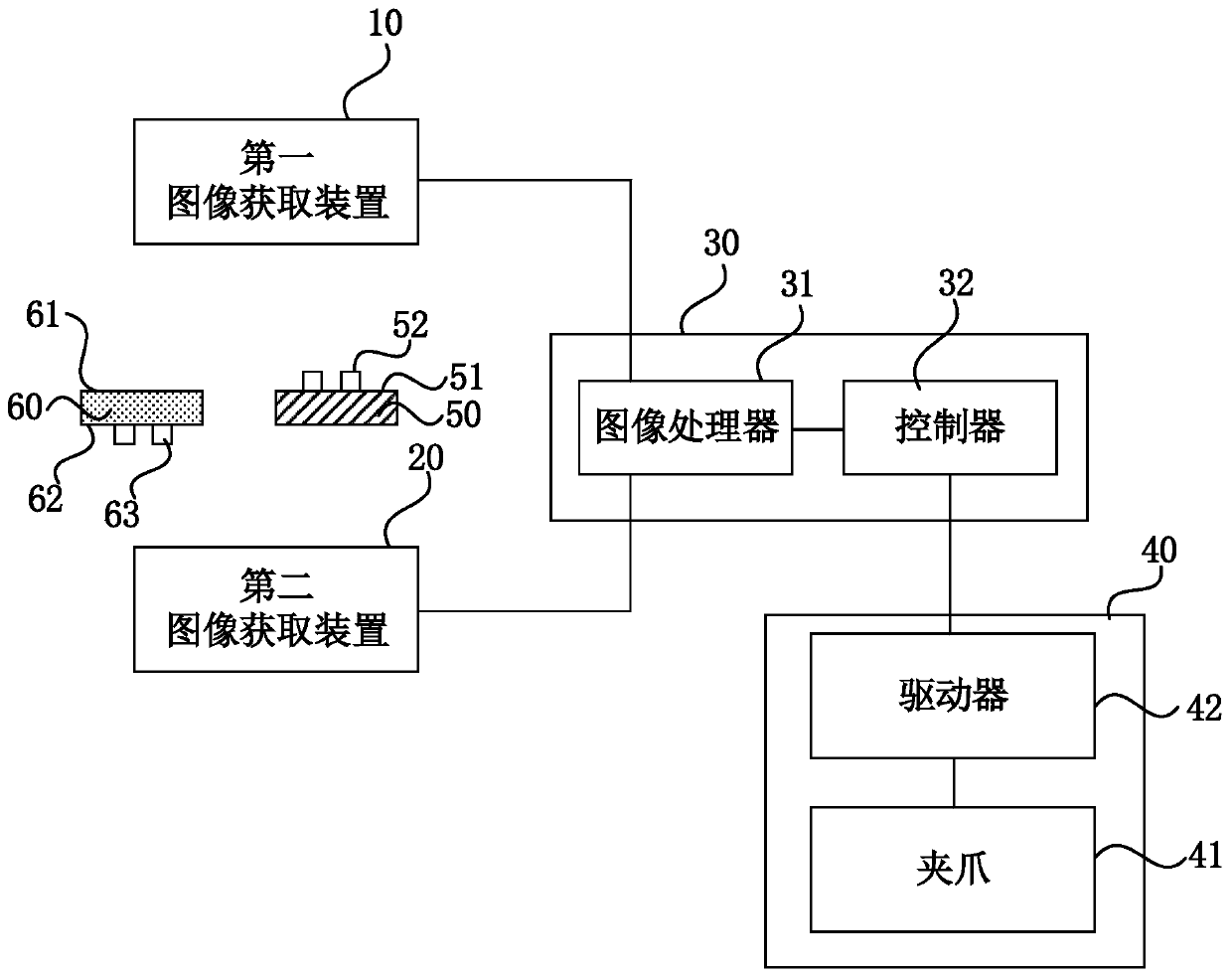

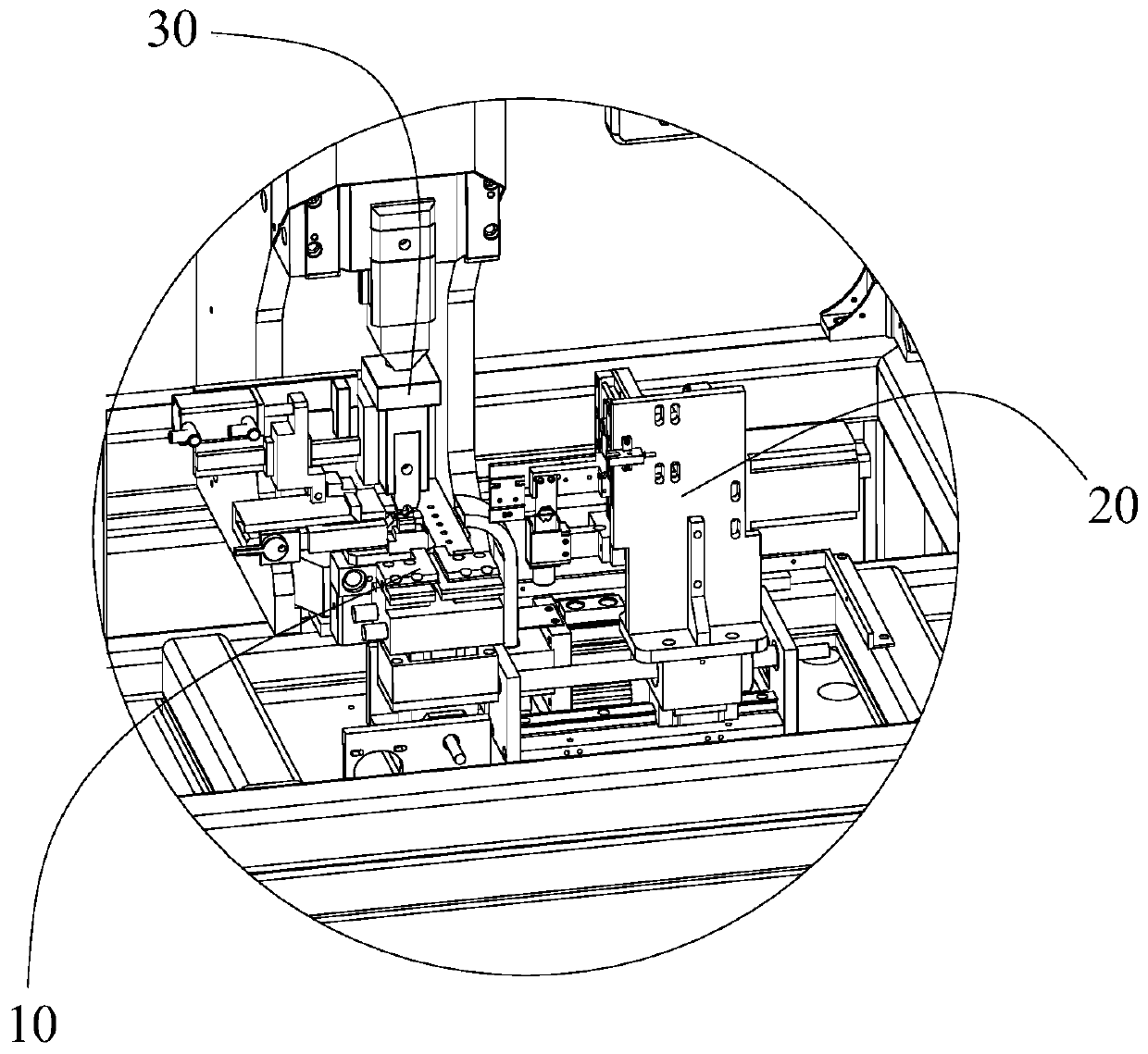

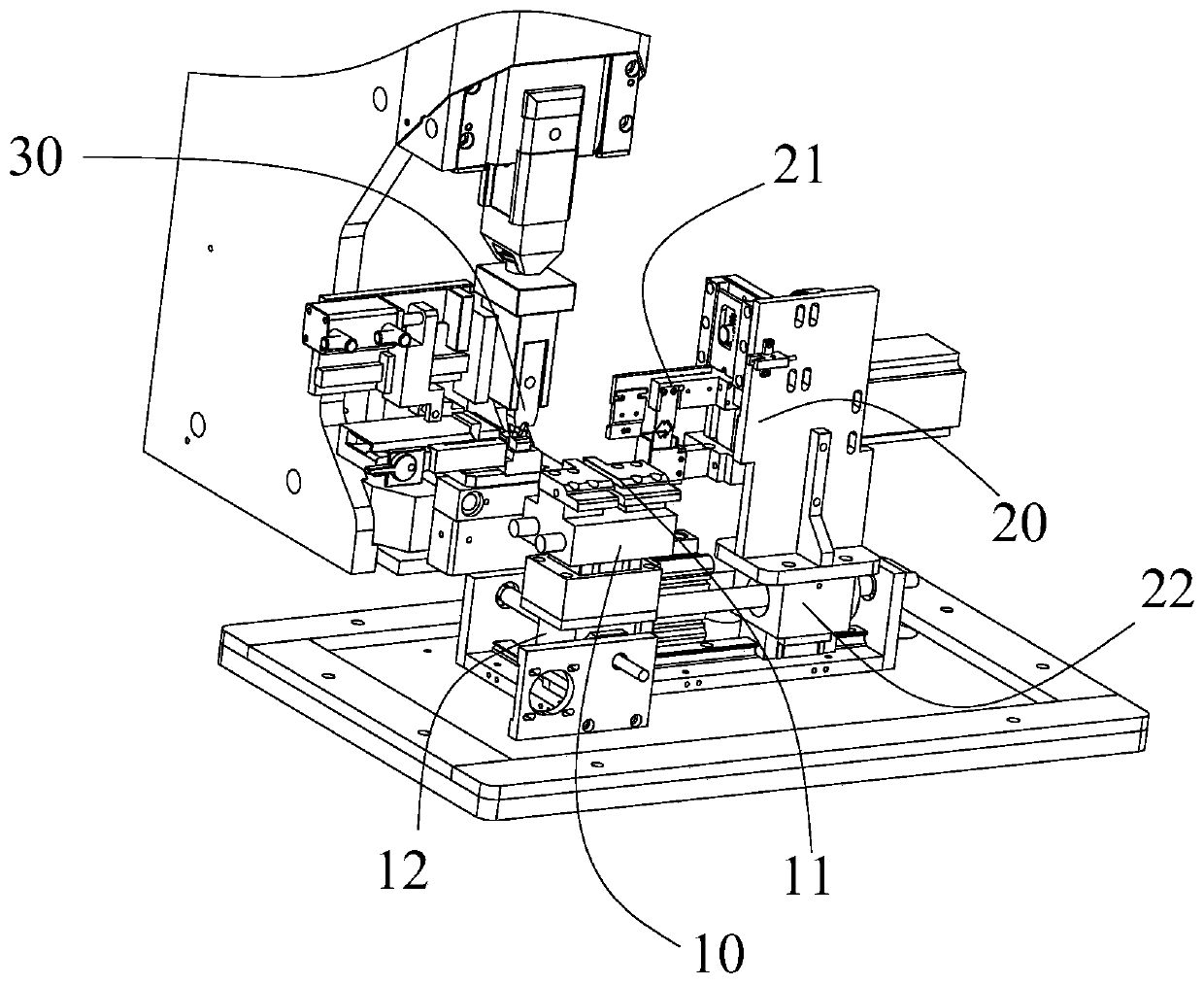

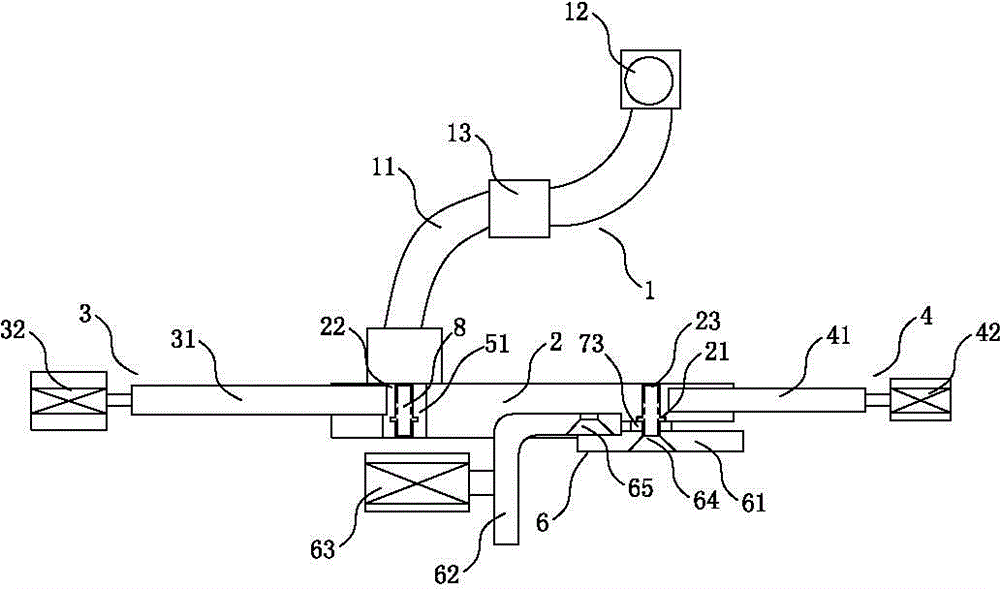

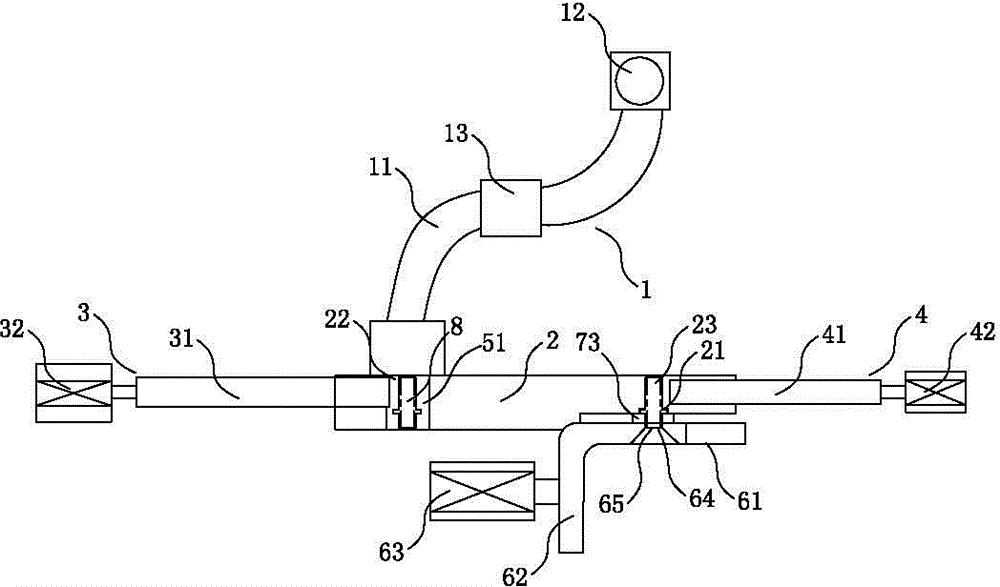

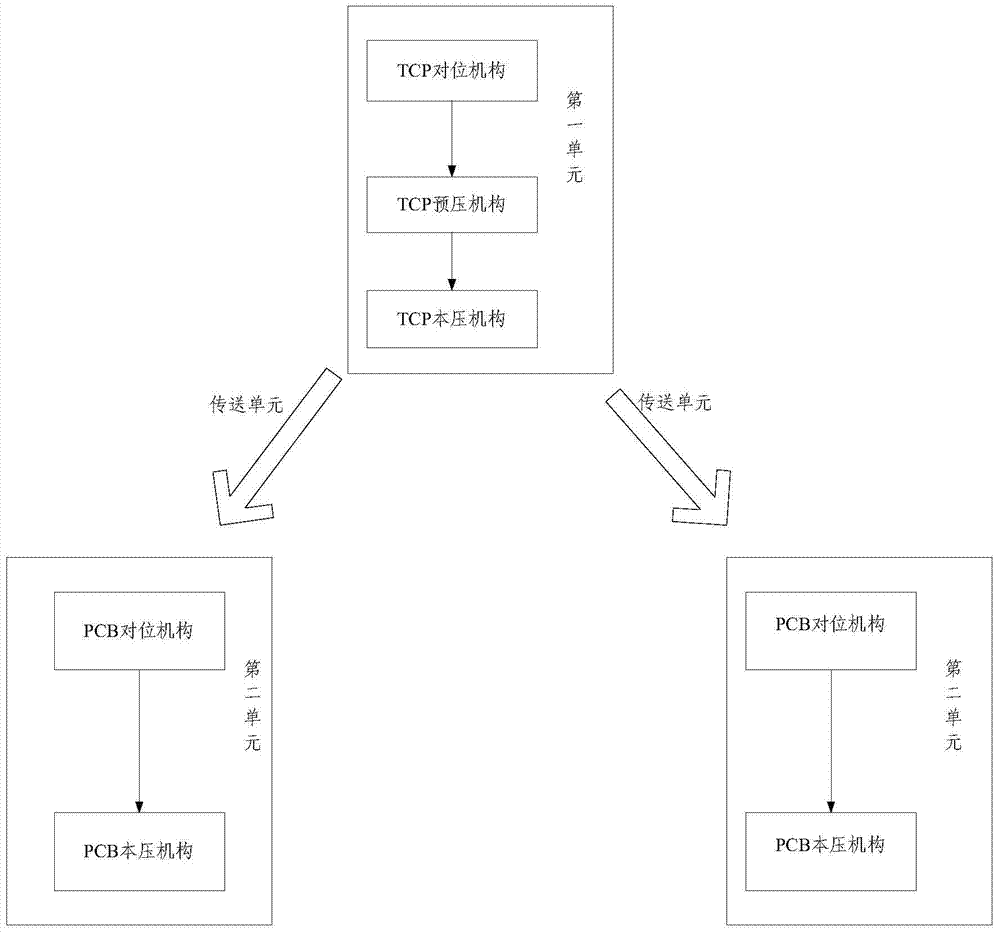

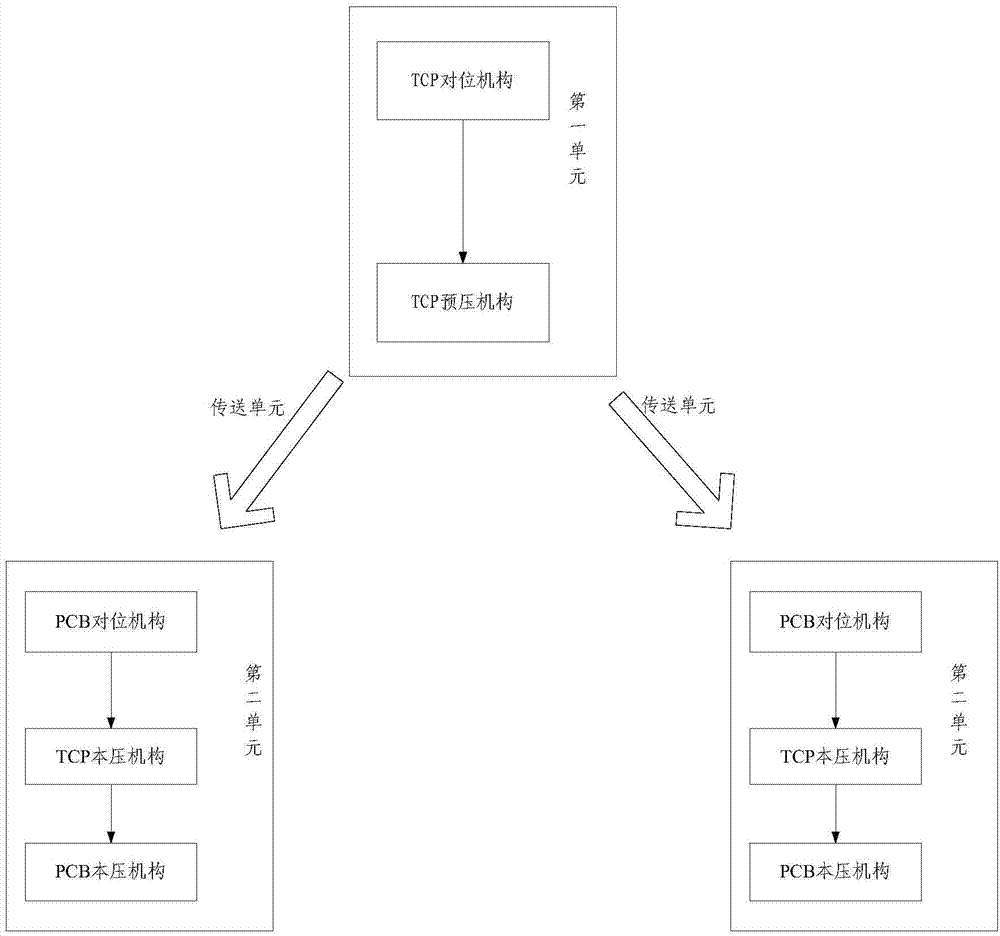

Automatic alignment crimping system and method

PendingCN110346612ARealize automatic alignment crimpingImprove crimping efficiencyProgramme controlComputer controlControl signalComputer science

The embodiment of the invention discloses an automatic alignment crimping system and method. The system comprises: a first image acquisition device for acquiring a first image of a first surface of acrimping carrier and the first surface of a product to be crimped; a second image acquisition device for acquiring a second image of a second surface of the product to be crimped; a control device forgenerating a grabbing control signal according to a feedback result of the position of the product to be crimped on the first image, and sending the grabbing control signal to a grabbing device; andthe grabbing device for grabbing the product to be crimped according to the grabbing control signal; the control device is further used for generating a crimping control signal according to the feedback result of the position of a first crimping member on the first image and the feedback result of the position of a second crimping member on the second image, and sending the crimping control signalto the grabbing device; and the grabbing device is further used for crimping the first crimping member and the second crimping member according to the crimping control signal. By adopting the automatic alignment crimping system and method disclosed by the invention, the alignment crimping efficiency is improved.

Owner:SUZHOU HUAXING YUANCHUANG TECH CO LTD

Double-wire sheath stripping servo crimping machine

ActiveCN110350378ARealize the integration functionImprove crimping efficiencyConnection formation by deformationEngineeringMechanical engineering

The invention belongs to the technical field of cable processing and relates to a double-wire sheath stripping servo crimping machine. The double-wire sheath stripping servo crimping machine comprisesa wire clamping module, a cutting and stripping module and a crimping module; the wire clamping module and the crimping module are oppositely arranged with an interval formed between the wire clamping module and the crimping module; the wire clamping module is provided with a wire clamping assembly used for clamping a cable and a first driving assembly used for driving the wire clamping module toapproach the crimping module and move away from the crimping module; the cutting and stripping module is arranged in the interval between the wire clamping module and the crimping module; the cuttingand stripping module is provided with a cutting assembly and a second driving assembly; the second driving assembly drives the cutting assembly to move to a direction perpendicular to the direction of the connection line of the wire clamping module and the crimping module, so as to make the cutting assembly move to the cable between the wire clamping module and the crimping module; and the cutting assembly is used for cutting the cable or an insulating sheath. The cutting and stripping module is movably arranged, so that the wire clamping module and the crimping module only need to move linearly to realize sheath stripping and crimping functions.

Owner:JIANGSU BOZHIWANG AUTOMATION EQUIP CO LTD

Hairbrush for hot curling

ActiveUS20070174986A1Shorten hair drying timeImprove hair curling efficiencyBristleHair combsBristleCombing

A hairbrush for hot curling. A brush body constituting a hairbrush is formed to have a substantially quadrangular sectional shape with rounded corners to thereby shorten a hair drying time and improve hair curling efficiency. A slippage prevention part is formed on the outer surface of each steel wire constituting a core element to increase frictional force between bristles and the steel wire, maintain the firmly fastened state of the bristles for an extended period of time and lengthen the lifetime of the hairbrush. A rounded part is formed on each end of each bristle through grinding to prevent damage to the skin of the head, ensure smooth combing of hair and increase the value of the hairbrush.

Owner:SANG SHIN INDAL

Hydraulic crimping method of strain clamp of bus in power substation

InactiveCN102545119AOvercoming the Phenomenon of "Lantern Flower"Improve crimp qualityBus-bar installationPower gridEngineering

The invention relates to a hydraulic crimping method of a strain clamp of a bus in a power substation, which comprises the following steps: (1) crimping a first mode a: outwards crimping the first mode a from an orifice end of a steel anchor in an aluminium wire steel anchor; (2) crimping a second mode b: on the basis of crimping the first mode, outwards crimping the second mode along the first mode; (3) crimping a third mode c: on the basis of crimping the second mode, outwards crimping the third mode along the second mode, and reserving a steel anchor part simultaneously; (4) crimping a fourth mode d: crimping the fourth mode d between the reserved steel anchor part and a lead plate; and (5) rubbing burrs down after crimping. The method is simple and easy to operate, the phenomenon of lantern flower after crimping wires is avoided, the quality and the efficiency for crimping the wires are improved, and the attractiveness, the electric conduction effect and the born tension of the wires are improved. Wastes of the wires and wire clamps caused by disqualified construction quality are saved, and the capacity of a power grid for resisting external force damage is enhanced.

Owner:LIAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Pneumatic crimping connector for electric engineering

PendingCN107809046ASimple structureImprove crimp stabilityLine/current collector detailsEngineeringPower engineering

The invention relates to a pneumatic crimping connector for electric engineering. The machine is provided with a base. A cylinder room is fixedly arranged on the upper end of the base. A piston rod isvertically inserted into the upper end of the cylinder room. The lower end of the piston rod passes through the rear end of the cylinder room to be connected with a piston piece. The piston piece ishorizontally arranged in the cylinder room. An air inlet and an air outlet are respectively arranged on the two sides of the cylinder room below the piston piece. A semicircular movable pressing pieceis fixedly arranged on the upper end of the piston rod. Columns are fixedly arranged in positions which are on the upper end of the cylinder room and on the two sides of the semicircular movable pressing piece. A beam is horizontally and fixedly arranged on the upper ends of the columns. A connecting rod is arranged between the columns at the lower end of the beam. A semicircular fixed pressing piece is fixedly arranged at the lower end of the connecting rod and at the upper end of the semicircular movable pressing piece. The pneumatic crimping connector for electric engineering has a simplestructure. Wires are pneumatically crimped at fixed time and at fixed pressure. The overall crimping quality of wires is ensured. The weight of the whole device is reduced. The device is easy to carry. The crimping stability and the crimping efficiency of the crimping connector are improved.

Owner:湖州铭腾电力工程科技有限公司

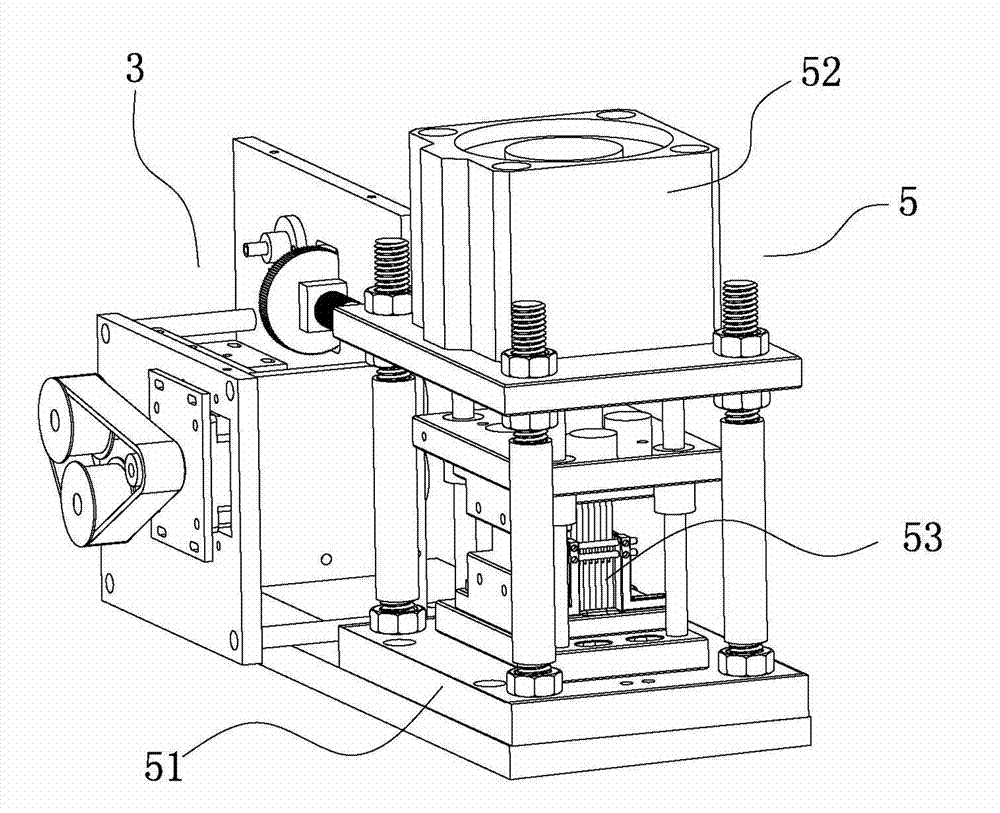

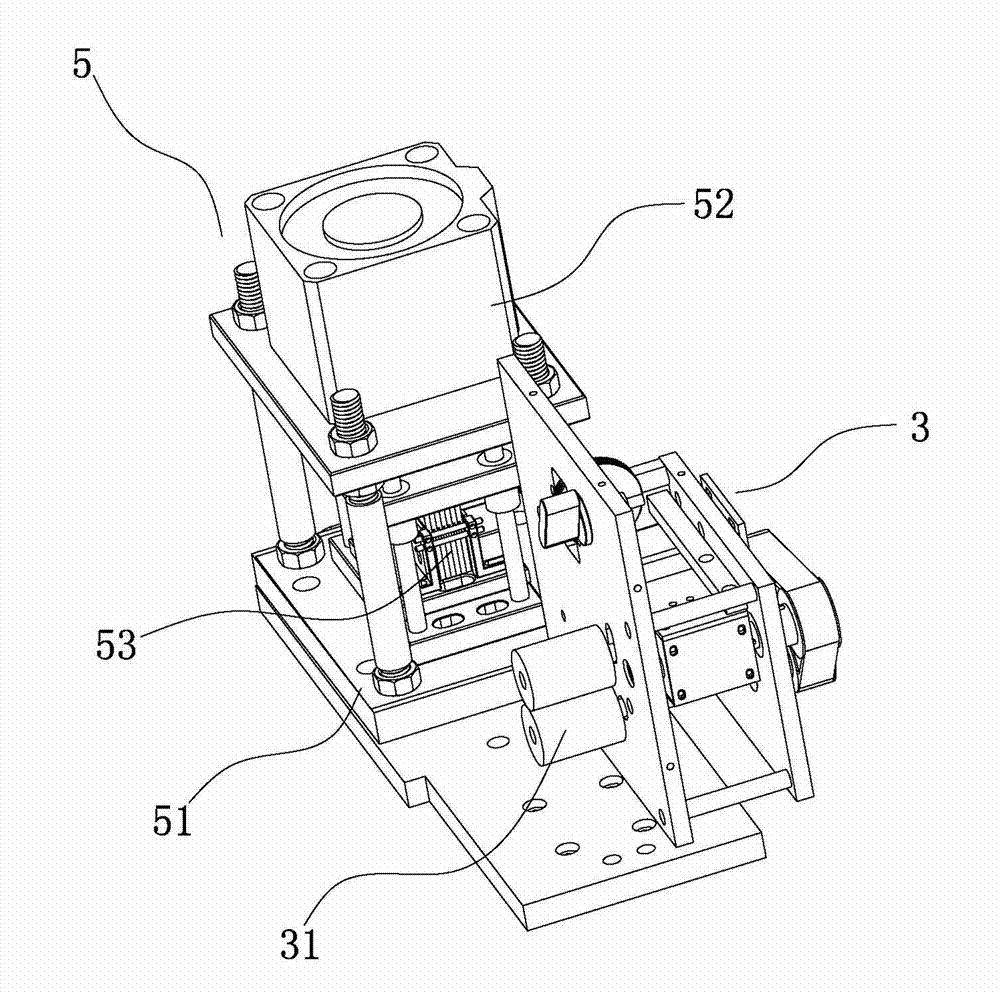

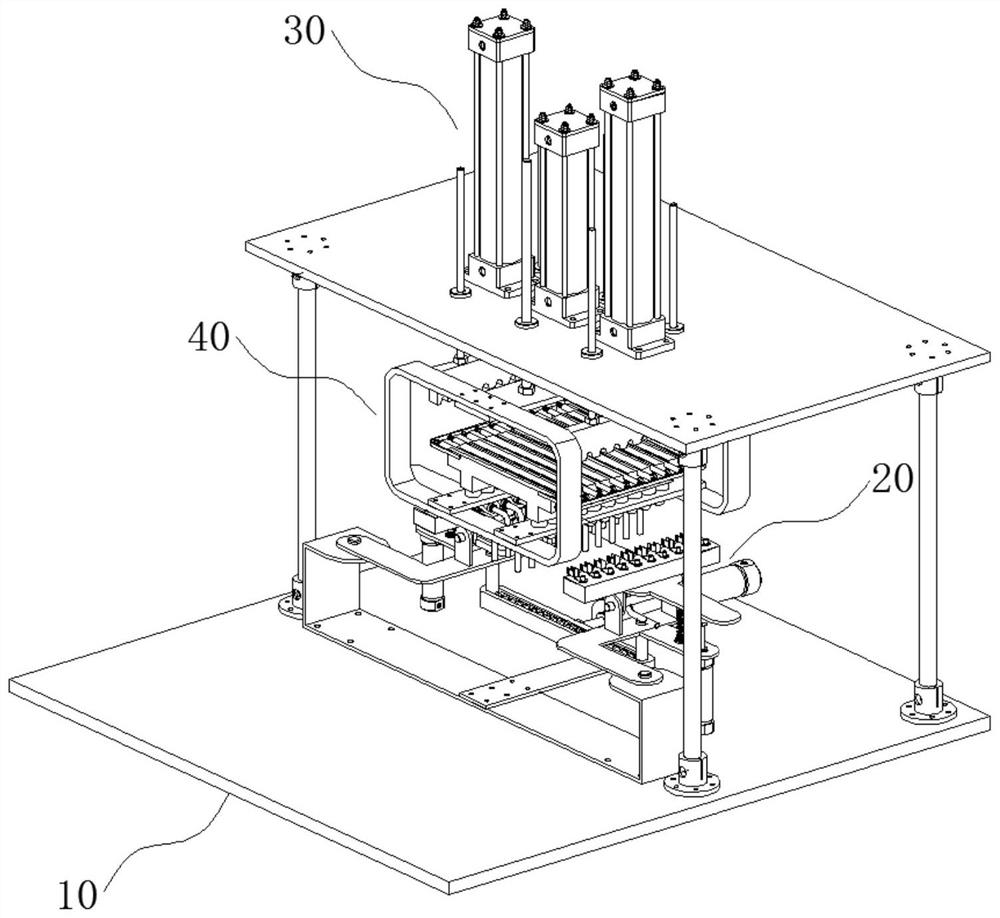

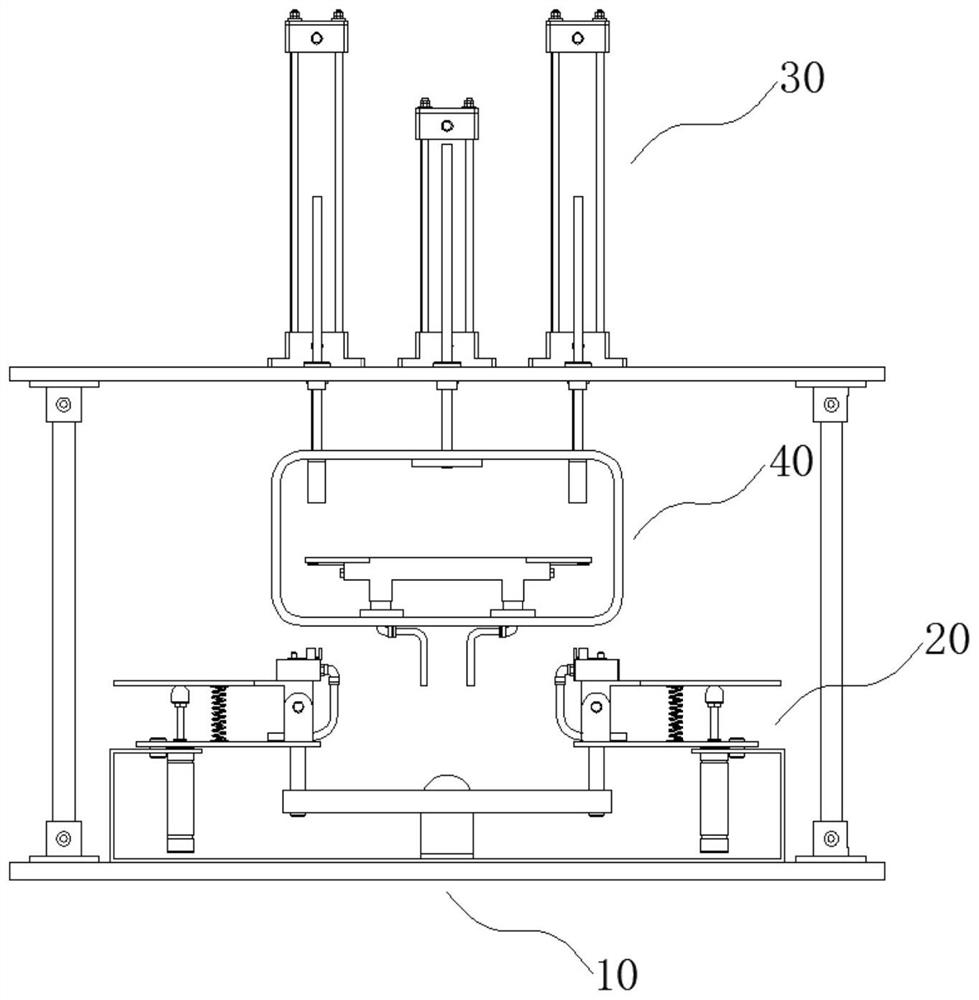

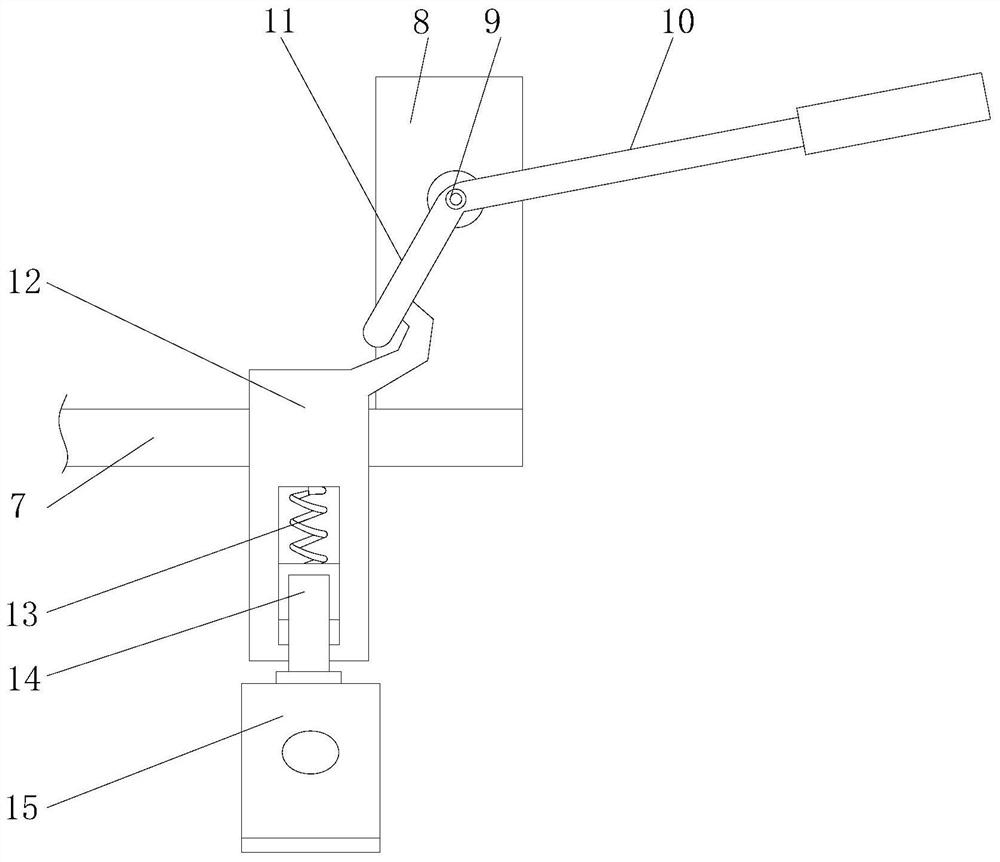

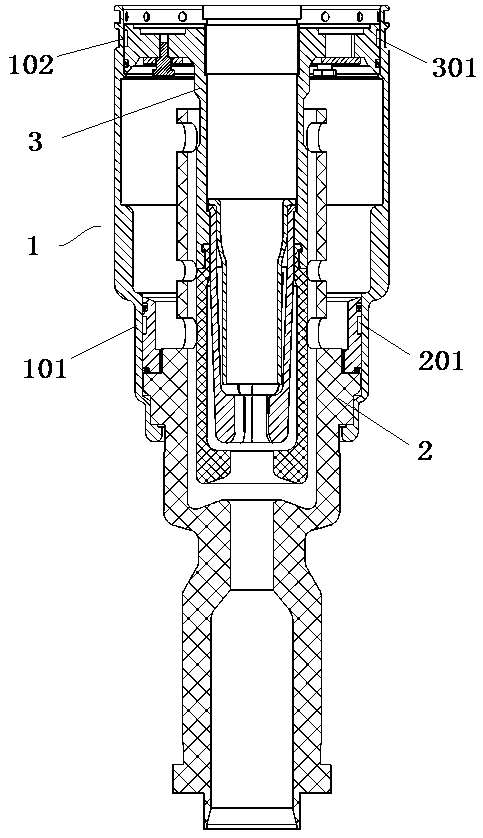

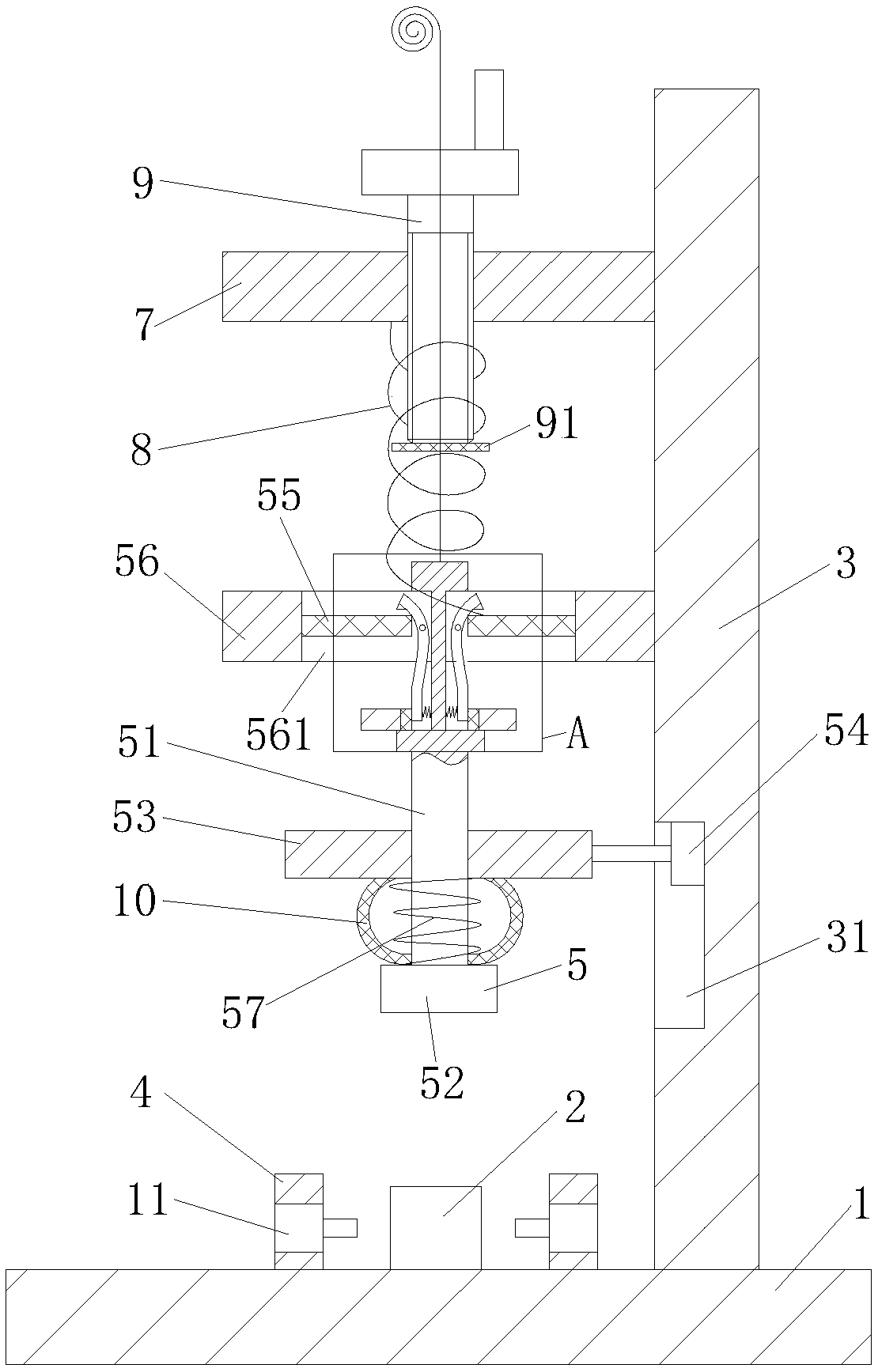

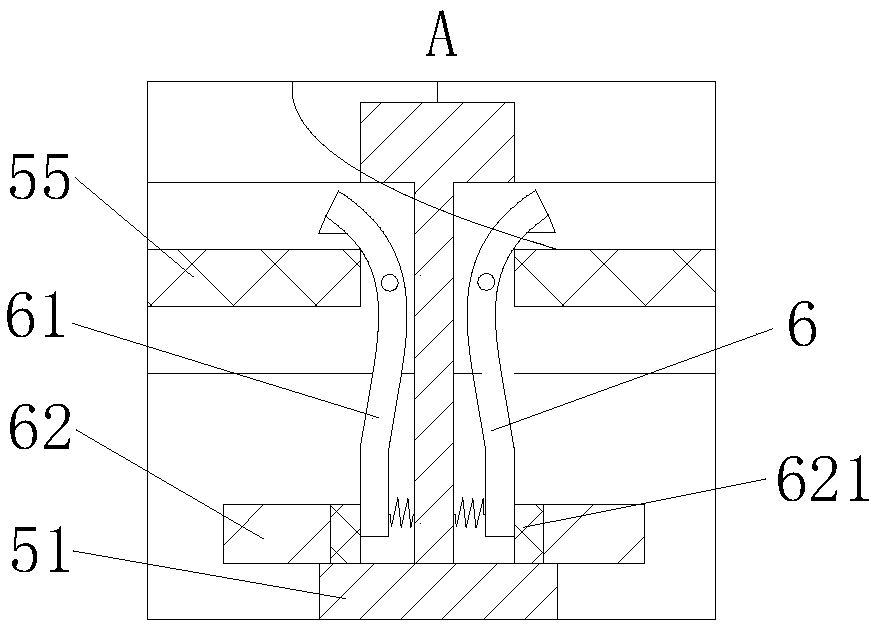

Crimping device for assembling moving end assembly of circuit breaker

ActiveCN111243907ATo achieve a fixed connectionAchieve connectionEmergency protective device manufactureAxial pressureCircuit breaker

The invention relates to a crimping device for assembling a moving end assembly of a circuit breaker. The crimping device for assembling the moving end assembly of the circuit breaker comprises: a workpiece positioning seat which is provided with a moving main contact positioning cavity for positioning a moving main contact along the axial direction and the radial direction; an axial pressure applying devices for pressing and positioning the corresponding nozzle assemblies or valve assemblies to the moving main contact; and a first crimping device and a second crimping device, wherein the first crimping device is used for applying pressure to a first crimping part on the moving main contact, and the second crimping device is used for applying pressure to a second crimping part on the moving main contact. According to the crimping device, connection among the moving main contact, the nozzle assembly and the valve assembly can be realized, interference assembly of the valve assembly andthe moving main contact can also be realized, the operation is convenient, and the crimping efficiency is high.

Owner:HENAN PINGGAO ELECTRIC +2

Rapid glove hemming equipment

PendingCN113370511AImprove crimping efficiencyPrevent missed rollsDomestic articlesElectric machineryElectric machine

Owner:安徽百通达科技医疗用品有限公司

Wire quick-wiring device

ActiveCN109346853ANot easy to fall offImprove crimping efficiencyLine/current collector detailsConnections effected by permanent deformationElectric wire

The invention belongs to the field of line conductor connection equipment, and particularly relates to a wire quick-wiring device. The device includes a substrate, a connection sleeve and a bracket. The bracket is fixedly mounted on one side of the substrate. A chute is disposed on one side of the bracket. The connection sleeve is placed on the substrate. A stamping mechanism is disposed on the substrate, is located above the substrate, is used for stamping on the connection sleeve, and includes a stamping rod, a stamping block, a moving plate, a sliding block, an elastic film, a fixing plateand a connection rod. One end of the moving plate is fixedly connected with the sliding block through the connection rod. The stamping block is located below the moving plate. An impacting spring is connected between the stamping block and the moving plate in a sleeving manner. The stamping rod is mounted on the moving plate in a vertical sliding manner. The fixing plate is fixedly mounted on thebracket. According to the device, a wire needing to be connected is peeled and then inserted into the connection sleeve, then ejection impacting is carried out on the connection sleeve through the stamping mechanism, thus quick connection of the wire is realized, connection is firm, and shedding is not liable to occur.

Owner:绍兴欣耀机电科技有限公司

Automatic terminal crimping machine

ActiveCN104319596AFast and efficient crimping processImprove crimping efficiencyLine/current collector detailsElectrical conductorAutomatic testing

The invention relates to an automatic terminal crimping machine which structurally comprises a machine frame and a feeding device, a pushing device, a return material retreating device, a return material blanking device, a clamping device and a crimping device which are arranged on the machine frame. In the crimping process, a terminal enters the feeding position through a feeding pipe of the feeding device, and meanwhile the pushing rod pushes the terminal to the crimping position along a feeding slide. When the direction of the terminal is correct, a conductor of a cable is inserted into the crimping portion of the terminal, then an upper clamping plate and a lower clamping plate clamp the terminal in a fastening mode, and then an upper press die moves downwards to be matched with a lower press die to extrude and deform the crimping portion of the terminal to achieve crimping molding. When the direction of the terminal is wrong, a return material retreating rod pushes the terminal to the return material blanking plate, meanwhile the return material blanking plate moves to enable the terminal to fall into a recycling device below a support. The machine can greatly improve the crimping efficiency, saves time and labor, improves the crimping yield and improves product competitiveness.

Owner:GUANGDONG ZHONGDE CABLE

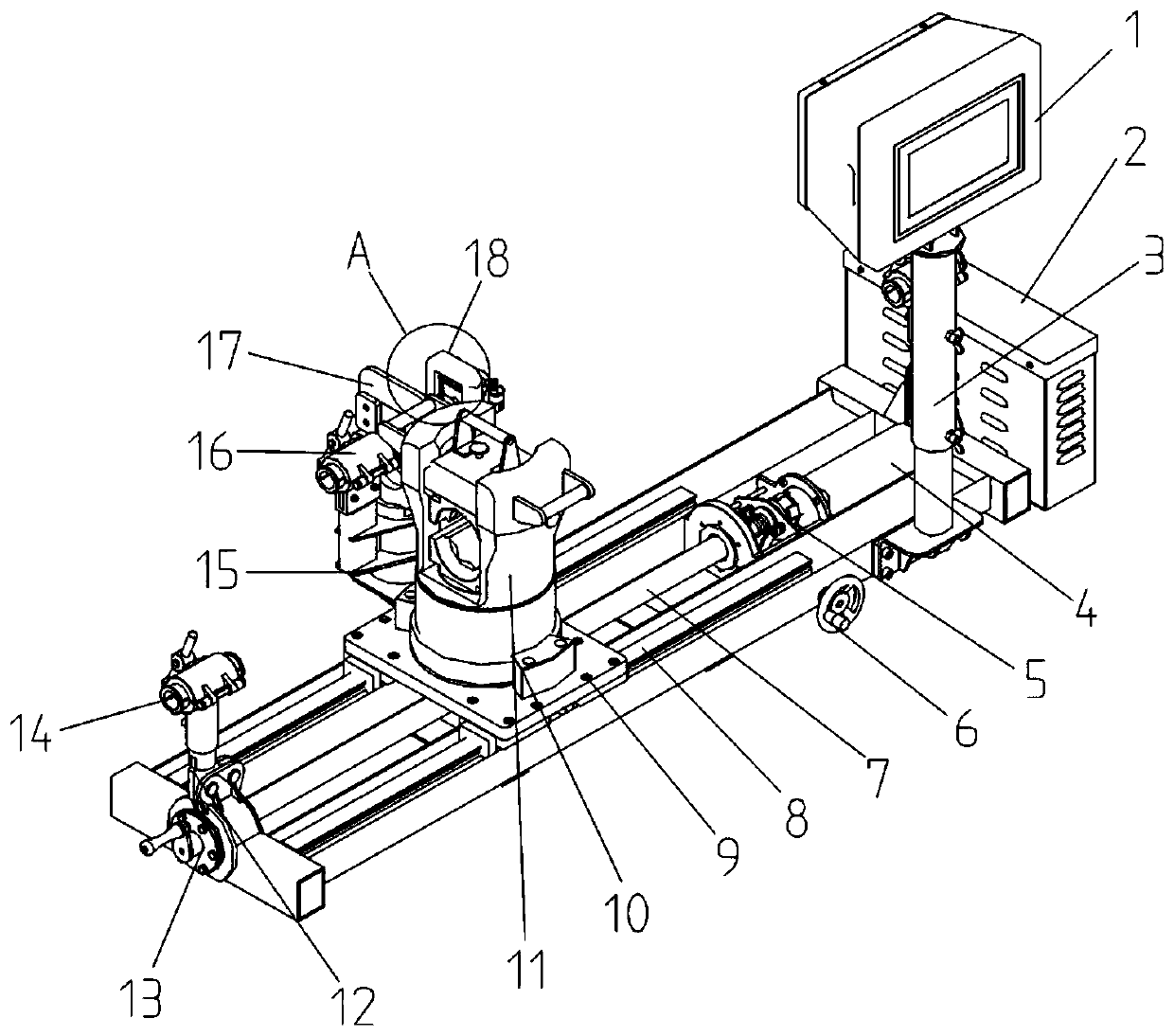

Wire crimping machine

PendingCN111129905ALocate the crimping positionImprove crimp qualityConnection formation by deformationElectric machineBall screw

The invention discloses a wire crimping machine, and belongs to the technical field of power construction. The wire crimping machine comprises a bottom frame body and a linear guide rail module, a crimping module and a wire cutting and stripping module which are respectively arranged on the bottom frame body, wherein the linear guide rail module comprises a driving motor and a lead screw guide rail, and the output end of the driving motor is fixedly connected with the lead screw guide rail; the bottom end of the crimping module is screwed with the lead screw guide rail to form a ball screw structure; and the wire cutting and stripping module comprises a wire cutting module and a wire stripping module which are respectively and fixedly connected with the crimping module, and the wire cutting module and the wire stripping module are linearly and correspondingly arranged. According to the device, the crimping module can be effectively moved according to the linear guide rail module, the crimping position of the wire can be found accurately, automatic crimping can be realized, and the crimping quality and efficiency of the wire can be greatly improved.

Owner:北京争先甲电力科技开发有限公司 +1

Compression splicing equipment and method

Owner:BOE TECH GRP CO LTD +1

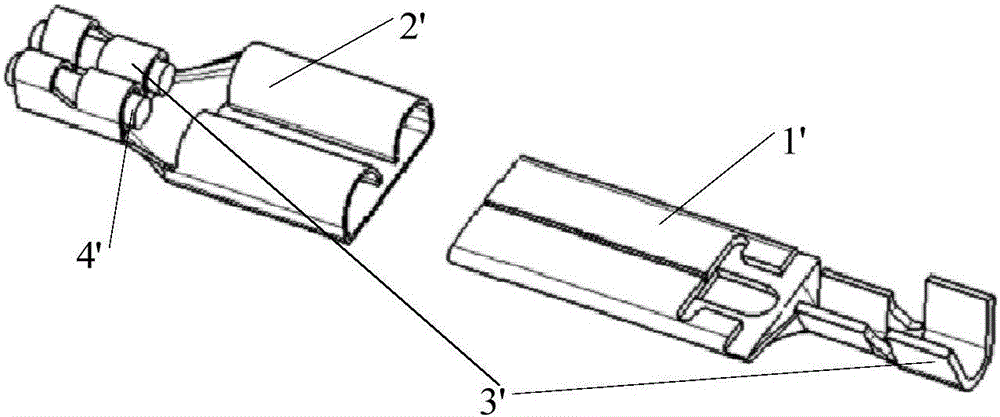

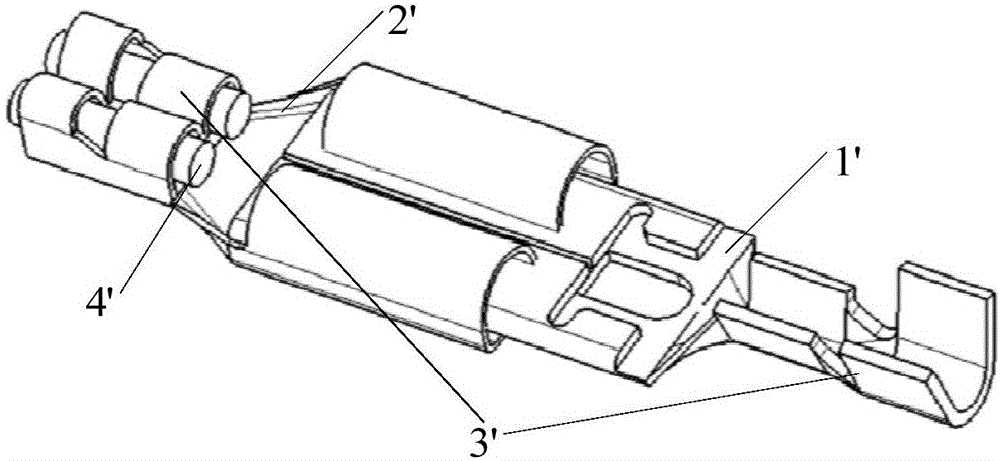

Vehicle harness terminal and installation structure thereof

ActiveCN106207549ASave wireImprove crimping efficiencyVehicle connectorsCoupling contact membersEngineeringMechanical engineering

The invention relates to a vehicle harness terminal and an installation structure thereof. The vehicle harness terminal comprises a female terminal and a male terminal, wherein the female terminal comprises a jack part and a first crimping part, two first jacks and a second jack are formed in the jack part, the second jack is arranged between the two first jacks, elastic sheets are arranged in the first jacks and the second jack, the male terminal comprises a needle-shaped part, a rod-shaped part and a second crimping part, the needle-shaped part comprises three insertion ends, the three insertion ends are used for being inserted to the female terminal and are connected by a connection part, and the rod-shaped part is connected with the needle-shaped part and the second crimping part. The two first jacks and the second jack are combined for use, the male terminal with the three insertion ends is matched, the two terminals are connected with the crimping parts respectively by a wire, connection can be achieved by dividing to three paths, the usage amount of the wires is saved, and the plug-in efficiency can also be improved. A first elastic sheet, a second elastic sheet and a third elastic sheet are matched with a first spring and a second spring, thus, the plug-in reliability can be improved, and more reliable plug-in is achieved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Portable on-site buckling device and buckling method

PendingCN110815124AImprove application reliabilityInsufficient improvementMetal-working hand toolsTubular articlesFiberLine tubing

The invention relates to a portable on-site buckling device and buckling method. The device comprises a support connecting plate and a rotating mechanism. A connecting rod is movably connected to therotating mechanism, and the end portion of the connecting rod penetrates through the support connecting plate and is fixedly connected with an inner expansion head arranged on one side of the supportconnecting plate. The rotating mechanism drives the connecting rod to move, the inner expansion head is driven to perform inner expansion extrusion on a composite pipe and a thread head and core pipecombined body placed in a casing pipe. A sleeve, the thread head and core pipe combined body and the composite pipe are buckled together, buckling can be carried out on site, the buckling efficiency is improved, and the problem that the buckling strength is inconsistent (axial and radial grip strength is not uniform), and reinforcing fibers are damaged is solved, the application reliability of thepipe is improved, the inner expansion enables the effective drift diameter of a joint to be relatively expanded, the pipeline flow resistance is reduced, and the cost is reduced.

Owner:陕西欣欣智能管业有限公司

Thread pressing device of paper bag making machine

PendingCN107804032AEasy crimpingImprove crimping efficiencyBag making operationsPaper-makingEngineeringStructural engineering

The invention relates to the technical field of paper bag making machines, in particular to a thread pressing device of a paper bag making machine. The thread pressing device comprises two mounting blocks and a supporting platform of the paper bag making machine, and a second thread pressing device body corresponding to a first thread pressing device body in position is arranged on the upper surface of the supporting platform. The second thread pressing device body comprises a second groove formed in the upper surface of the supporting platform, and a second fixing shaft is arranged in the second groove and sleeved with a second thread pressing wheel, so that the second thread pressing wheel rotates along the upper surface of the second fixing shaft. Second sliding rods are arranged on thetwo sides of the second groove, a supporting plate is arranged between the two second sliding rods in a penetrating mode, and the supporting plate slides along the side surfaces of the second slidingrods. Baffles are arranged at the top ends of the two second sliding rods, and the bottom surfaces of the baffles are in contact with the upper surface of the supporting plate. The thread pressing device is simple in structure and convenient to use, can be used for conveniently pressing threads for the front face and the back face of a paper bag, and can further improve the production efficiencyof paper bags.

Owner:阜宁县华强纸品有限公司

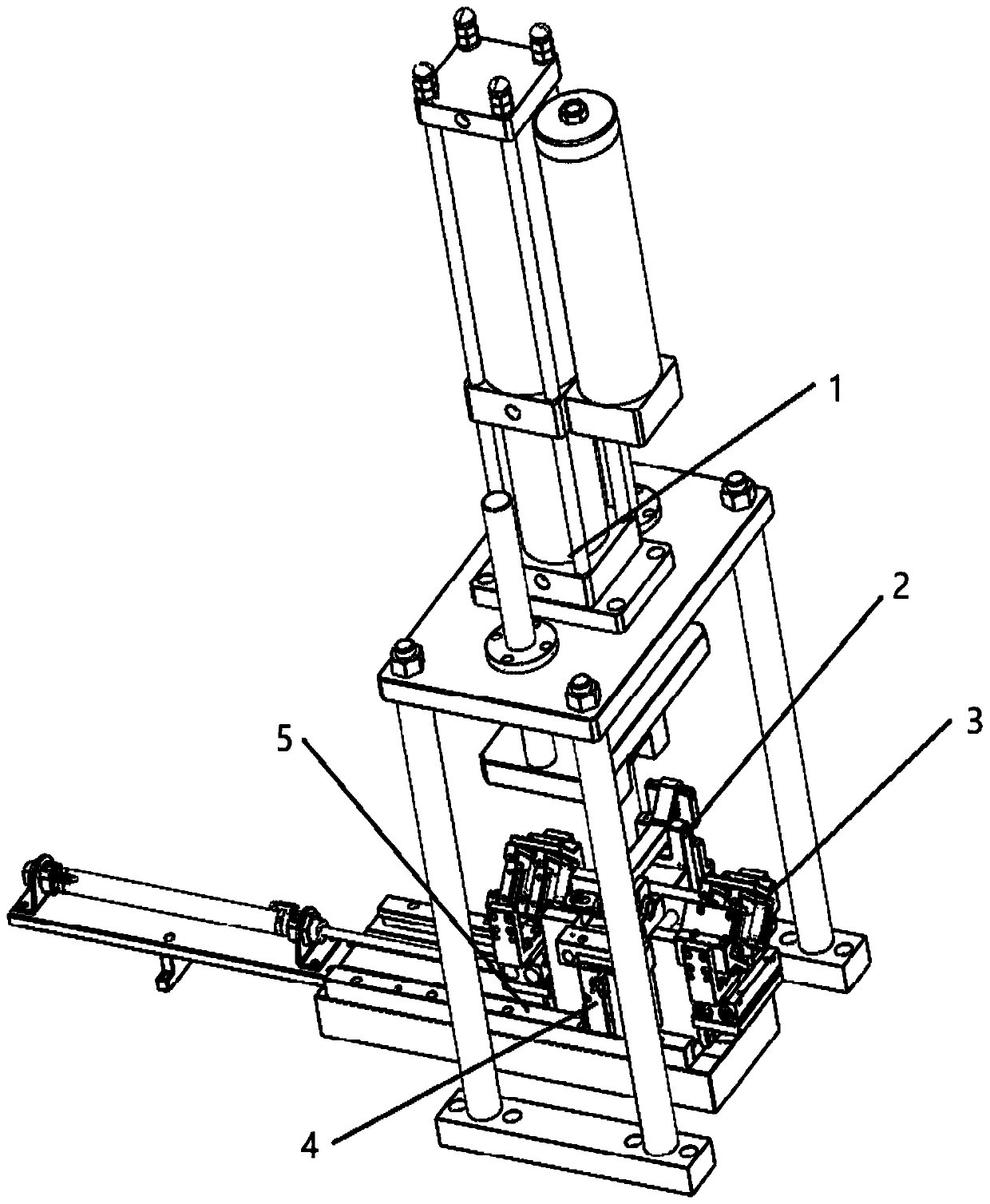

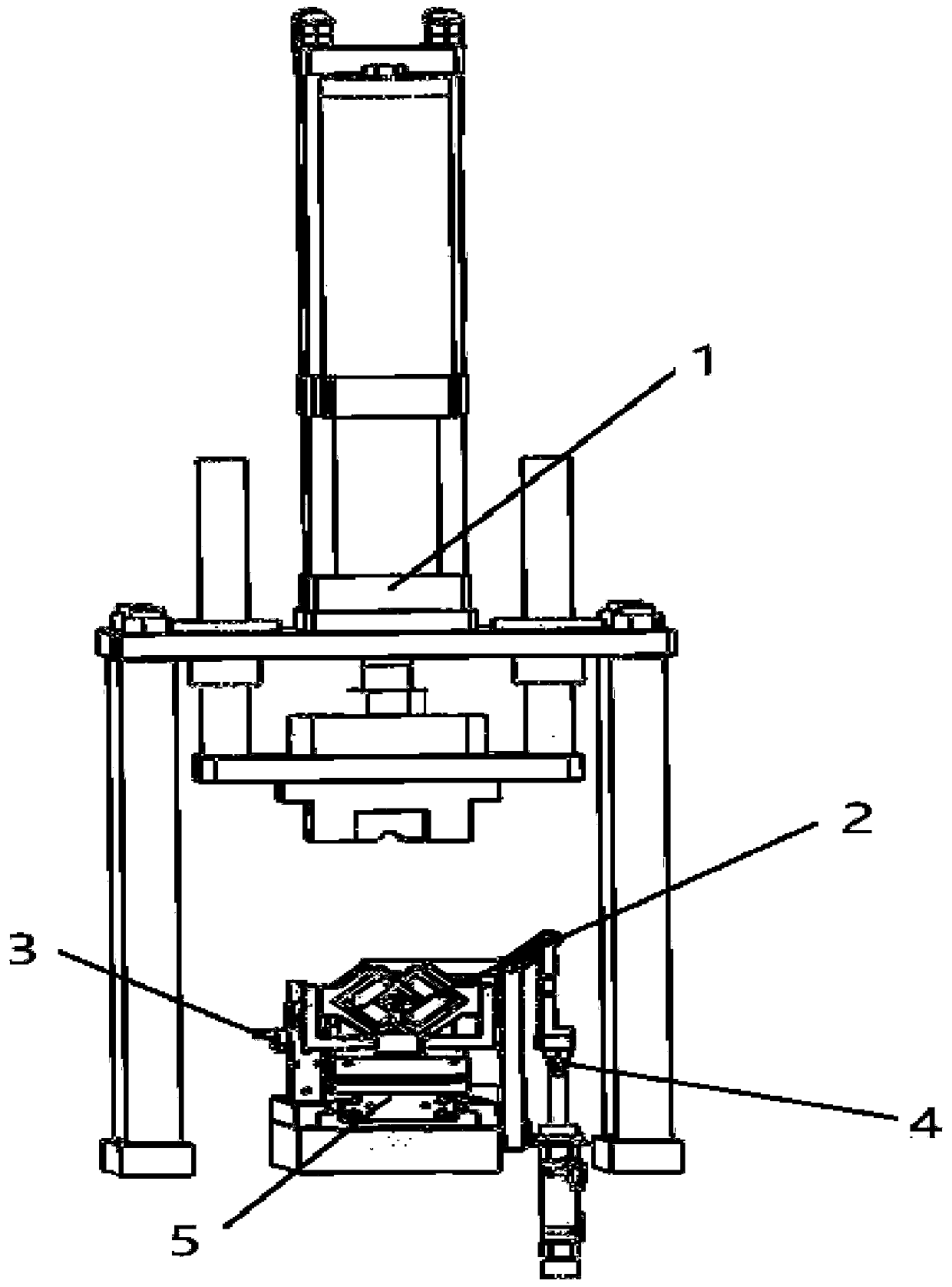

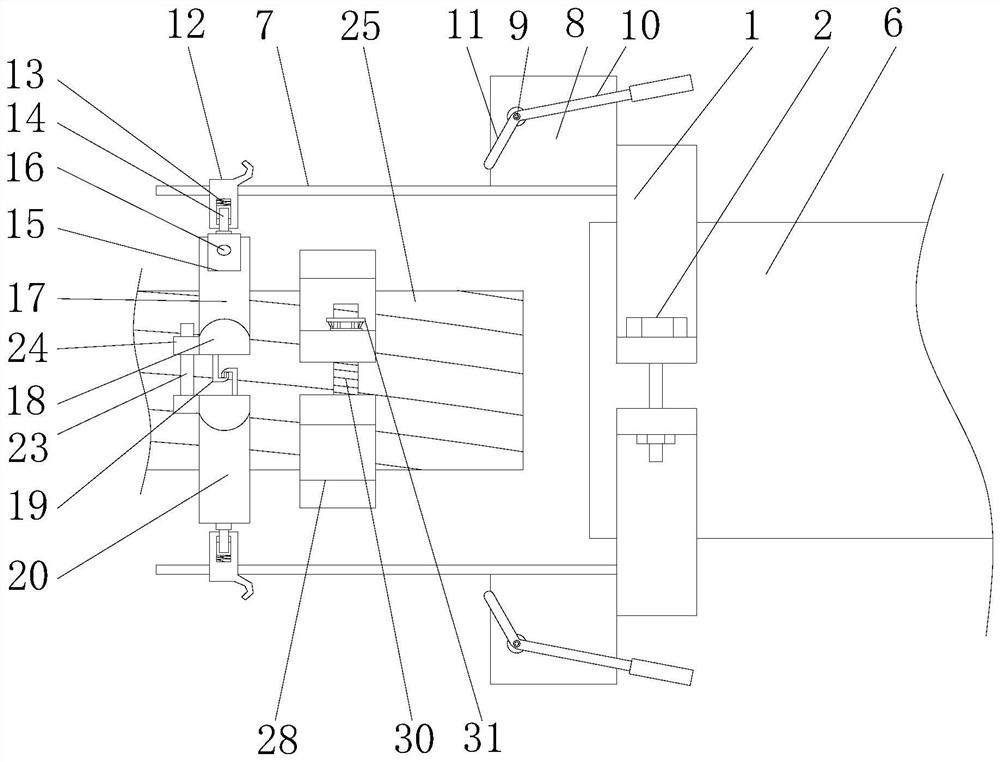

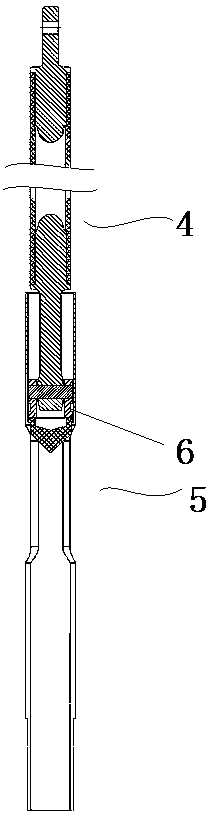

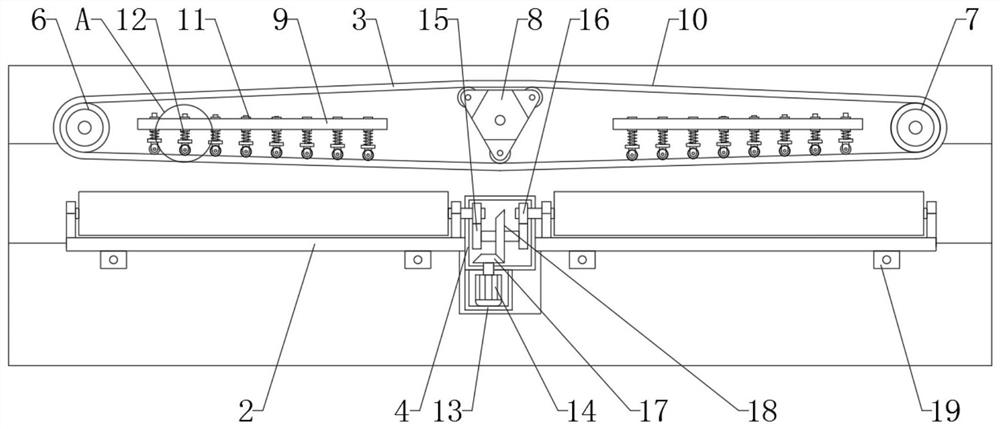

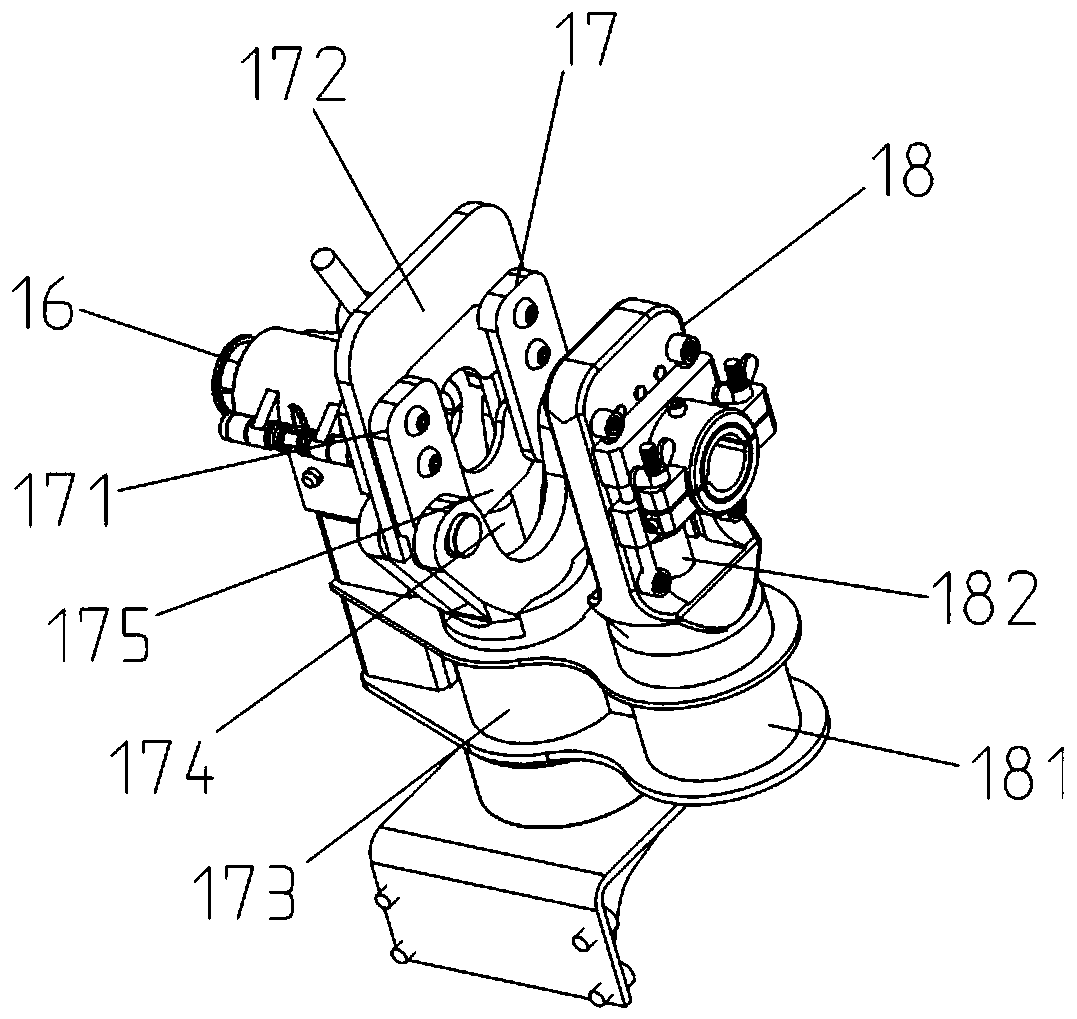

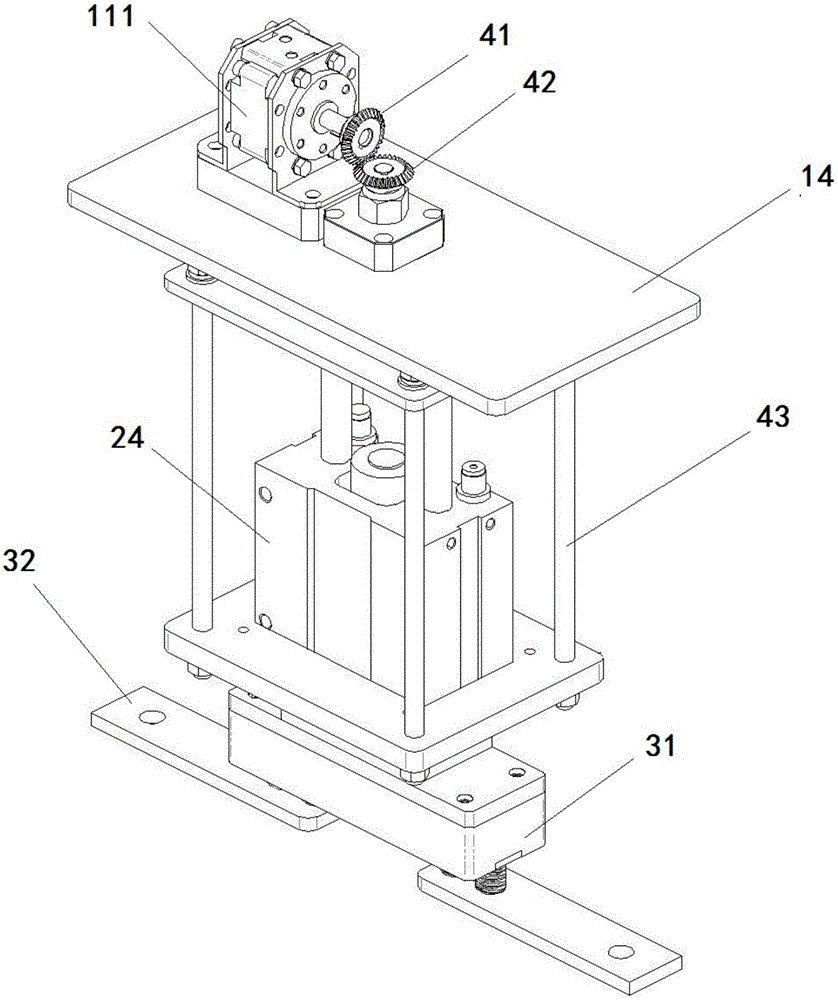

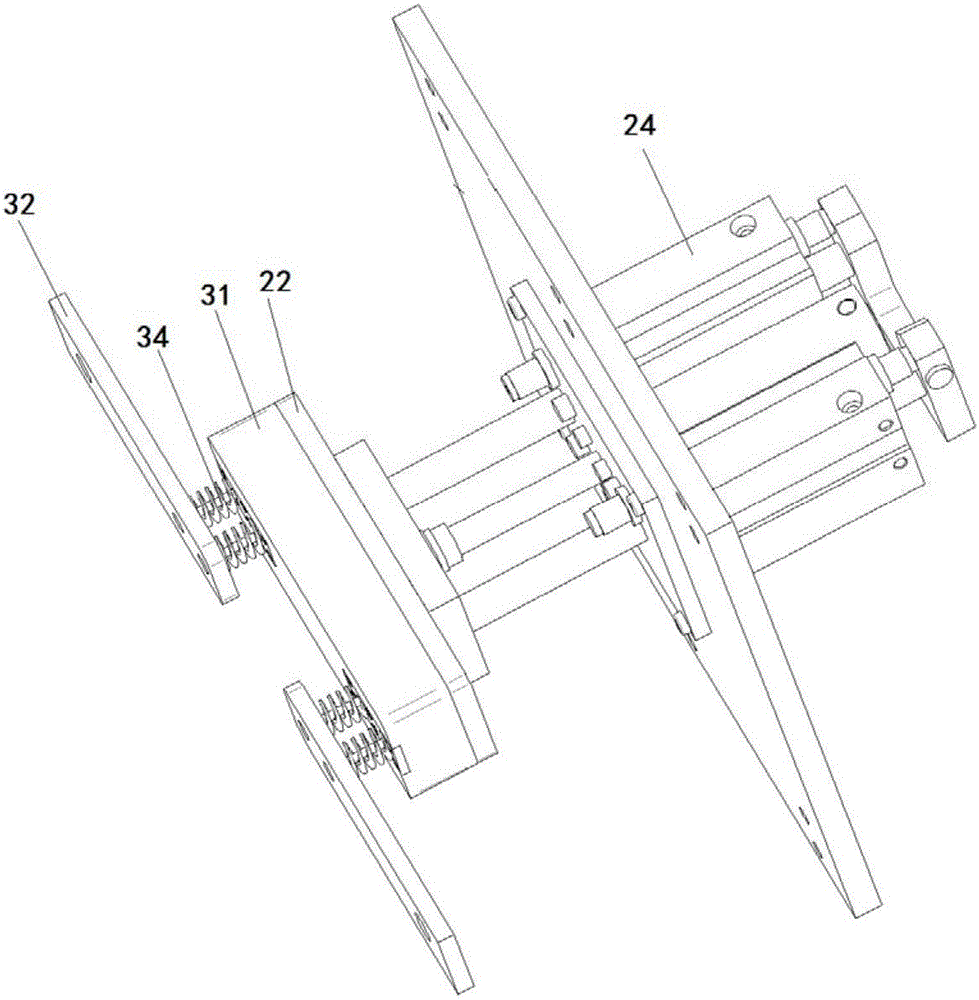

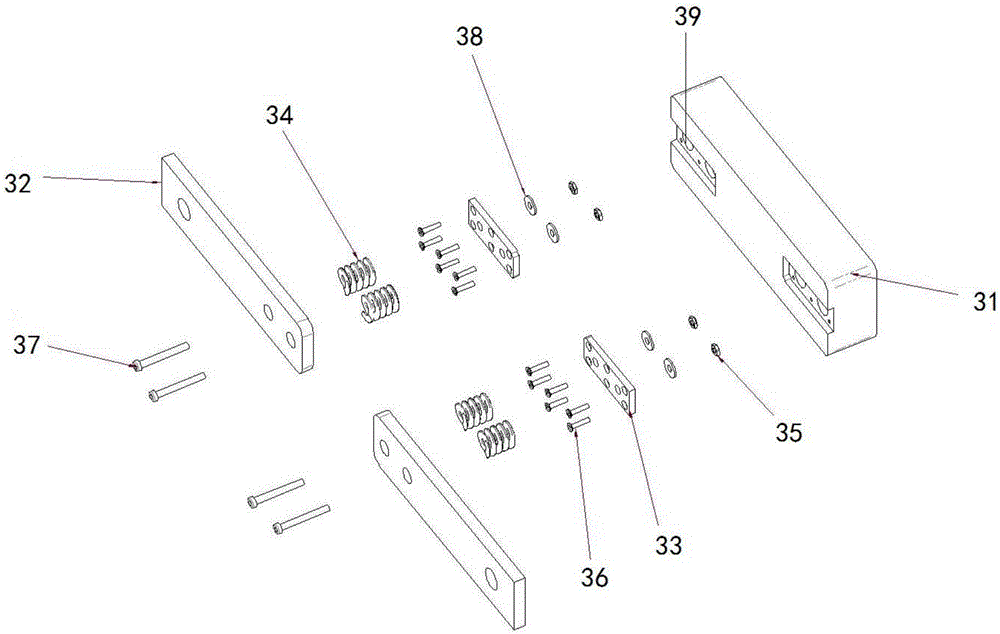

Primary connection crimping device of high-voltage current transformer

ActiveCN106531426ASolve unreliable contactImprove crimping efficiencyLine/current collector detailsInductances/transformers/magnets manufactureCoil springEngineering

The invention relates to a primary connection crimping device of a high-voltage current transformer. The primary connection crimping device of the high-voltage current transformer comprises a steering mechanism, a crimping mechanism and a following mechanism, wherein the steering mechanism comprises a rotary air cylinder (111); the crimping mechanism comprises a crimping air cylinder installation plate (21) and a crimping air cylinder (24); a main body of the crimping air cylinder (24) is arranged on the crimping air cylinder installation plate (21); an output shaft of the rotary air cylinder (111) is connected with the crimping air cylinder installation plate (21) through a gear transmission mechanism; the following mechanism comprises an insulating fixing block (31), a conductive copper bar fixing screw (37) and a spiral spring (34); and one end of the insulating fixing block (31) is fixedly connected with an output shaft of the crimping air cylinder (24) and an installation hole (39) is arranged in the other end. Compared with the prior art, the primary connection crimping device has the advantages that the rotating angle of a conductive copper bar is controlled by the steering mechanism, the conductive copper bar approaches a connection end through the crimping mechanism, the conductive copper bar is clung to a connection surface through deformation of the spiral spring, the contact is reliable and the crimping efficiency is high.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com