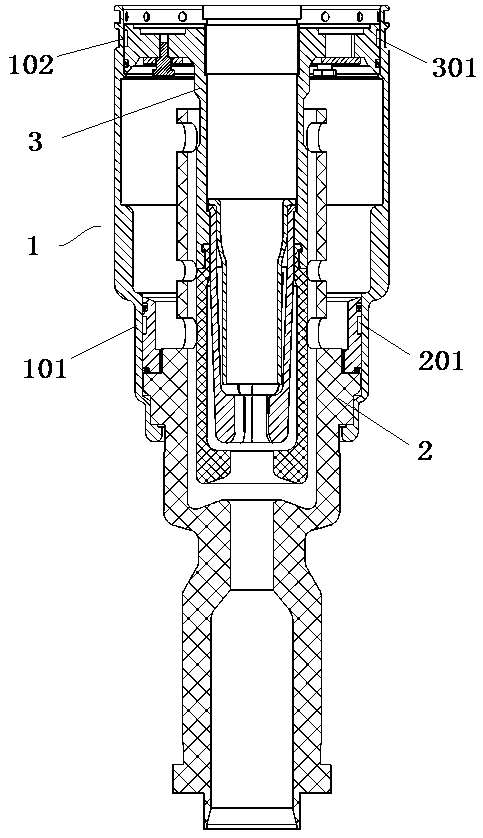

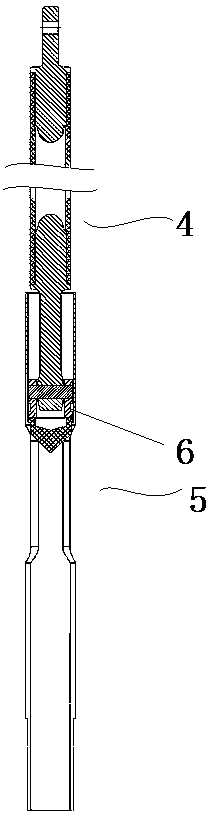

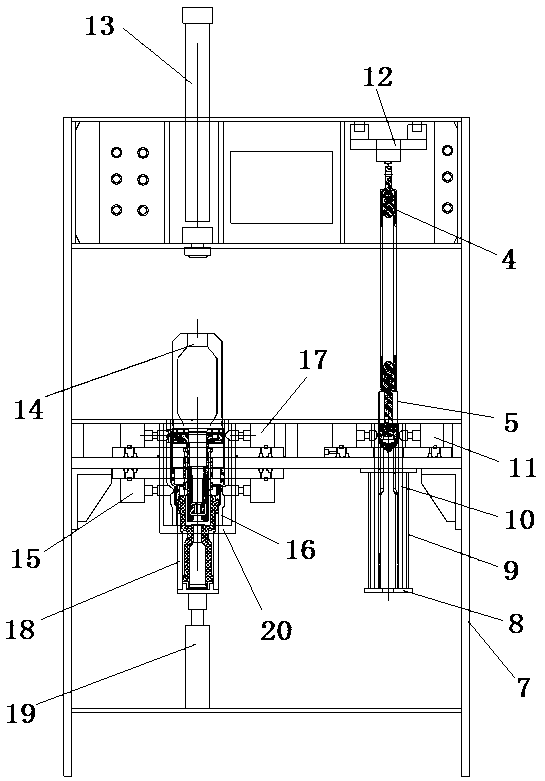

Crimping device for assembling moving end assembly of circuit breaker

A technology of crimping device and circuit breaker, applied in emergency protection device, emergency protection device manufacturing, circuit and other directions, can solve the problems of high cost of moving end components, low assembly efficiency, increase the weight of moving end components, etc., and achieve convenient operation. , The effect of high crimping efficiency, reducing floor space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0073] The specific embodiment 2 of the crimping device used for assembling the moving end assembly of the circuit breaker in this application: the difference between this embodiment and the specific embodiment 1 is that the bottom section of the workpiece positioning seat is provided with an inner flange, which is used to connect with The lower end surface of the moving main contact stops and cooperates to realize the axial positioning of the moving main contact by the workpiece positioning seat, relying on the small gap between the cavity wall of the moving main contact positioning cavity and the moving main contact, The contacts are limited in the radial direction to meet the crimping requirements of the moving contact assembly.

specific Embodiment 3

[0074] Specific embodiment 3 of the crimping device used to assemble the moving end assembly of the circuit breaker in this application: the difference between this embodiment and specific embodiment 1 is that the workpiece positioning seat is cylindrical, and the positioning cavity of the moving main contact The radial dimensions are consistent, and at this time, only an annular step for matching with the annular boss on the large-diameter section of the moving main contact is provided on the cavity wall of the moving main contact positioning cavity.

specific Embodiment 4

[0075] Specific embodiment 4 of the crimping device used to assemble the moving end assembly of the circuit breaker in this application: the difference between this embodiment and specific embodiment 1 is that the workpiece positioning seat is cylindrical, and the positioning cavity of the moving main contact The radial dimension is consistent, and the annular step matched with the annular boss on the small diameter section of the moving main contact has a larger radial dimension along the moving main contact positioning cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com