Food processor with heating function

A cooking machine and functional technology, applied in the field of food processing, can solve the problems of small heating area of electric heating plate, increased weight of cup body, unfavorable use, etc., and achieve the effects of increasing effective heating area, reducing working noise and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

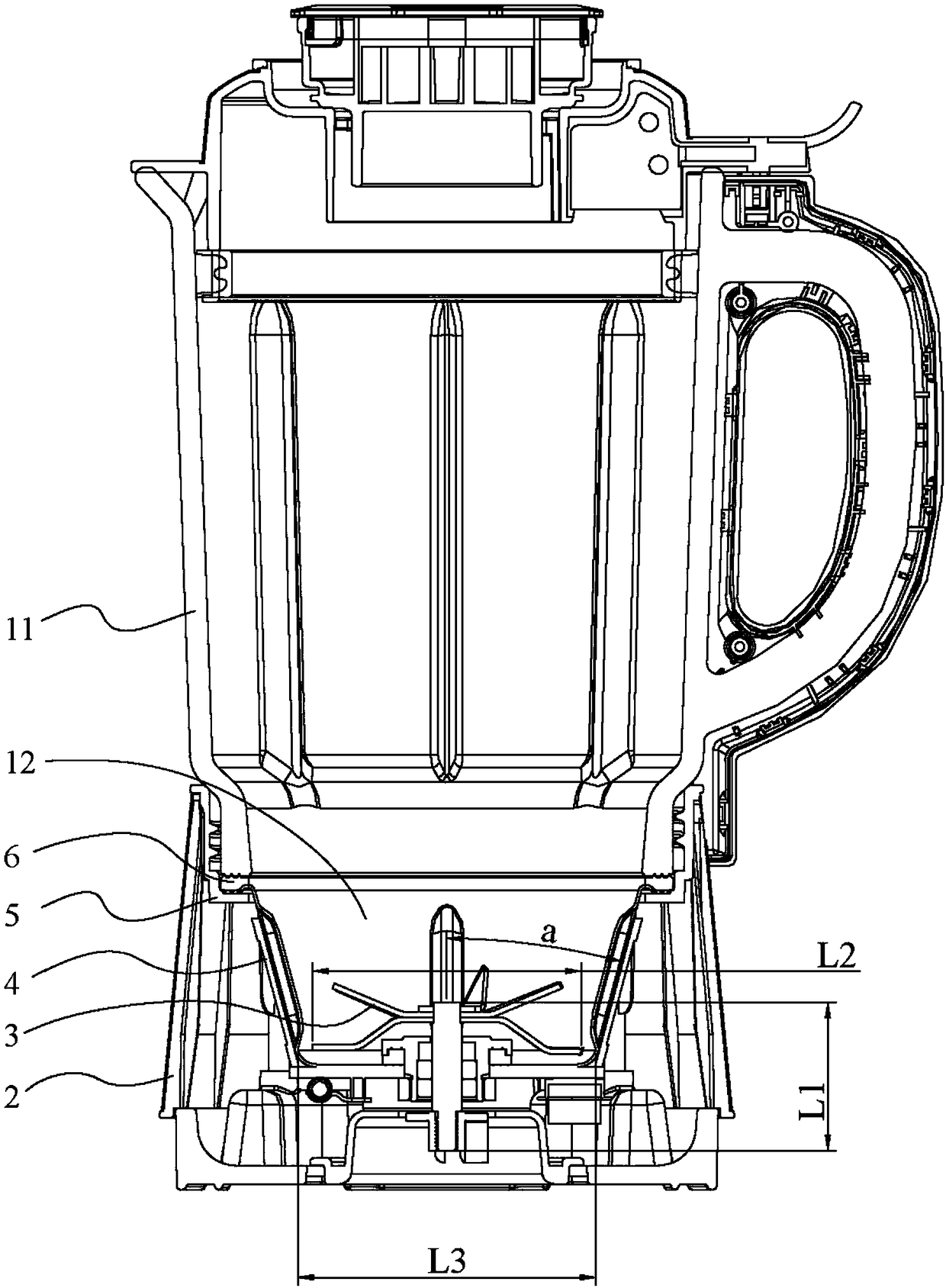

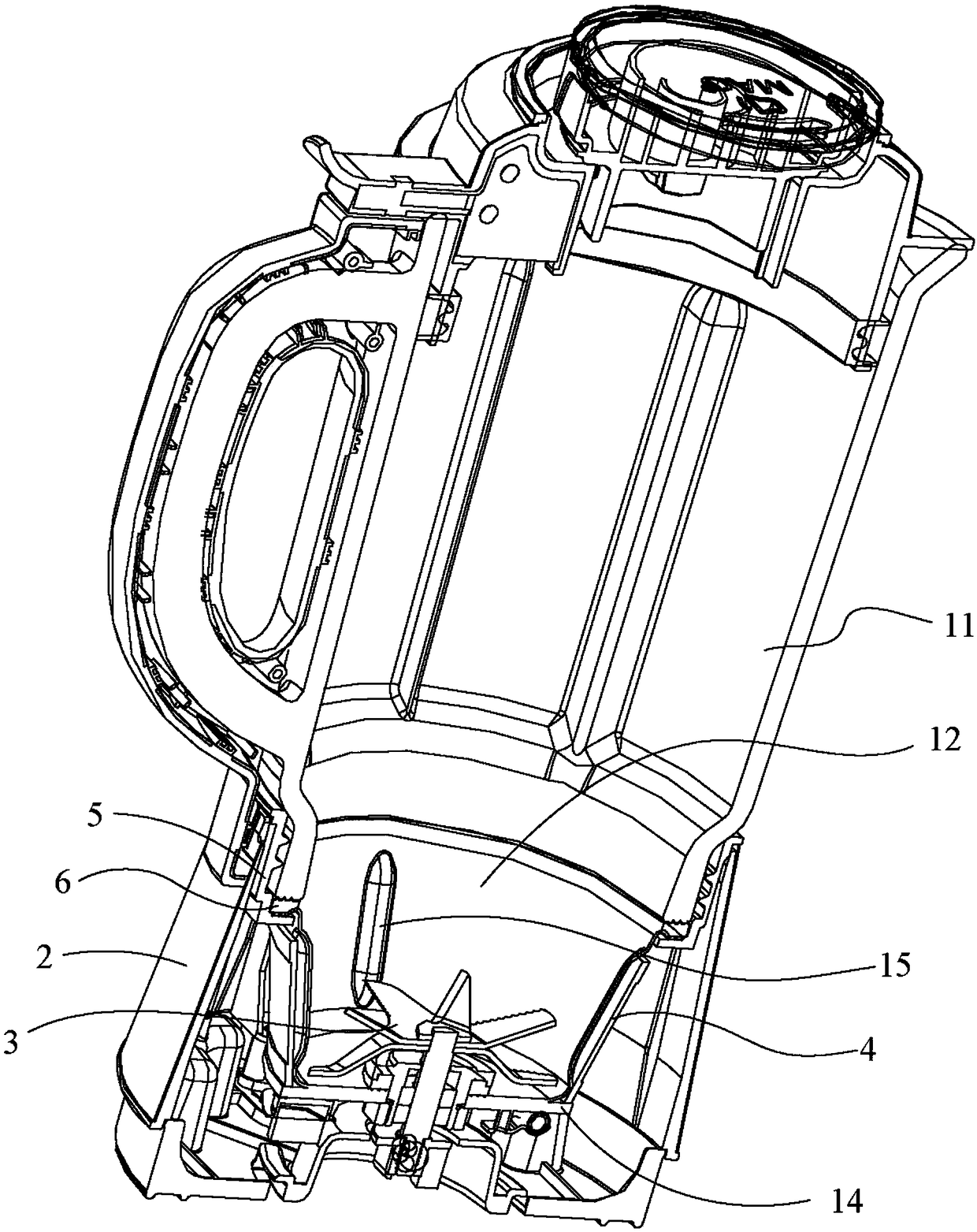

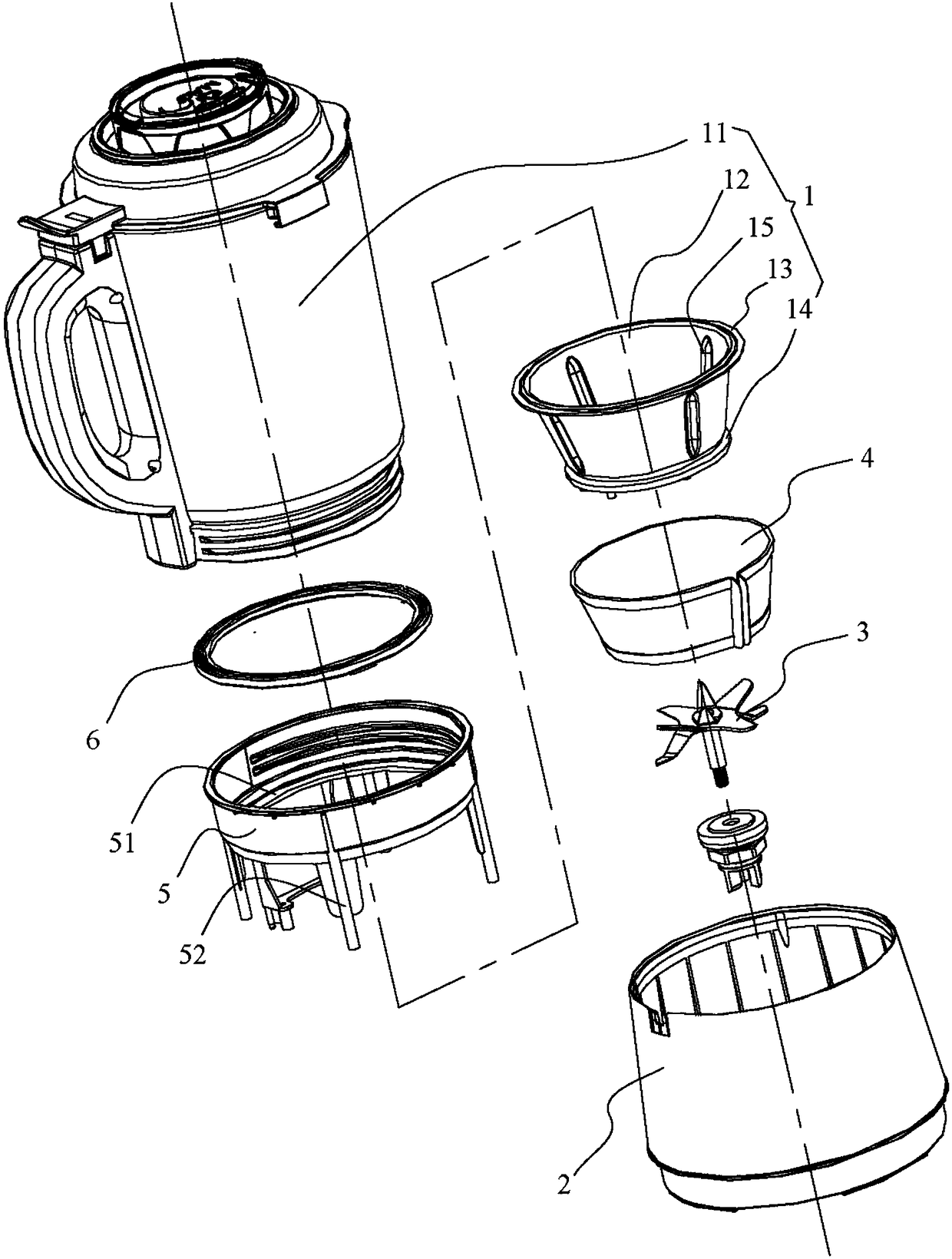

[0036] Such as Figure 1-Figure 5 As shown, this embodiment includes a cup body 1 and a cup holder 2 , a blade 3 is arranged inside the cup body 1 , and the knife shaft of the blade 3 passes through the cup body 1 and the cup holder 2 .

[0037] The cup body 1 includes a glass body 11 and a metal bottom cover 12 made of stainless steel. The glass body 11 is a cylindrical structure, and the metal bottom cover 12 closes the bottom of the glass body 11. Convex 15. A heating band 4 is pasted on the outer side wall of the metal bottom cover 12, and the heating band 4 is pasted on the outer side wall of the metal bottom cover 12 by glue or thermal paste. Insulation cotton (no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com