Compression splicing equipment and method

A technology for crimping equipment and equipment, applied in nonlinear optics, instruments, optics, etc., can solve problems such as low repair efficiency, and achieve the effect of high-voltage connection efficiency and less structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

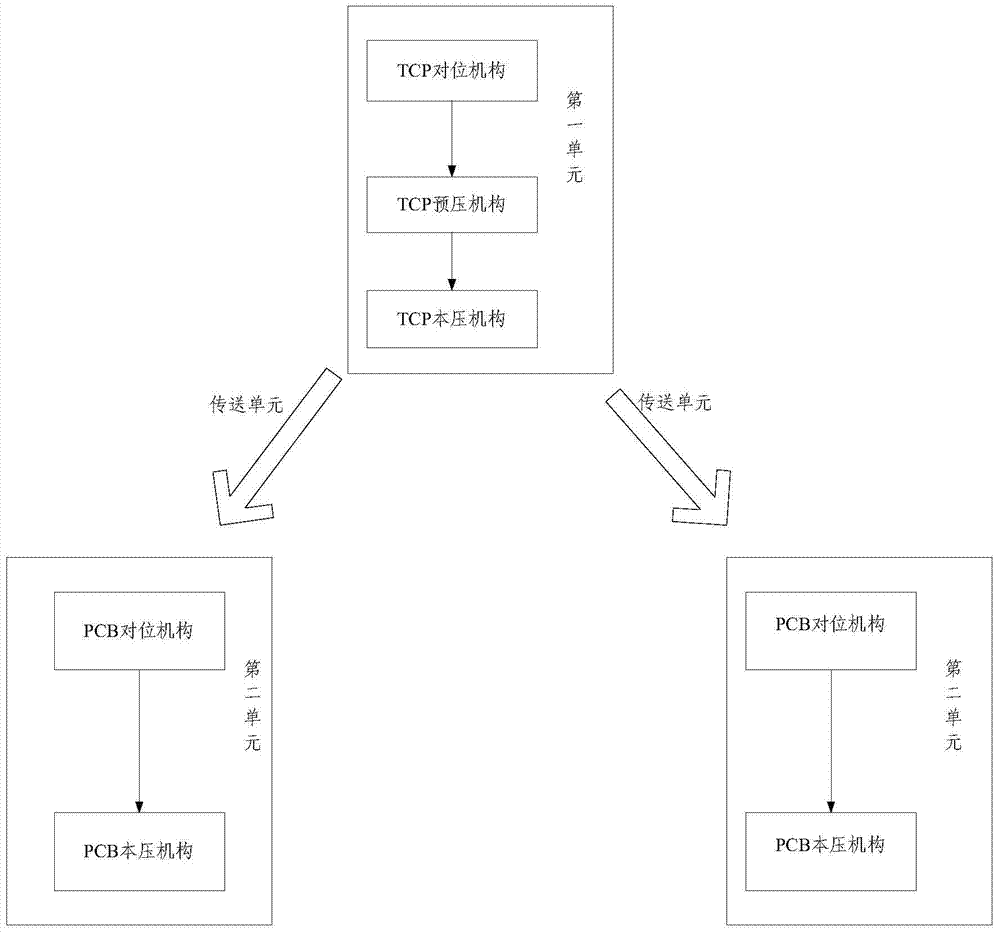

[0035] Embodiment 1 of the present invention provides a crimping device, which can be used to crimp a flexible connection circuit board to a panel and a circuit board during maintenance, such as figure 1 Shown is a schematic structural diagram of the device, including: a first unit, two left and right second units, and a transmission unit (transmission unit not shown) for connecting the second unit and the first unit, wherein the first unit It includes a panel side preloading mechanism (corresponding to the TCP preloading in the figure), and the panel side preloading mechanism includes a pressure head (not shown in the figure), and each second unit includes a local pressure mechanism, each of which The pressing mechanism includes a plurality of pressing heads (not shown in the figure), and the position of each of the pressing heads included in each pressing mechanism can be adjusted independently.

[0036] In the embodiment of the present invention, on the one hand, the crimpi...

Embodiment 2

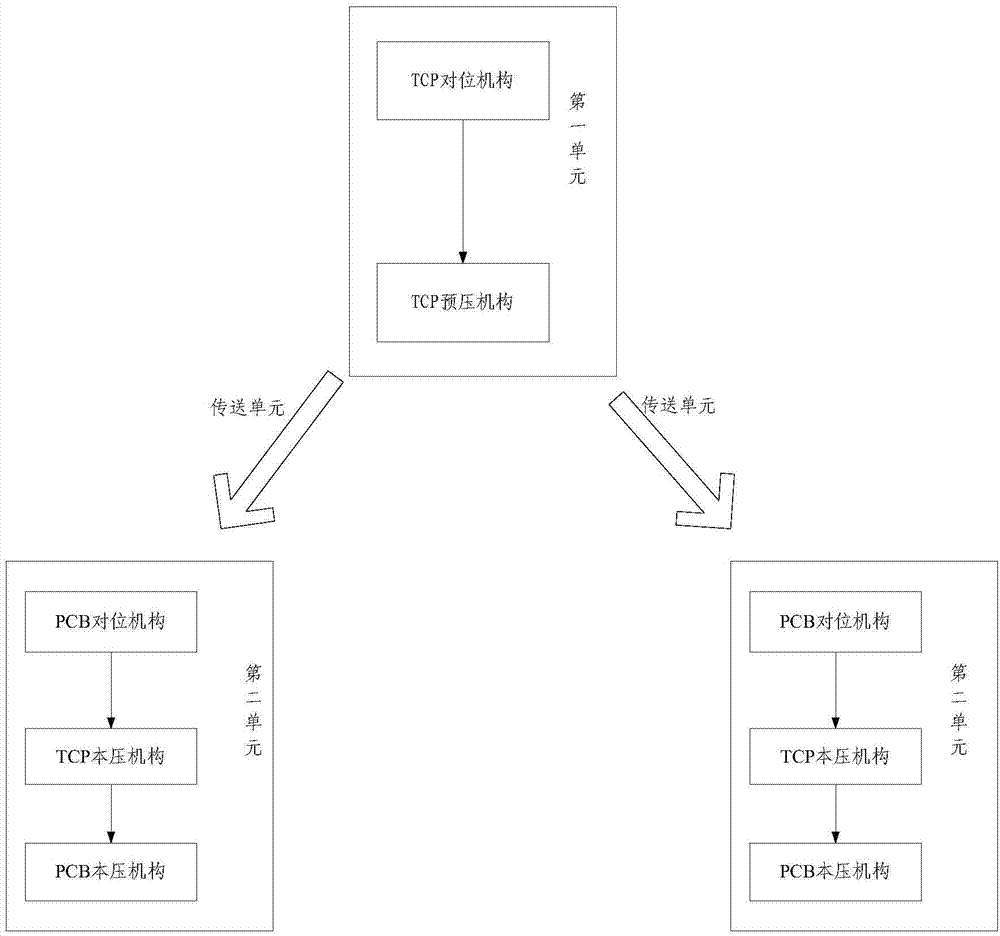

[0055] Such as figure 2 As shown, it is a schematic structural diagram of a crimping equipment provided in Embodiment 2 of the present invention, and figure 1 The difference is that in the crimping equipment provided in the embodiment of the present invention, the first unit includes a panel-side alignment mechanism (corresponding to the TCP alignment in the figure), a panel-side pre-pressing mechanism (corresponding to TCP preloading in the figure); each second unit includes a panel-side pressure mechanism (corresponding to the TCP pressure in the figure), a printed circuit side alignment mechanism (corresponding to the PCB alignment in the figure) and a The printed circuit side pressure mechanism (corresponding to the PCB pressure mechanism in the figure); the specific structure of the panel side pressure mechanism and the panel side preload mechanism here can be consistent with the corresponding structure of the first embodiment.

[0056] In a specific application, if the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com