Patents

Literature

87results about How to "Good crimping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

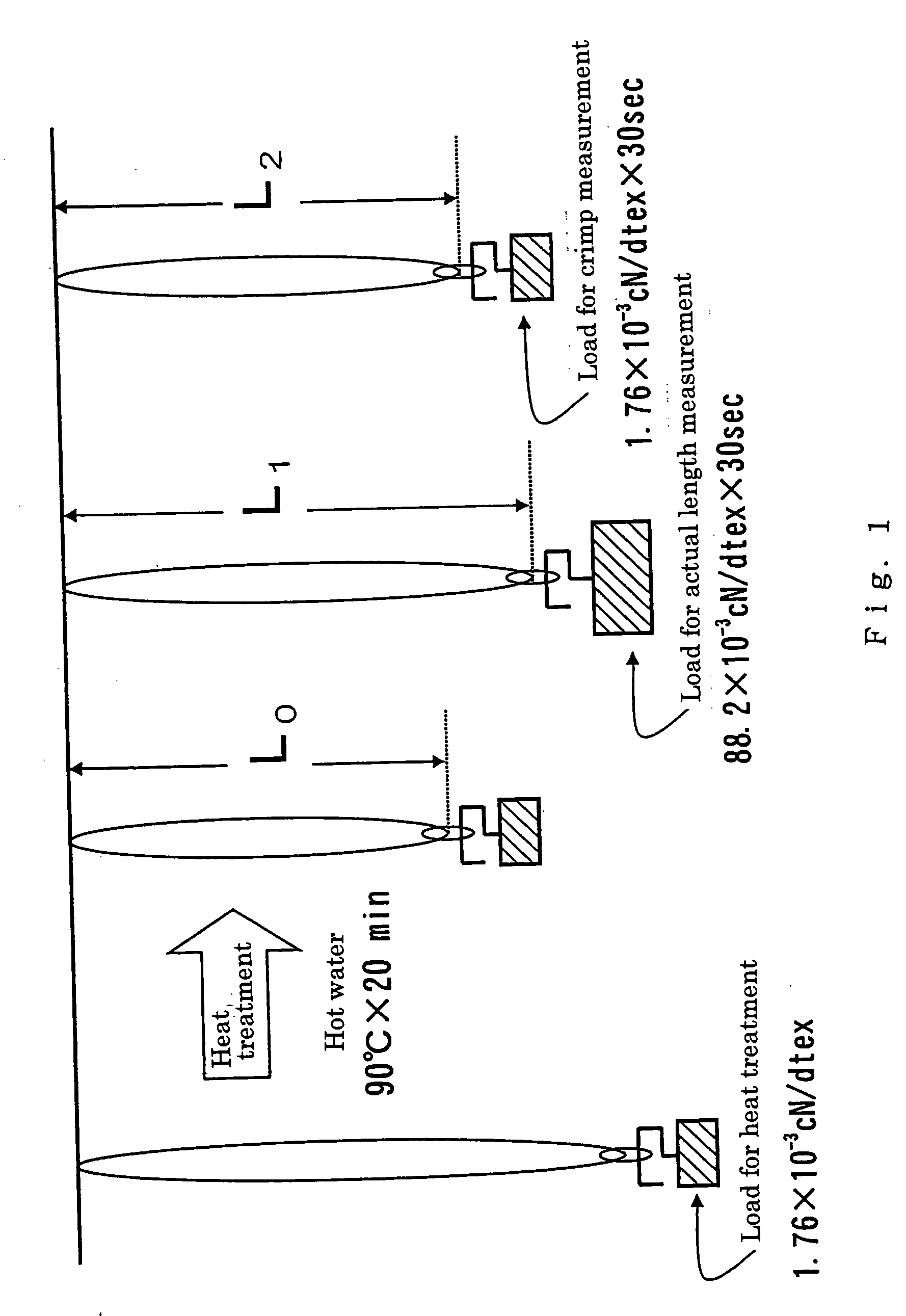

Highly Crimped Conjugated Fiber Cheese Package and Process for Its Production

InactiveUS20080317984A1Easy alignmentImprove shrinkageNew-spun product collectionHollow filament manufacturePolymer sciencePolytrimethylene terephthalate

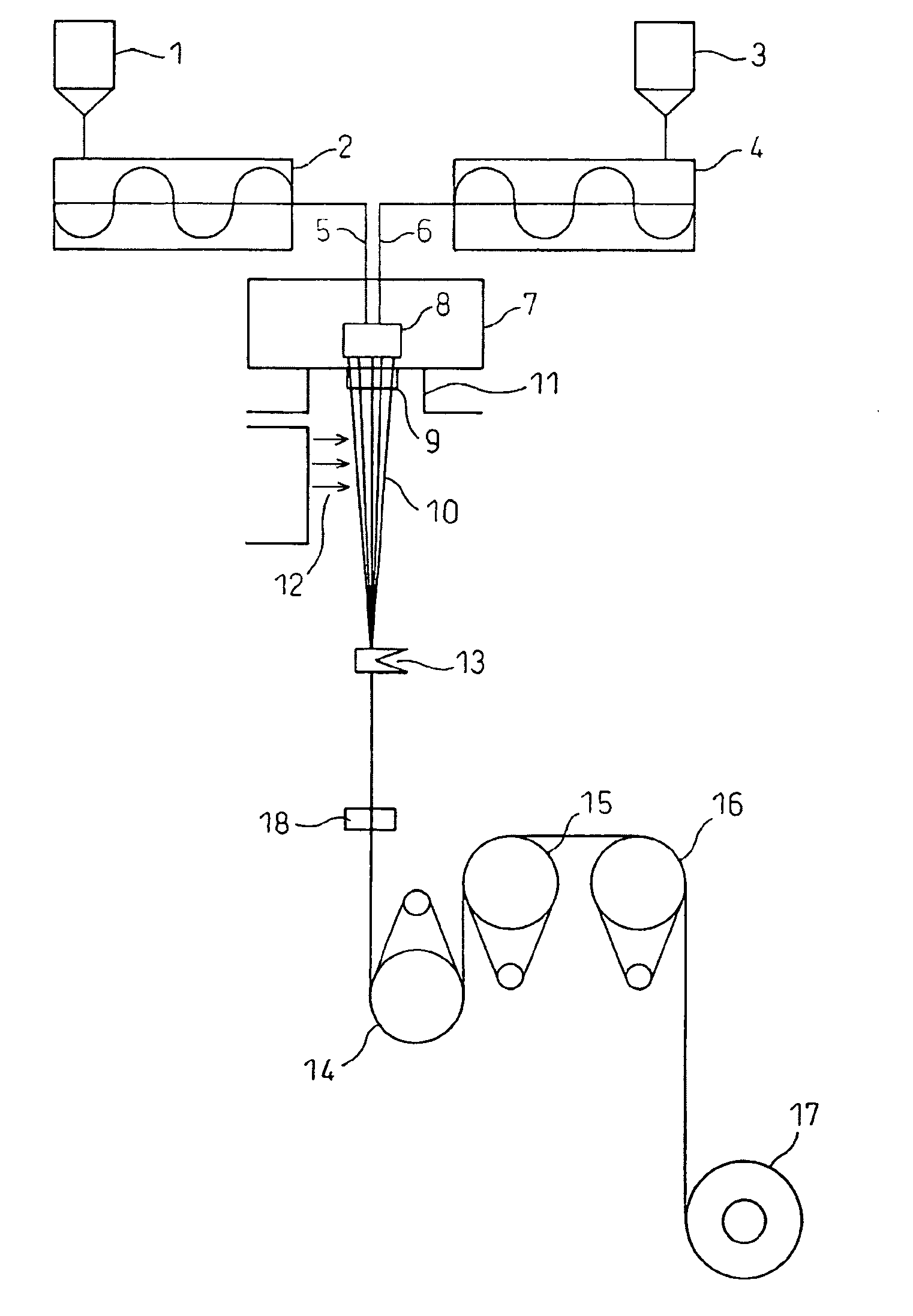

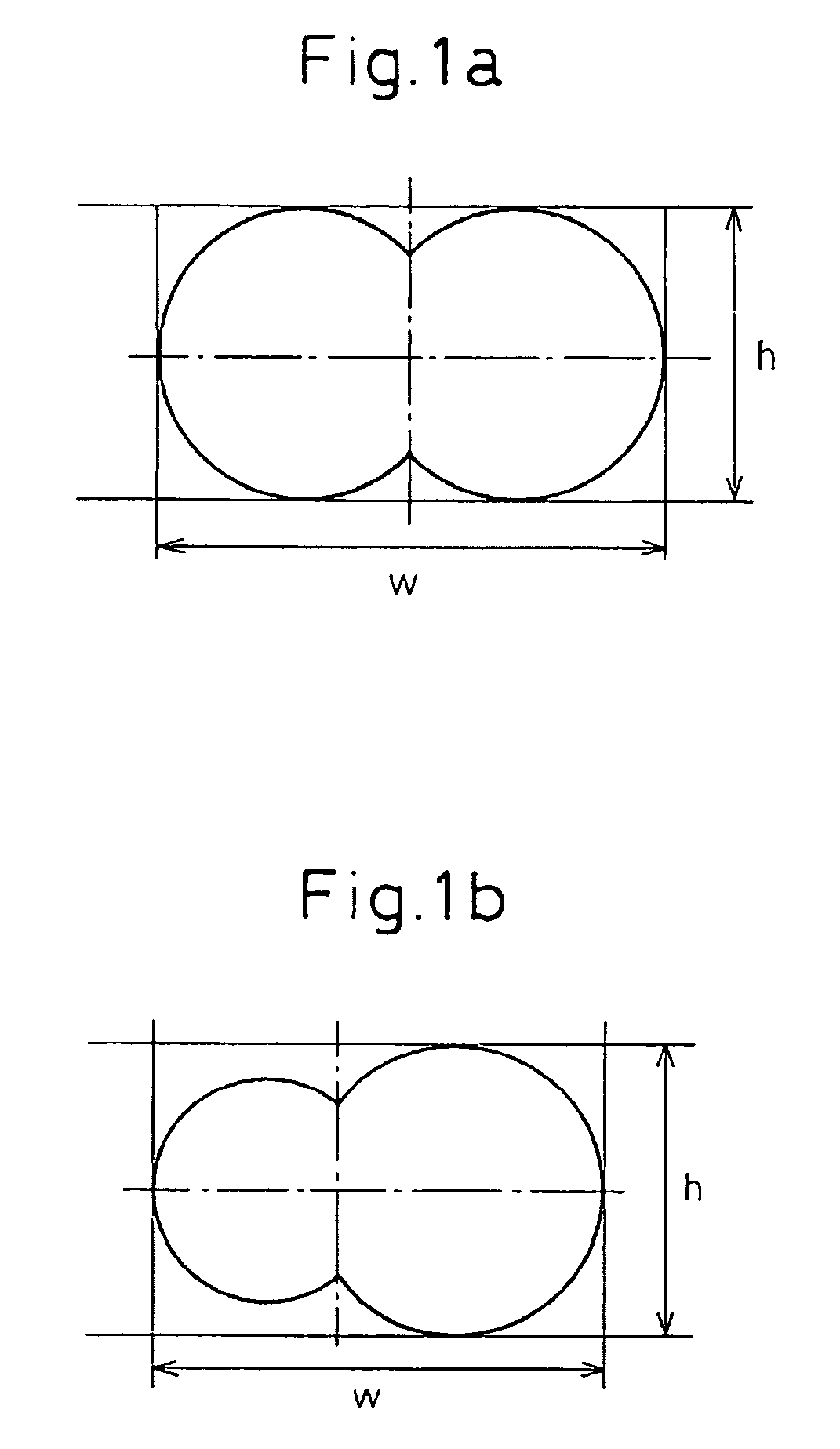

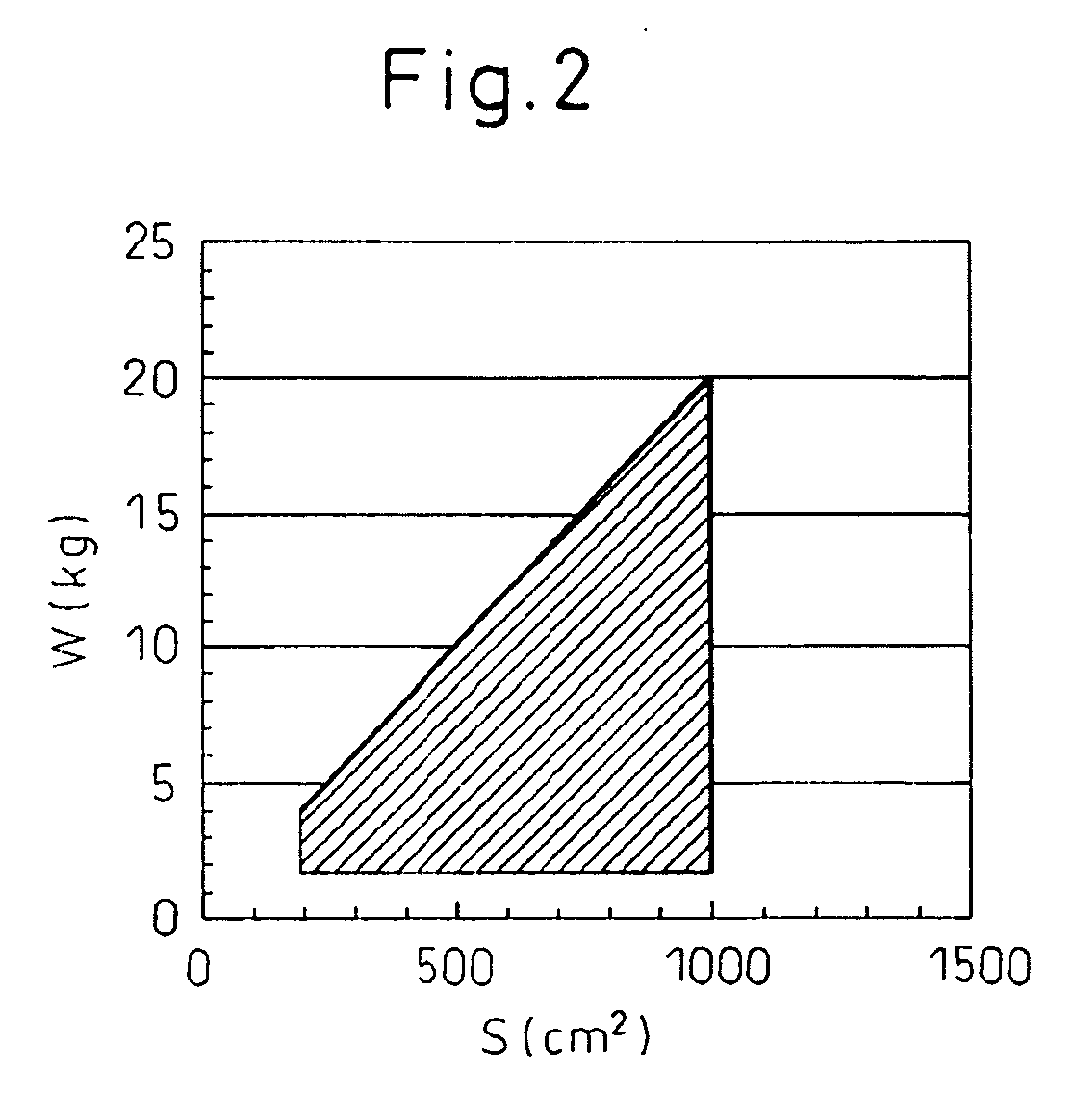

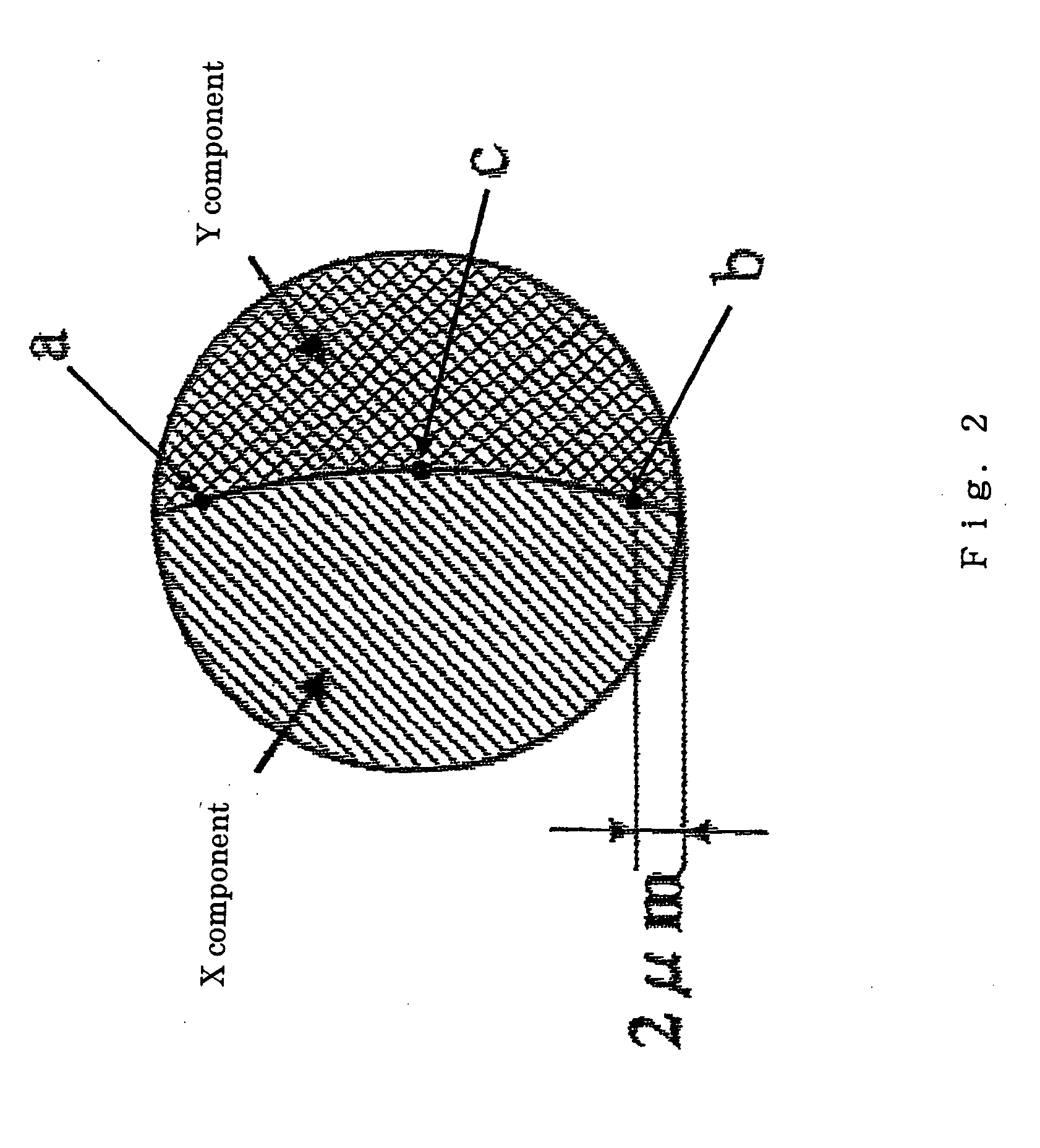

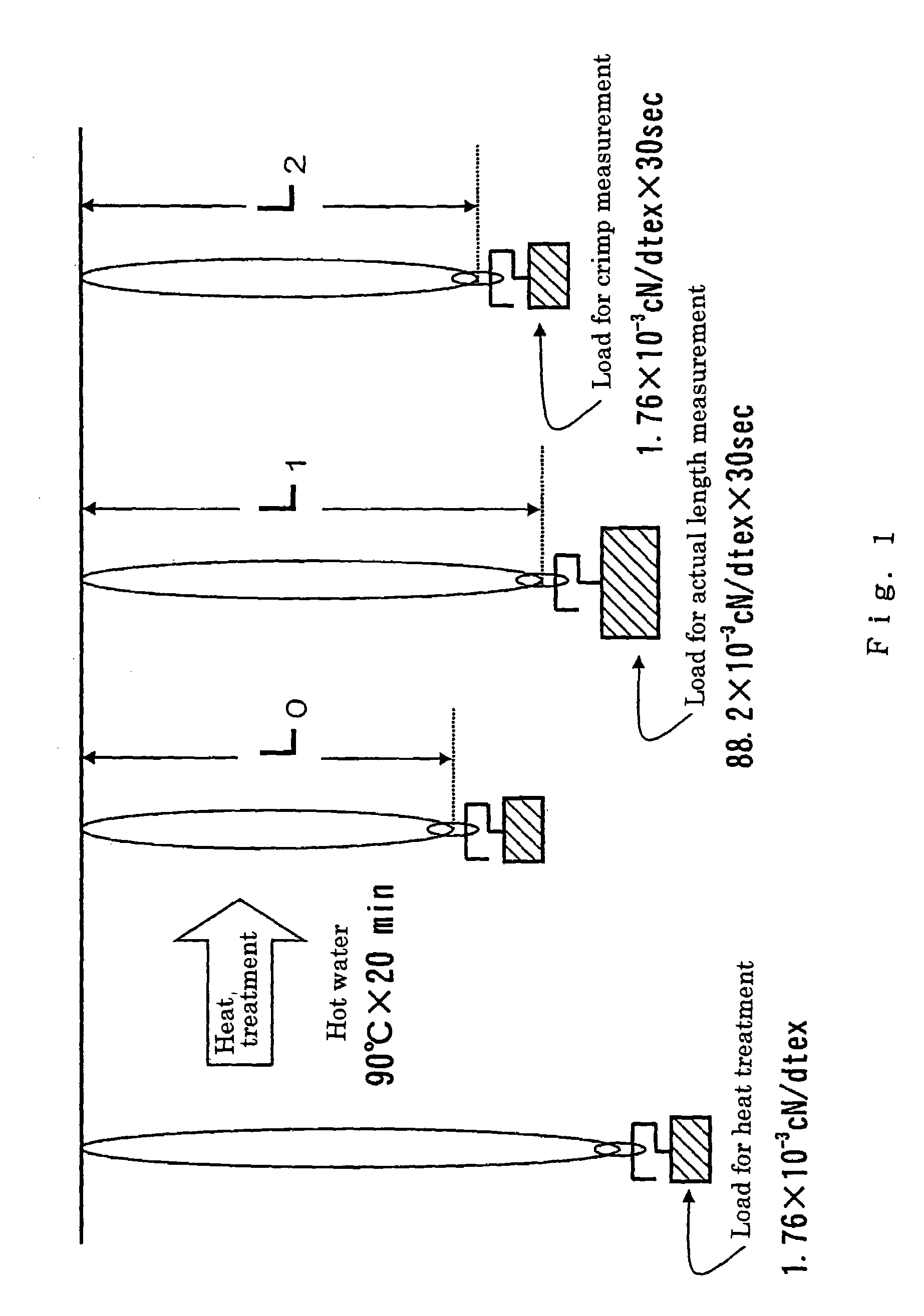

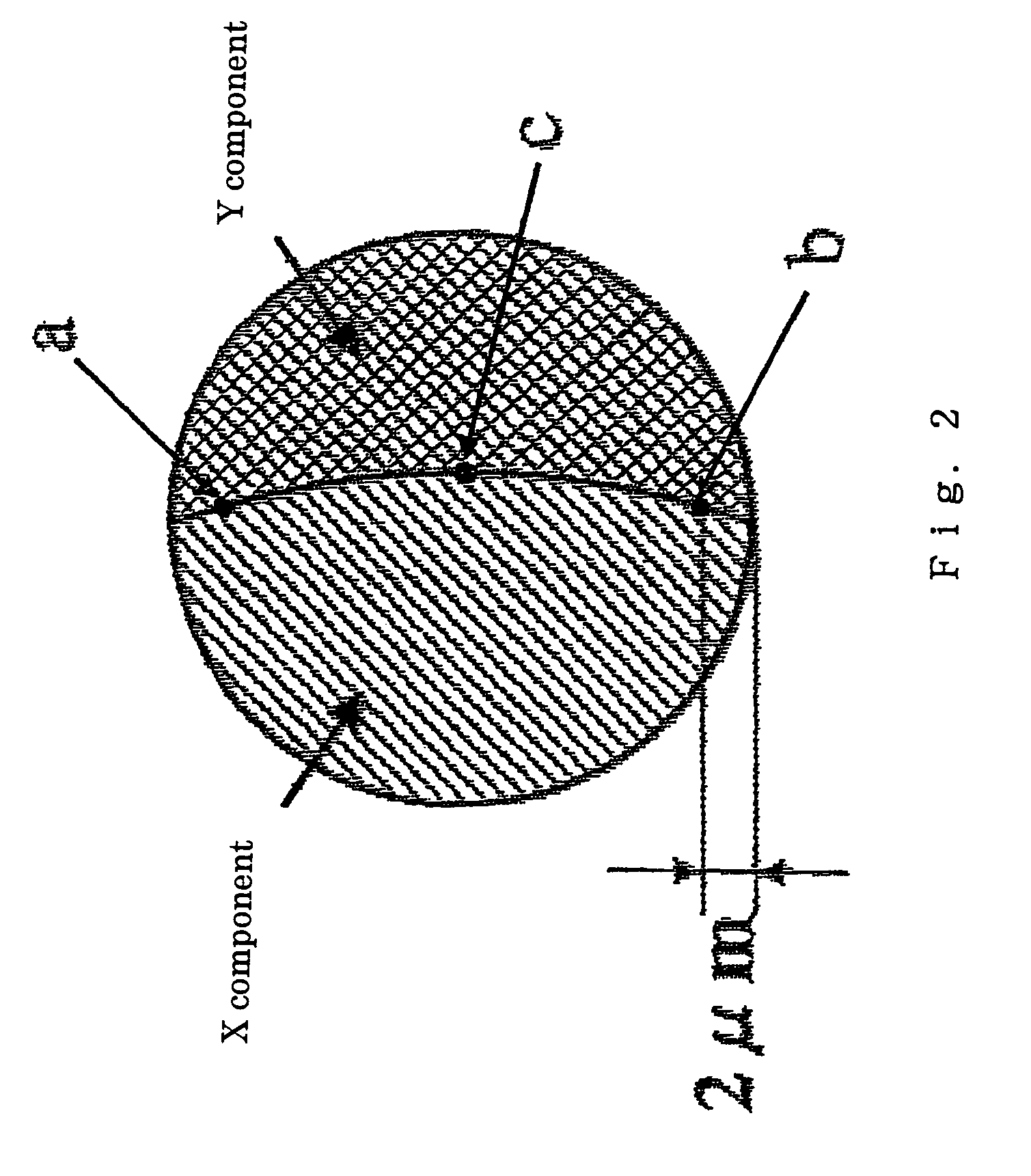

A highly crimped conjugate fiber cheese package which is obtained by layering on a paper bobbin a conjugate fiber consisting of a plurality of single filament composed of polytrimethylene terephthalate components having different intrinsic viscosities and consisting of at least 90 mol % of a trimethylene terephthalate unit and no more than 10 mol % of another ester repeating unit and laminated to each other in a side-by-side type, the cheese package being characterized by satisfying the following conditions (1)-(4).(1) The single filament composing the conjugate fiber has cross-sectional shape which is flat cross-section with a flatness of 1.1-3 as the ratio between the long axis and short axis.(2) The developed crimp elongation of the conjugate fiber is 30-200%.(3) The relationship between the contact area (compressed net area) S (cm2) between the paper bobbin and conjugate fiber and the wound weight W (kg) satisfies the following formula (1):2≦W≦0.02S (Formula 1)where 240≦S≦1000(4) The package density of the conjugate fiber cheese package is 0.92-1.05 g / cm3.

Owner:SOLOTEX CORP

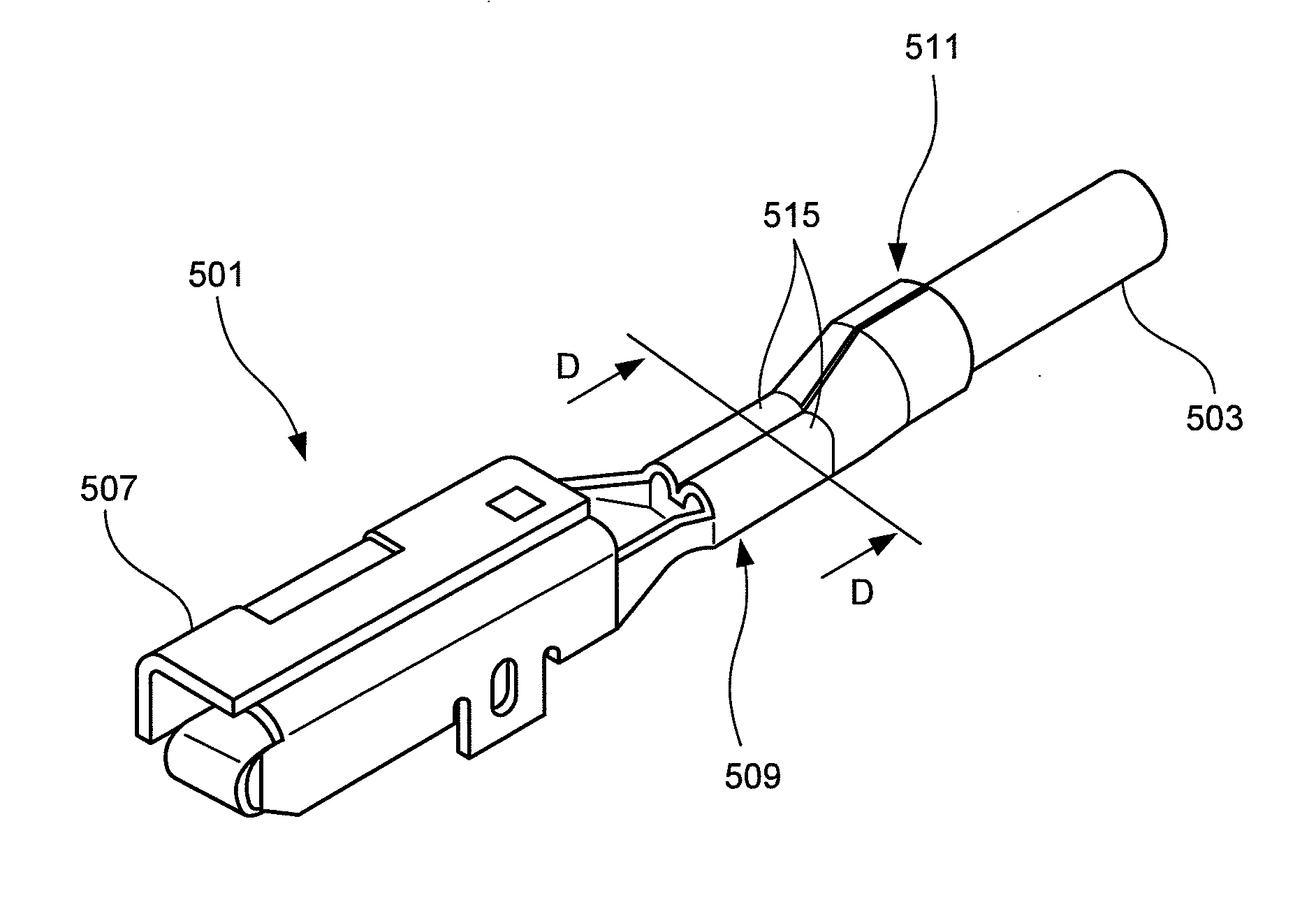

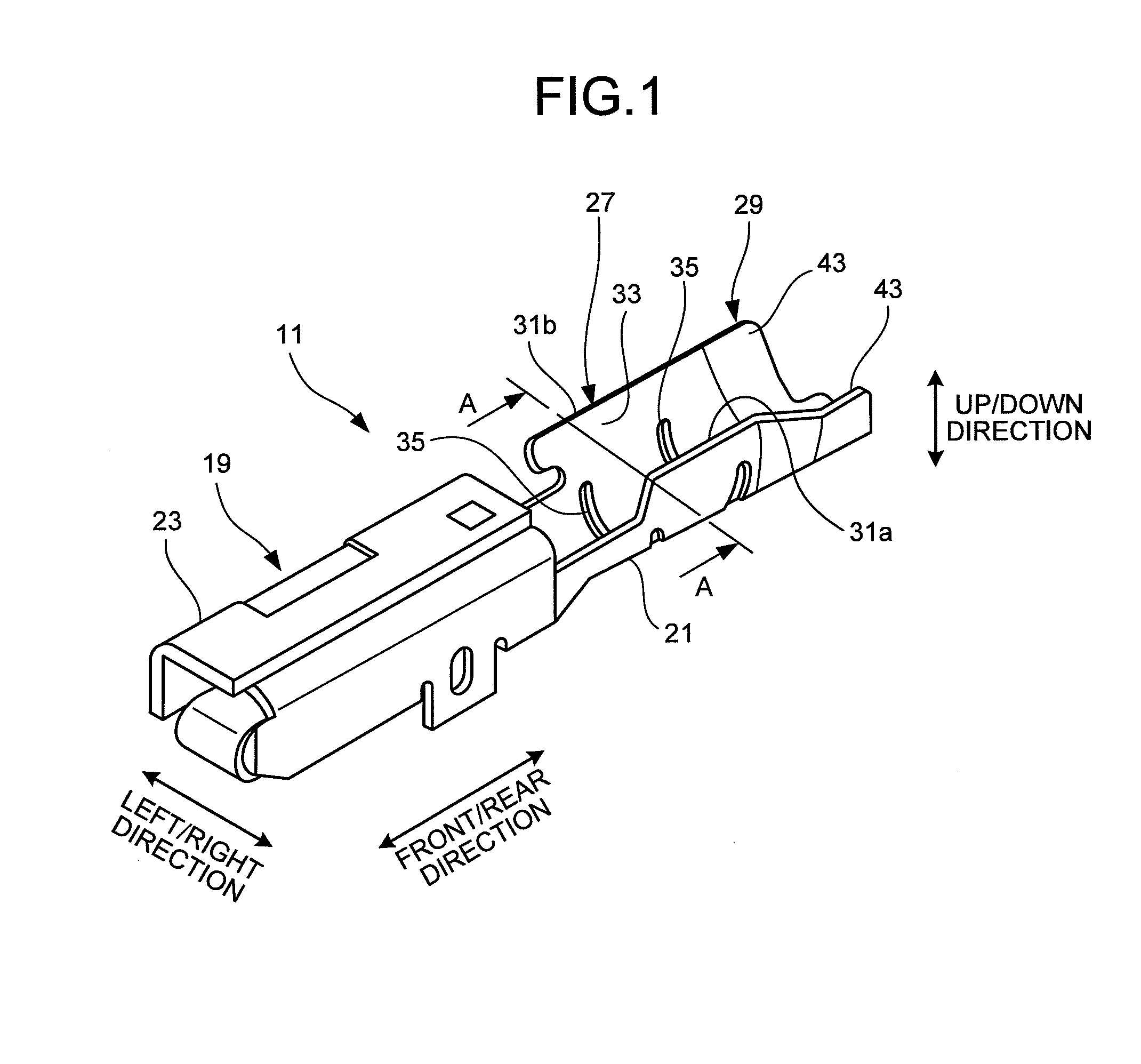

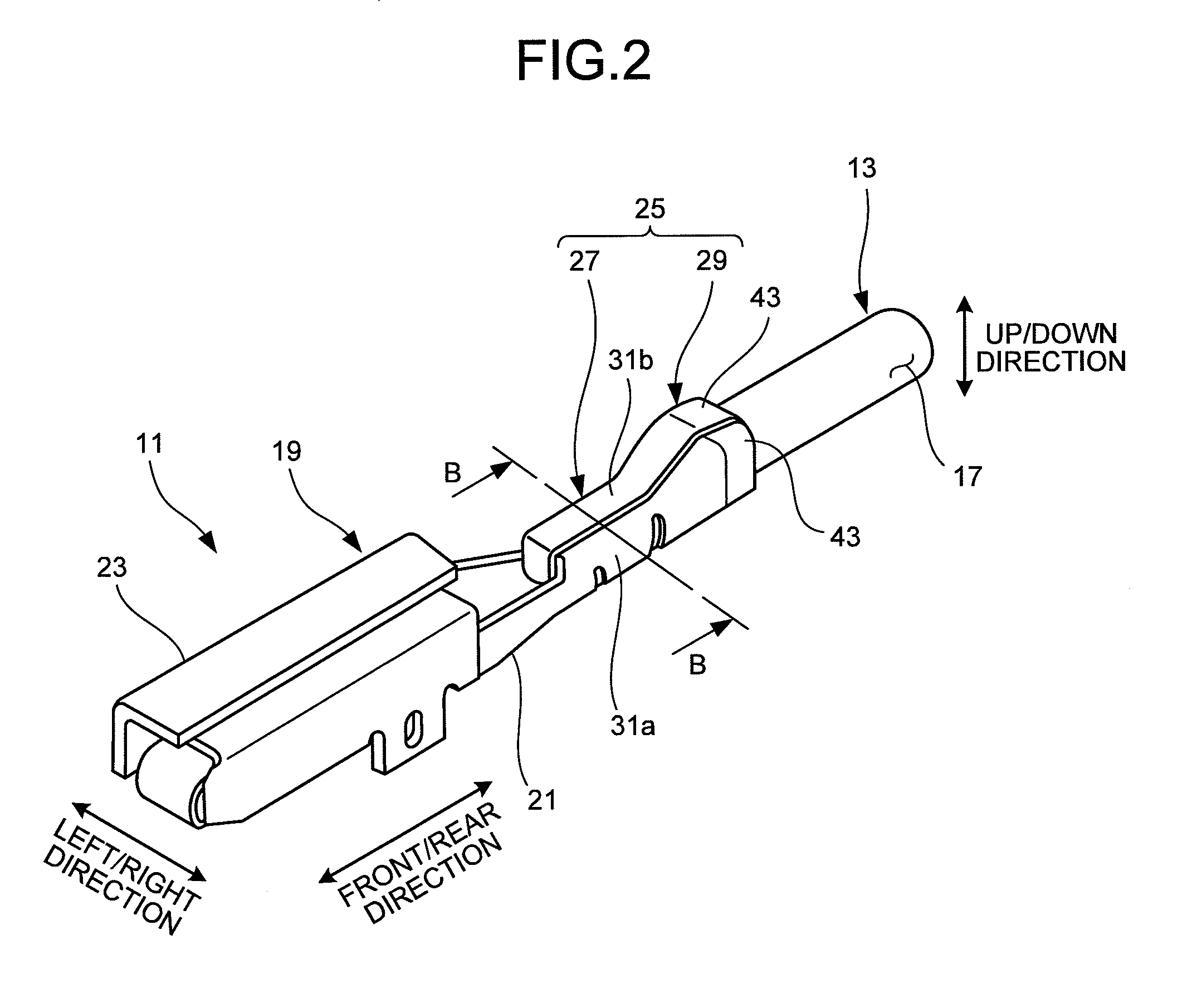

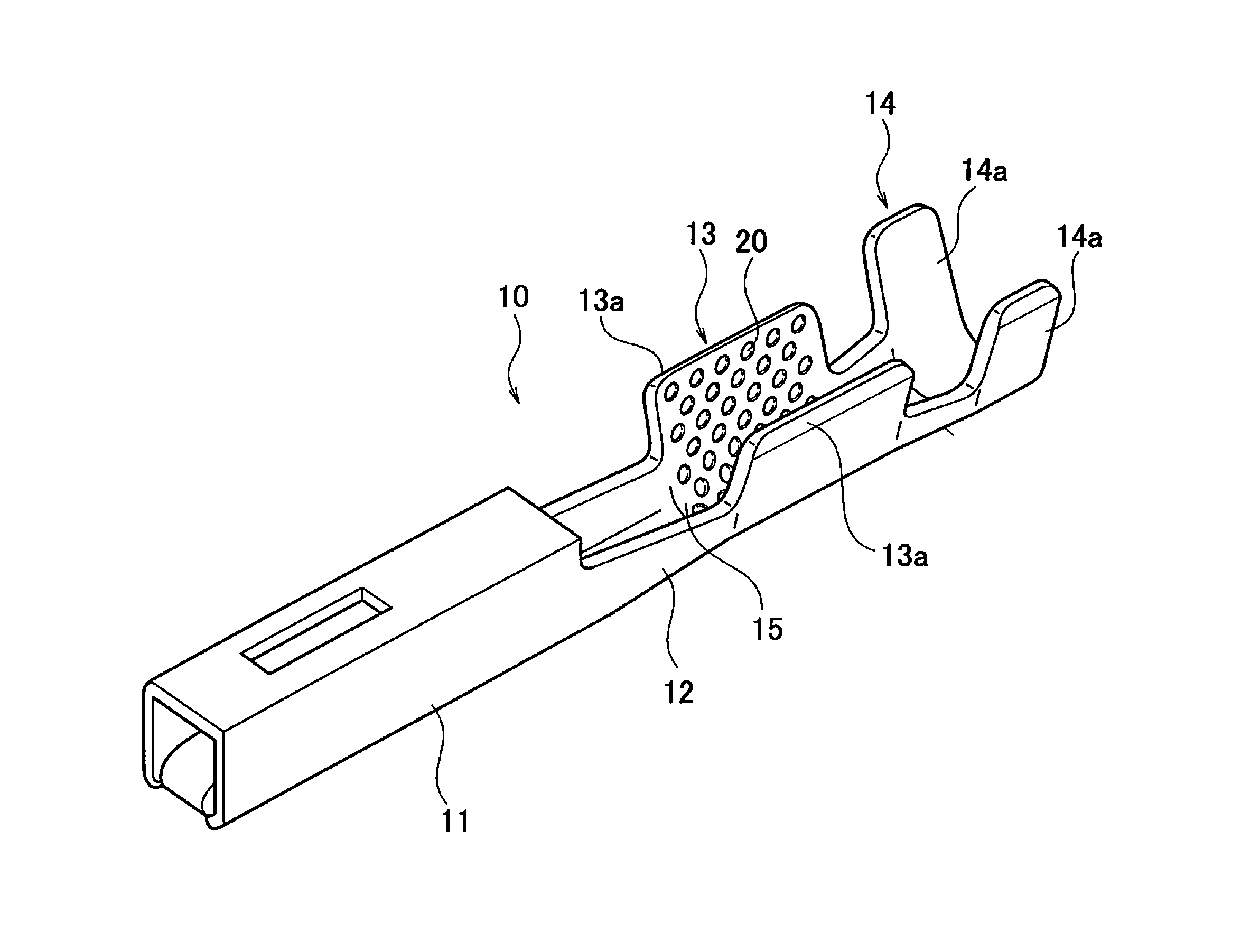

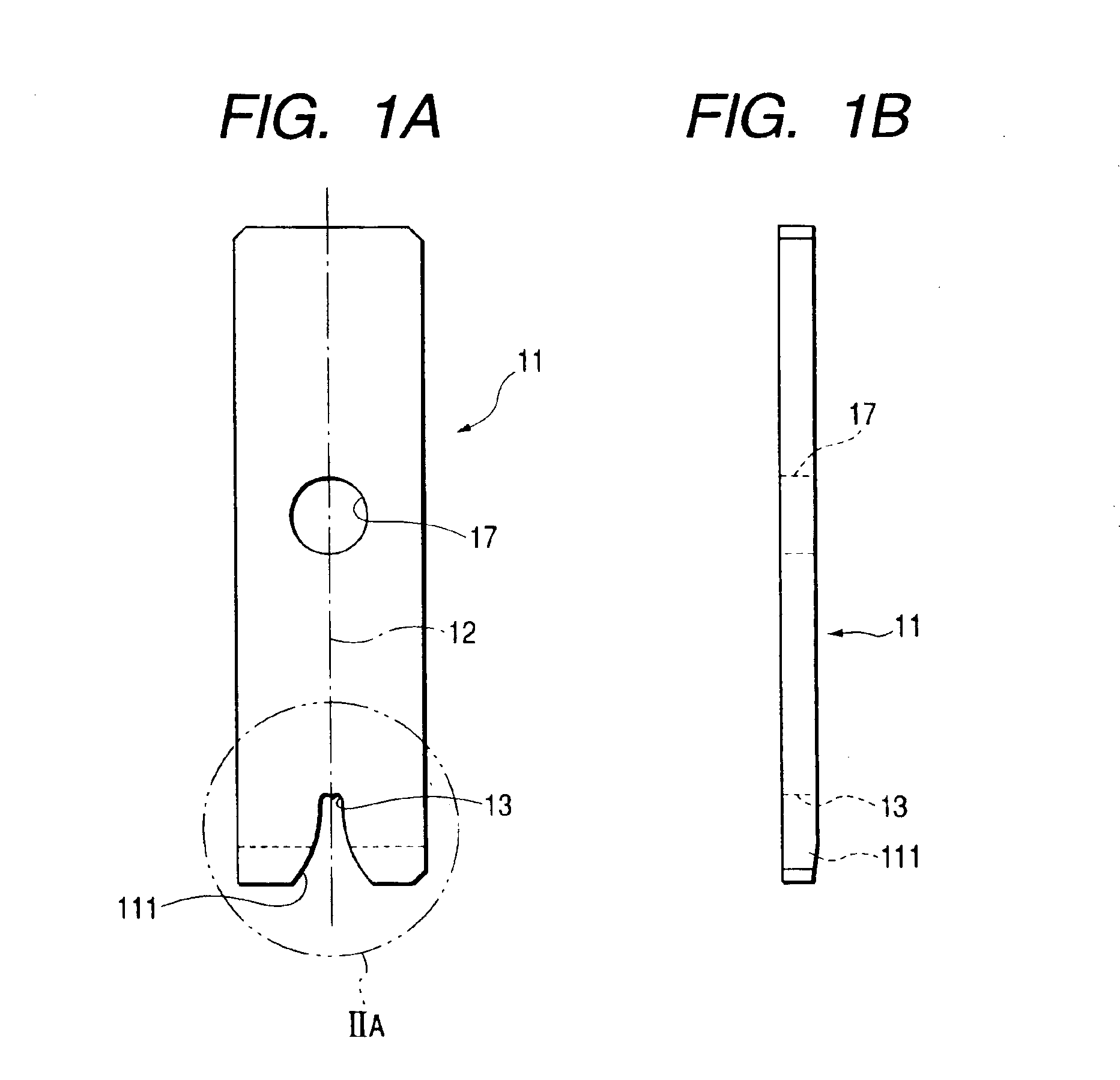

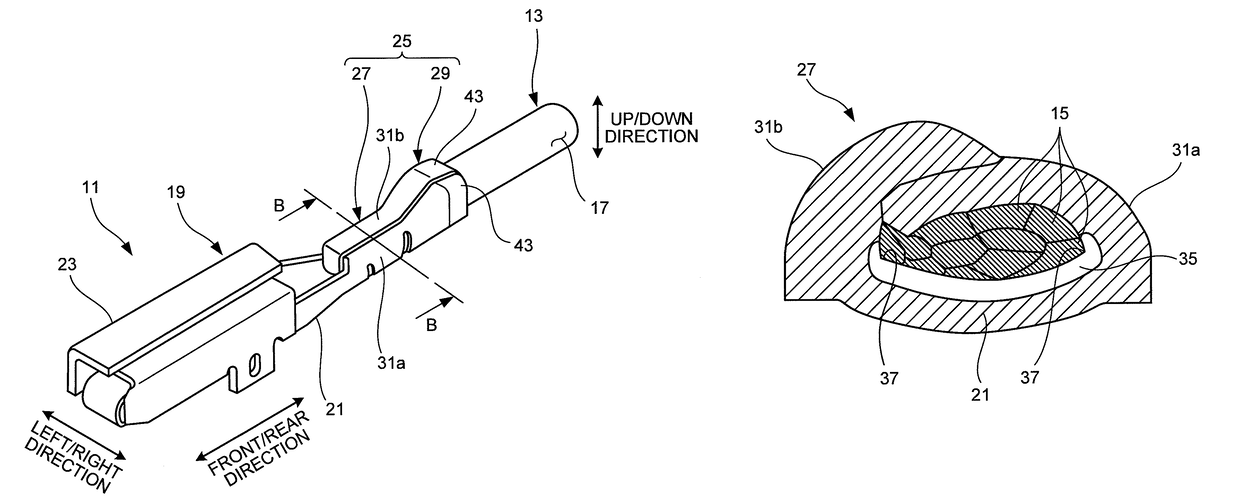

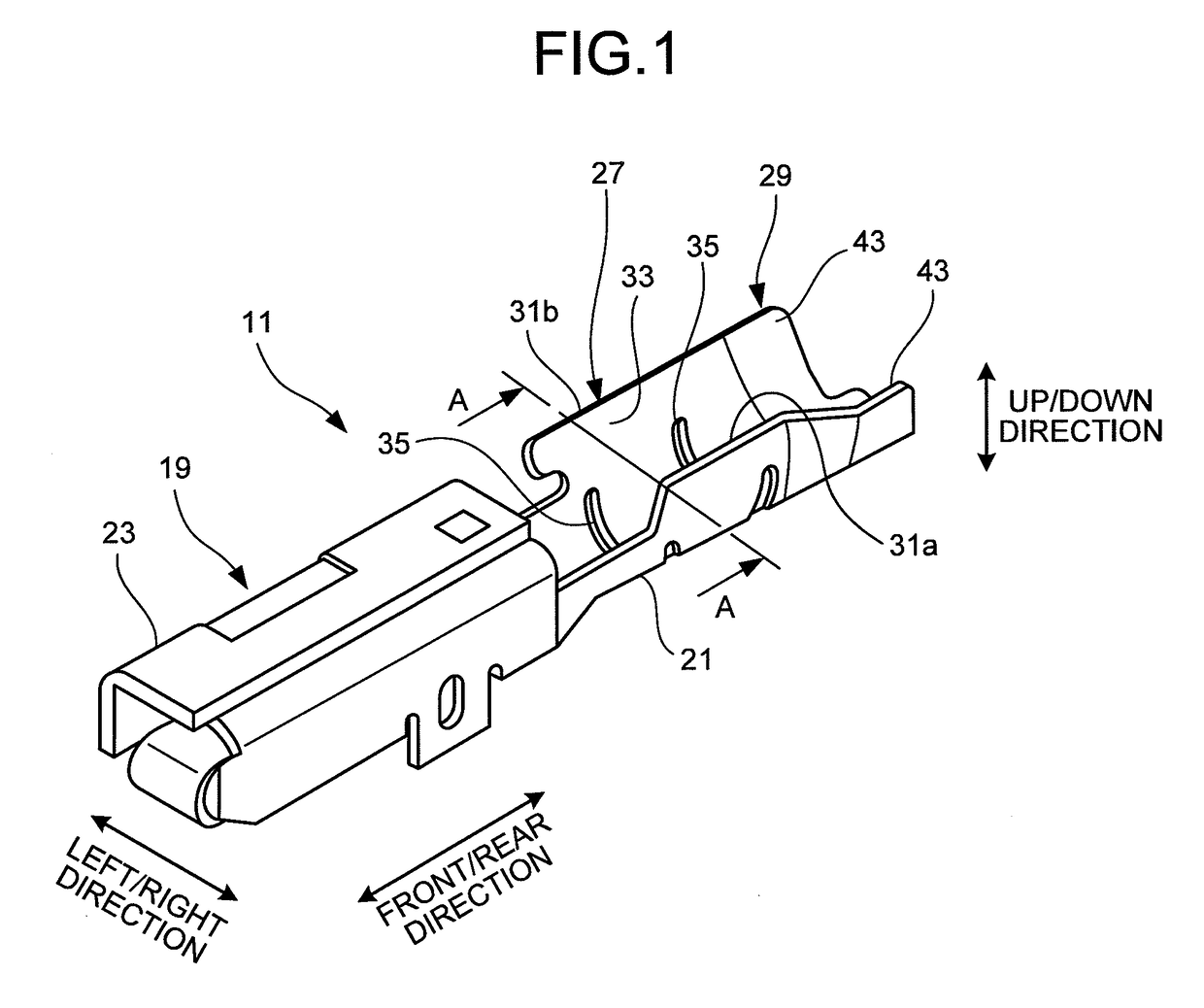

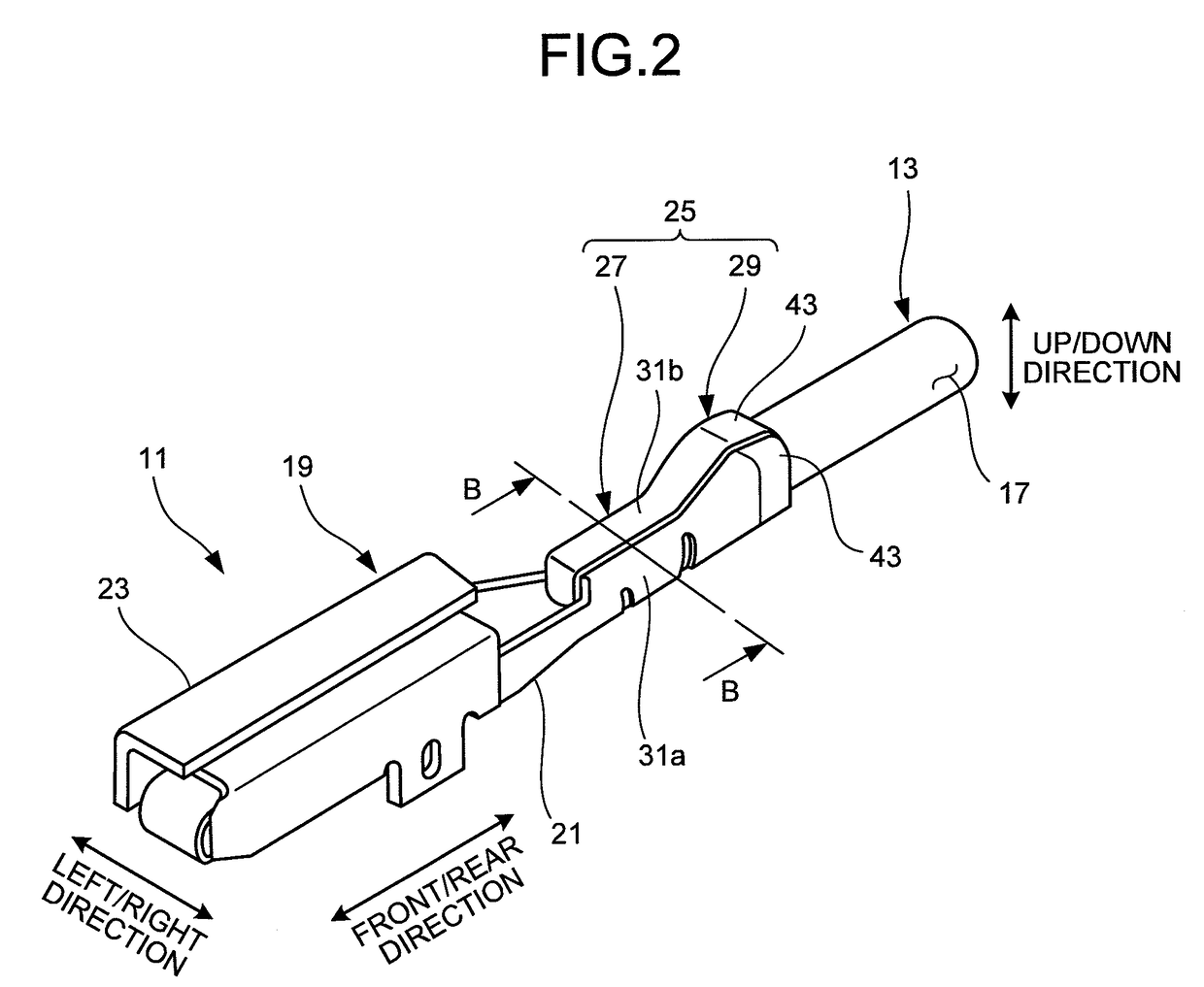

Crimping terminal

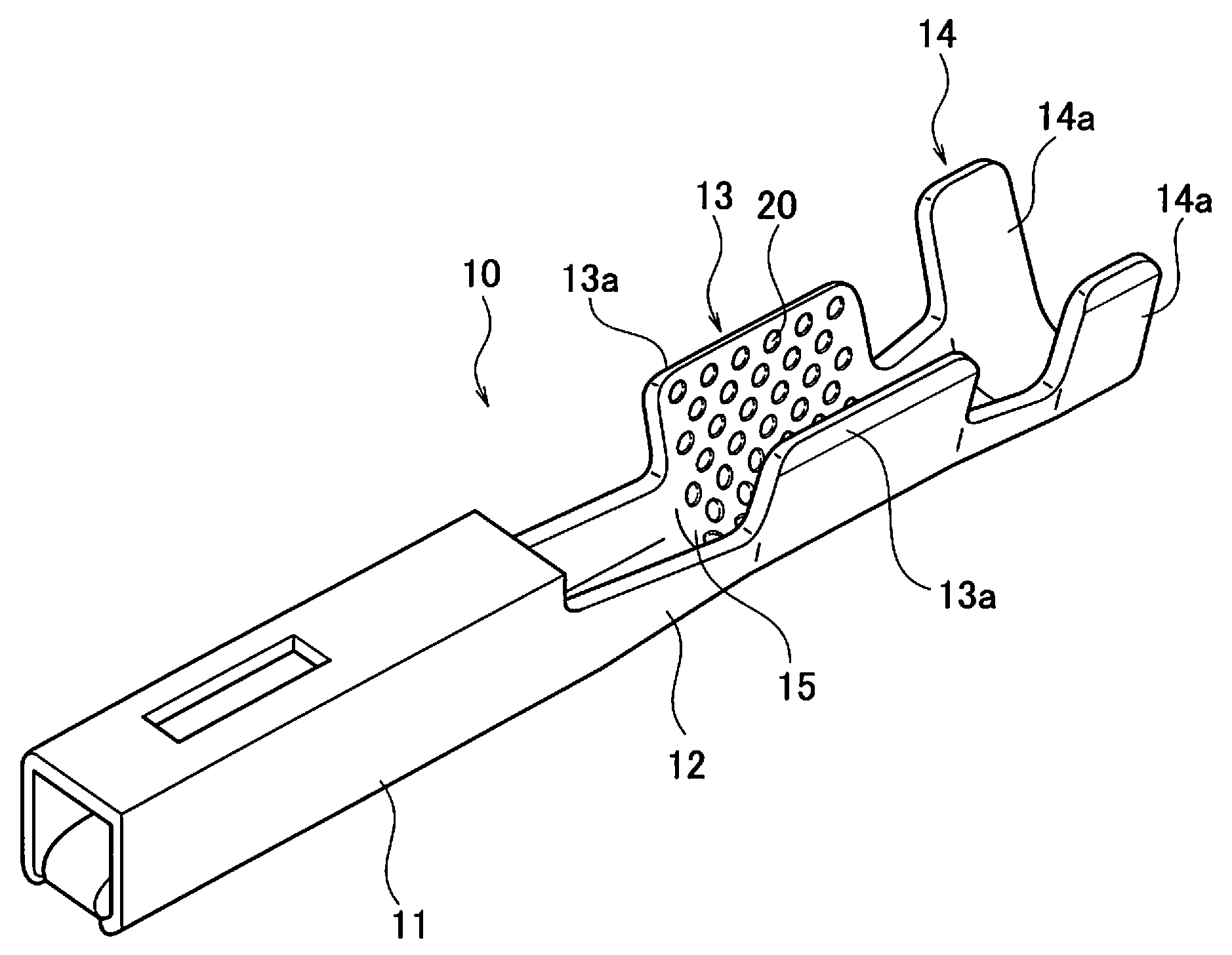

ActiveUS20160013567A1Good crimping effectImprove electrical reliabilityConnections effected by permanent deformationConnection contact member materialElectrical conductorMechanical engineering

A crimping terminal includes a conductor crimping portion having a U-shaped cross section. The conductor crimping portion includes a base plate portion and a pair of conductor caulking pieces. On an inner surface of the conductor crimping portion, a conductor is disposed, being exposed to a distal end of an aluminum electric wire. The pair of conductor caulking pieces, extending upwardly from both side edges in a longitudinal direction of the base plate portion, are bent inwardly so as to wrap the conductor of the aluminum electric wire to caulk the conductor such that the conductor is in close contact with the inner surface of the base plate portion. On the inner surface of the conductor crimping portion, a protruding indent is provided so as to extend continuously.

Owner:YAZAKI CORP

Leather-like sheet and process for producing thereof

InactiveUS20070166509A1Fit closelyAchieve stretchDomestic upholsteryWarp knittingPolytrimethylene terephthalateEngineering

A leather-like sheet excellent in stretchability which is obtained by integrating by entanglement of a woven or knitted fabric and an ultrafine fiber of 0.0001 to 0.5 dtex, wherein at least one face of the leather-like sheet is substantially composed of said ultrafine fibers, and said woven or knitted fabric consists of a conjugate fiber in which two or more kinds of polyester-based polymers, at least one of which consists essentially of polytrimethylene terephthalate, are stuck along the fiber length direction side-by-side, or a conjugate fiber in which two or more kinds of polyester-based polymers, at least one of which consists essentially of polytrimethylene terephthalate, forms an eccentric sheath-core type conjugate structure, and the fiber constituting the woven or knitted fabric has a twist coefficient of 20000 or below.

Owner:TORAY IND INC

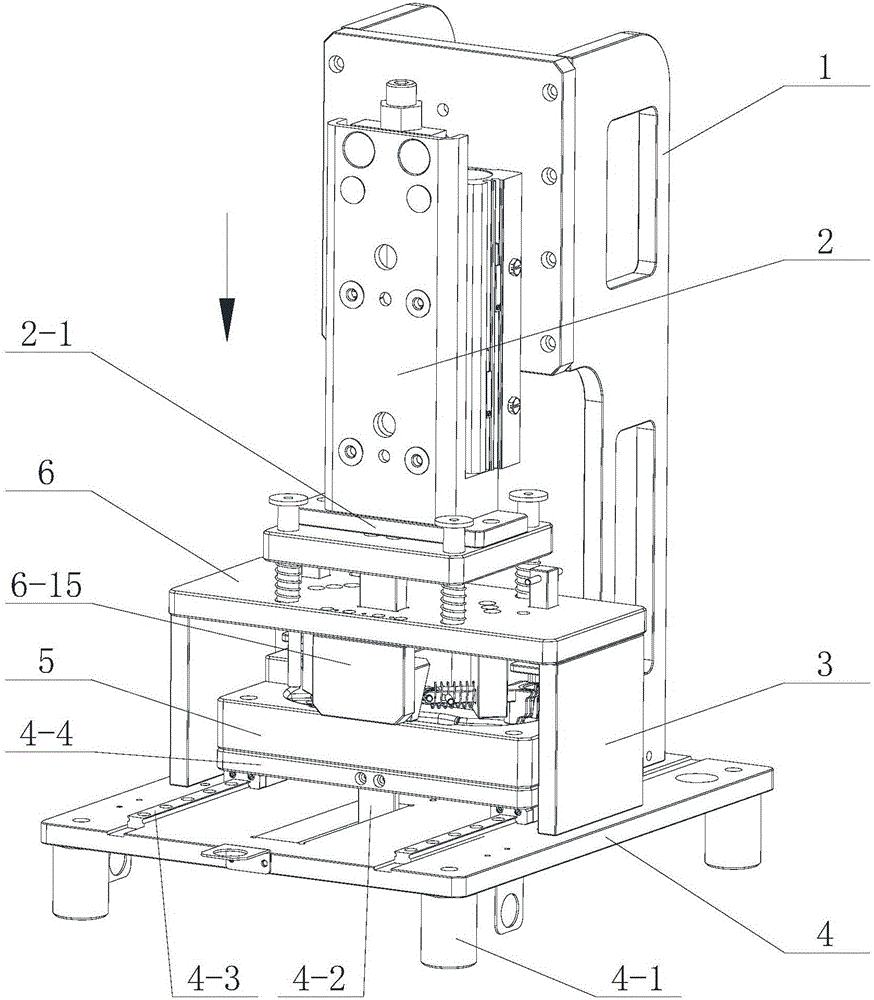

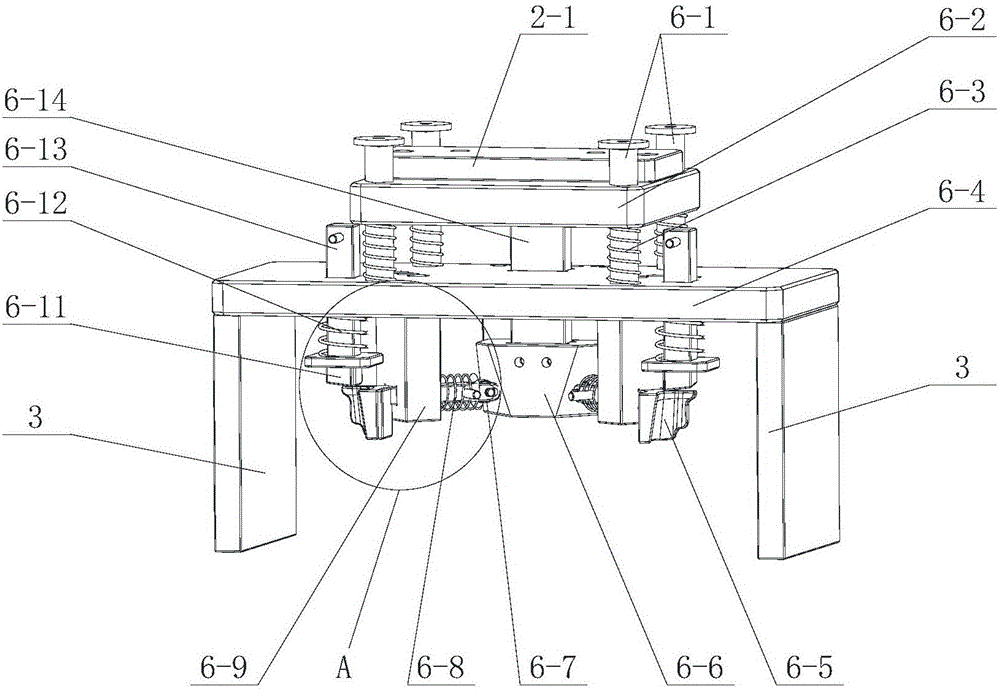

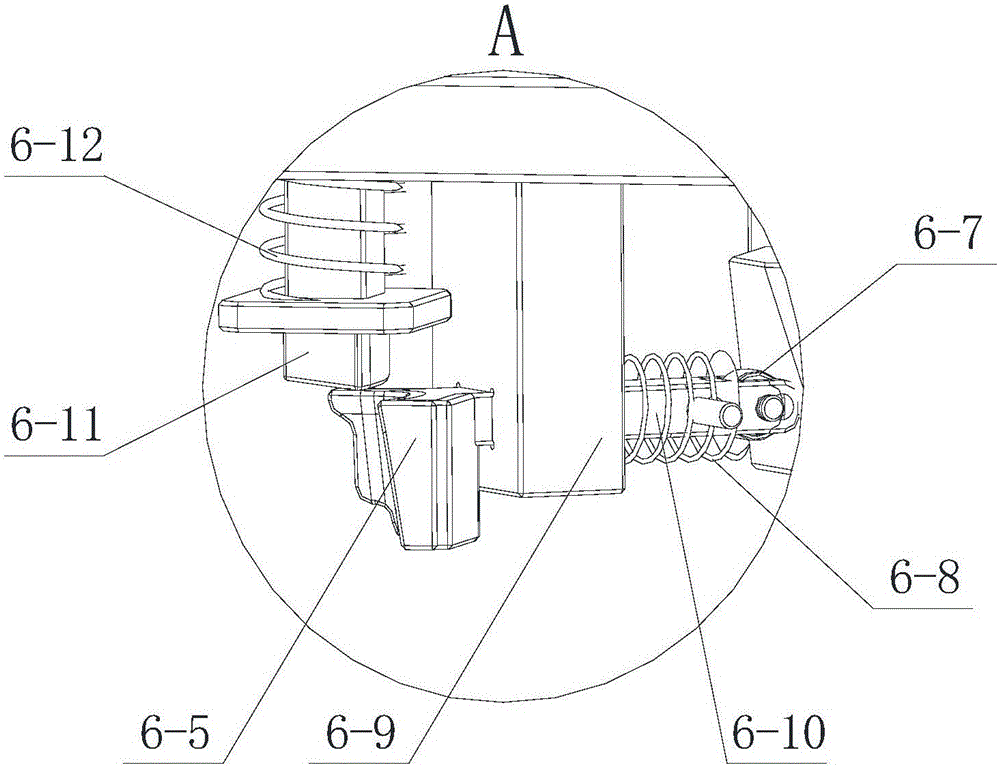

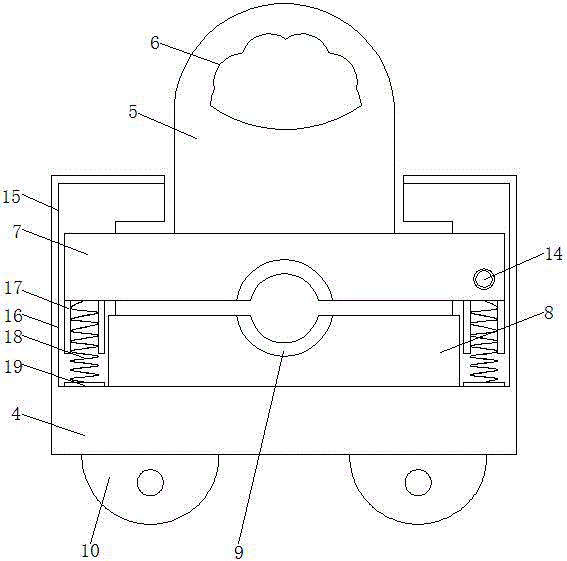

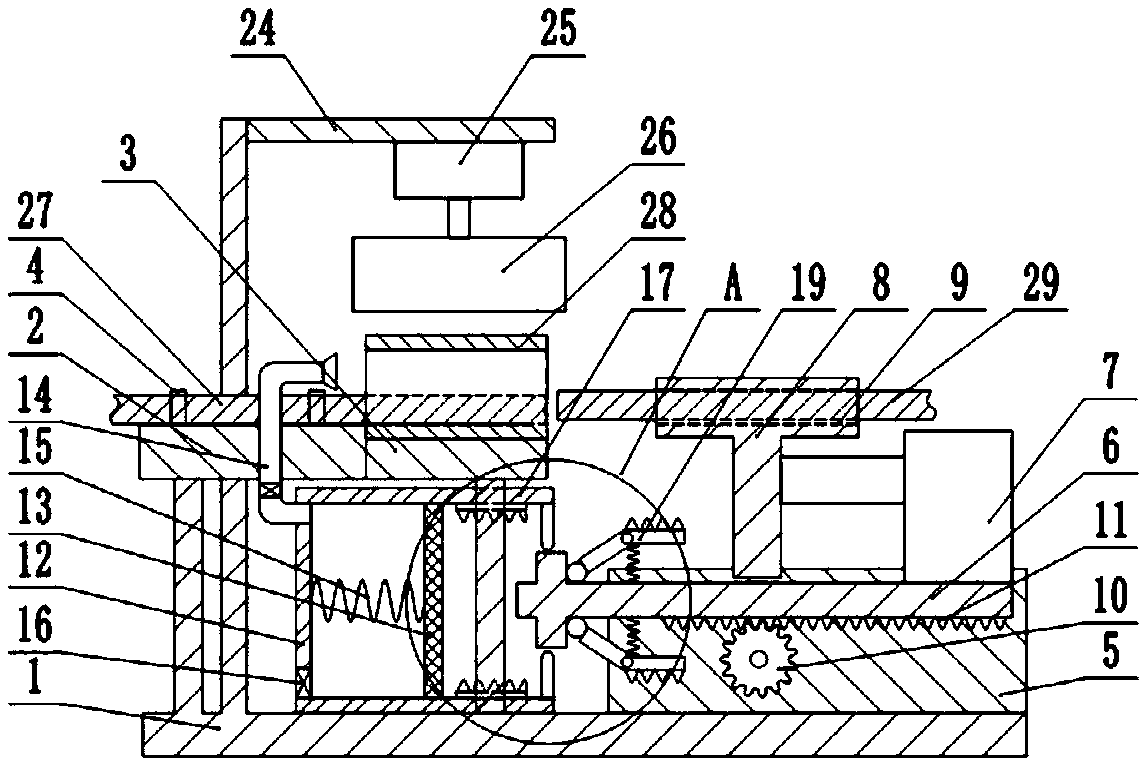

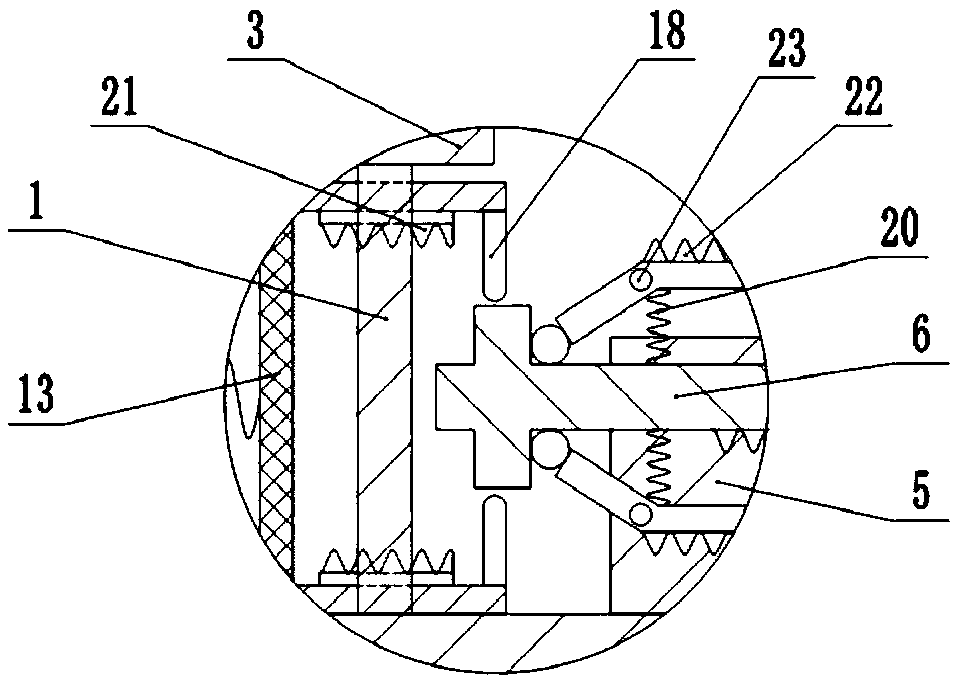

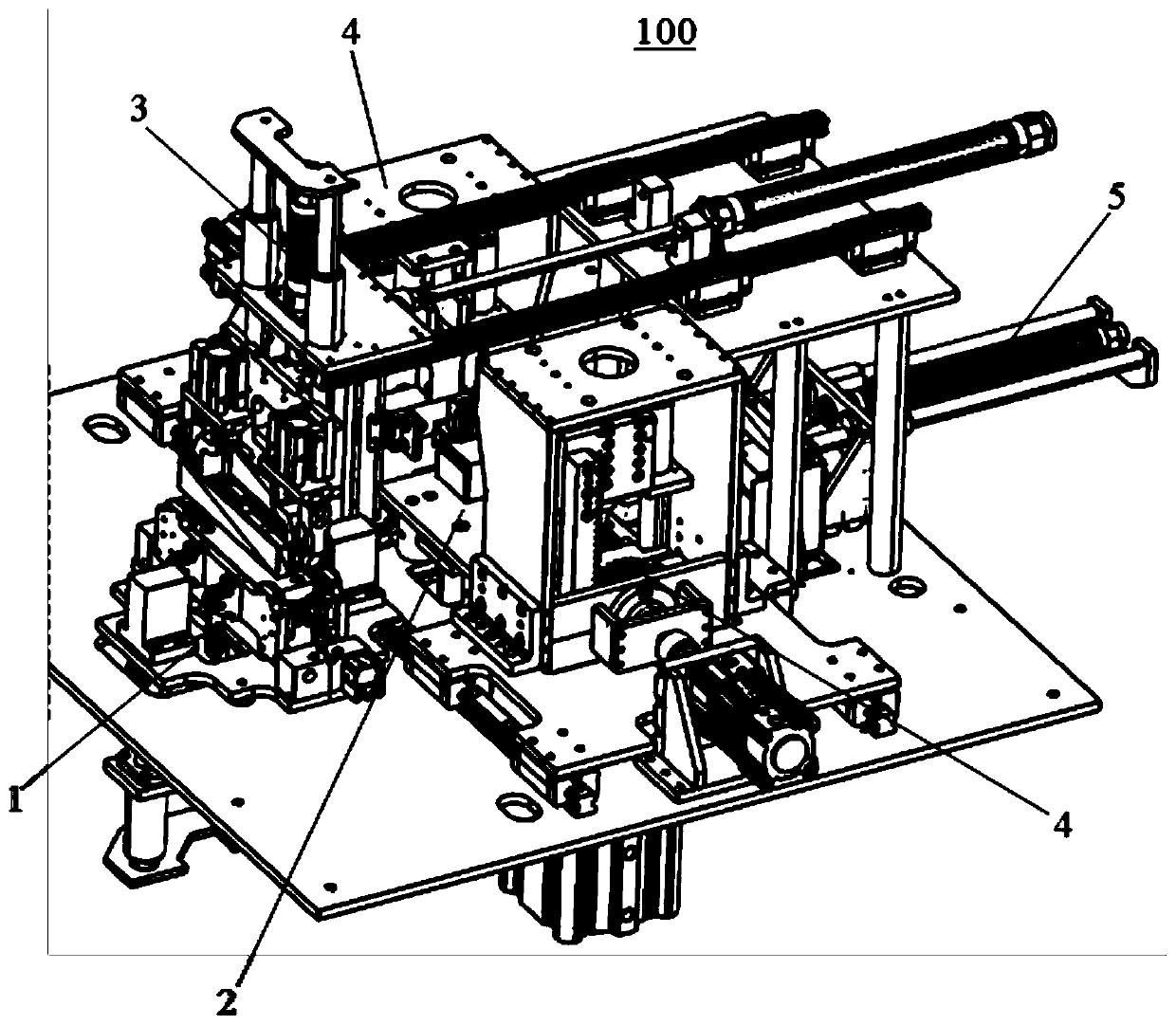

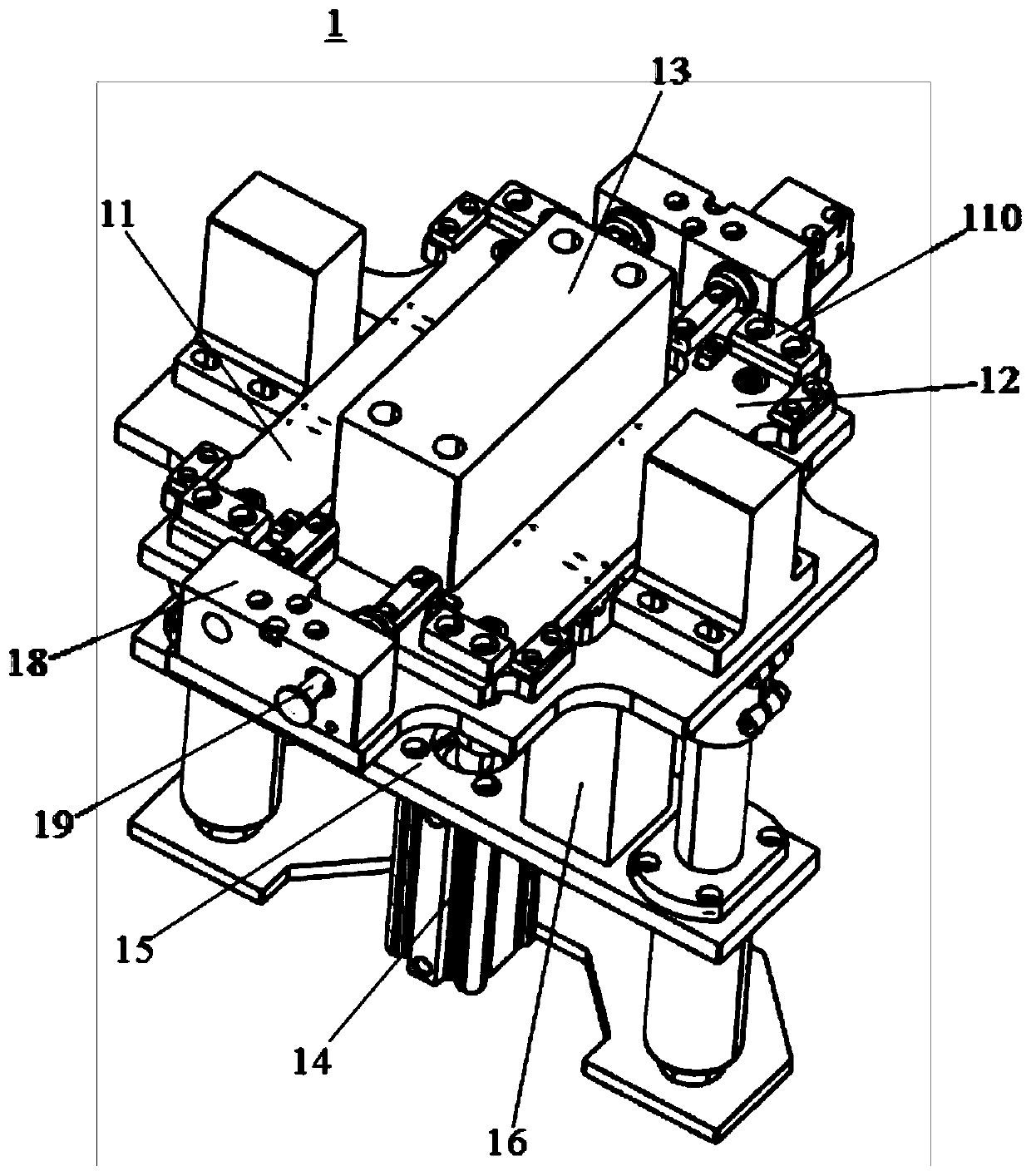

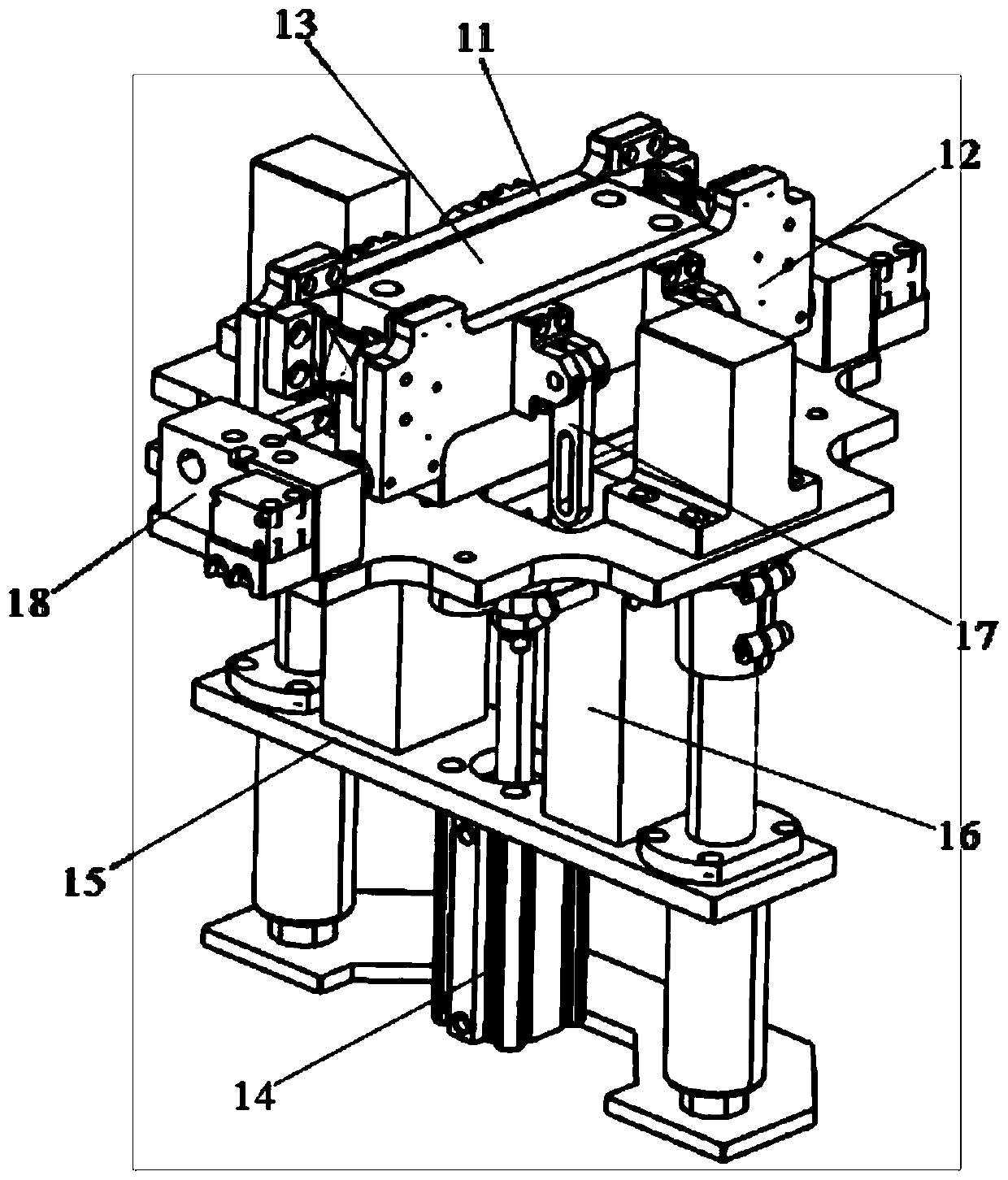

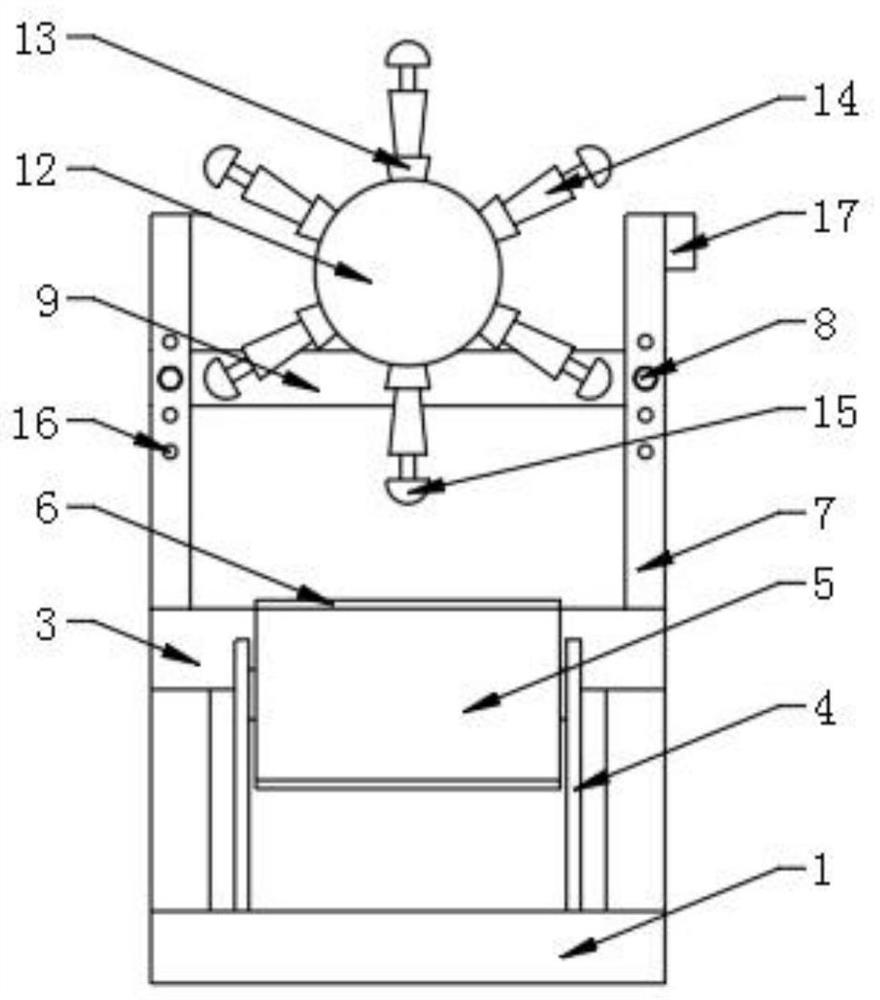

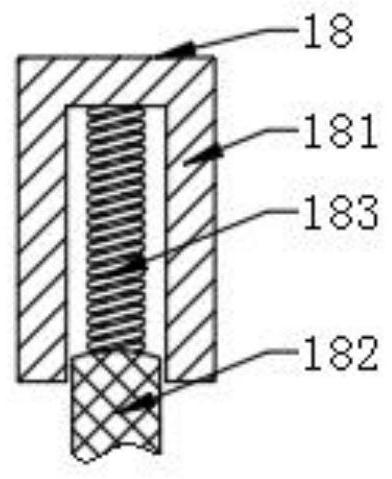

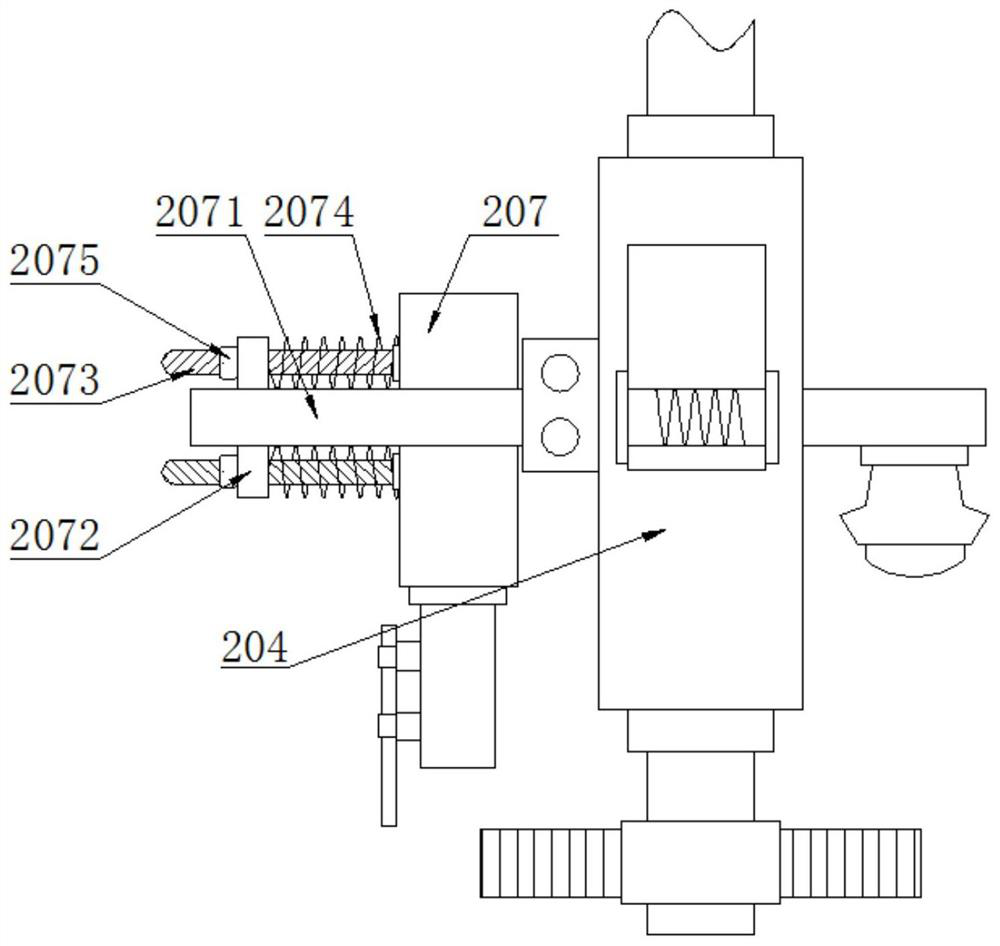

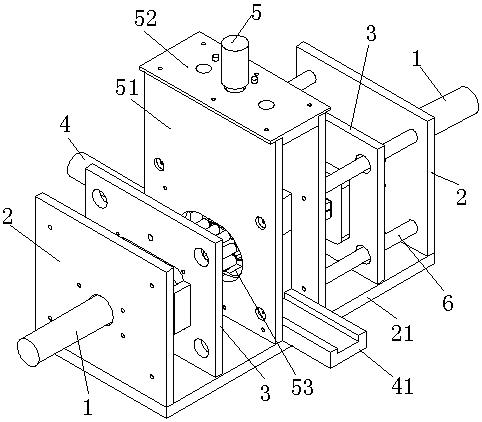

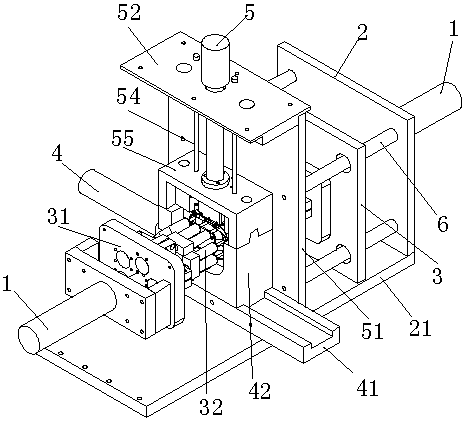

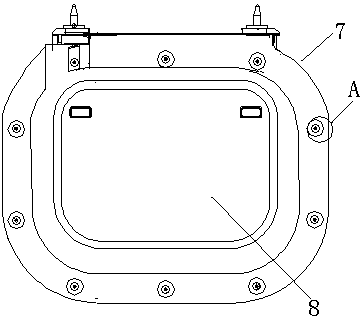

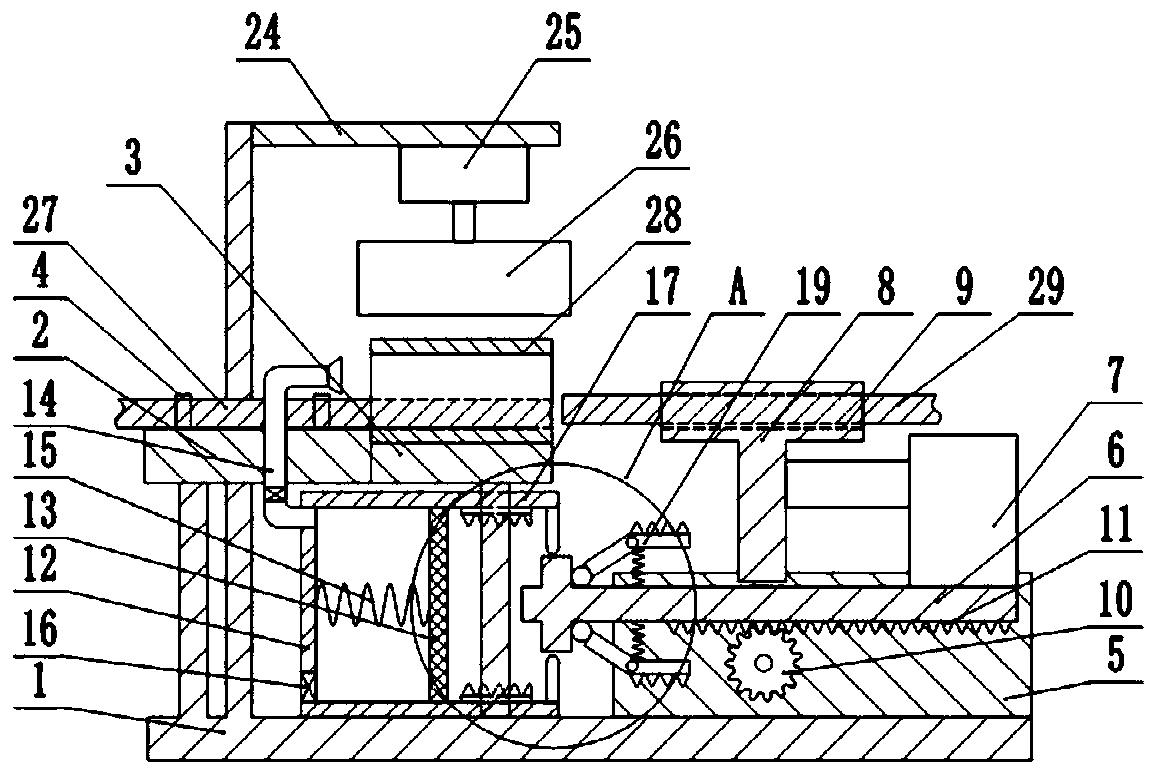

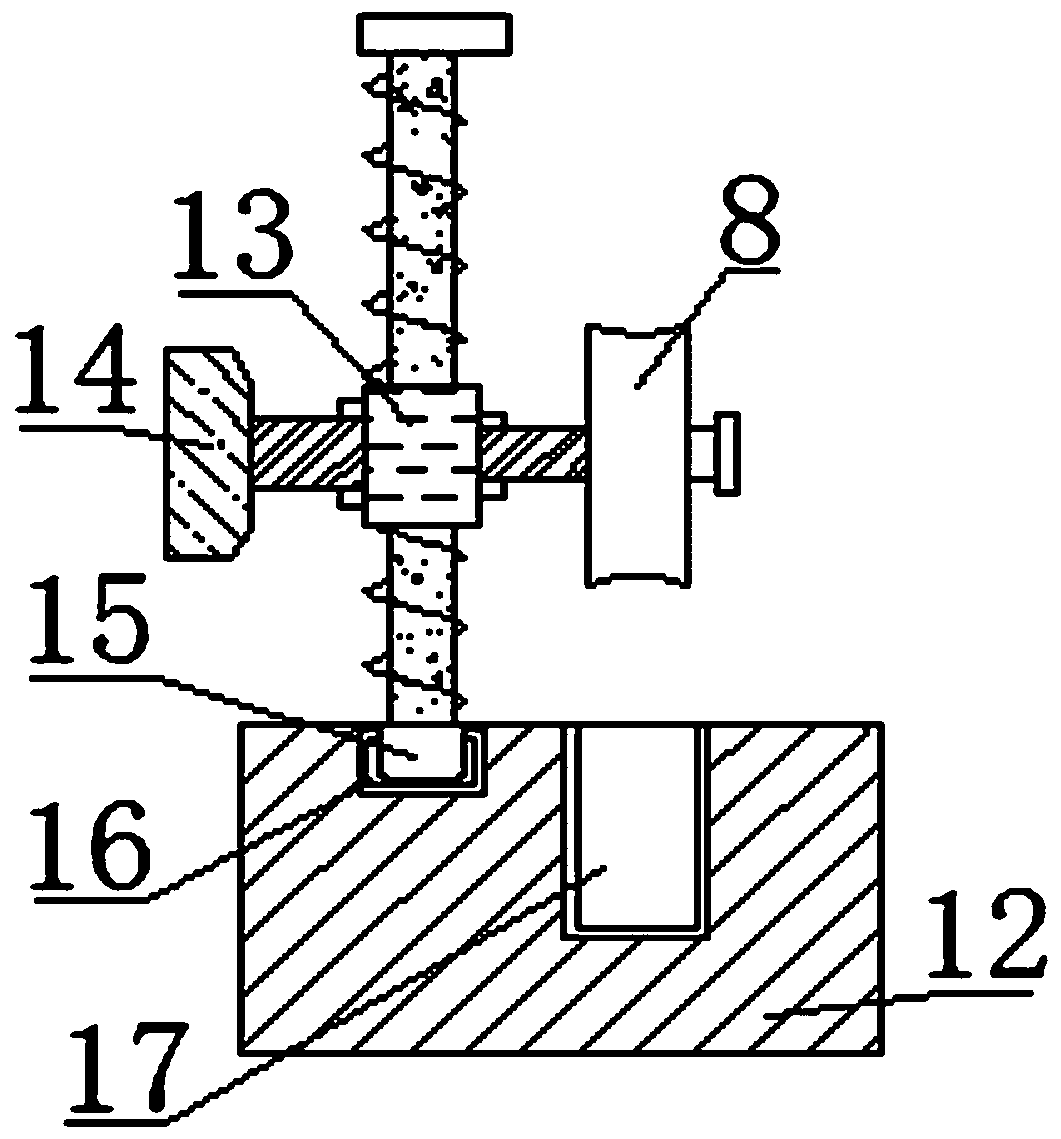

Three-dimensional-direction pressure maintaining equipment

The invention discloses three-dimensional-direction pressure maintaining equipment and solves the technical problems that three-dimensional-direction pressure equipment in the prior art is complex in structure and relatively large in size. The equipment is provided with a rack; a downward-pressing driving mechanism is arranged on the rack; the rack is mounted on a base; a product accommodating plate is arranged on the base and is used for accommodating a product to be subjected to pressure maintaining; the lower side of the downward-pressing driving mechanism is connected with a partial pressure mechanism; the downward-pressing driving mechanism drives the partial pressure mechanism to rise and fall; multiple vertical pressure heads and multiple lateral pressure heads are arranged in the partial pressure mechanism; a partial pressure block matched with the lateral pressure heads is arranged; slopes are arranged on the partial pressure block; the lateral pressure heads can be driven through the slopes to extend out; and in the falling process of the partial pressure mechanism, the vertical pressure heads make contact with the product for pressing firstly, in the process that the partial pressure mechanism continues to fall, the partial pressure block begins to move downwards relative to the lateral pressure heads, the slopes of the partial pressure block drive the lateral pressure heads to extend out to make contact with the product for pressing, and thus three-dimensional-direction pressure maintaining is performed on the product.

Owner:GEER TECH CO LTD

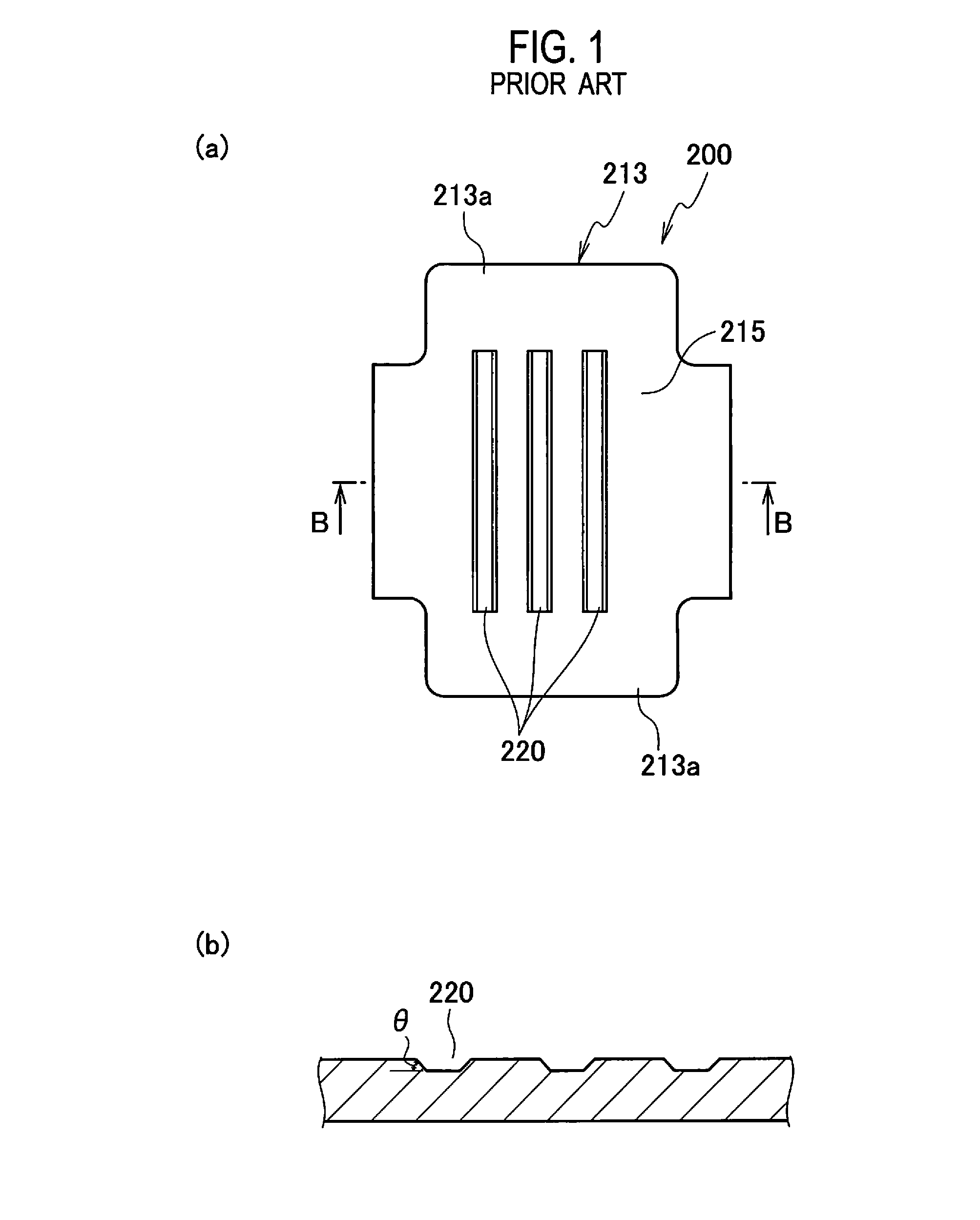

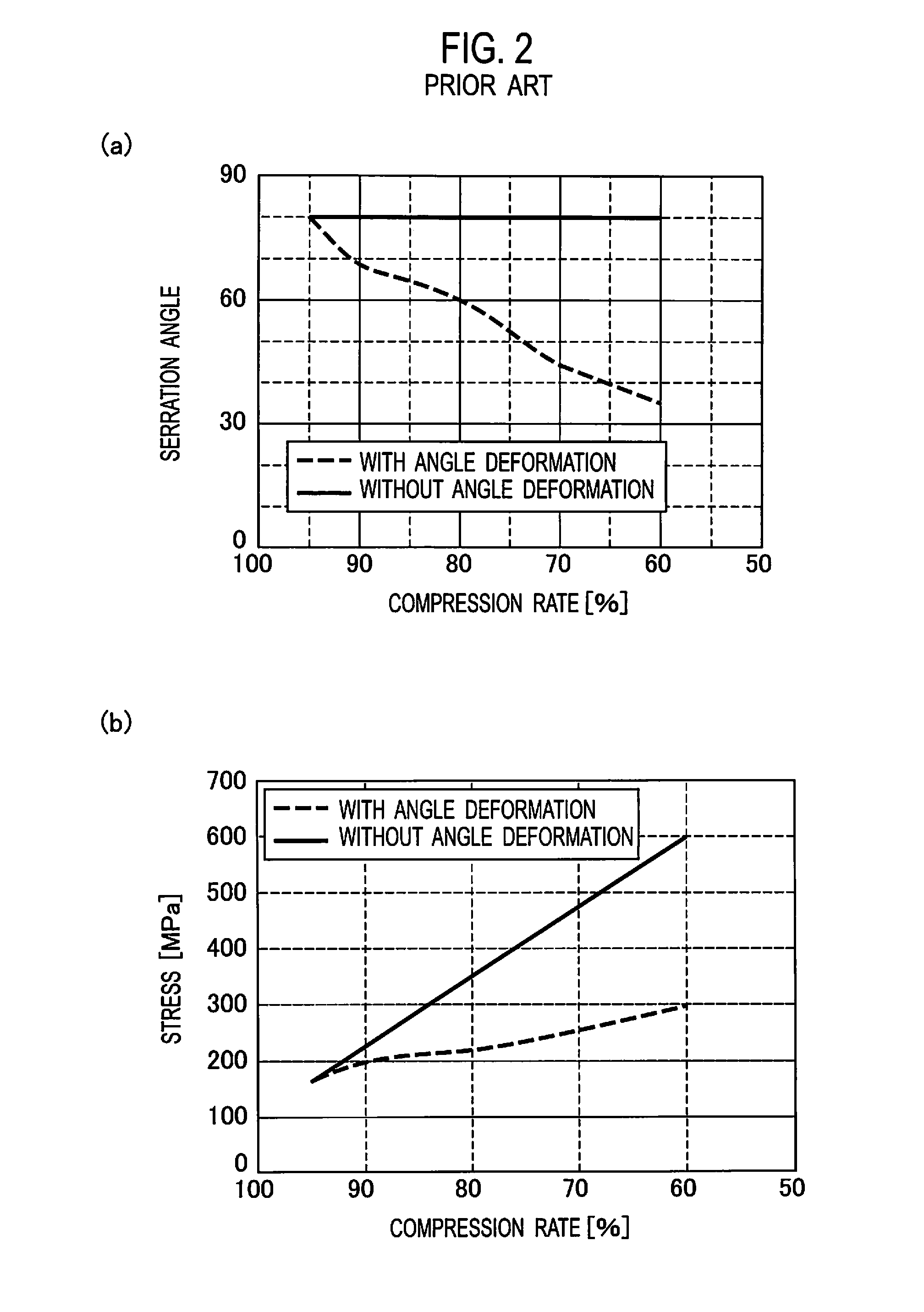

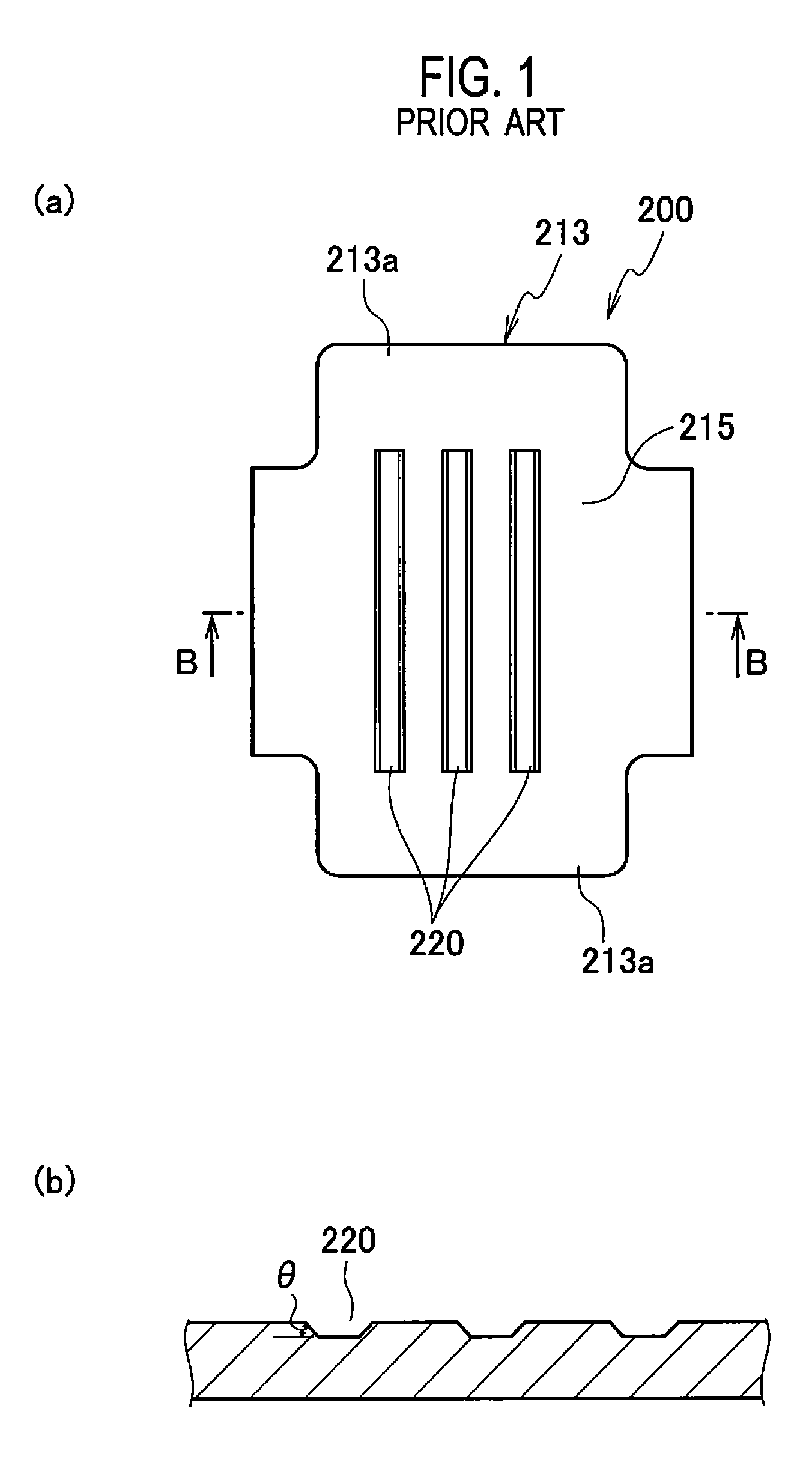

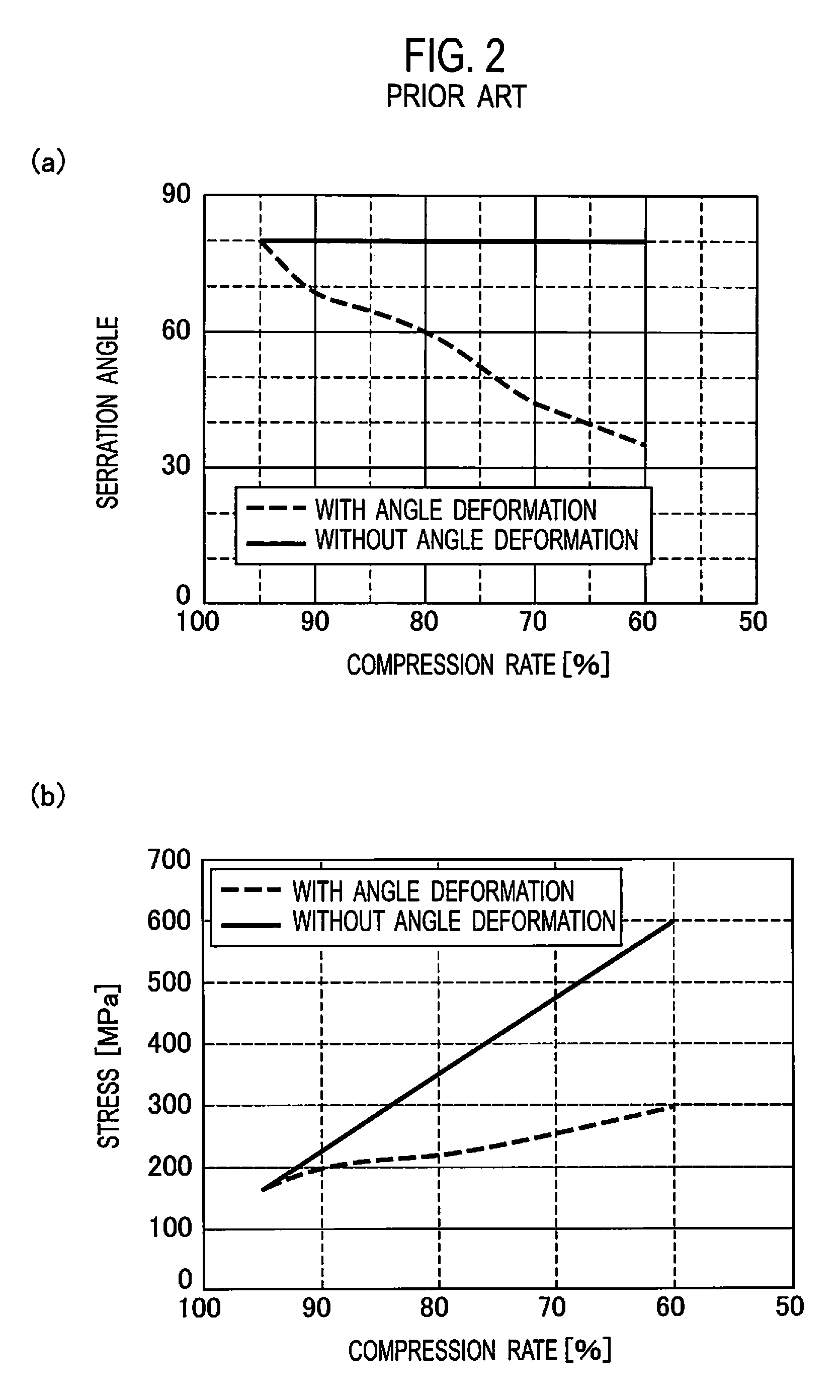

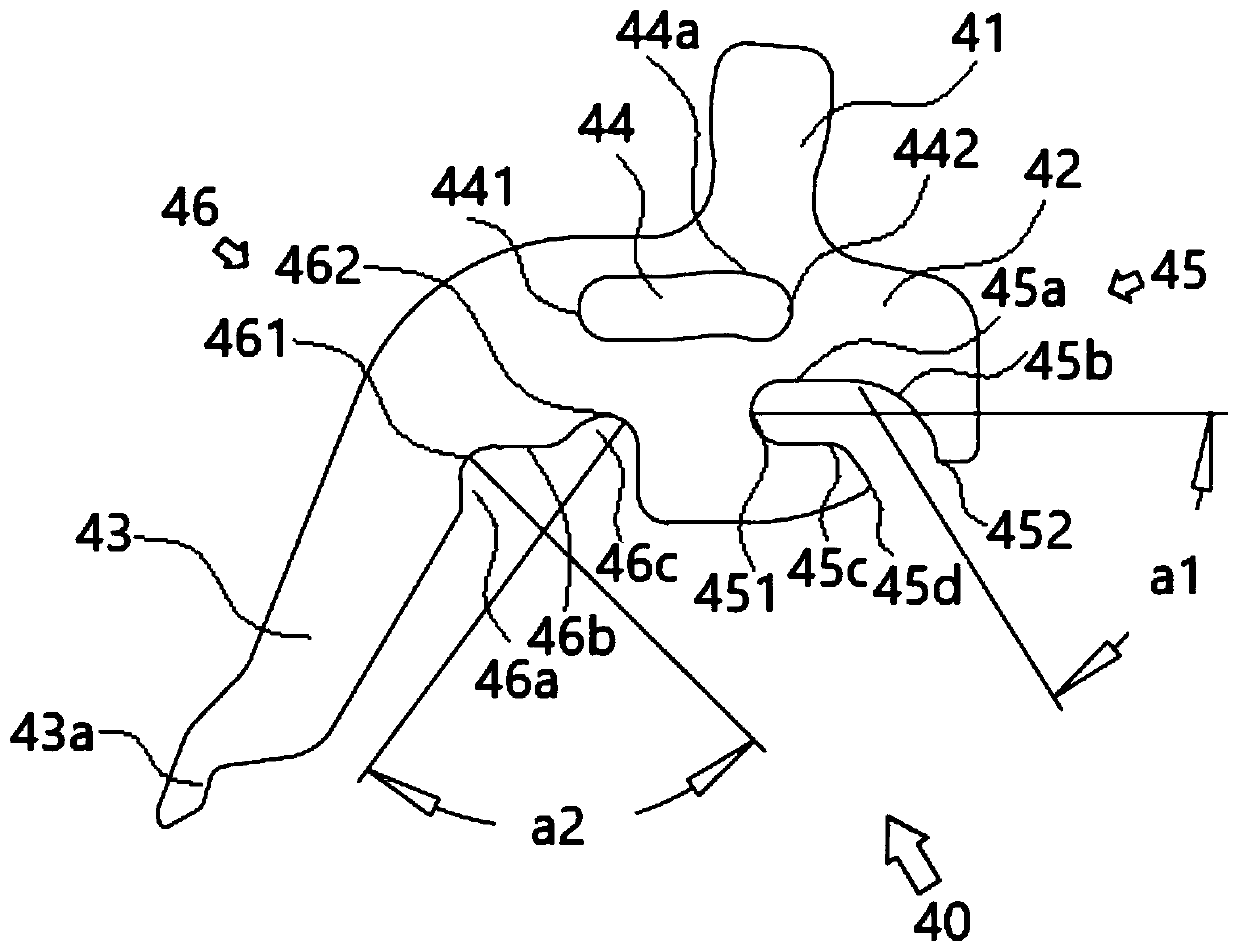

Crimp terminal

ActiveUS20140213123A1Good crimping effectIncrease pressureConnections effected by permanent deformationElectrical conductorShortest distance

Concave serrations are provided in an inner surface of a conductor crimping portion of a crimp terminal. A number of circular concave portions are provided in the inner surface of the conductor crimping portion as the concave serrations so as to be scattered in a state of being spaced aside from one another. A diameter of an inner bottom surface of each circular concave portion is set within a range of 0.15 (an error range is ±0.04) mm to 0.8 (the error range is ±0.04) mm. A serration angle between an extension surface of the inner bottom surface and an inner side surface of each circular concave portion is set within a range of 60 to 90 degrees. A shortest distance of a flat surface portion between peripheries of mutually adjacent circular concave portions is set to be 0.17 (the error range is ±0.09) mm.

Owner:YAZAKI CORP

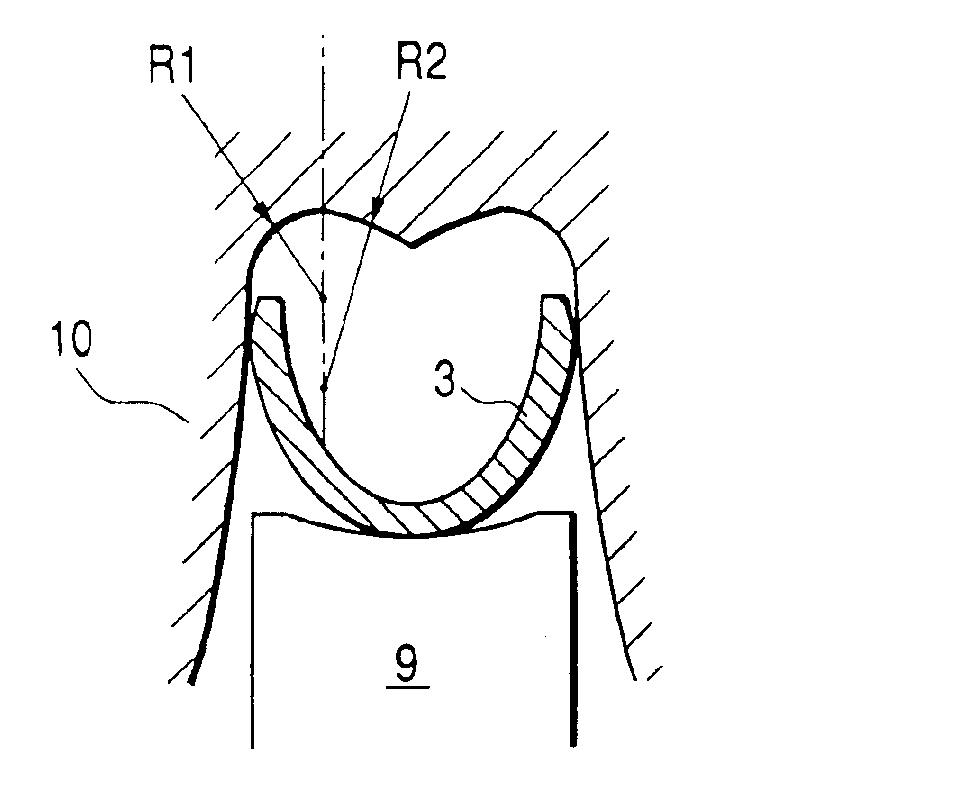

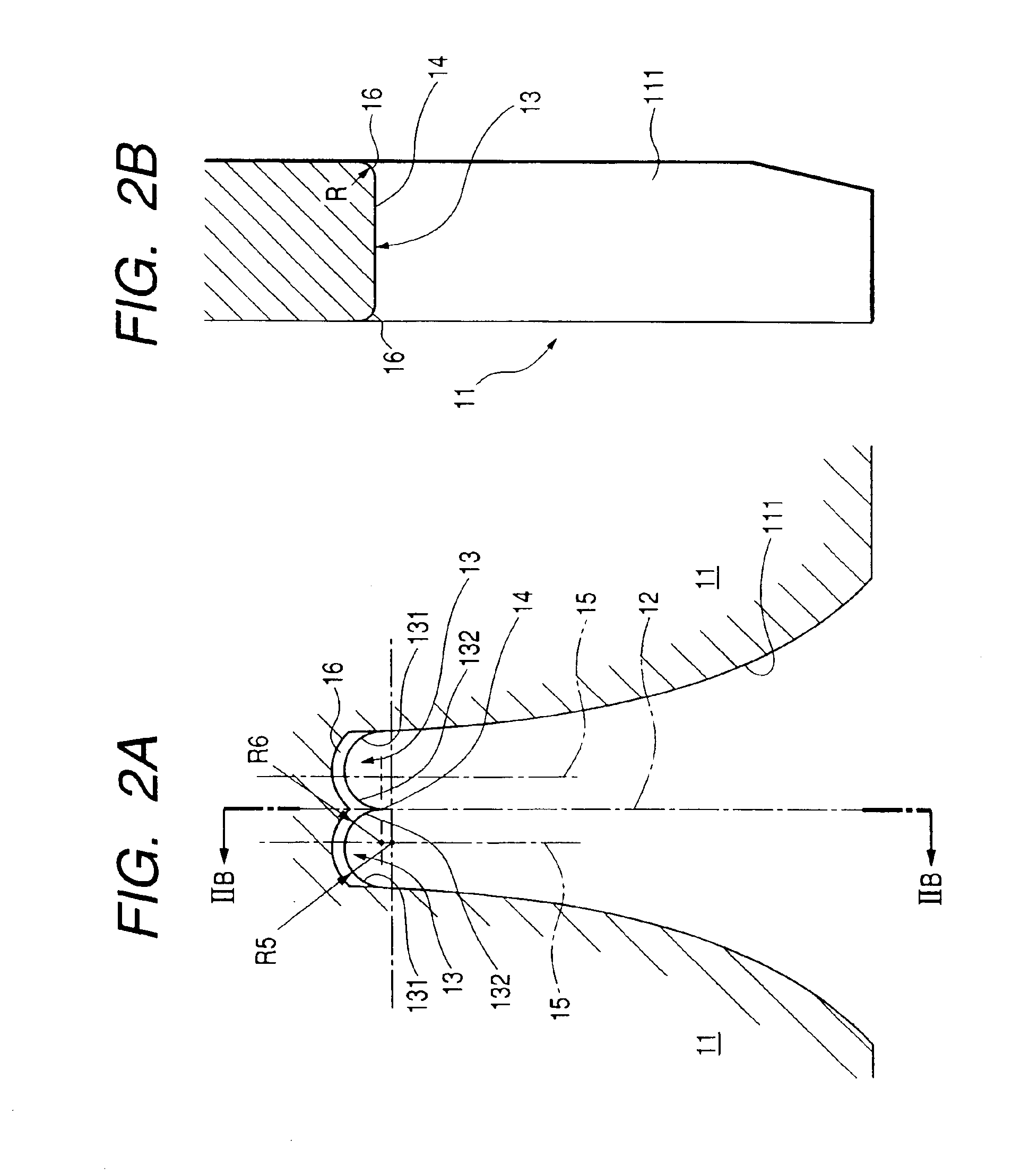

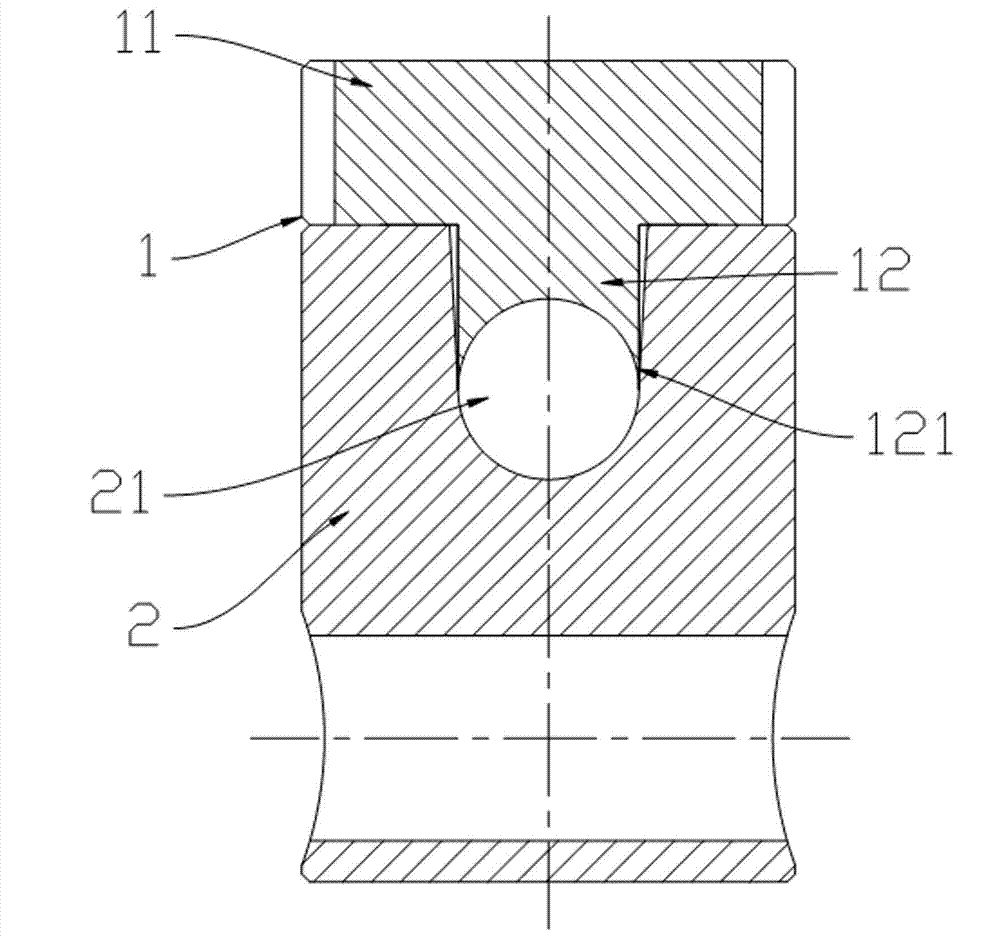

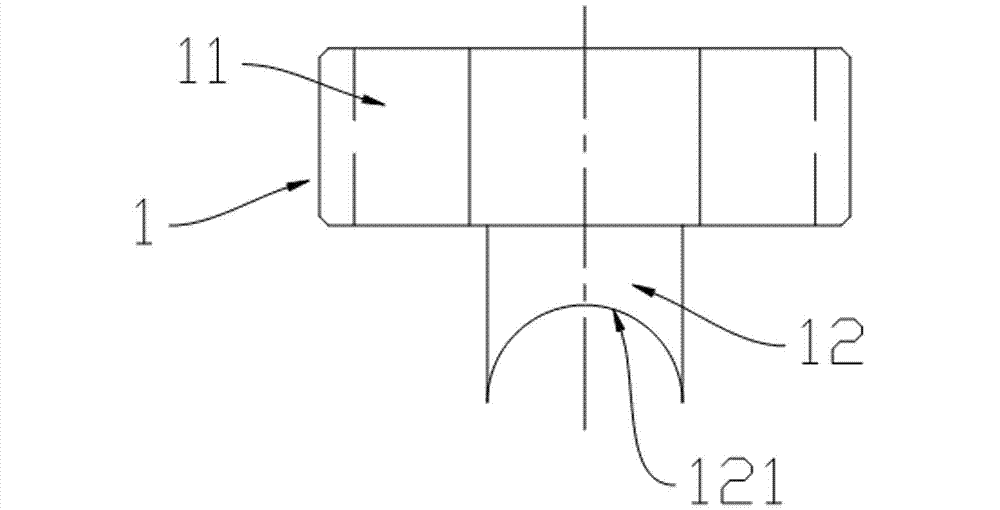

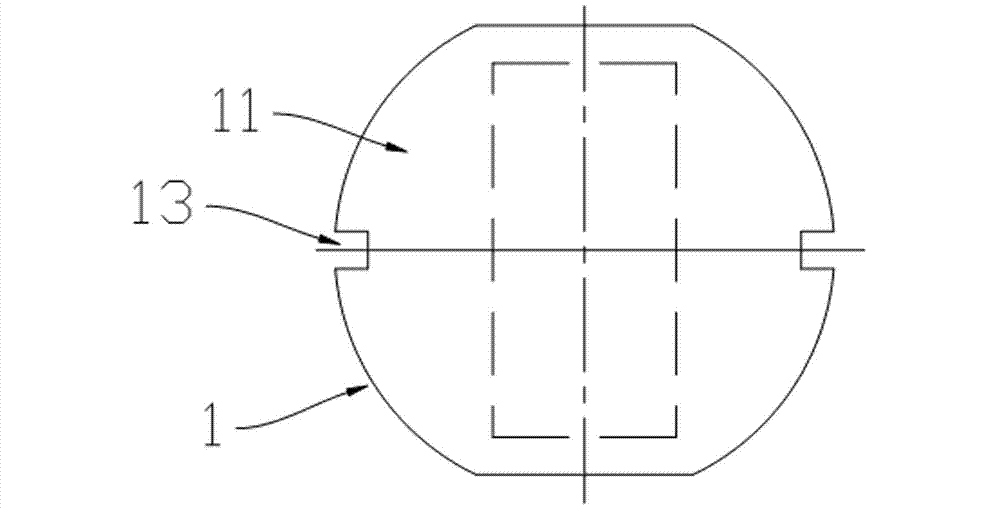

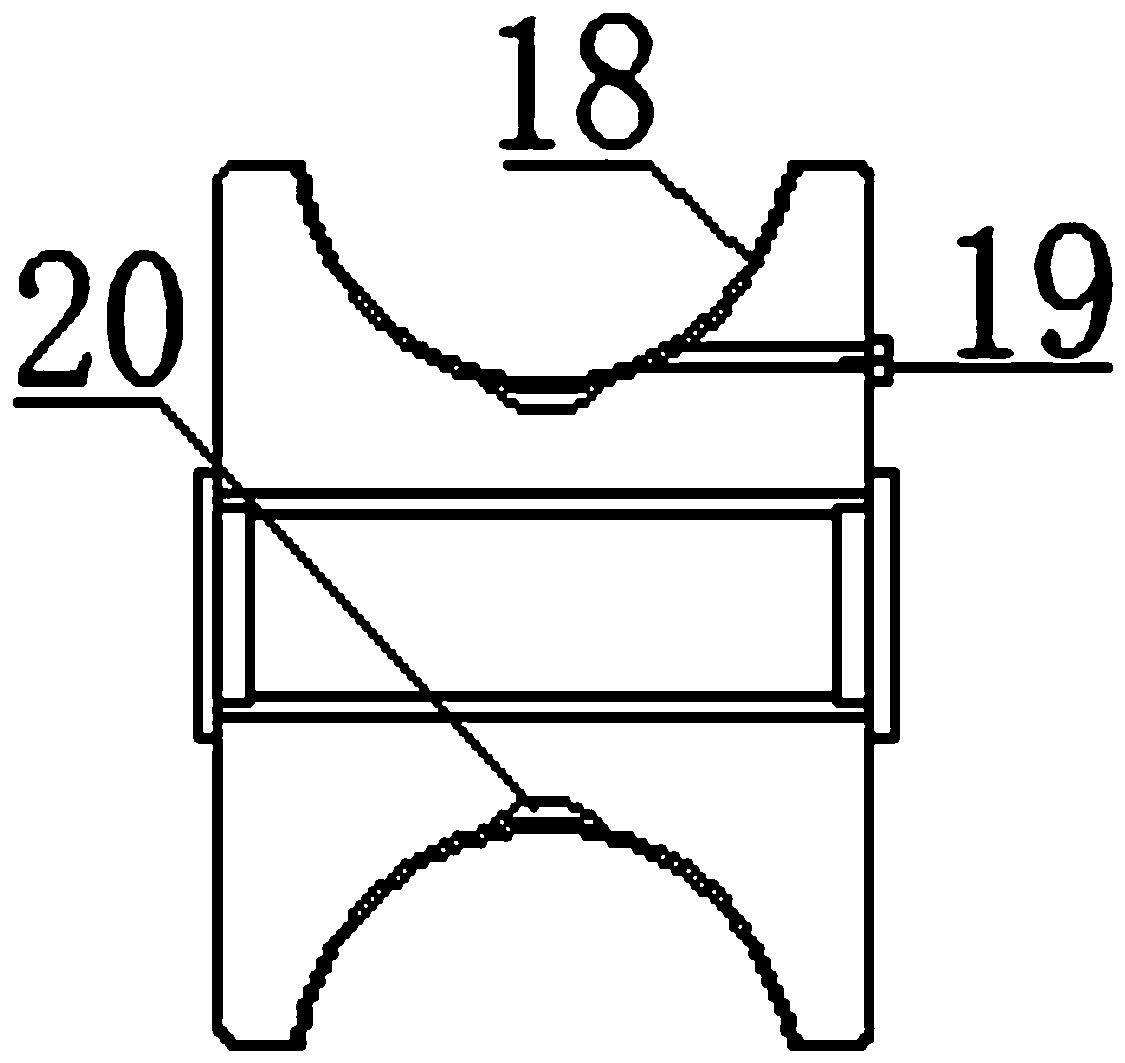

Crimping device for crimping crimp pieces of a metal terminal

InactiveUS6880240B2Good crimping effectImprove coupling strengthPliersConnection formation by deformationEngineeringMechanical engineering

Crimp pieces (21) of a metal terminal and a conductor wire placed on an inner side of the crimp pieces are positioned between a crimp indenter (11) and a crimp anvil (18). Then, at least one of the crimp indenter (11) and the crimp anvil (18) is moved toward another one thereof along a direction of a longitudinal center axis (12) to crimp the crimp pieces (21). At least two arch-shaped portions (13) are disposed on an inner surface of the crimp indenter (11), and are adjacent to each other and symmetric with respect to a plane including the longitudinal center axis (12). A sharply pointed portion (14) is defined by curves of the at least two arch-shaped portions (13) intersecting on the longitudinal center axis (12). Curvature of each of the curves is set to be greater toward the sharply pointed portion (14).

Owner:YAZAKI CORP

Hydraulic clamp with auxiliary fixing function

InactiveCN105932610ASimple structureEasy to operateApparatus for joining/termination cablesEngineering

Owner:国网山东省电力公司东营市垦利区供电公司

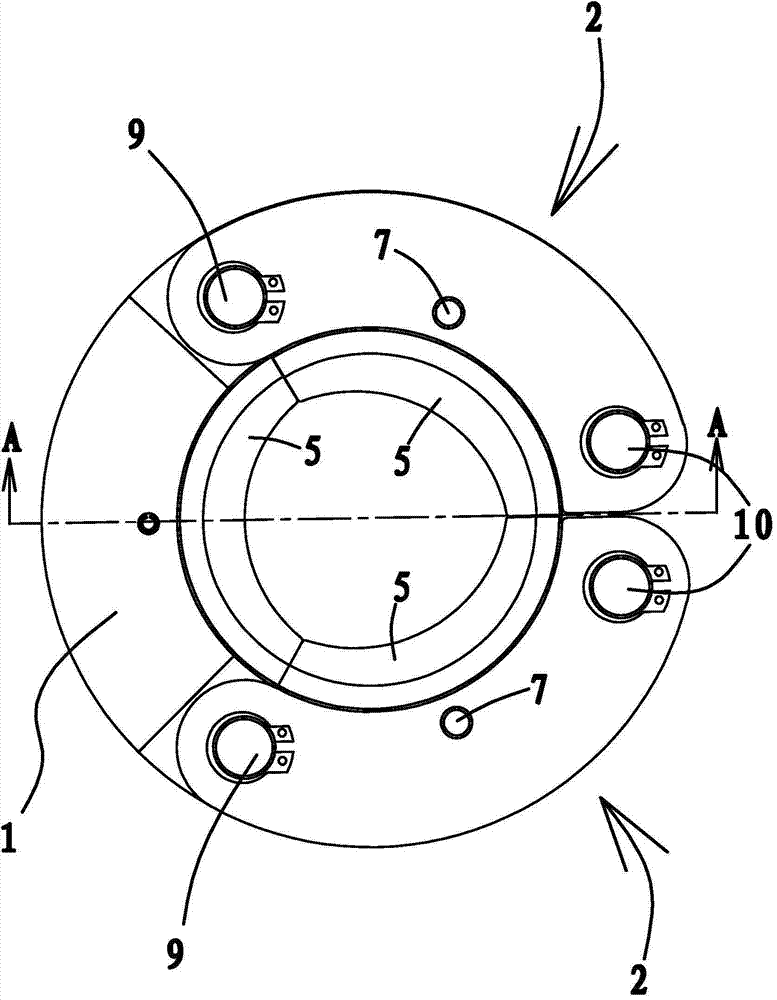

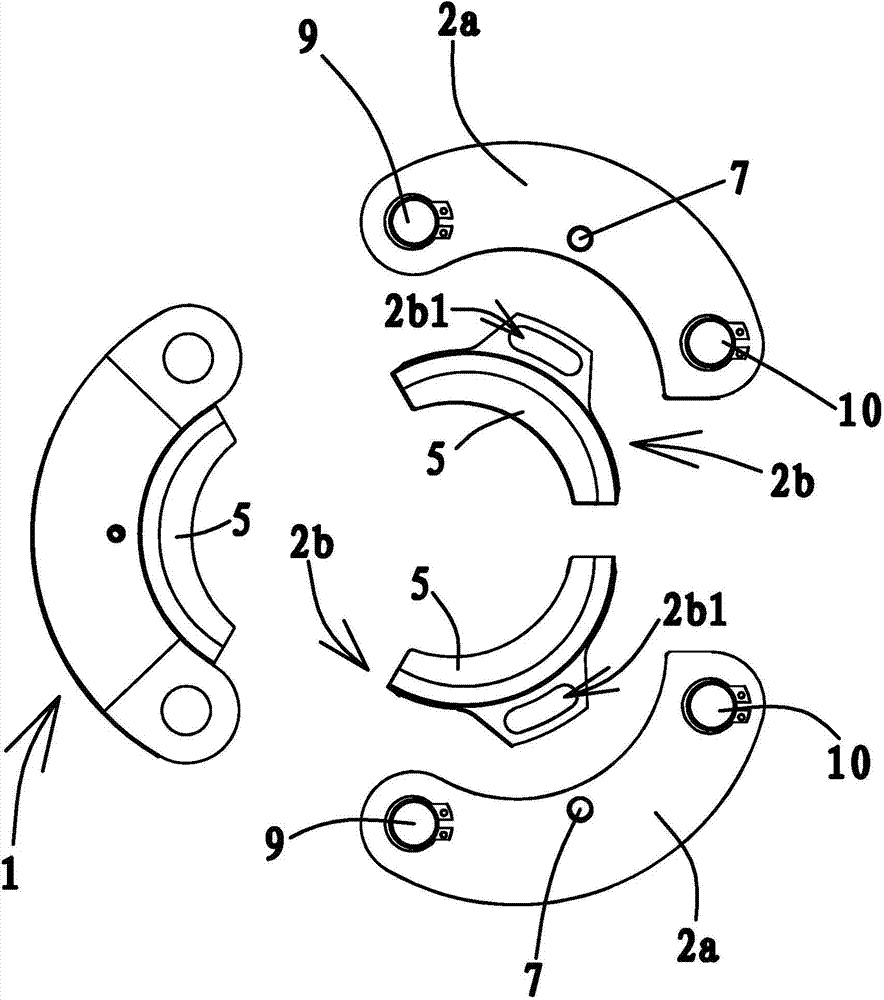

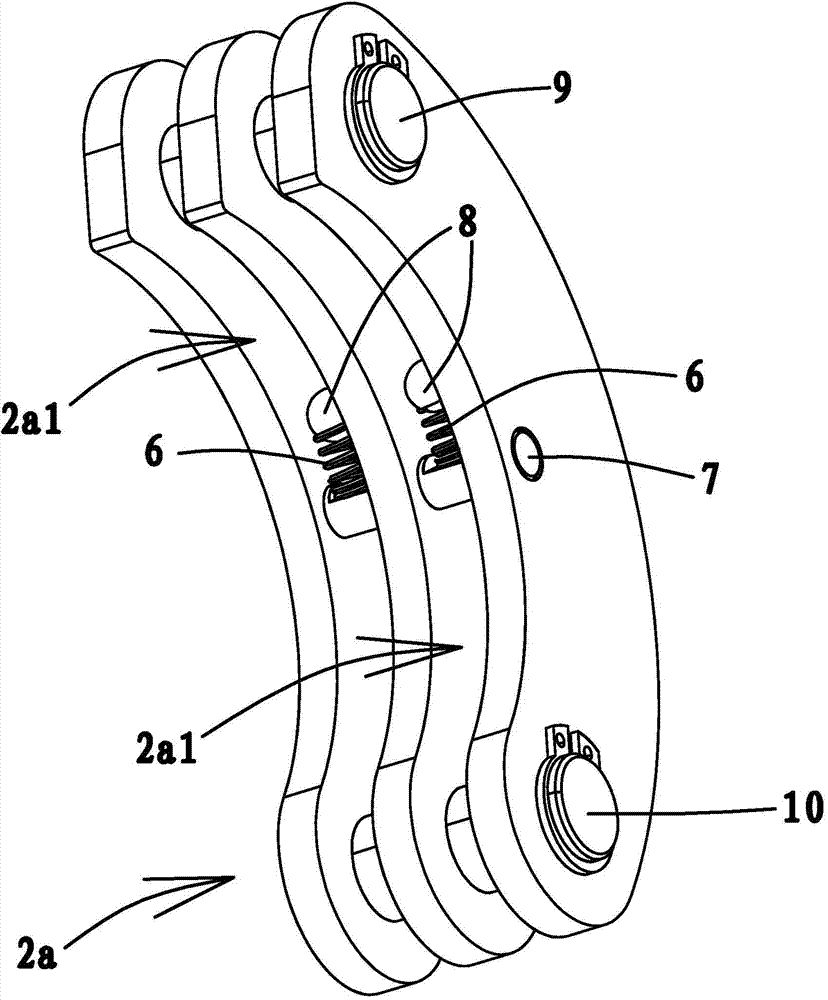

Extrusion die of press pipe fitting

The invention provides an extrusion die of a press pipe fitting and belongs to the mechanical technical field. The extrusion die of the press pipe fitting solves the problem that the press effect on pipe fittings of the existing extrusion die is poor. The extrusion die of the press pipe fitting comprises a fixed die which is circular-arc-shaped and two moving dies which are circular-arc-shaped; the inner ends of the two moving dies are hinged to two ends of the fixed die respectively; the outer ends of the two moving dies can be buckled together; the inner sides of the fixed die and the moving dies form a press ring which is in an annular shape and is used for pressing the outer side of the pipe fitting after the outer ends of the two moving dies are buckled together; the press ring is provided with a plurality of press portions which are uniformly distributed; the contact between the press portions and the pipe fitting can be converted from line contact or local surface contact into the state that the press portions press the outer side of the pipe fitting completely after the extrusion die is buckled. According to the extrusion die of the press pipe fitting, the contact between the press portions and the pipe fitting can be converted from the line contact or the local surface contact into the state that the press portions press the outer side of the pipe fitting completely when the pipe fitting is pressed, so that the intensity of pressure on the pipe fitting of the press portions is large when press is just started, the press portions completely abut against and press the outside of the pipe fitting finally, and accordingly the press effect of the pipe fitting is good.

Owner:TAIZHOU JULI TOOLS

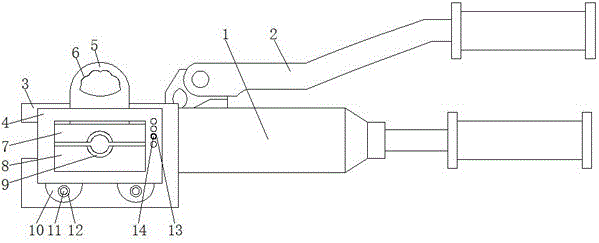

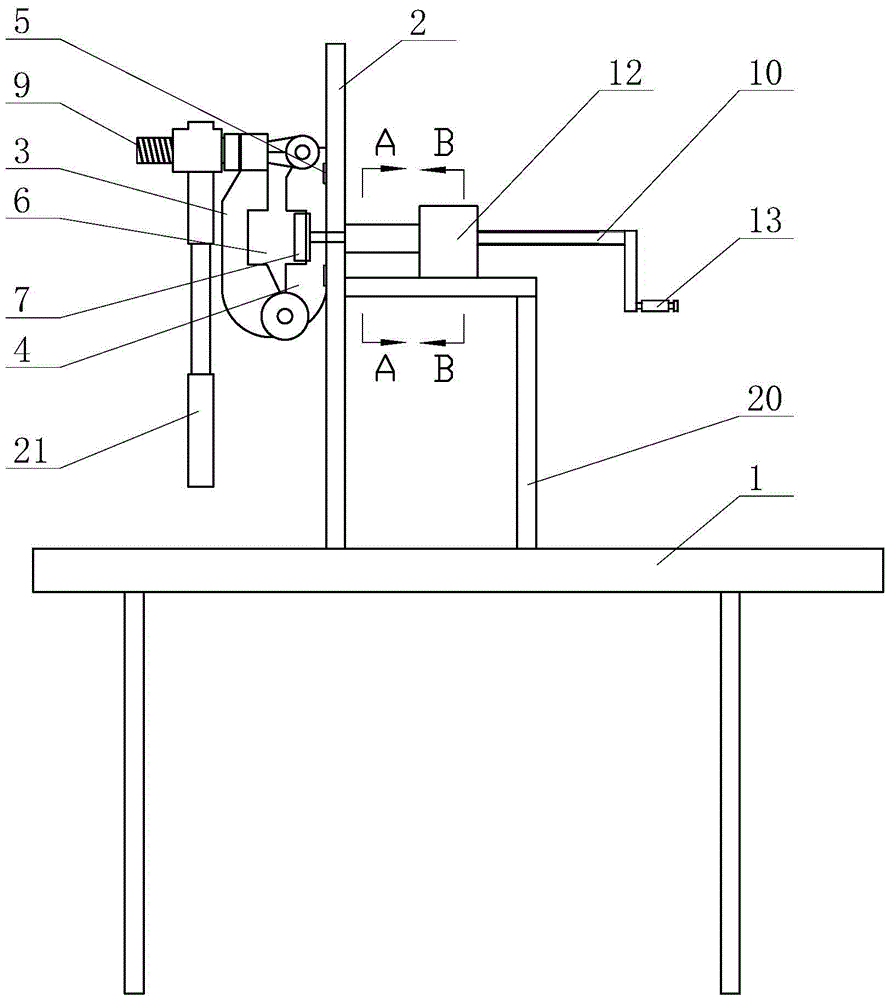

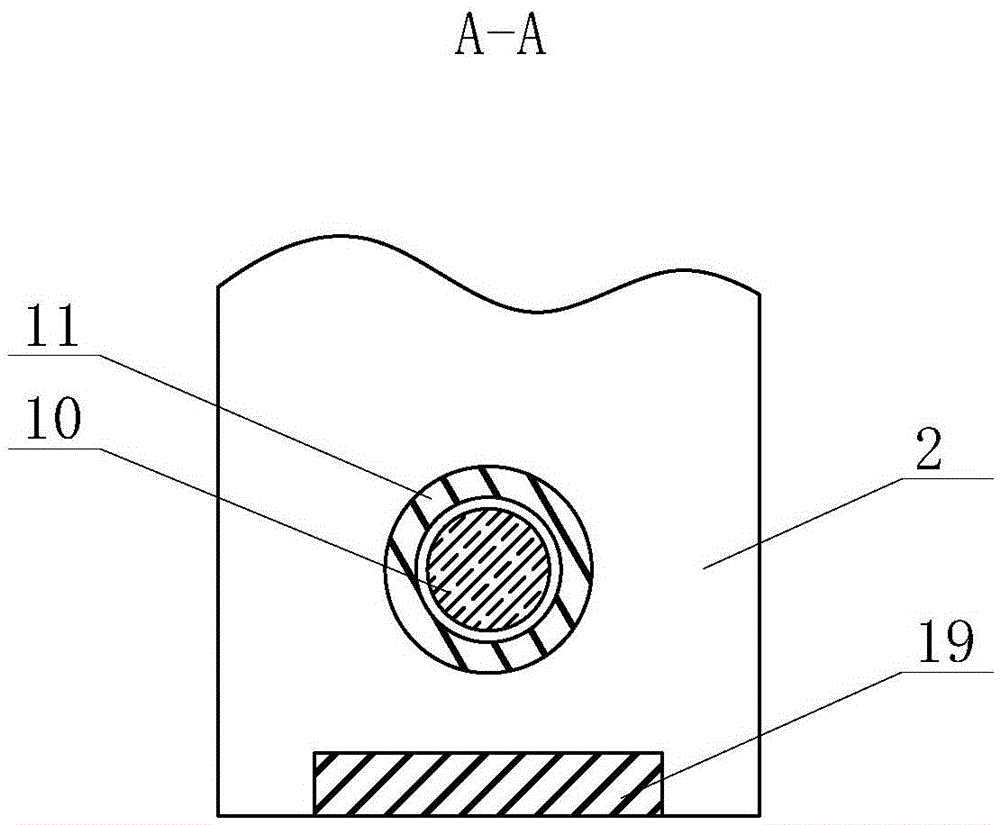

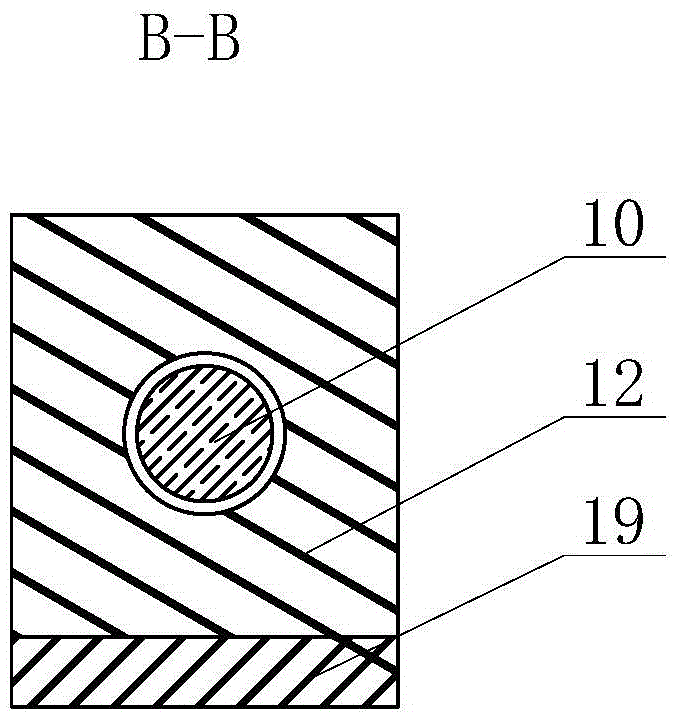

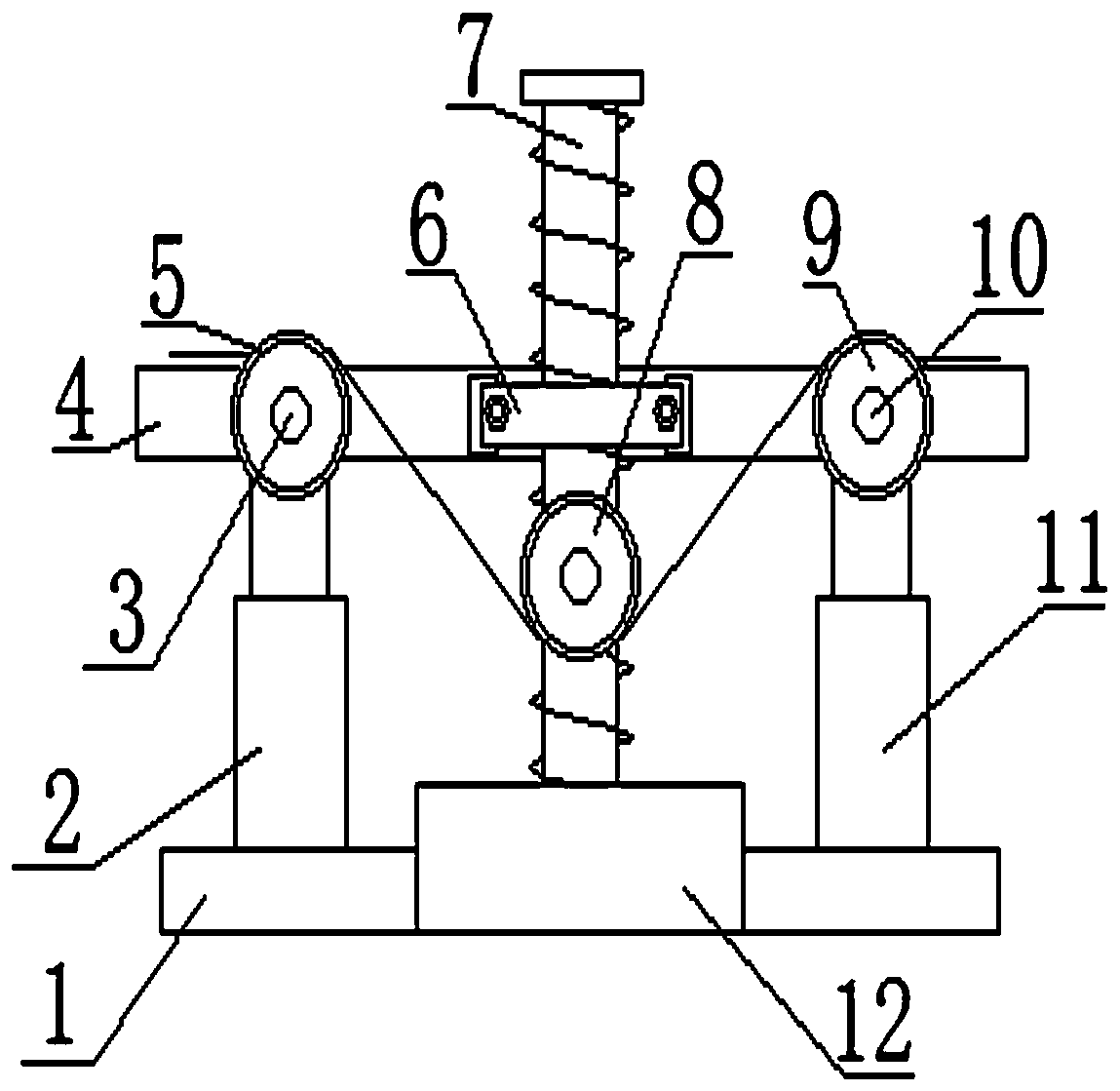

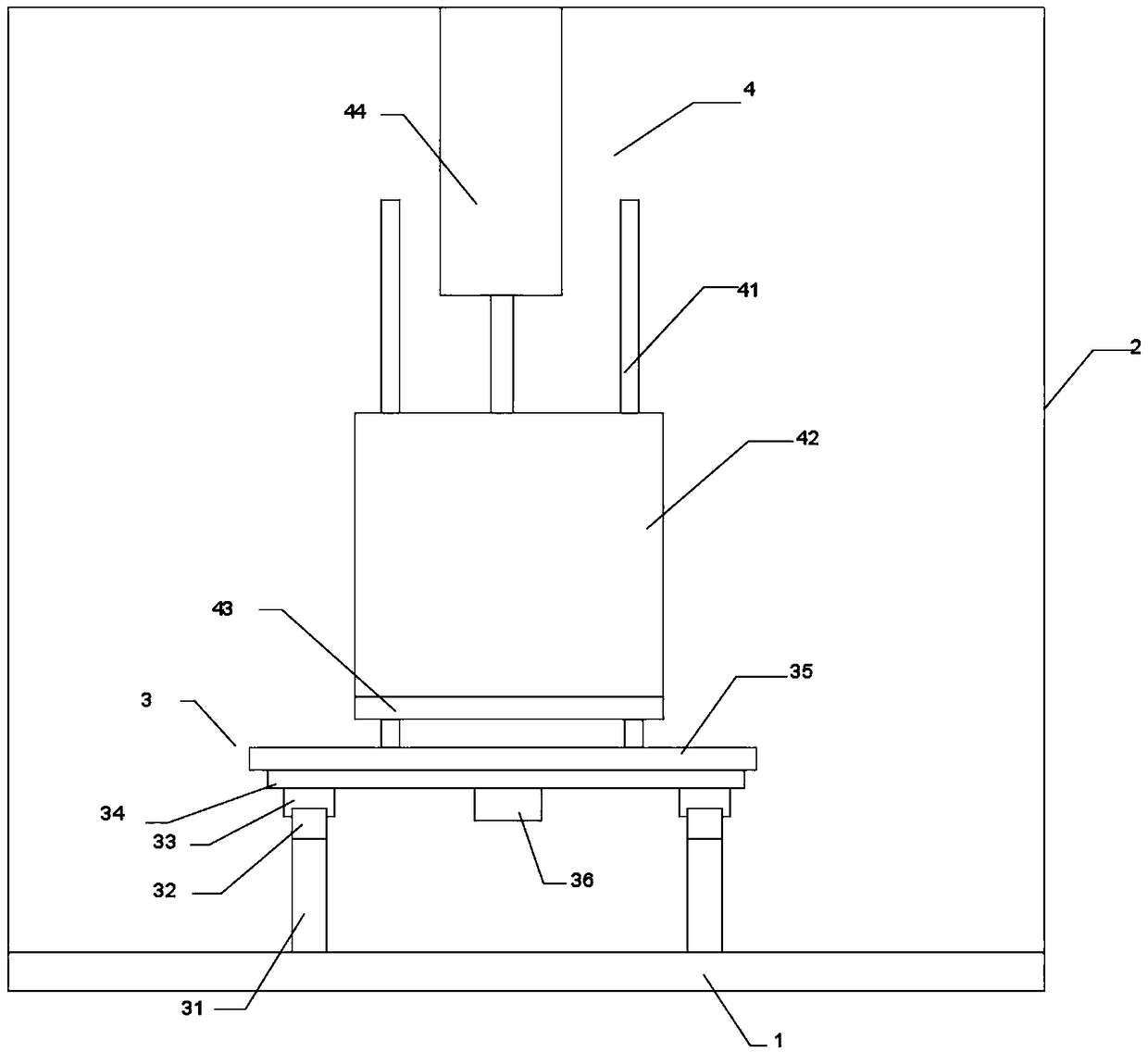

Portable cable crimping platform

InactiveCN105490126AEasy to useEasy to carryLine/current collector detailsPiston cylinderEngineering

The invention provides a portable cable crimping platform. A vertical plate is mounted on a bracket; elephant-shaped press pliers and a power mechanism are mounted at two sides of the vertical plate; a press block is mounted in a groove formed in a second side plate in the elephant-shaped press pliers; the power mechanism comprises a screw rod and a piston cylinder; a piston rod is arranged at the right end of the piston cylinder; the piston cylinder and the piston rod are both ring-shaped; the middle part of the screw rod is connected with a fixed base through a threaded structure; the left end of the screw rod extends into the piston cylinder and the piston rod; the press block is of a two-layer structure comprising a first press block and a second press block; the first press block is provided with a through groove in which the second press block is arranged; a clamping structure is arranged between the through groove and the second press block; the right end of the second press block extends out of the first press block to get contact with the left end of the screw rod; the screw rod can drive the second press block to move horizontally alone; the right end of the first press block is in contact with the left end of the piston rod; the piston rod can drive the first press block and the second press block to move as a whole. The portable cable crimping platform is convenient to operate, is portable, is capable of cable crimping in many ways, and has relatively good crimping efficiency and crimping quality.

Owner:国网山东郓城县供电公司 +1

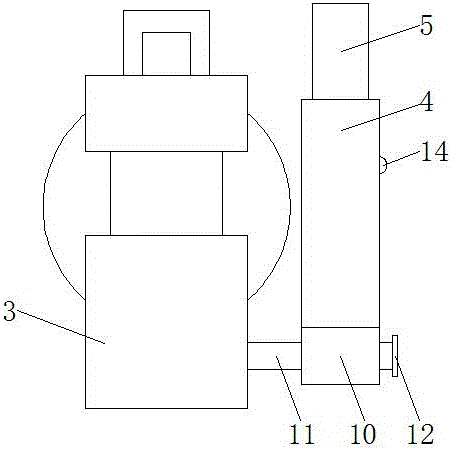

Pneumatic terminal machine

The invention discloses a pneumatic terminal machine. The pneumatic terminal machine comprises a frame, a workbench and a feeding mechanism, wherein an air cylinder is connected with the upper part of the frame; the air cylinder drives a punch below the air cylinder to move; an die upper die is fixedly connected with the lower part of the punch; the frame is fixed on the workbench; a die lower die is fixed on the workbench and positioned in a corresponding position below the die upper die; a positioning blocking piece is arranged on the die lower die; the feeding mechanism is positioned on one side of the frame. The pneumatic terminal machine is convenient and practical, can be operated continuously, has high efficiency, is low in cost, is applied to the pressure welding machining of a small amount of various of terminals, and is also applicable to the pressure welding of terminals required to be reworked.

Owner:WUHU SHUNCHENG ELECTRONICS

Conducting wire rounding die

InactiveCN103050868AEasy to insertGood crimping effectLine/current collector detailsTransformers/inductances coils/windings/connectionsElectrical and Electronics engineeringWelding

The invention discloses a conducting wire rounding die, which is used for pressing a conducting wire to be round. The conducting wire rounding die comprises an upper die and a lower die. The upper die comprises a body and a protruding part which downwards protrudes relative to the body. A circular-arc groove with a downward opening is arranged at the lower part of the protruding part. The cross section of the circular-arc groove in the length direction perpendicular to the protruding part is circular-arc-shaped. An open groove with an upward opening is arranged at the upper part of the lower die. When the upper die and the lower die are closed, the open groove contains the protruding part of the upper die, and the open groove and the circular-arc groove form a round cavity. By adopting the structure, scattered coil outgoing ends can be pressed to be round and tightened, so that the coil outgoing ends can be very easily inserted into a wiring terminal and an ideal pressure welding effect is achieved.

Owner:WUJIANG TRANSFORMER

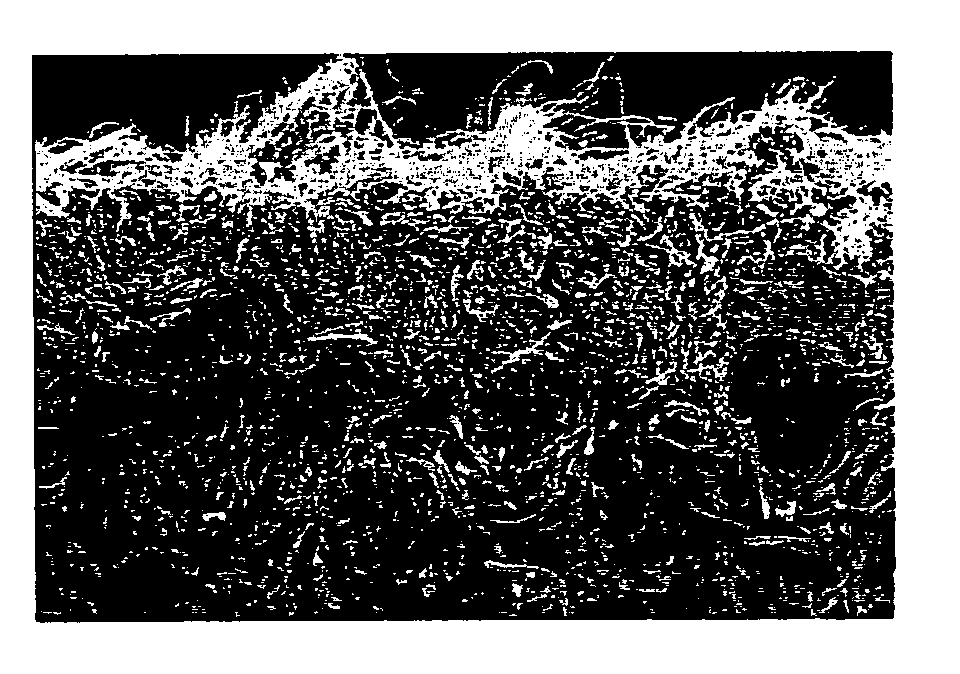

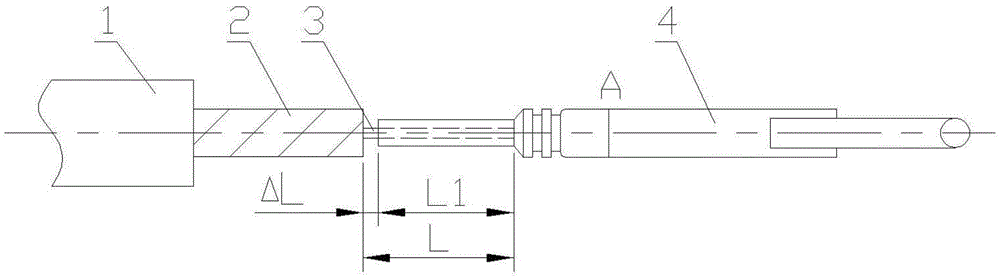

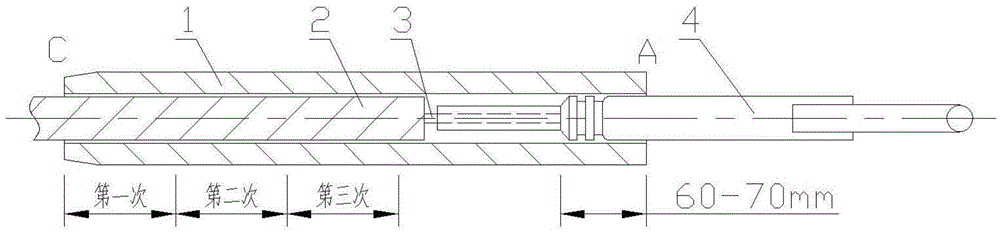

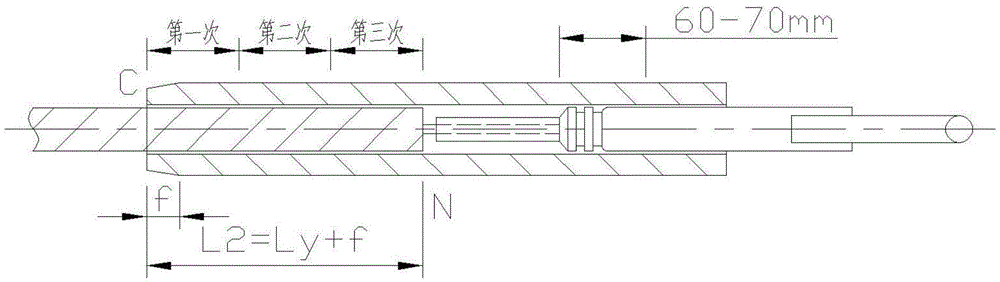

Hydraulic crimping technology forstrain clamp for steel-cored aluminum stranded wire

InactiveCN105490130AGood crimping effectImprove crimping efficiencyConnection formation by deformationAluminiumEnkianthus

The invention provides a hydraulic crimping technology for a strain clamp for a steel-cored aluminum stranded wire. The technology comprises the following steps: peeling off the aluminum stranded wire outside a steel-cored aluminum stranded wire; sleeving an aluminum tube from one end of the steel-cored aluminum stranded wire, and inserting an exposed steel core into an inserting hole from a steel anchor port; pressing and fixing the front part of a steel anchor and the steel core of the steel-cored aluminum stranded wire; marking the position which is 20-30mm to the rear end of the steel anchor from the edge of a final annular groove of the steel anchor asa positioning mark A, and making a positioning mark C on the steel-cored aluminum stranded wire; pushing the aluminum tube to the side of the steel anchor; carrying out crimping by a hydraulic machine, continuously exerting pressure from left to right from the left end of the aluminum tube corresponding to the mark C for at least three times; not crimping an inserting segment, corresponding to the steel core and the steel anchor, of the aluminum tube, and finally exerting pressure once towards the right from the annular groove of the steel anchor. The hydraulic crimping technology has the beneficial effects that the 'Chinese enkianthus' phenomenon at the side of the crimped wire can be avoided by the crimping technology; the wire crimping effect is good; the crimping efficiency is high; and the conductive effect and the born tension after crimping can be ensured.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

A manufacturing process of steel-core aluminium stranded wire

ActiveCN109004487AReduce manual labor intensityNot easy to slipLine/current collector detailsAfter treatmentTreatment results

The invention discloses a manufacturing process of a steel-core aluminium stranded wire, and the manufacturing process comprises the following steps: painting and printing; measuring the depth of an aluminium tube and marking on a steel-core aluminium stranded wire; performing secondary treatment after crimping; and performing secondary treatment on burrs, flash or bending after crimping, after treatment, checking whether a product is qualified, if a treatment result cannot be qualified, performing crimping again. The manufacturing process also comprises the following steps: penetrating a tube; placing the right end of a left side steel-core aluminium stranded wire to be crimped into the aluminium tube and positioning, the right side steel-core aluminium stranded wire being located at thetube orifice of the aluminium tube; performing intertwining; gradually stretching the left end of the right side steel-core aluminium stranded wire into the aluminium tube; gas generated by a piston in a cylinder block being pushed by a support plate being used for clearing the residue and dust in the aluminium tube; a first motor driving the right side steel-core aluminium stranded wire through aT-shaped plate to be wound on the left side steel-core aluminium stranded wire in the aluminium tube; crimping; and utilizing a hydraulic press to crimp the aluminium tube, i.e., realizing the hydraulic pressure welding of the steel-core aluminium stranded wire. The scheme mainly solves the problem that at present a steel-core aluminium stranded wire is easy to slip off an aluminium tube after pressure welding.

Owner:CHONGQING YONGFU WIRE & CABLE CO LTD

Leather-like sheet and process for producing thereof

InactiveUS7601656B2Easy to stretchGood crimping effectDomestic upholsteryLayered productsPolytrimethylene terephthalateEngineering

A leather-like sheet excellent in stretchability which is obtained by integrating by entanglement of a woven or knitted fabric and an ultrafine fiber of 0.0001 to 0.5 dtex, wherein at least one face of the leather-like sheet is substantially composed of said ultrafine fibers, and said woven or knitted fabric consists of a conjugate fiber in which two or more kinds of polyester-based polymers, at least one of which consists essentially of polytrimethylene terephthalate, are stuck along the fiber length direction side-by-side, or a conjugate fiber in which two or more kinds of polyester-based polymers, at least one of which consists essentially of polytrimethylene terephthalate, forms an eccentric sheath-core type conjugate structure, and the fiber constituting the woven or knitted fabric has a twist coefficient of 20000 or below.

Owner:TORAY IND INC

Crimp terminal

ActiveUS9099794B2Good crimping effectIncrease pressureConnections effected by permanent deformationElectrical conductorShortest distance

Concave serrations are provided in an inner surface of a conductor crimping portion of a crimp terminal. A number of circular concave portions are provided in the inner surface of the conductor crimping portion as the concave serrations so as to be scattered in a state of being spaced aside from one another. A diameter of an inner bottom surface of each circular concave portion is set within a range of 0.15 (an error range is ±0.04) mm to 0.8 (the error range is ±0.04) mm. A serration angle between an extension surface of the inner bottom surface and an inner side surface of each circular concave portion is set within a range of 60 to 90 degrees. A shortest distance of a flat surface portion between peripheries of mutually adjacent circular concave portions is set to be 0.17 (the error range is ±0.09) mm.

Owner:YAZAKI CORP

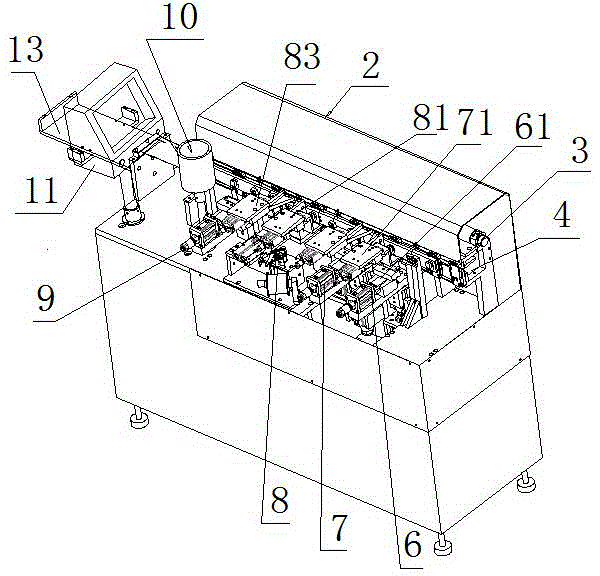

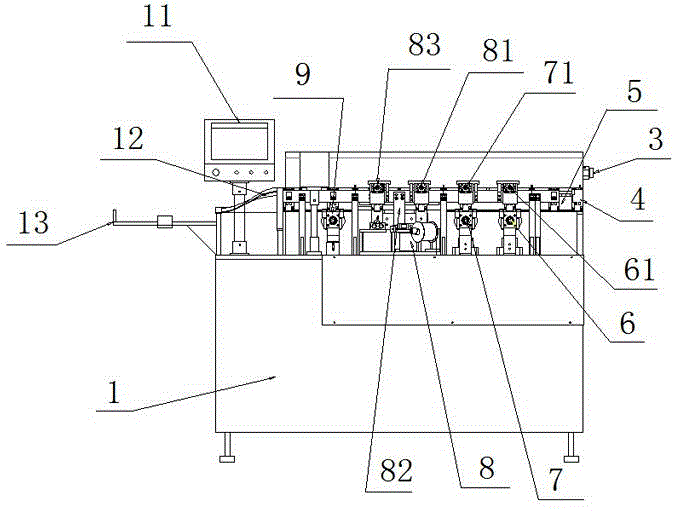

Multi-core cable stripping pre-tinning cutting machine

InactiveCN104868344ASolve the problem of LianxiVersatileLine/current collector detailsSolderingBatch production

The invention provides a multi-core cable stripping pre-tinning cutting machine, comprising a cabinet power distribution cabinet, a wire-through platform, a moving track mechanism, a wire clamping fixture, an optical fiber induction position, a round wire stripping mechanism, a round wire positioning mechanism, a flat wire stripping mechanism, a flat wire positioning mechanism, a soldering flux circulation and tin-feeding mechanism, a soldering flux soaking wire pressing mechanism, a soldering flux soaking pre-tinning lifting mechanism, a pre-tinning wire pressing mechanism, a core wire proportional cutting mechanism, a soldering flux storage bottle, an operation control panel, a wire clamping fixture backward mechanism, and a wire clamping fixture tray. The multi-core cable stripping pre-tinning cutting machine integrates core wire automatic transmission, automatic positioning, automatic stripping, automatic soldering flux soaking, automatic tin scraping, automatic tin blowing, automatic blanking, and is intelligentized in the whole process, and is high in automatic operation degree. The machine is suitable for stripping and pre-tinning operation of round wires and flat wires in various different models and specifications. The machine is high in positioning precision, good in wire pressing effect, high in operation efficiency, high in capacity, and low in cost, and satisfies requirements of batch production of industrialization development.

Owner:汪全鹏

Shell product full-automatic pressing connecting and assembling mechanism

PendingCN110560585AReduce adjustmentImprove crimp assembly efficiencyMetal-working feeding devicesStripping-off devicesEngineeringMaterial transfer

Owner:苏州鼎成精密科技有限公司

Copper Alloy Article Containing Polyester-Based Resin and Method for Producing the Same

InactiveUS20190184682A1Sufficient bonding strengthGood crimping effectLamination ancillary operationsLayered product treatmentPolyesterCopper alloy

Owner:ADVANCED TECH +1

Food packaging carton adsorption folding and indentation device

InactiveCN111844893AGuaranteed linearityAvoid wrinklesBox making operationsPaper-makingCardboardReduction drive

The invention discloses a food packaging carton adsorption folding and indentation device, and relates to the technical field of packaging carton folding and indentation. A storage board is fixedly arranged between four groups of stand columns through reinforced fastening bolts. A motor is fixedly arranged on the left side of the top of the storage board, a reducer is fixedly arranged at the output end of the motor, a mounting disc is fixedly arranged at the output end of the reducer, mounting seats are uniformly integrally formed on the outer wall of the mounting disc, extruders are arrangedon the mounting seats in a threaded mode, indentation knives are fixedly arranged at the ends of the extruders, electric control boxes are fixedly arranged at the tops of the rear side walls of the stand columns on the rear sides, pressing devices are fixedly arranged on the front side and the rear side of the bottom of the storage board, guiding wheels are fixedly arranged at the bottom ends of the pressing devices, blower plates are fixedly arranged on the front side and the rear side of the bottom of a workbench, a cardboard can be absorbed, and the cardboard is prevented from deviating inthe indentation process, so that the indentation strength is improved, and the effect of folding and indentation is improved.

Owner:广西天品科技有限公司

Mounting machine for chip processing

InactiveCN112382586AReduce gapImprove conductivitySemiconductor/solid-state device manufacturingStructural engineeringMechanical engineering

The invention discloses a mounting machine for chip processing in the technical field of chip processing and production, which comprises a base, conveying guide rails arranged on the two sides of thetop end of the base, a horizontal groove formed in the base, a screw rod arranged in the horizontal groove, a screw rod sliding block slidably sleeving the screw rod, and stand columns arranged on thetwo sides of the top end of the base, wherein thescrew rod sliding block penetrates through the base and a substrate, the stand columns are connected with push rods, a supporting plate is arranged between the two sets of pull rods, a front-back guide rail is arranged on the supporting plate, a chip is placed on the front-back guide rail, a transverse rod is arranged between the top ends of the two sets of stand columns, a fixing base is arranged in the middle of the transverse rod, and the bottom end of the fixing base is connected with a front-back guide rod which is sleeved with a front-back sliding block in a sliding mode. The bottom end of the front-back sliding block is connected with a clamping block through a connecting rod, the left side stand column is connected with a left supporting rod, a glue dripping barrel is arranged on the left supporting rod, the right side stand column is connected with a right supporting rod, and the right supporting rod is slidably sleeved with acrimping device, so that overflowing glue can be effectively utilized during mounting, the mounting attractiveness is enhanced, and the mounting quality is improved.

Owner:郝建兵

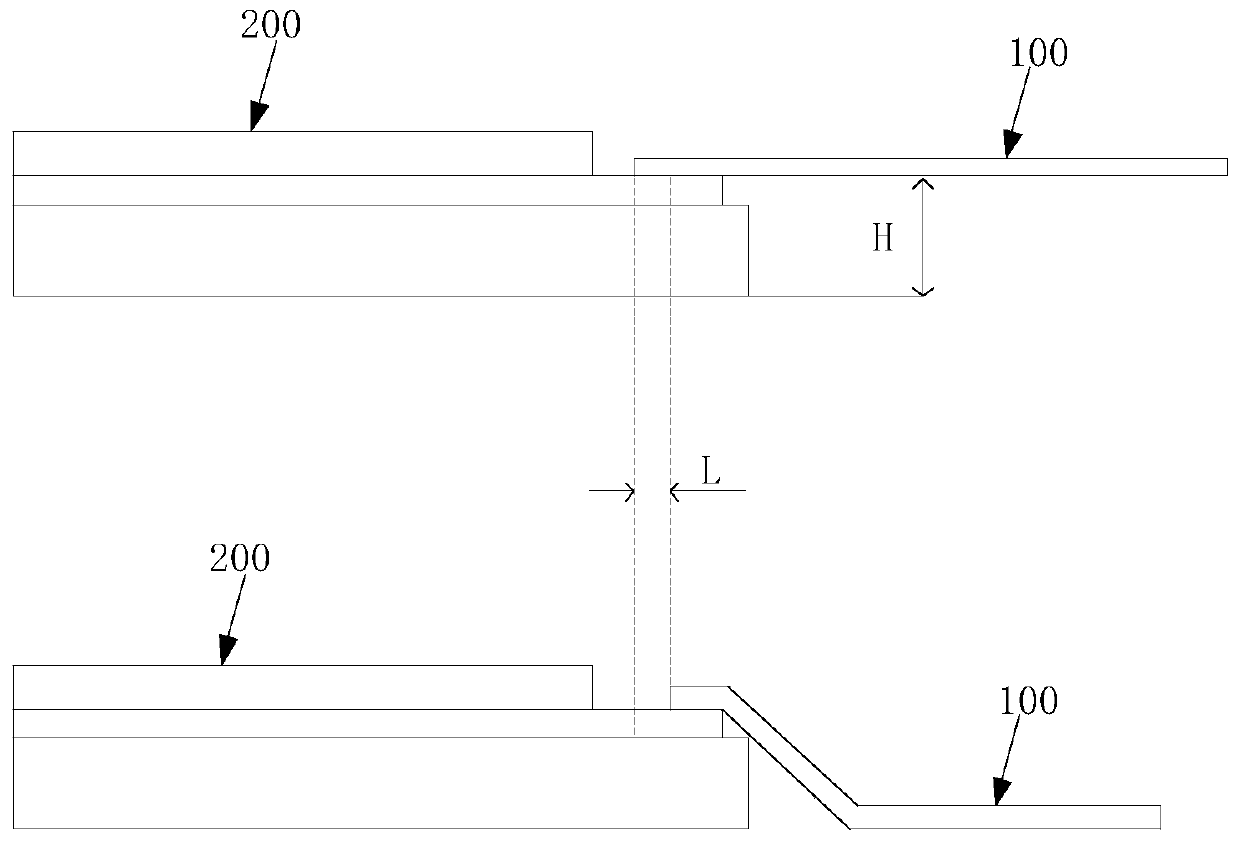

Flexible circuit board and test tool

ActiveCN110191578ACompensation for altitude differenceAvoid bend offsetCircuit bendability/stretchabilityStatic indicating devicesFlexible circuitsElectrical connection

The invention relates to the technical field of circuit testing and discloses a flexible circuit board and a test tool. The flexible circuit board includes a flexible body having a first crimping portion and an extension portion, wherein the first crimping portion is configured to be press-fitted into the second crimping portion of a substrate to be tested; a first electrical connection structurelocated at the first side of the flexible body, disposed on the first crimping portion and configured to be press-fitted into the a second electrical connection structure on the second crimping portion; and a support structure located on the first side of the flexible body and including a first support portion and a second support portion, wherein the first support portion is disposed on the extension portion and is configured to support the extension portion in a press-fit state to make the extension portion have the same horizontal height as the first crimping portion, and the second support portion is disposed on the first crimping portion and is configured to be supported between the first crimping portion and the second crimping portion in a press-fit state to isolate the first crimping portion from the second crimping portion. The flexible circuit board can be improved in press-fit effect and test success rate in a pseudo-pressure test.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

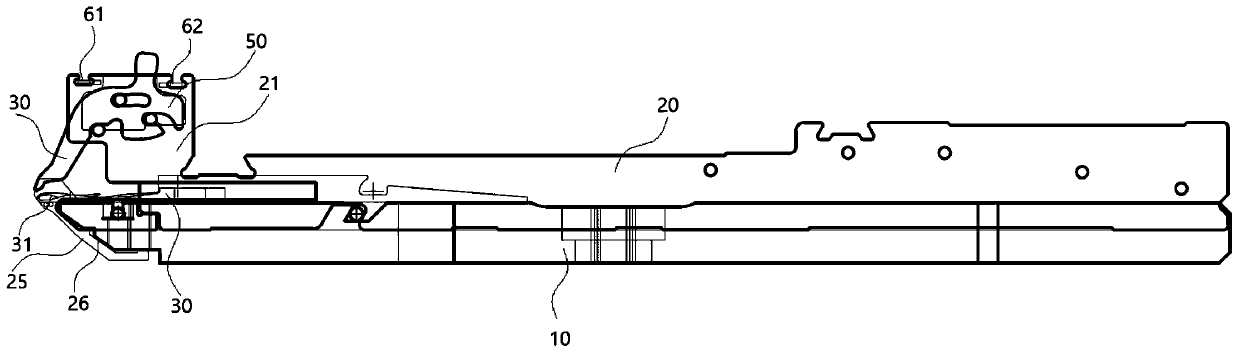

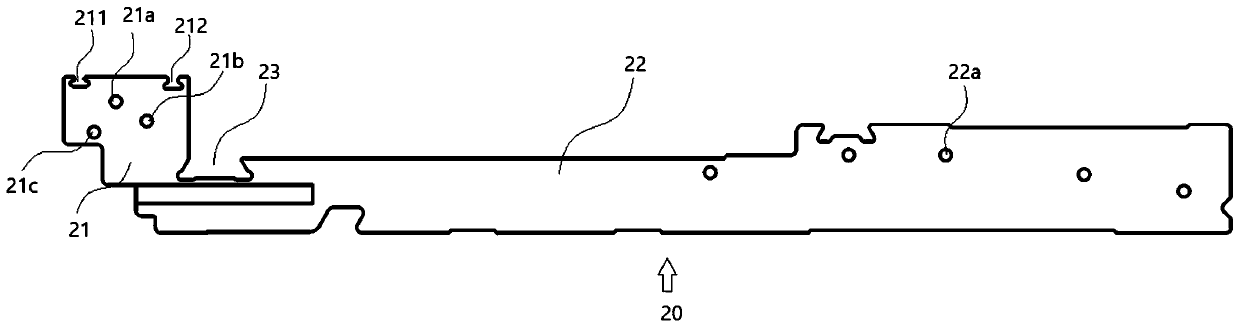

Crimping terminal

ActiveUS9601839B2Good crimping effectImprove electrical reliabilityConnections effected by permanent deformationConnection contact member materialElectrical conductorEngineering

A crimping terminal includes a conductor crimping portion having a U-shaped cross section. The conductor crimping portion includes a base plate portion and a pair of conductor caulking pieces. On an inner surface of the conductor crimping portion, a conductor is disposed, being exposed to a distal end of an aluminum electric wire. The pair of conductor caulking pieces, extending upwardly from both side edges in a longitudinal direction of the base plate portion, are bent inwardly so as to wrap the conductor of the aluminum electric wire to caulk the conductor such that the conductor is in close contact with the inner surface of the base plate portion. On the inner surface of the conductor crimping portion, a protruding indent is provided so as to extend continuously.

Owner:YAZAKI CORP

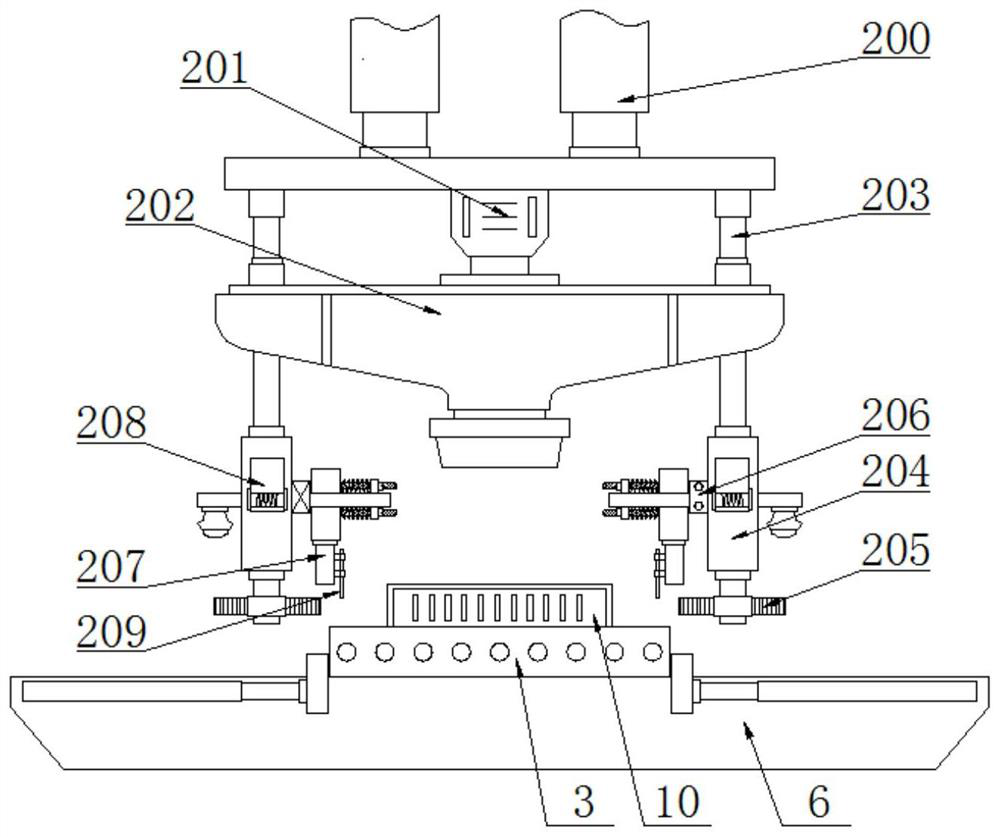

Welding fixing device of gas meter room cover

PendingCN110181216AFast assemblyGood crimping effectWelding/cutting auxillary devicesAuxillary welding devicesGas meterEngineering

The invention discloses a welding fixing device of a gas meter room cover. The welding fixing device is used for welding fixing of the room cover on a movement body. According to the technical measure, in the welding fixing device of the gas meter room cover, a gas meter comprises the movement body, two separated distribution rooms are arranged in the movement body, and the room cover is arrangedon openings of the distribution rooms. The welding fixing device is characterized in that multiple connecting columns are integrally formed in the positions, at the positions of opening edges of the distribution rooms, of the movement body, the connecting columns penetrate through connecting holes in the room cover and stretch to the outer side, the welding device is used for welding the ends of the connecting columns from the side face of the movement body, and then the room cover is connected and fixed to the movement body.

Owner:台州杜瑞仪表有限公司

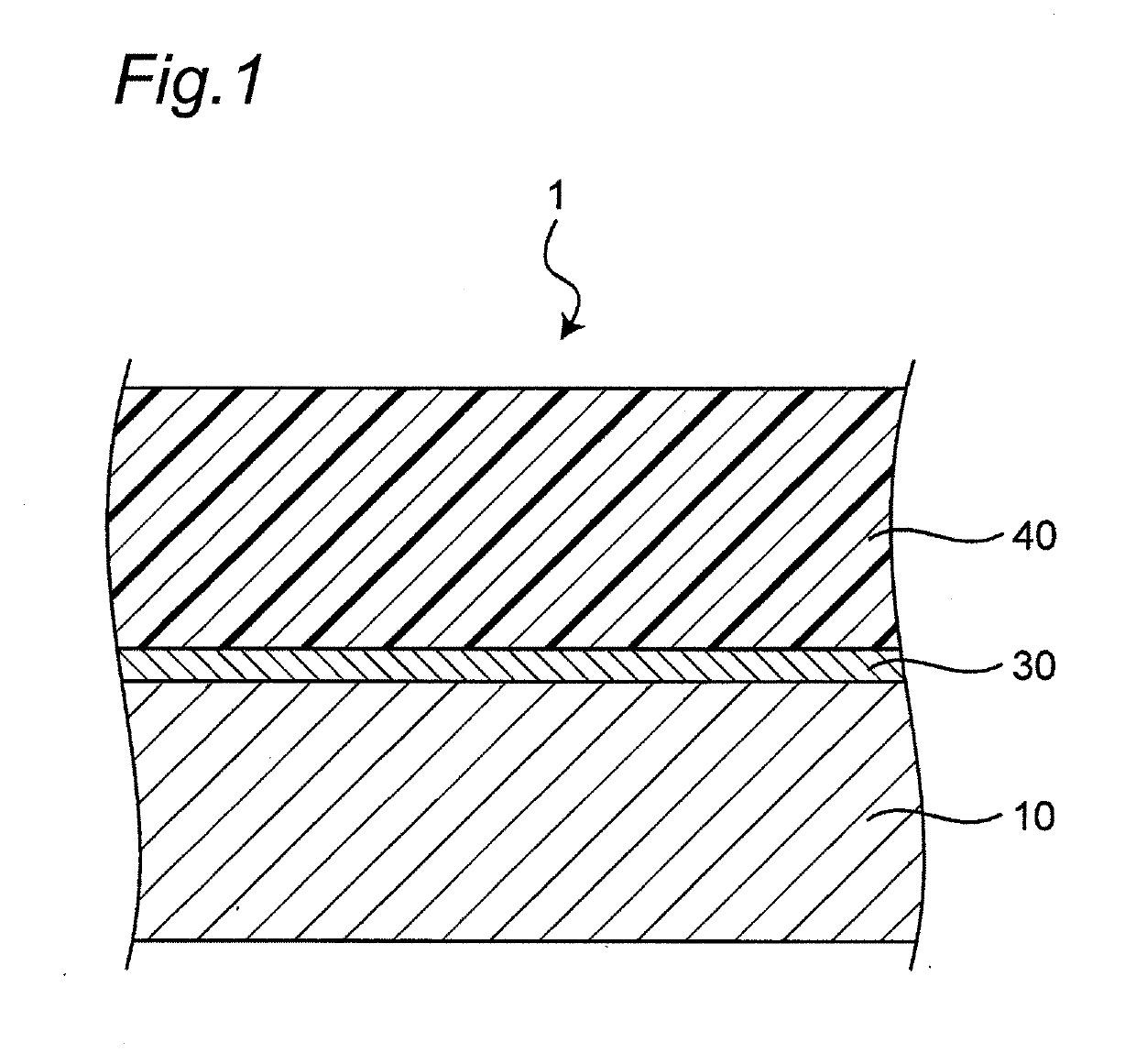

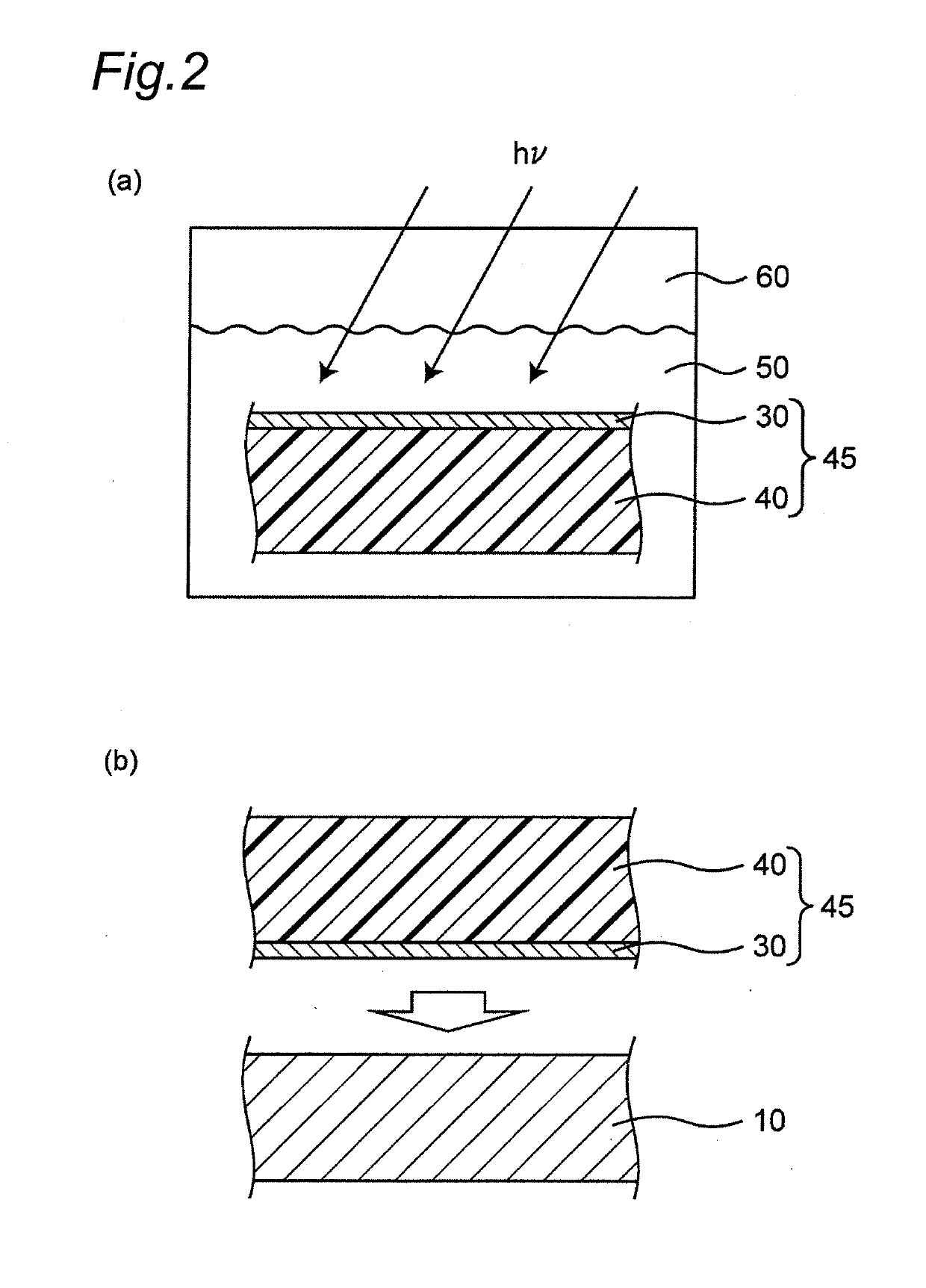

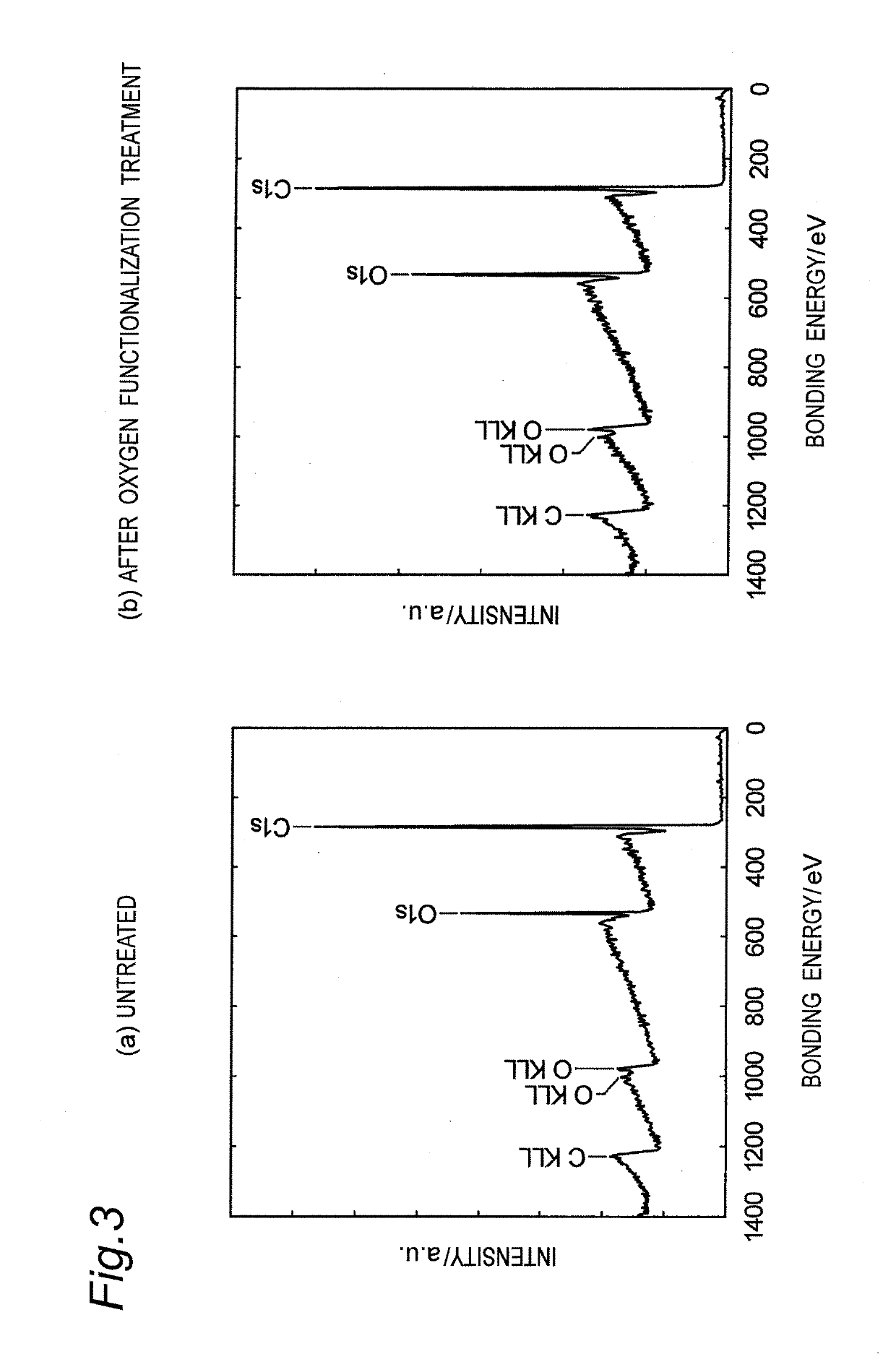

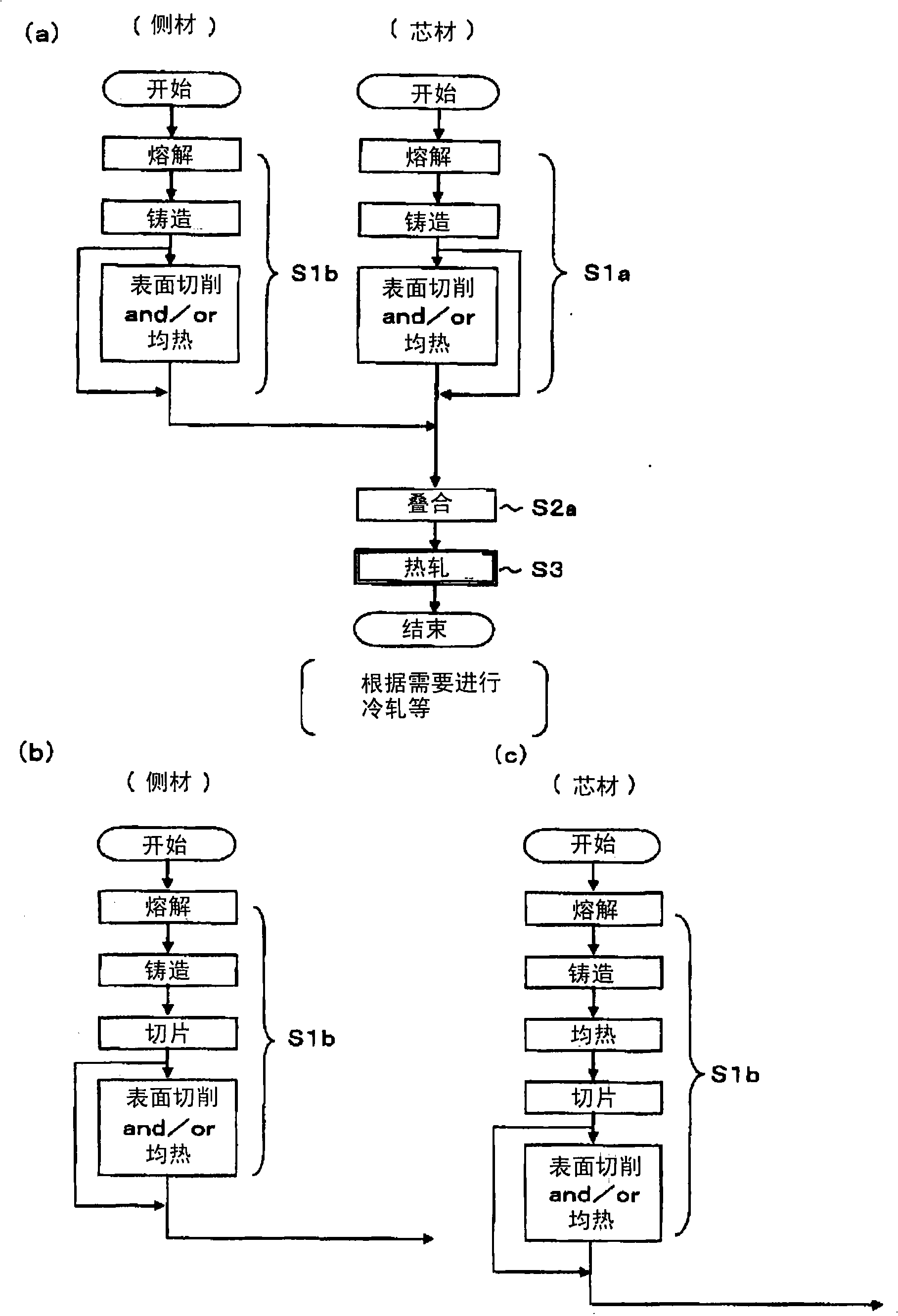

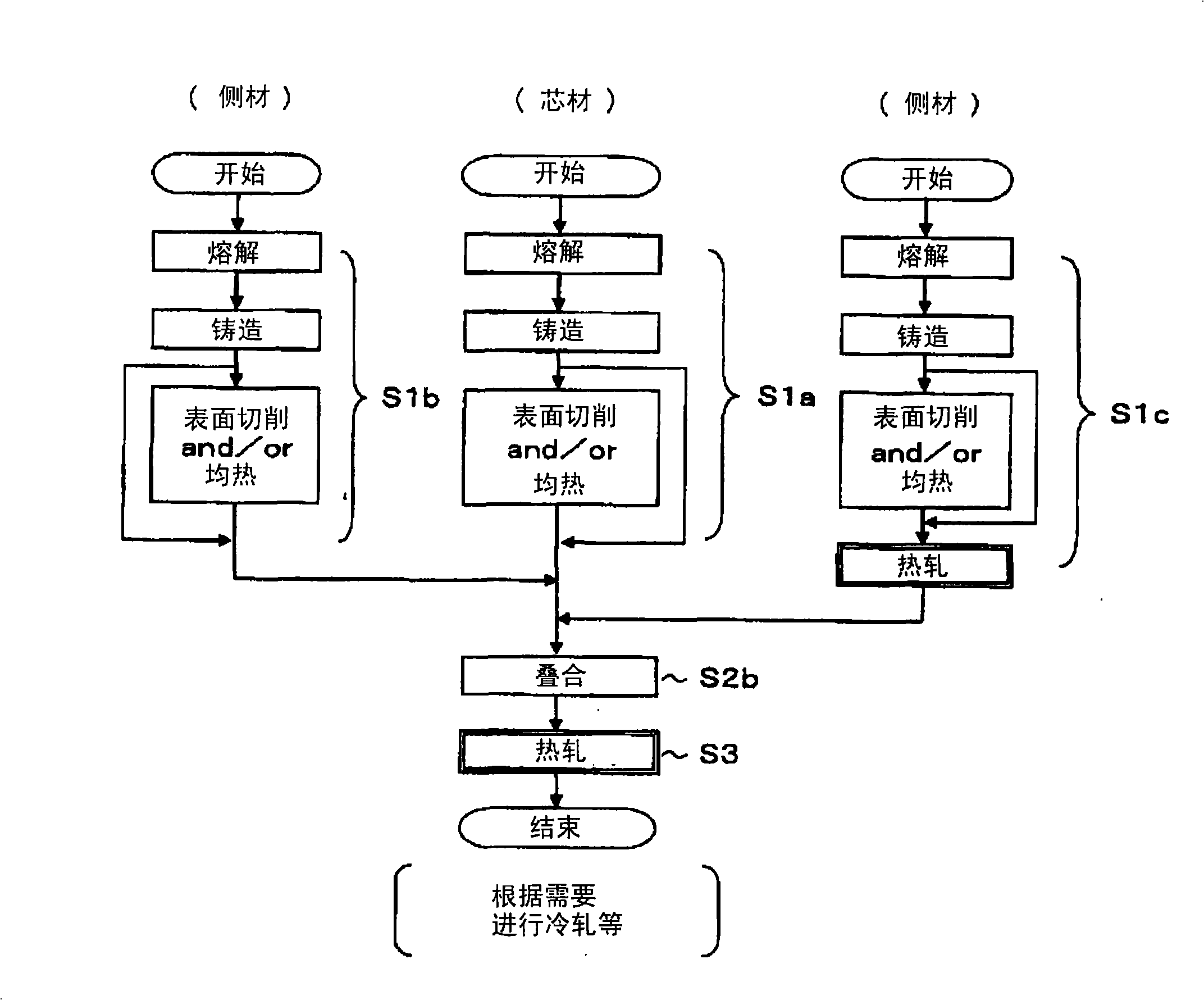

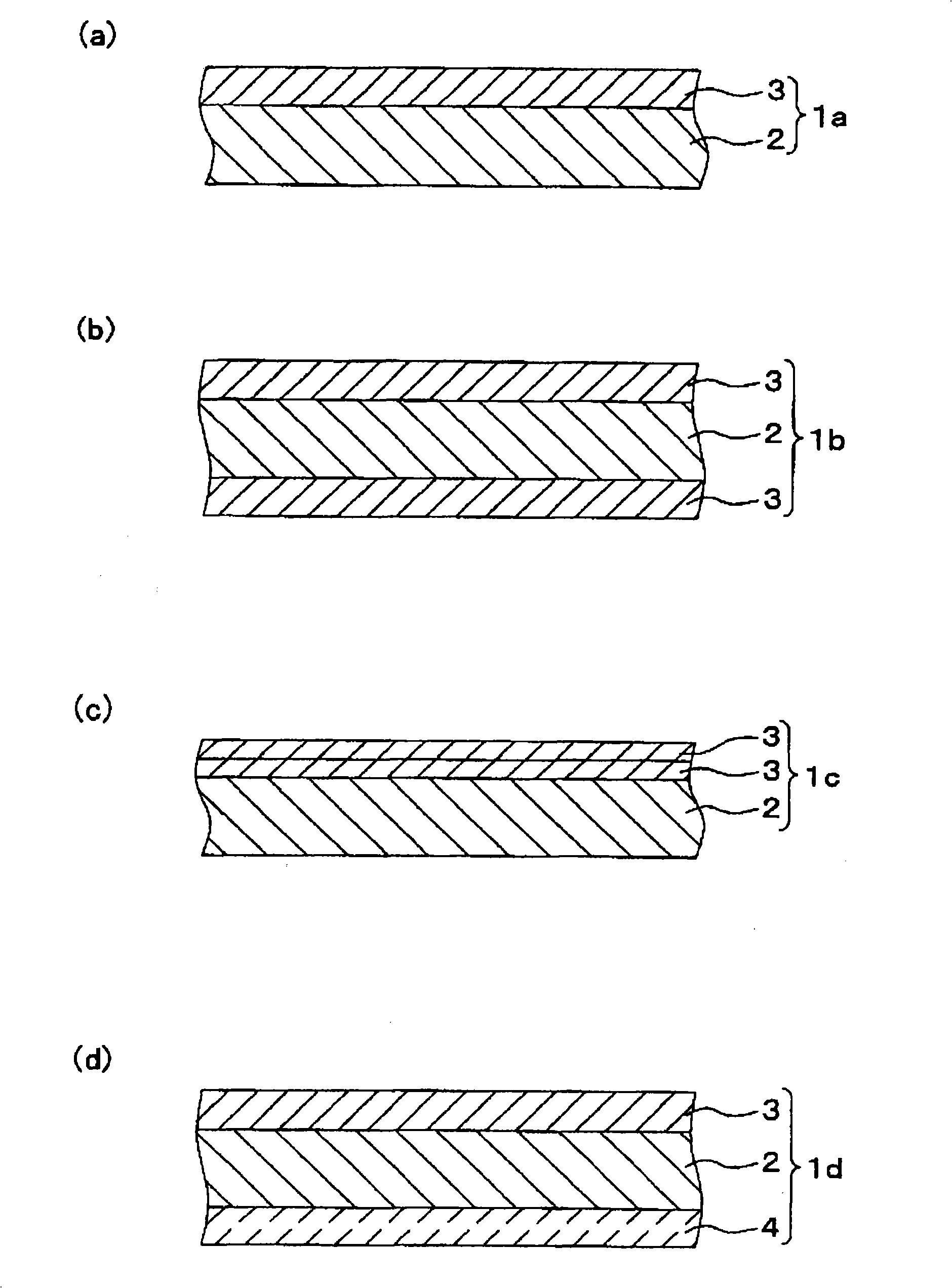

Process for producing clad material and equipment therefor

ActiveCN101296774AImprove corrosion resistanceReduce thicknessWelding/cutting media/materialsWelding/soldering/cutting articlesMaterials preparationSurface conditions

A process for producing a clad material, which excels in productivity, facilitating control of the surface condition and flatness of side material member, and which suppresses bonding failure; and equipment therefor. There is provided a process for producing a clad material composed of a core material and, superimposed on one surface or both surfaces thereof, one or two or more side materials, comprising the clad material preparation step of preparing a core material ingot through melting and casting of a metal for core material in the core material preparation step and preparing a side material ingot through melting and casting of a metal for side material with a component formulation different from that of the metal for core material in the side material preparation step; the laminating step of laminating one surface or both surfaces of the core material ingot at given position with the side material ingot as a side material to thereby obtain a laminate; and the cladding hot rolling step of carrying out hot rolling of the laminate to thereby obtain a clad material.

Owner:KOBE STEEL LTD

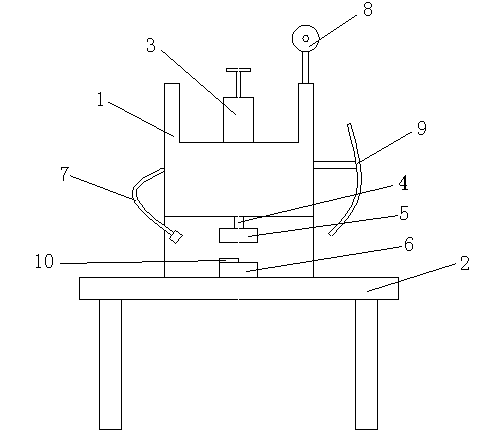

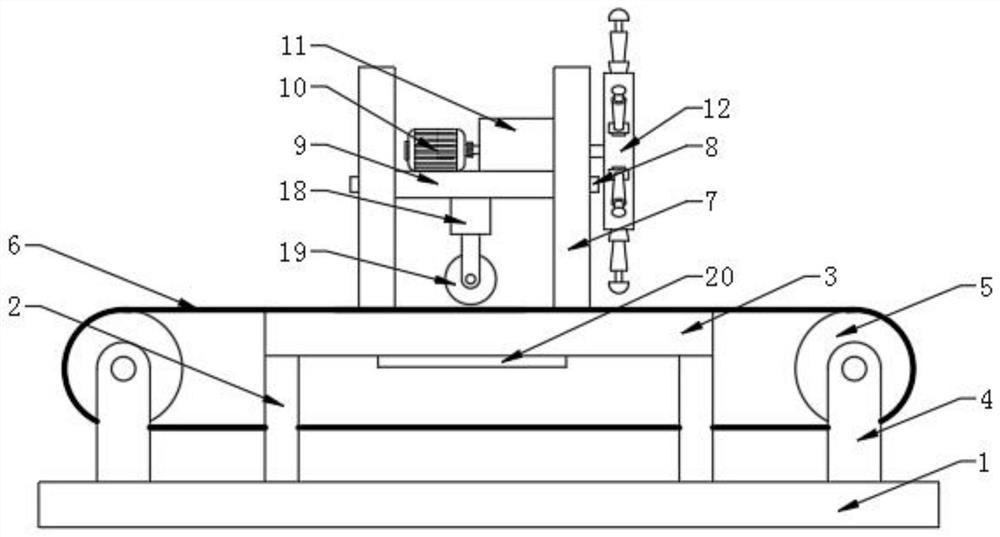

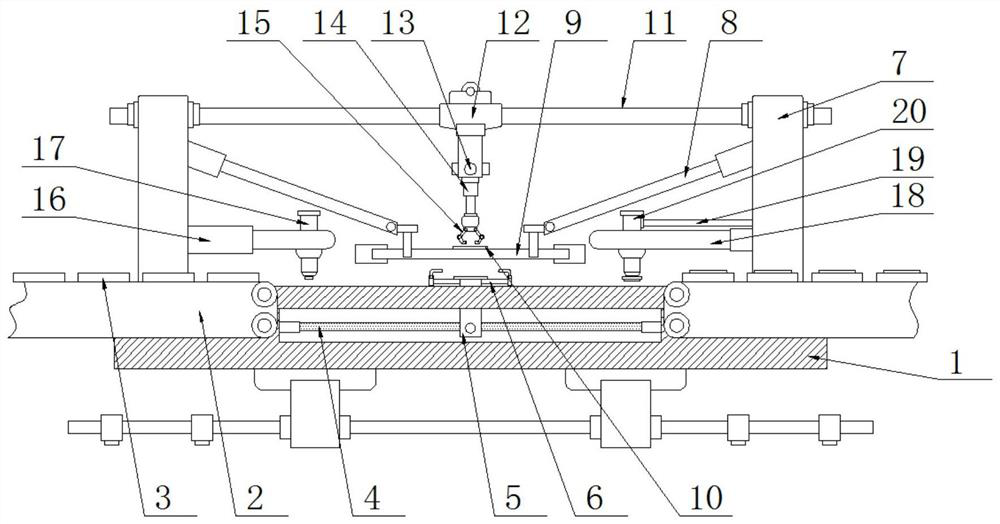

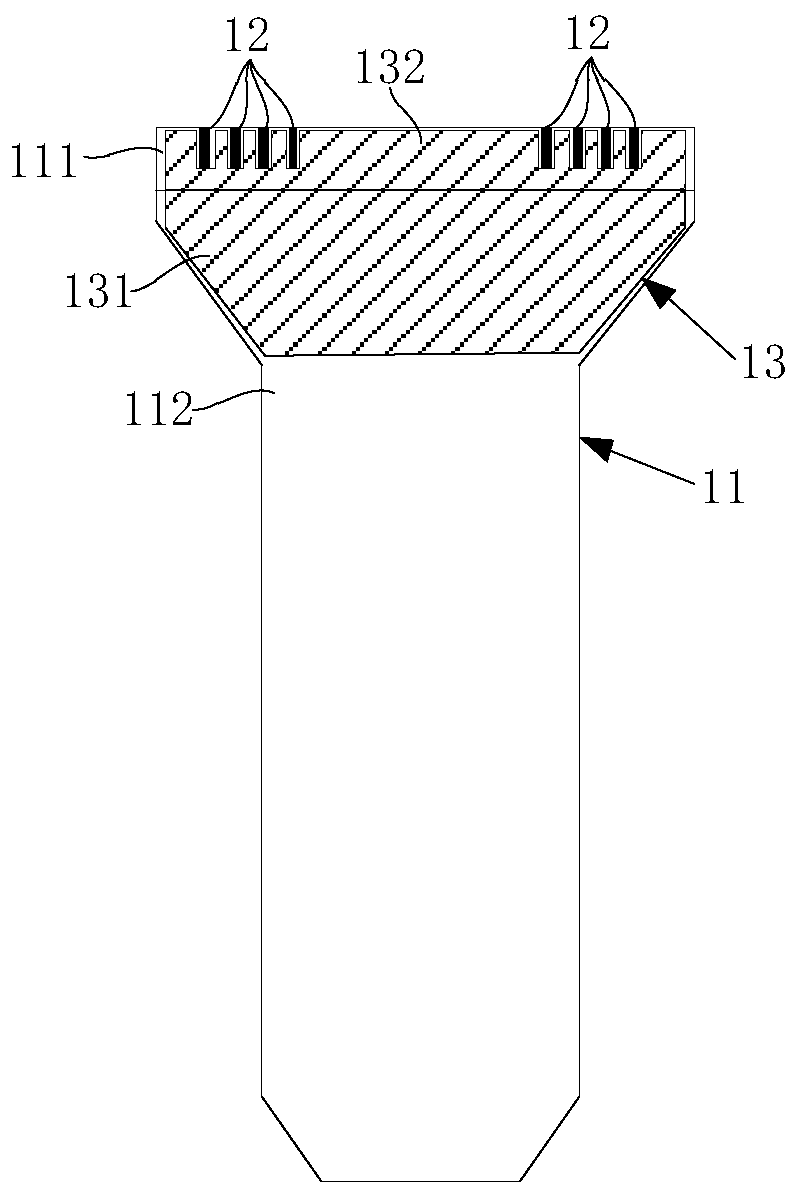

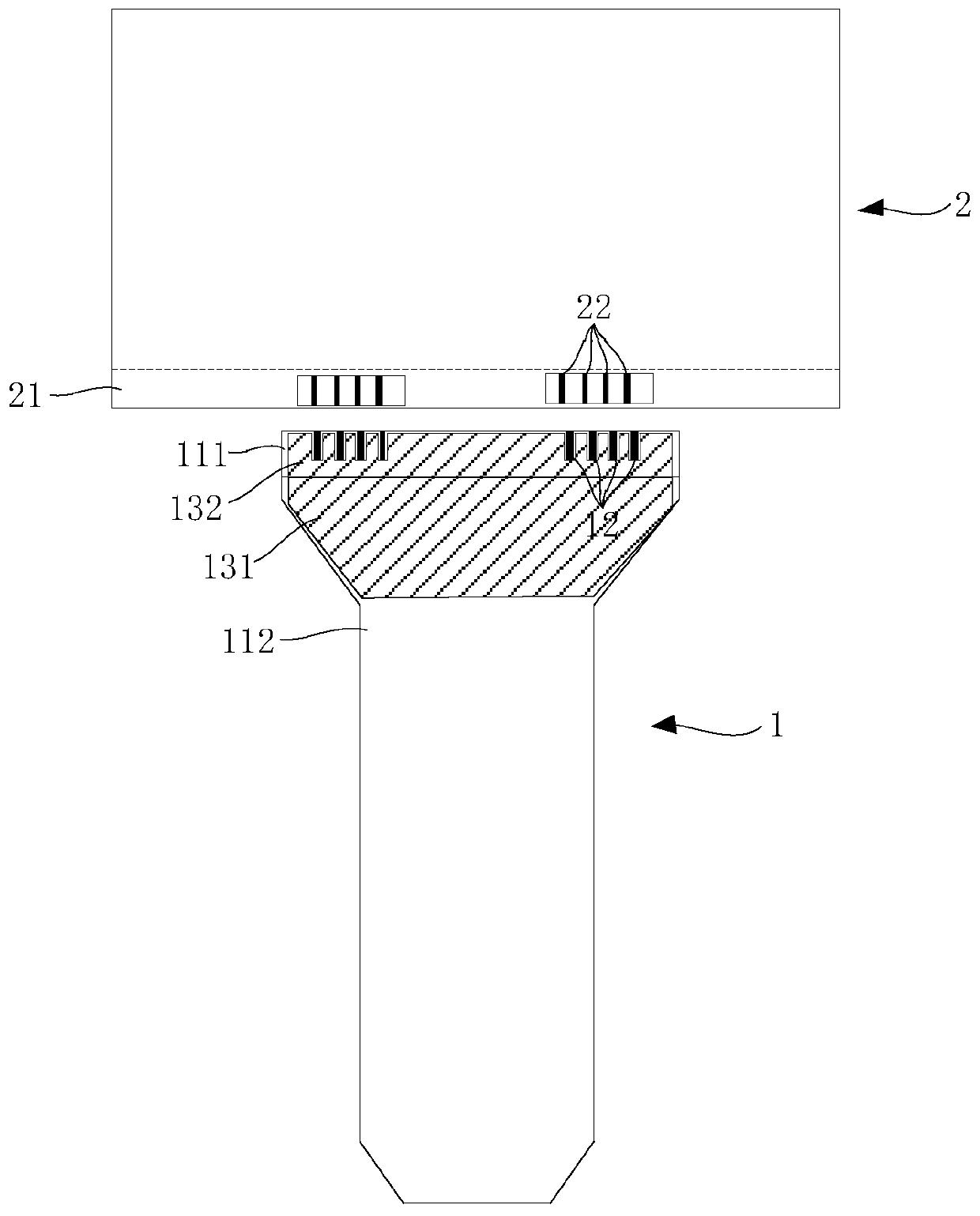

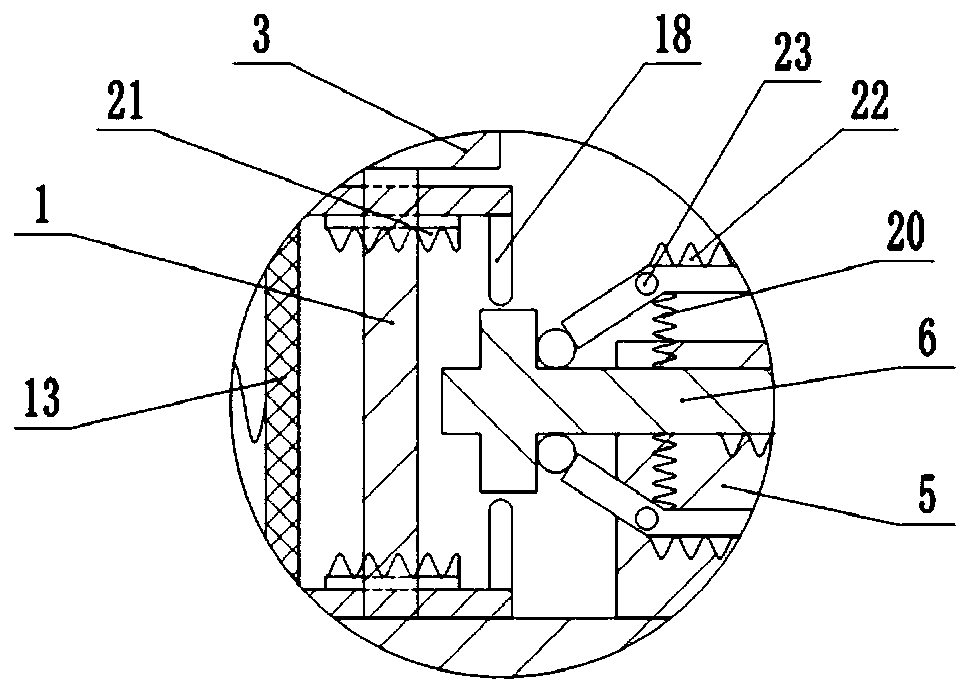

Crimp structure of aluminum steel cored wire

ActiveCN109066255BIncrease contact surfaceGood crimping effectLine/current collector detailsArchitectural engineeringTube placement

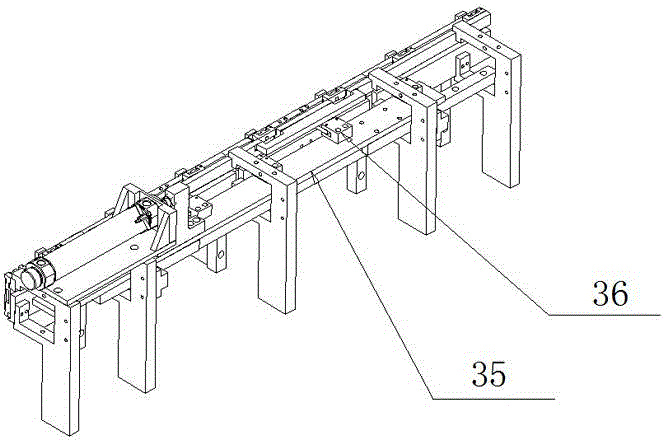

This patent discloses a crimping structure of a steel core aluminum strand, including the rack, Conductor placement table, aluminium tube placement table, Wire feed unit and hydraulic unit, Conductorplacement table, An aluminum tube placing table and a wire feeding unit are sequentially fixed on the rack from left to right, A lead feed unit include a side plate, Support plate, first motor, A T-shape plate and a drive mechanism, the side panels are secured to the frame, A support plate is slidably connected to that side plate, the T-shaped plate is fixedly connected with the output shaft of the first motor, The upper part of the T-shaped plate is provided with a through groove through which the steel core aluminum strand can pass, and the driving mechanism can push the support plate to move to the left. The hydraulic unit comprises a top plate, an air cylinder and a hydraulic press, wherein the top plate is fixed on the frame, the air cylinder is fixed on the top plate, the hydraulic press is fixedly connected with the output shaft of the air cylinder, and the hydraulic unit is positioned directly above the aluminum pipe placing table. The invention can complete the crimping step by using the mechanical movement, and solves the problem that the steel core aluminum strand is easy to slide out of the aluminum pipe after being crimped.

Owner:CHONGQING YONGFU WIRE & CABLE CO LTD

Yarn compressing device for hosiery knitter

InactiveCN110079930ATo achieve the compression effectImprove compaction efficiencyWeft knittingYarnEngineering

The invention discloses a yarn compressing device for a hosiery knitter. The yarn compressing device comprises bottom plates, wherein a first hydraulic cylinder and a second hydraulic cylinder are respectively fixed on outer walls of tops of the two bottom plates through bolts; a same base is fixed on the outer walls of opposite sides of the two bottom plates through bolts; mounting plates are fixed on extended rods of both the first hydraulic cylinder and the second hydraulic cylinder through bolts; two fixing bearings are fixed on the outer walls of front surfaces of the sides, close to thefirst hydraulic cylinder and the second hydraulic cylinder, of the two mounting plates through bolts; a first rotating shaft and a third rotating shaft are respectively inserted into circumferential inner walls of the two fixing bearings; a first yarn wheel and a third yarn wheel are respectively connected with circumferential outer walls of the first rotating shaft and the third rotating shaft ina sleeving manner. By adopting the yarn compressing device, the compressing efficiency of the overall device is improved, the compressing angle can be adjusted, compressing effects in different directions can be achieved, the practicability of the overall device can be improved, yarns can be kept smooth when being conveyed by the yarn wheels, and blocking situations can be avoided.

Owner:诸暨市宏光机械配件厂

Sealing washer pressing connection machine

InactiveCN109382647AImprove crimping efficiencyGood crimping effectMetal working apparatusEngineeringSlide plate

The invention relates to the field of sealing piece mounting equipment, and provides a sealing washer pressing connection machine. The pressing connection machine comprises a base plate, a fixing plate vertically welded to the rear side of the base plate, a sealing ring fixing mechanism fixed to the upper end of the base plate and a pressing connection mechanism which is installed at the front side of the fixing plate and located at the upper end of the sealing ring fixing mechanism. According to the sealing ring pressing connection machine, the sealing ring is placed at a first fixing block,then a sealing washer is placed in an annular groove of the sealing ring, a first pushing air cylinder is controlled to move the sealing ring and the sealing washer to the lower end of a lifting plate, and then a second pushing air cylinder is controlled to conduct pressing connection accordingly. The sealing washer pressing connection machine is novel and ingenious in design, the pressing connection efficiency of the sealing washer is high, the pressing connection effect is good, and the improvement of the production efficiency is facilitated; it can be ensured that a first sliding plate cannot fall off through the arrangement of a first stopping block, and through the arrangement of a second stopping block, it can be ensured that the sealing ring cannot be damaged in the pressing connection process.

Owner:嘉善浩辰机械密封有限公司

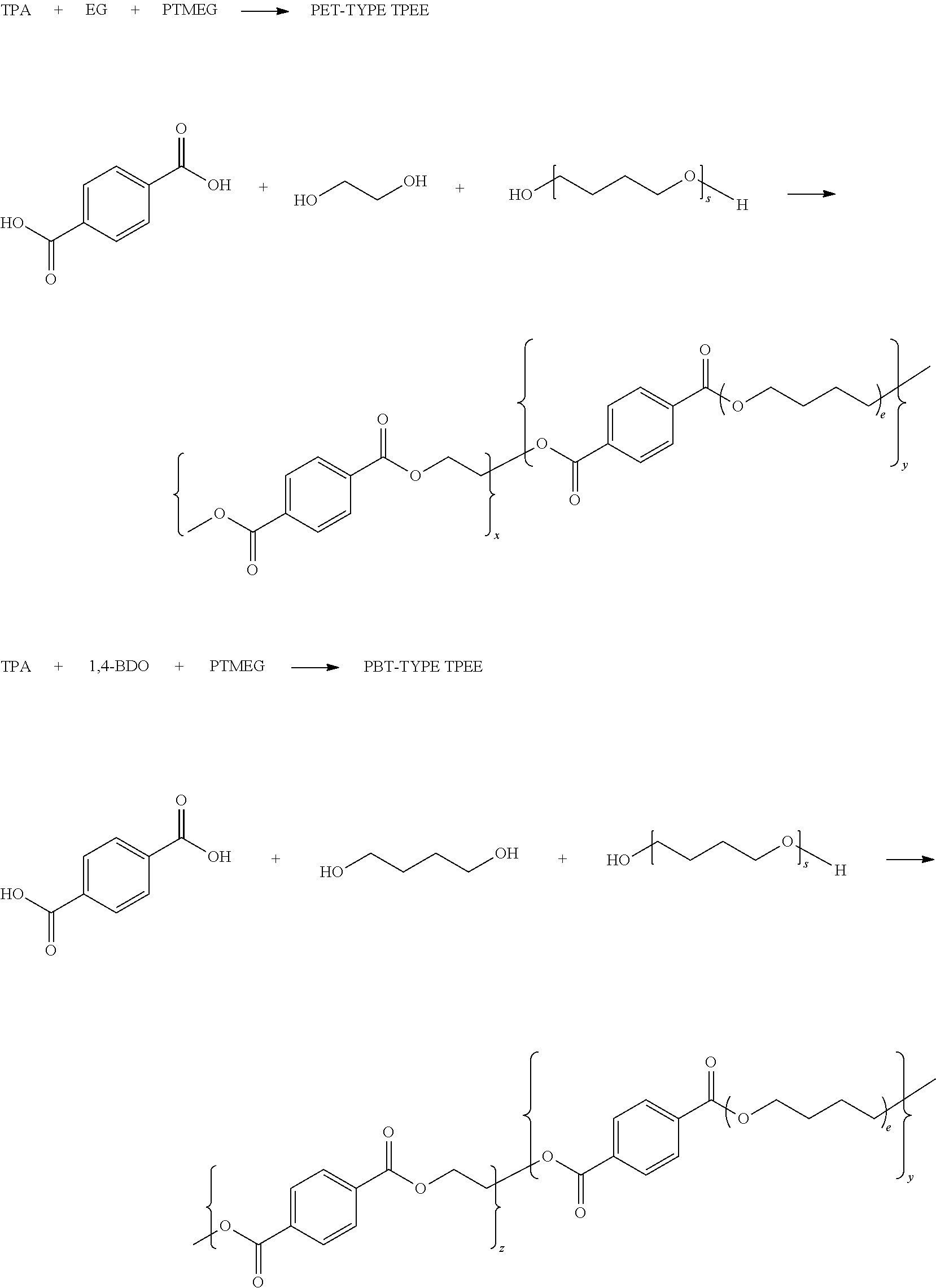

Bicomponent conjugate fibers, complex yarns and fabrics having high crimping property

InactiveUS20160222549A1Good crimping effectIncrease elasticityWoven fabricsConjugated synthetic polymer artificial filamentsPolyesterChemistry

The present invention relates to bicomponent conjugate fibers having excellent crimping property, comprising: (A) a thermoplastic polyester elastomer (TPEE) as a first component, and (B) a polyester polymer as a second component. The present invention also relates to yarns and fabrics comprising said bicomponent conjugate fibers.

Owner:SHINKONG SYNTHETIC FIBERS

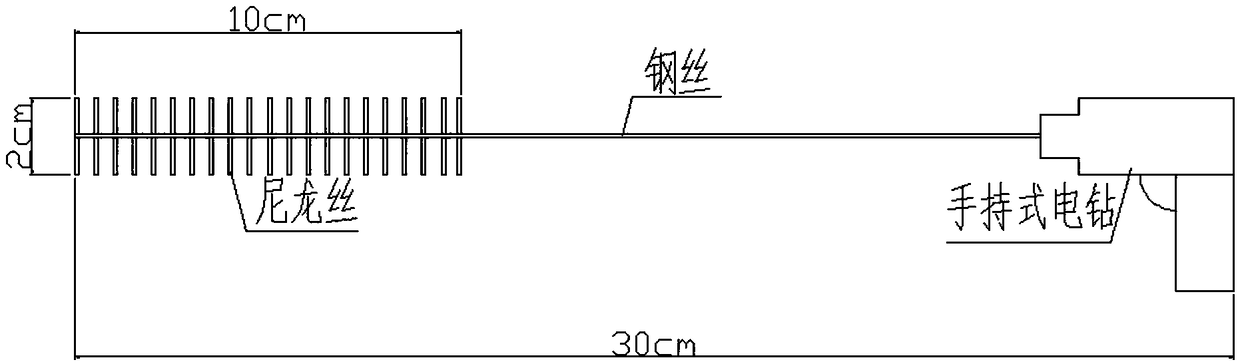

Steel anchor pipe inner wall cleaning brush

PendingCN108523400AThere will be no phenomenon of falling into the tubeImprove operational safetyBrush bodiesHollow article cleaningDrill bitEngineering

The invention discloses a steel anchor pipe inner wall cleaning brush. The cleaning brush comprises a hand-holding drill, a brush body and a brush head, wherein the brush head is arranged on the top of the brush body, and the bottom of the brush body is connected with the drill bit of the hand-holding drill; the connection manner of the brush body and the drill bit of the hand-holding drill is oneof threaded connection or clamping connection; the brush head is composed by nylon filaments which are twisted on the top of the brush body. The cleaning brush is a device which can be used for multiple times, electric cleaning is not strength consuming, and the cleaning brush has excellent application prospect in wire construction.

Owner:GUANGDONG POWER GRID CO LTD +1

Efficient swing sinker of computerized flat knitting machine

ActiveCN111235740AAvoid floating yarn problemsGood crimping effectWeft knittingStructural engineeringMechanical engineering

The invention discloses an efficient swing sinker of a computerized flat knitting machine. A sedimentation hinge mounting part is provided with a first sliding part, a second sliding part and a thirdsliding part; a first hinged hole, a second hinged hole and a third hinged hole in limited, sliding and hinged matching with the first sliding part, the second sliding part and the third sliding partare formed in the front end of an inserting piece on a faller of the computerized flat knitting machine for forming a reliable and stable triangular sliding hinged structure; an inserting piece hingedmounting block is adopted at the front end of the inserting piece, and the inserting piece hinged mounting block is mounted and hinged with the sinker in a matched mode through a separating piece; and the sinker is located between the inserting piece hinged mounting block and the separating piece. Stable movement track of the sinker is ensured, so that a reliable thread pressing effect is achieved; and meanwhile, the efficient swing sinker adopts an integrally formed part, is simple in structure and firm in installation, does not cause the problem of loosening or accidental play, and is convenient and efficient in processing, mounting and detaching procedures.

Owner:常熟创富针织机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com