Welding fixing device of gas meter room cover

A technology for fixing devices and gas meters, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problem that the accuracy of the preparation of the clamping structure cannot be well guaranteed, the air tightness of the distribution chamber cannot be well guaranteed, and the The problem of slow assembly speed, etc., can ensure the air tightness, good connection firmness, and improve the effect of crimping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

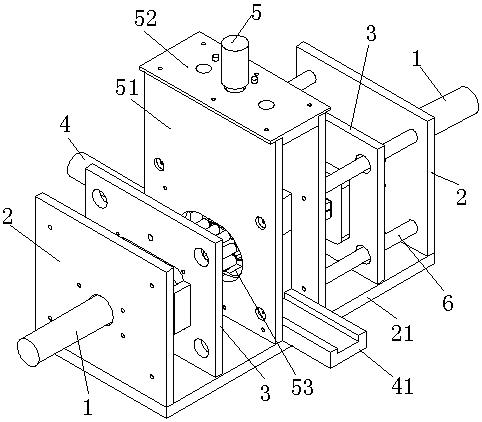

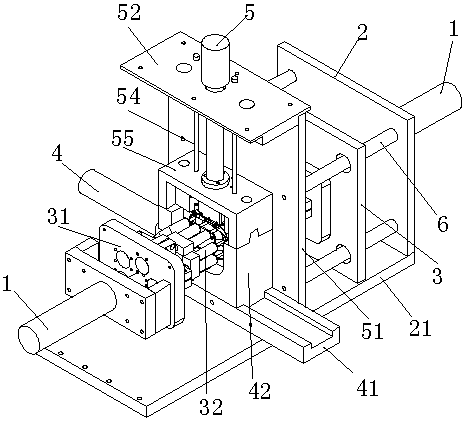

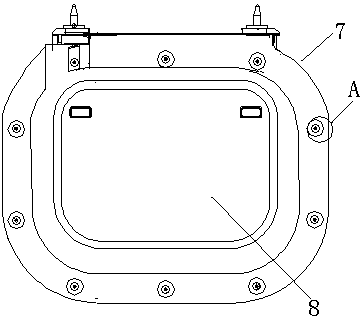

[0022] With reference to the accompanying drawings, the gas meter chamber cover welding and fixing device is used to weld the connection structure between the chamber cover 8 and the core body 7, so as to realize the stable connection of the chamber cover 8 to the core body 7. The gas meter includes a core body 7, which is an integrally formed piece of plastic material. Two separate distribution chambers are formed in the core body 7 , one distribution chamber has an opening, and the two openings face opposite sides of the core body 7 respectively. A chamber cover 8 is provided at the opening of the dispensing chamber so that the dispensing chamber is hermetically sealed. The distribution chamber has an air inlet and an air outlet. The gas enters the distribution chamber from the inlet and enters the outlet pipe from the outlet. When the gas flows through the distribution chamber, it will push the valve in the distribution chamber to move. The valve passes through the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com