Hydraulic crimping technology forstrain clamp for steel-cored aluminum stranded wire

A steel-cored aluminum stranded wire and strain-resistant clamp technology, which is applied in the field of technology, can solve the problems of reduced wire tension, unsightly appearance, and "lantern flowers" to achieve high crimping efficiency, good crimping effect, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

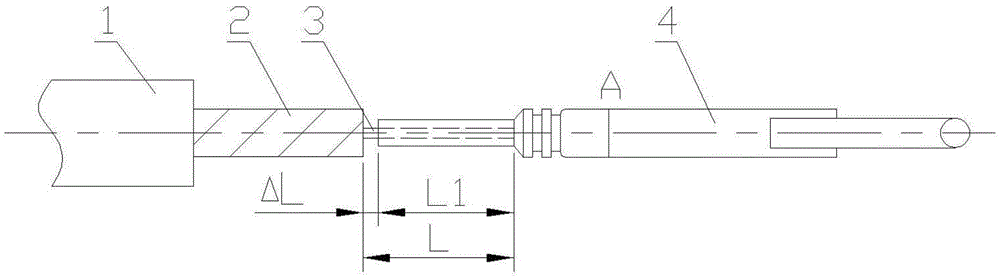

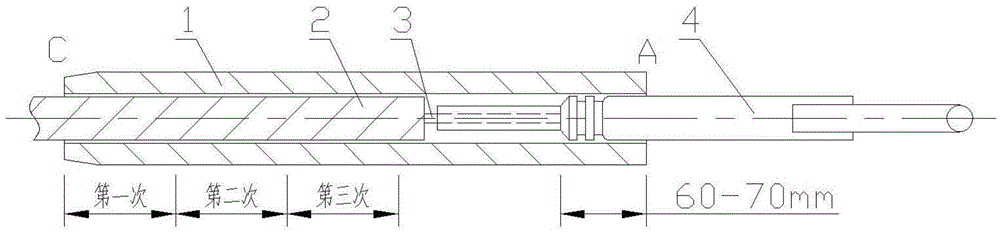

[0033] Such as figure 1 and figure 2 As shown, the hydraulic crimping process of a steel-cored aluminum stranded wire tension clamp related to the present invention includes the following steps:

[0034] 1. Peel off the aluminum stranded wire outside the steel cored aluminum stranded wire 2, so that the length of the leaked steel core 3 is L=L1+△L; where L1=the length of the socket to be connected to the steel anchor 4; the length of △L is 8-12mm .

[0035] 2. Insert the aluminum tube 1 for crimping from the steel core 3 end of the steel-cored aluminum stranded wire 2, and then insert the steel core 3 leaked from the steel-cored aluminum stranded wire 2 into its socket from the steel anchor 4 port, insert Rotate and push in along the stranding direction of the steel core 3, until the end of the steel core 3 touches the bottom of the socket of the steel anchor 4, that is, the distance from the end of the steel anchor 4 to the end of the aluminum strand of the steel core alum...

Embodiment 2

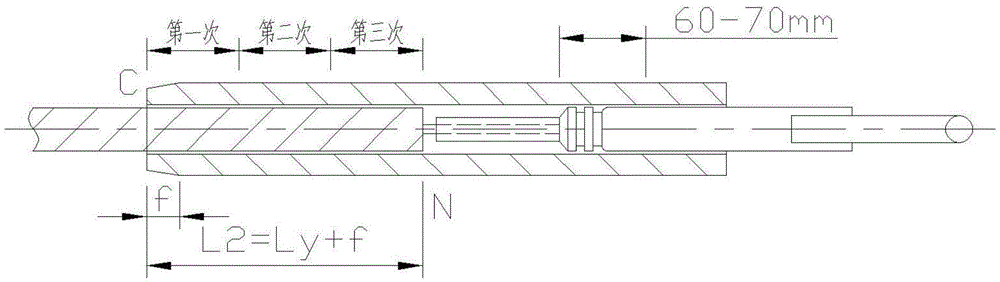

[0040] Such as figure 1 and image 3 As shown, the present invention discloses a hydraulic crimping process of steel-cored aluminum stranded wire tension clamps, which includes the following steps:

[0041] 1. Strip the aluminum stranded wire outside the aluminum stranded wire 2, so that the length of the leaked steel core 3 is L=L1+△L; where L1=the length of the socket to be connected to the steel anchor; the length of △L is 8-12mm.

[0042] 2. Insert the aluminum tube 1 for crimping from one end of the steel-cored aluminum stranded wire 2, and then insert the steel core 3 leaked from the steel-reinforced aluminum stranded wire 2 into its jack from the steel anchor 4 port, and insert it along the The steel core 3 is twisted and pushed in until the end of the steel core 3 touches the bottom of the socket of the steel anchor 4, that is, the distance from the end of the steel anchor 4 to the end of the aluminum stranded wire of the steel-reinforced aluminum stranded wire 2 is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com