Steel anchor pipe inner wall cleaning brush

A technology for steel anchor pipes and cleaning brushes, which is applied in the direction of brushes, brush bodies, and cleaning hollow objects, etc. It can solve the problems of unusable, difficult to take out, and difficult cleaning of the inner wall, etc., and achieves good effects, improved effects, and good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

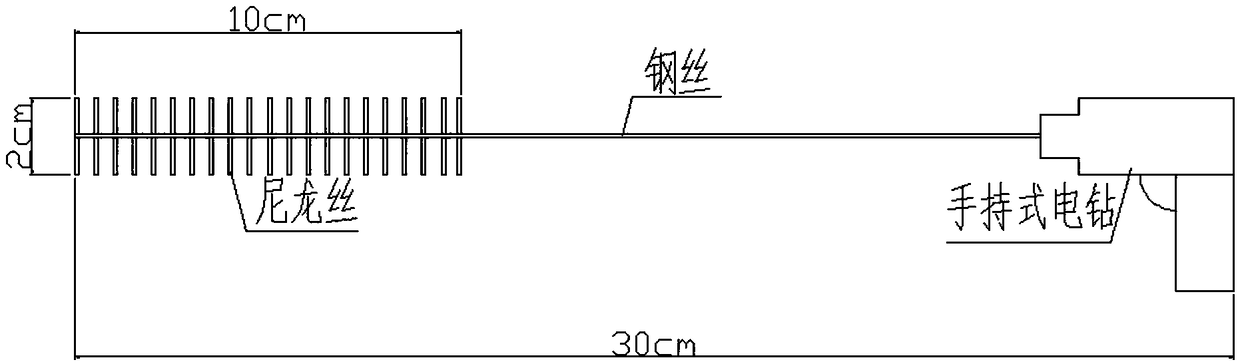

[0017] An electric cleaning brush for the inner wall of the steel anchor pipe with a sheath and a pneumatic pressure gasoline pot, please refer to figure 1 , including a hand-held electric drill, a brush body and a brush head; wherein the brush head is arranged on the top of the brush body, and the bottom end of the brush body is connected with the drill bit of the hand-held electric drill.

[0018] Preferably, the connection between the brush body and the drill bit of the hand-held electric drill is one of screw connection or buckle connection.

[0019] Preferably, the brush head is composed of nylon thread twisted on the top of the brush body.

[0020] Preferably, the size of the brush head is 10cm in length and 2cm in width.

[0021] Preferably, the brush rod is a steel wire structure.

[0022] Preferably, the length of the brush rod is 26cm.

[0023] The invention uses nylon wire as bristles, stainless steel wire as a fixed body, twisted to form a brush body, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com