Bicomponent conjugate fibers, complex yarns and fabrics having high crimping property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

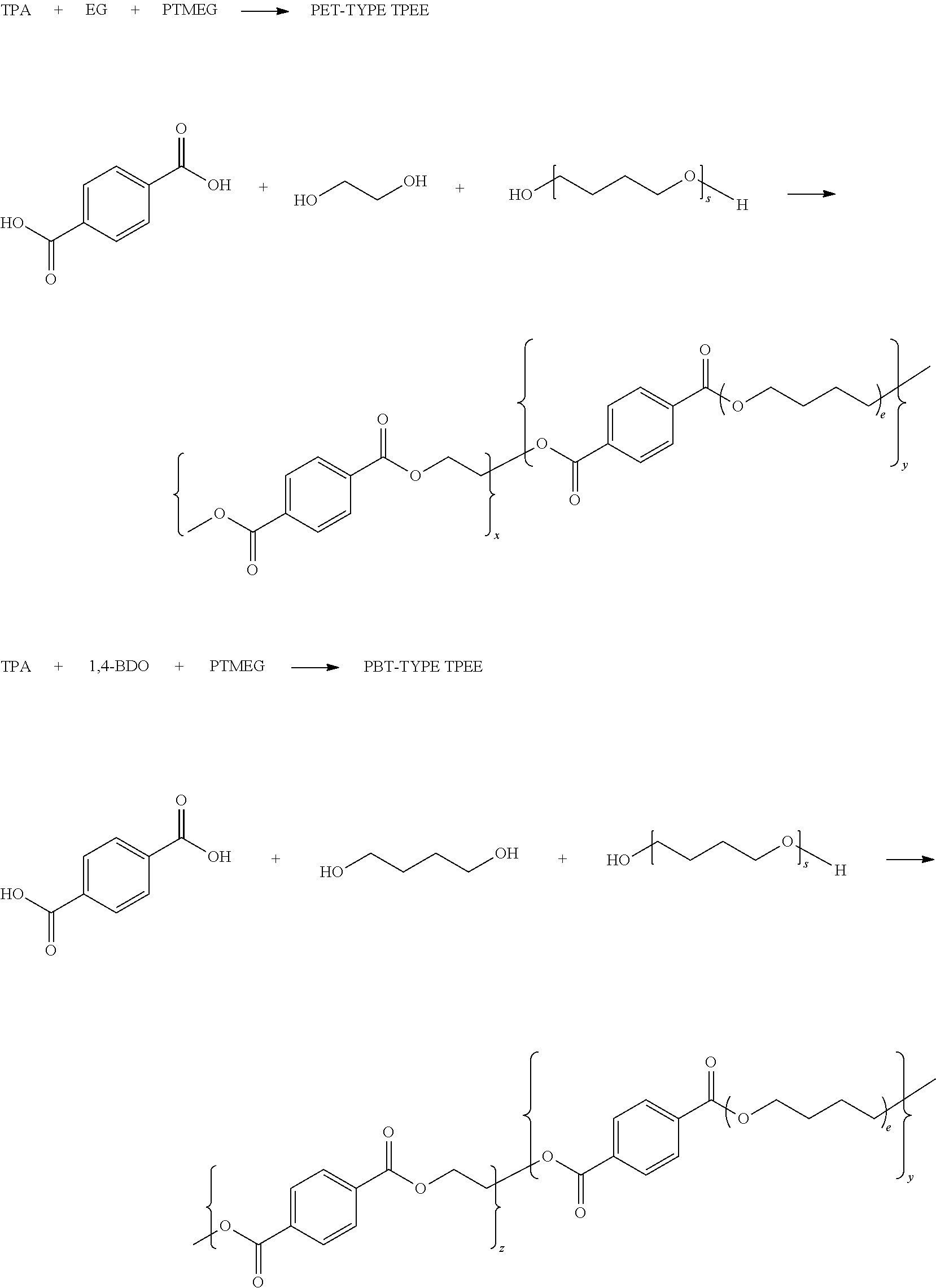

Method used

Image

Examples

example 1

[0040]The bicomponent conjugate fibers of Example 1 were prepared according to the method as described below. By using a screw extruder, the PBT-TYPE TPEE (the first component) having the intrinsic viscosity of 1.8 dl / g was melted at the melt temperature of 250° C., and the PET (the second component) having the intrinsic viscosity of 0.45 dl / g was melted at the melt temperature of 280° C., which were then quantitatively discharged, respectively. The first component and the second component were mixed in a weight ratio of 20:80 and then placed in a spinning cabinet at a spinning temperature of 285° C., which were subsequently extruded through a complex and side-by-side spinneret assembly, cooled down with cooling air and then spun and drawn at a spinning rate of 4000 m / min, a drawing temperature of 80° C., a heat setting temperature of 140° C. and a drawing ratio of 2.1 to produce 75 / 24 bicomponent fully drawn yarns (FDY). The results of the produced fibers are shown in Table 1.

example 2

[0041]The bicomponent conjugate fibers of Example 2 were prepared according to the production method described in Example 1, wherein the weight ratio of the first component and the second component was substituted with 50:50. The results of the produced fibers are shown in Table 1.

example 3

[0042]The bicomponent conjugate fibers of Example 3 were prepared according to the production method described in Example 1, wherein the weight ratio of the first component and the second component was substituted with 80:20. The results of the produced fibers are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific volume | aaaaa | aaaaa |

| Specific volume | aaaaa | aaaaa |

| Specific volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com