Crimp structure of aluminum steel cored wire

A steel-cored aluminum stranded wire and connection structure technology, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problem of steel-cored aluminum stranded wire slipping out, etc., to improve efficiency, save labor, crimp good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

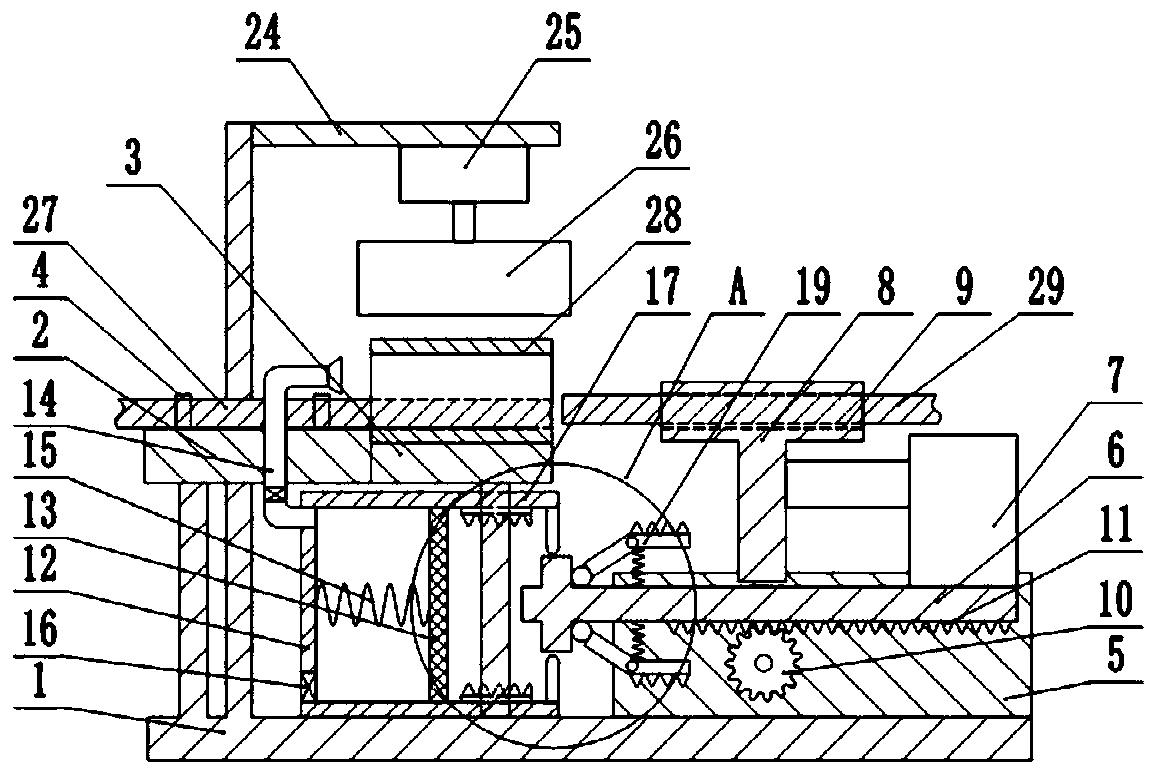

[0026] basically as figure 1 Shown: The crimping structure of the steel-reinforced aluminum stranded wire, including the frame 1, the wire placing table 2, the aluminum tube placing table 3, the wire feeding unit and the hydraulic unit. The wire placement table 2, the aluminum tube placement table 3 and the wire feeding unit are fixed on the frame 1 from left to right, and two snap rings 4 are welded on the wire placement table 2 and the aluminum tube placement table 3, and the wire placement table The upper end surface of 2 is 3mm higher than the upper end surface of aluminum tube placement table 3.

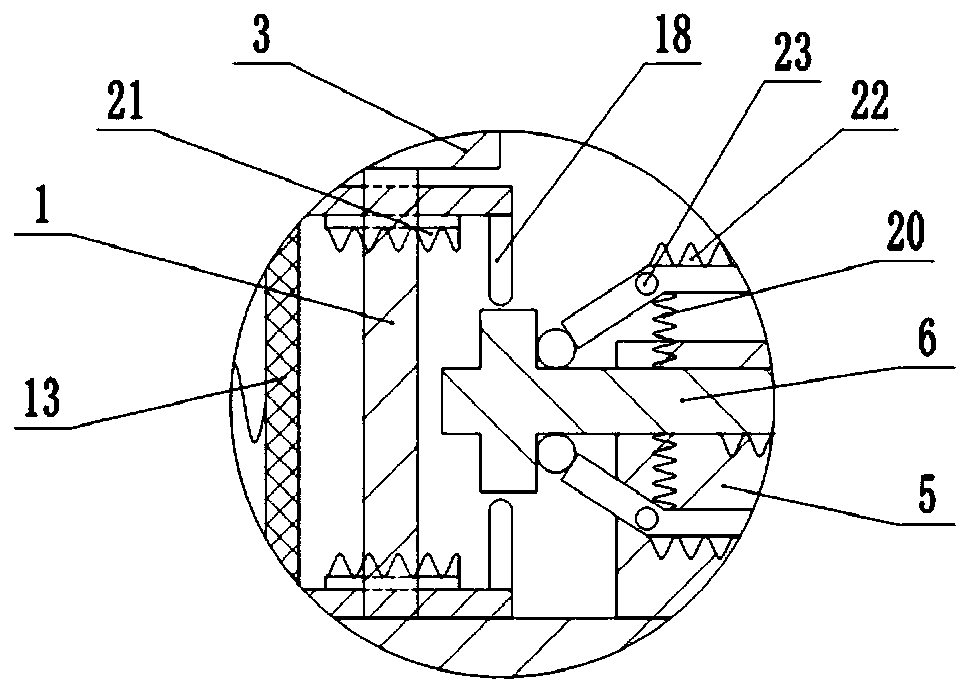

[0027] to combine figure 2 As shown, the wire feeding unit includes a side plate 5, a support plate 6, a first motor 7, a T-shaped plate 8 and a drive mechanism, the side plate 5 is welded on the frame 1, and a chute is provided on the side plate 5, and the support plate 6 slidingly connected in the chute. The first motor 7 is fixed on the support plate 6 by bolts, and the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com