Three-dimensional-direction pressure maintaining equipment

A three-dimensional, equipment technology, applied in the field of three-dimensional direction pressure-holding equipment, can solve the problems of complex and inapplicable pressure-holding equipment, complex structure, limited space, etc., and achieve the effect of saving equipment space, good crimping effect, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

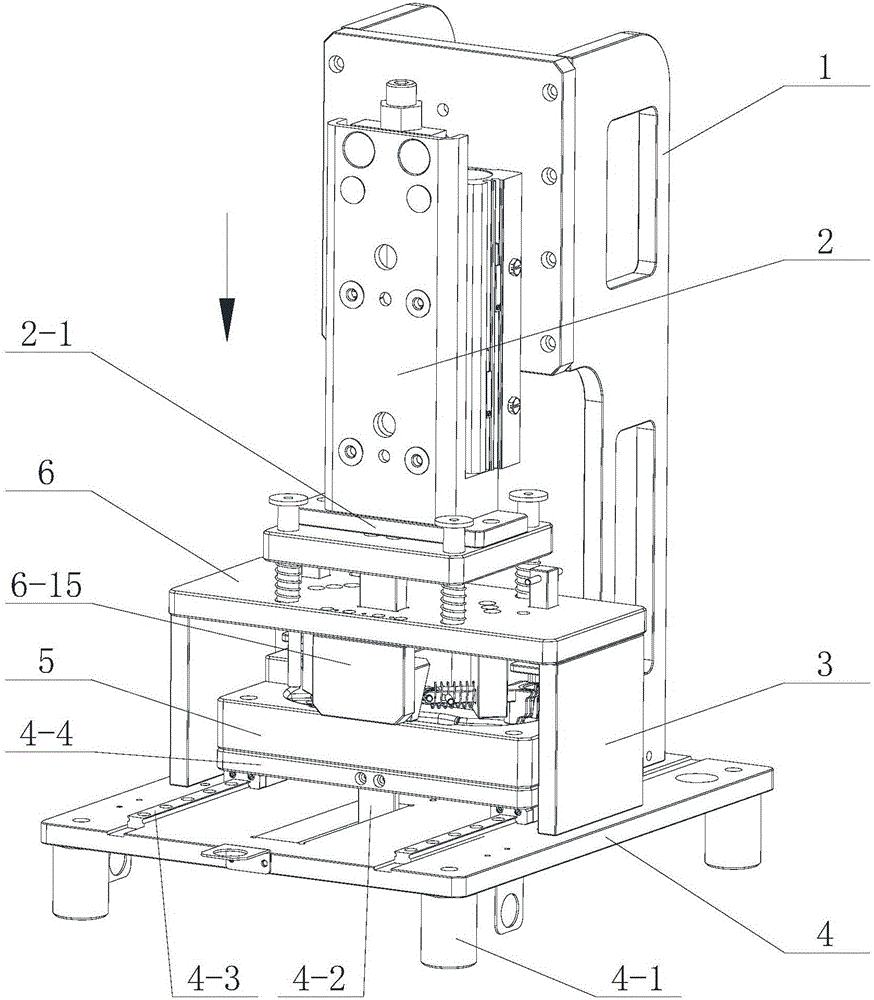

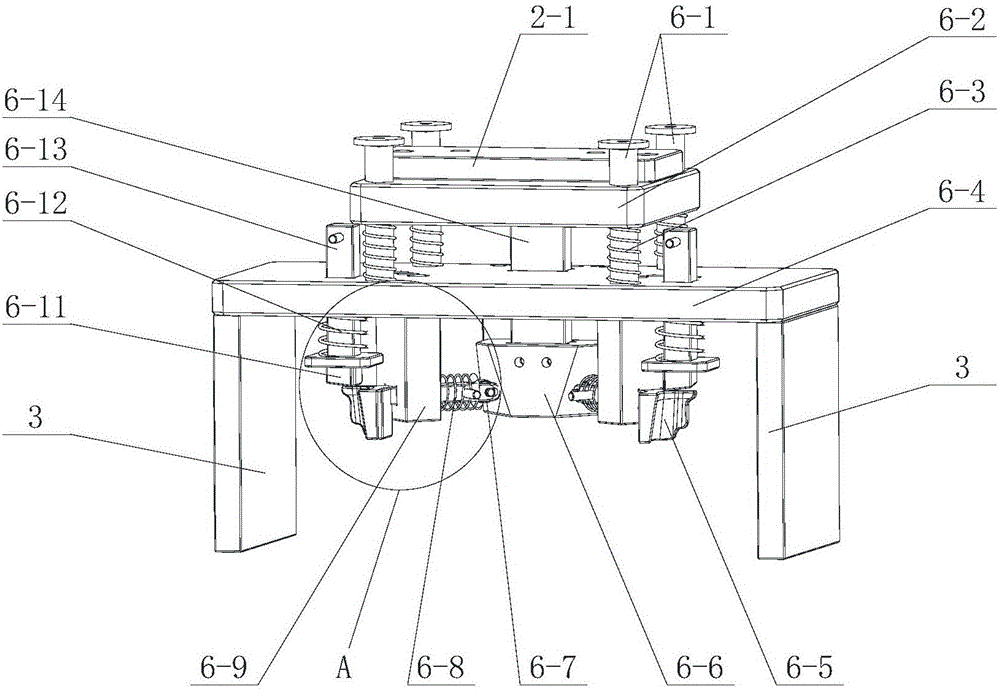

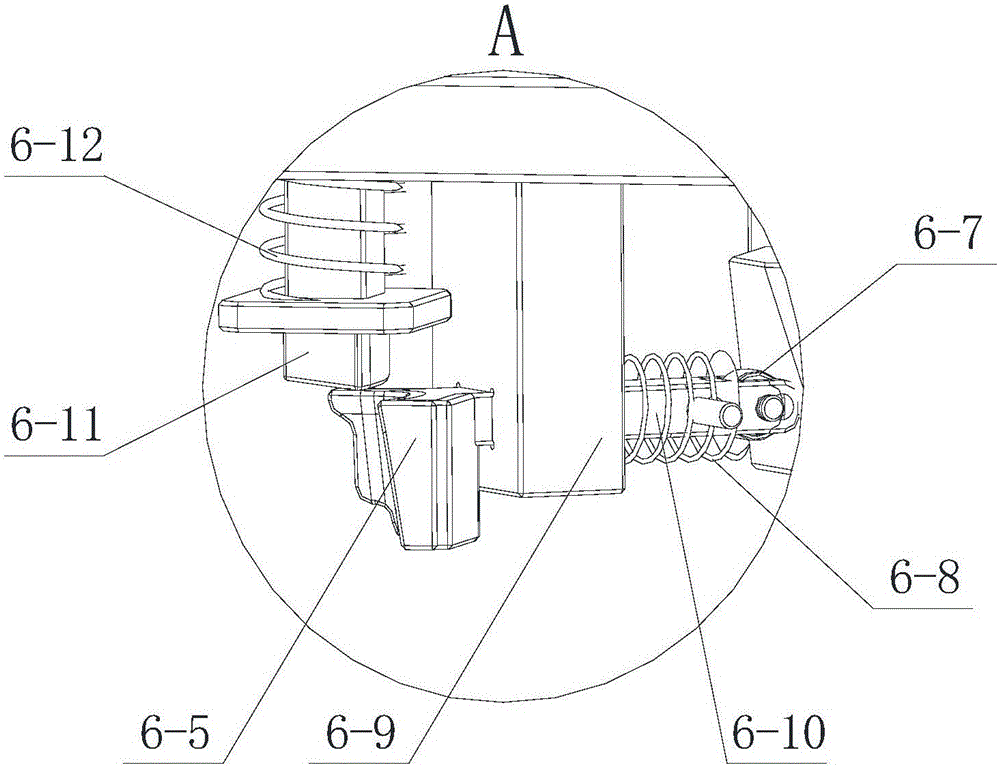

Embodiment 1

[0034] Such as figure 1 , figure 2 , Figure 4 Shown is one of the embodiments of the present invention. In this embodiment, a three-dimensional direction pressure maintaining device is provided with a frame 1, and a push-down driving mechanism 2 is arranged on the frame 1. The frame 1 is installed on a base 4 On the top, the base 4 is provided with a product placement plate 5, the product placement plate 5 is used to place the product to be kept under pressure, the pressure dividing mechanism 6 is connected to the lower part of the pressing driving mechanism 2, and the pressure dividing mechanism 6 is driven to rise and fall, and the pressure dividing mechanism 6 Several vertical pressure heads 6-11 and lateral pressure heads 6-5 are provided, and a pressure dividing block 6-6 is arranged in cooperation with the lateral pressure heads 6-5, and an inclined surface is arranged on the pressure dividing block 6-6, and the inclined surface is Downward and inclined to the inner ...

Embodiment 2

[0057] In this embodiment, the difference from Embodiment 1 is that the lateral pressure guide shafts 6-10 can move obliquely, and are inclined at a predetermined angle with respect to the horizontal plane. In order to achieve this technical purpose, the axis of the guide hole in the suspension bracket 6-9 can be inclined, that is, an inclined guide hole can be provided. Such a design can keep pressure on products with more complex shapes.

[0058] Other structures of the three-dimensional direction pressure maintaining device in this embodiment are the same as those in Embodiment 1, and will not be described again here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com