Shell product full-automatic pressing connecting and assembling mechanism

An assembly mechanism and fully automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of unfavorable physical and mental health of operators, low production efficiency, time-consuming and labor-intensive, etc., and achieve improved synchronization and crimping effect, Improve production efficiency and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

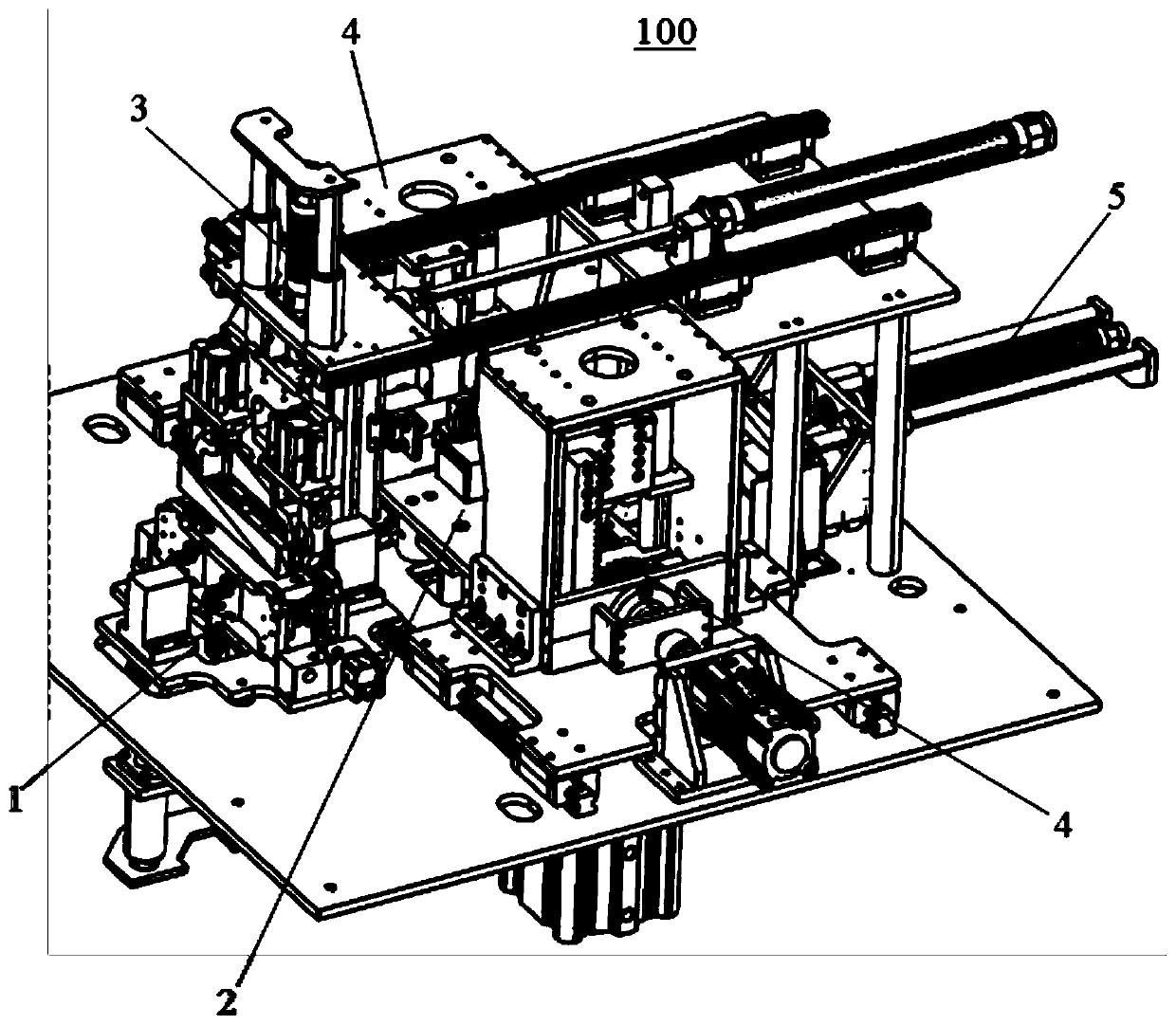

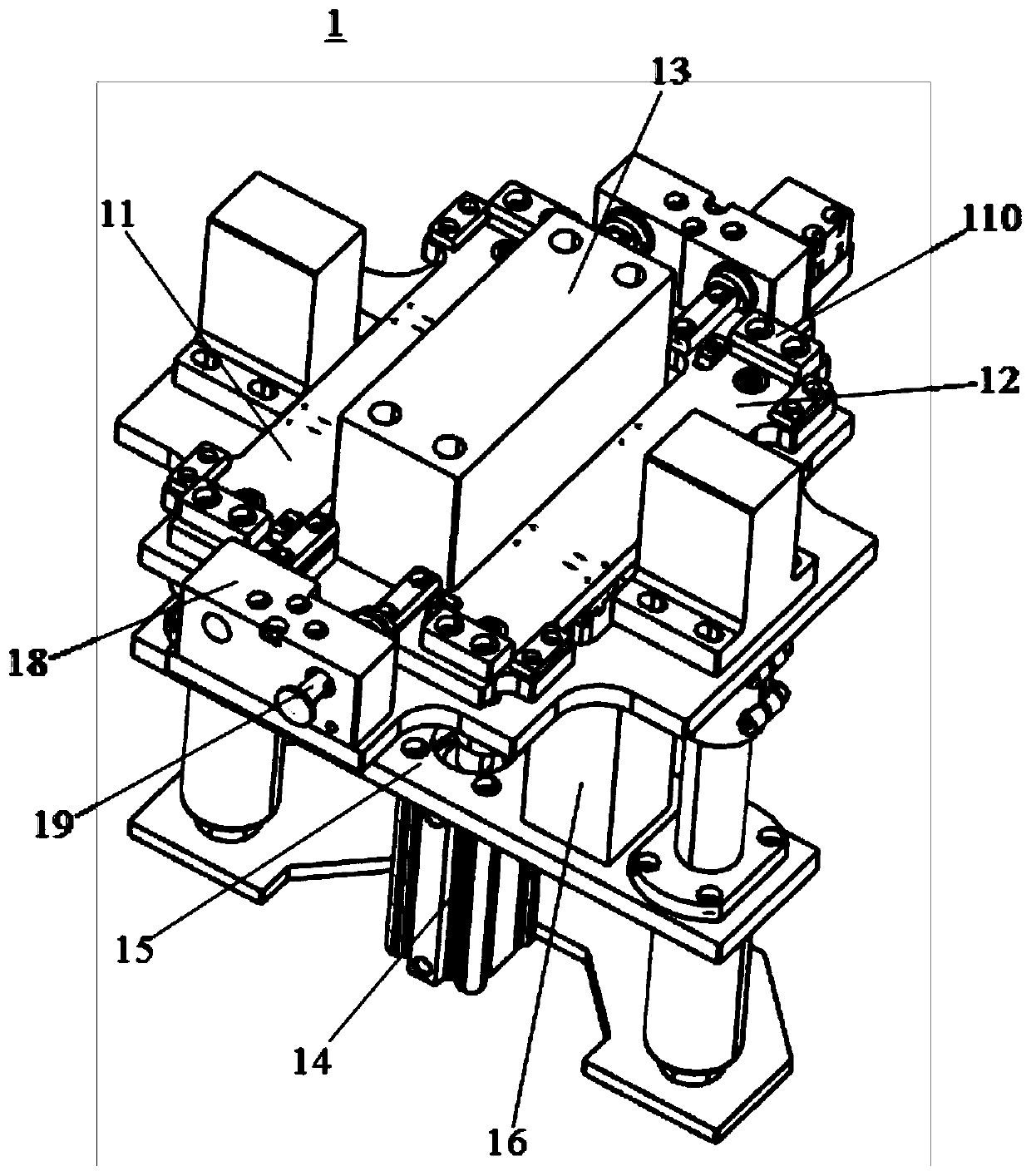

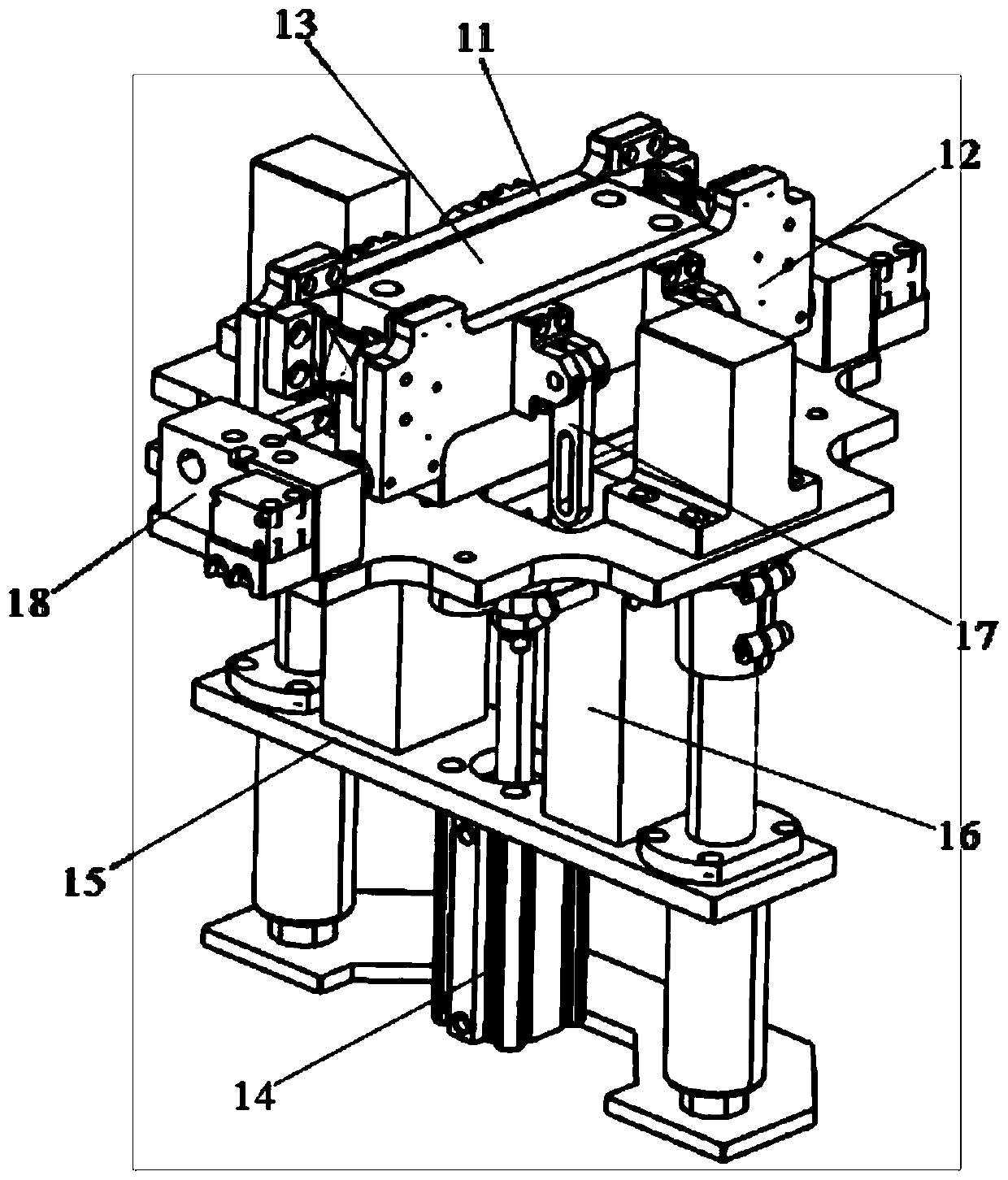

[0032] Please refer to Figure 1-Figure 7 , this embodiment is a fully automatic crimping assembly mechanism 100 for shell products, which includes a material receiving unit 1 that can be flipped by 90° and waits to grab two workpieces to be assembled according to the assembled state, located beside the material receiving unit 1 and The carrier unit 2 for carrying the workpieces to be assembled, the material transfer unit 3 for grabbing the workpieces to be assembled from the receiving unit 1 to the carrier unit 2, and the two sides of the carrier unit 2 symmetrically arranged on both sides of the workpieces to be assembled at the same time The crimping unit 4 for crimping and assembling side by side, and the unloading unit 5 for removing the crimped shell product from the carrier unit 2 .

[0033] This embodiment also includes a manipulator (not marked in the figure), which sucks two U-shaped steel sheets to be assembled, and then places them horizontally on the receiving uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com