High-speed automatic crimping machine for optical fiber insertion core

An optical fiber ferrule and crimping machine technology, which is applied in the coupling of optical waveguides and other directions, can solve the problems of complex overall structure design, low production efficiency, low crimping efficiency, etc. High connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

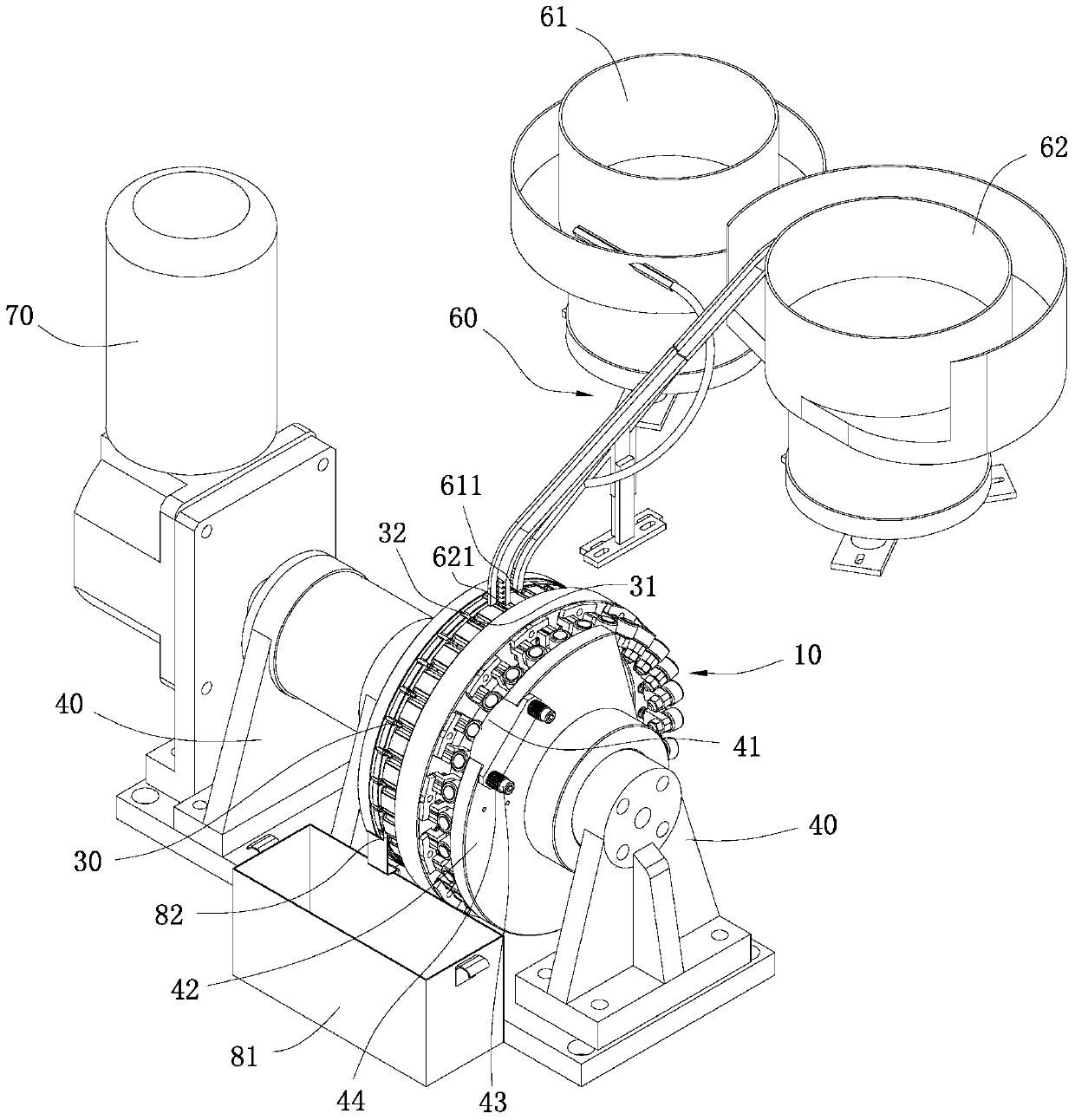

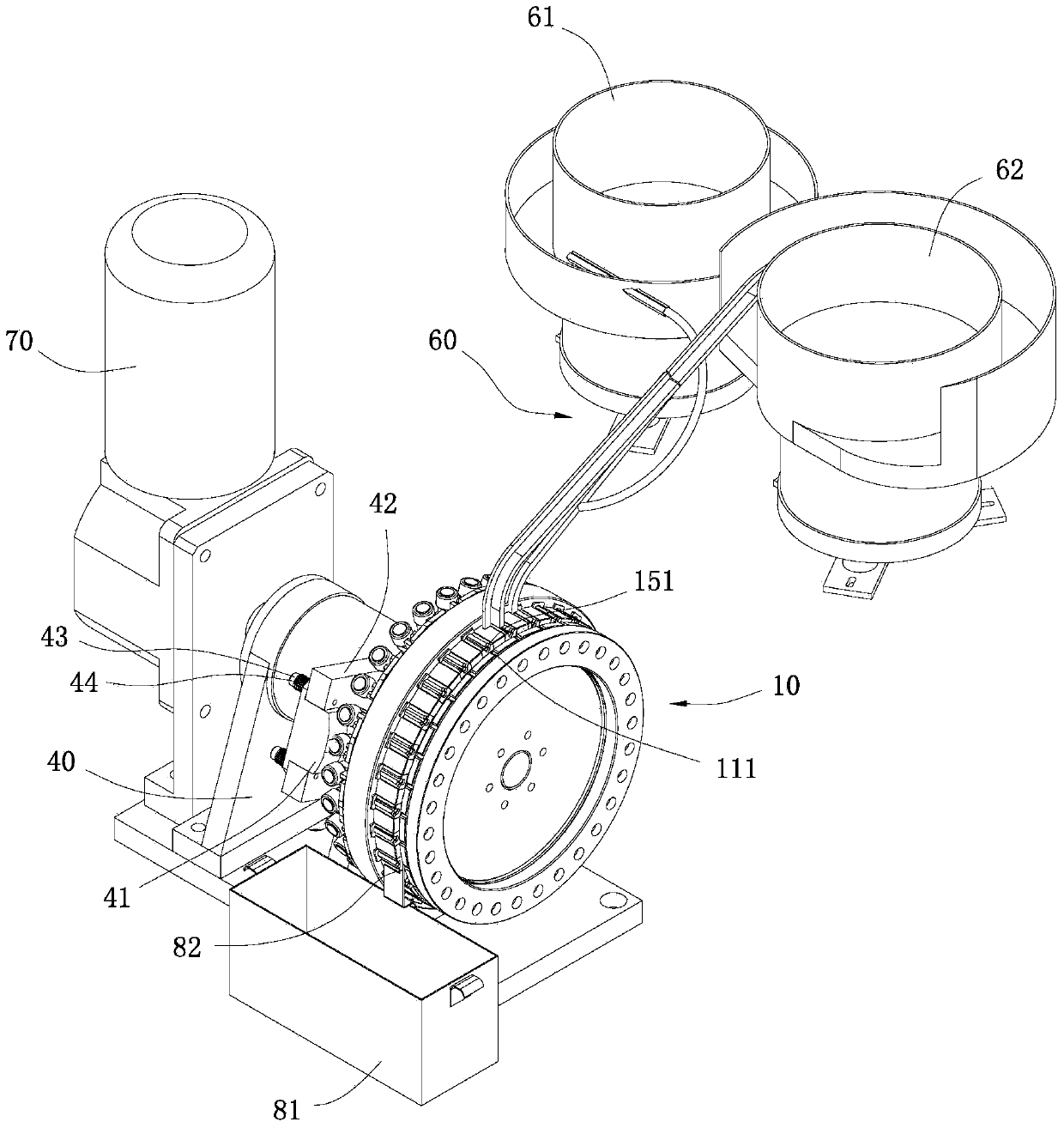

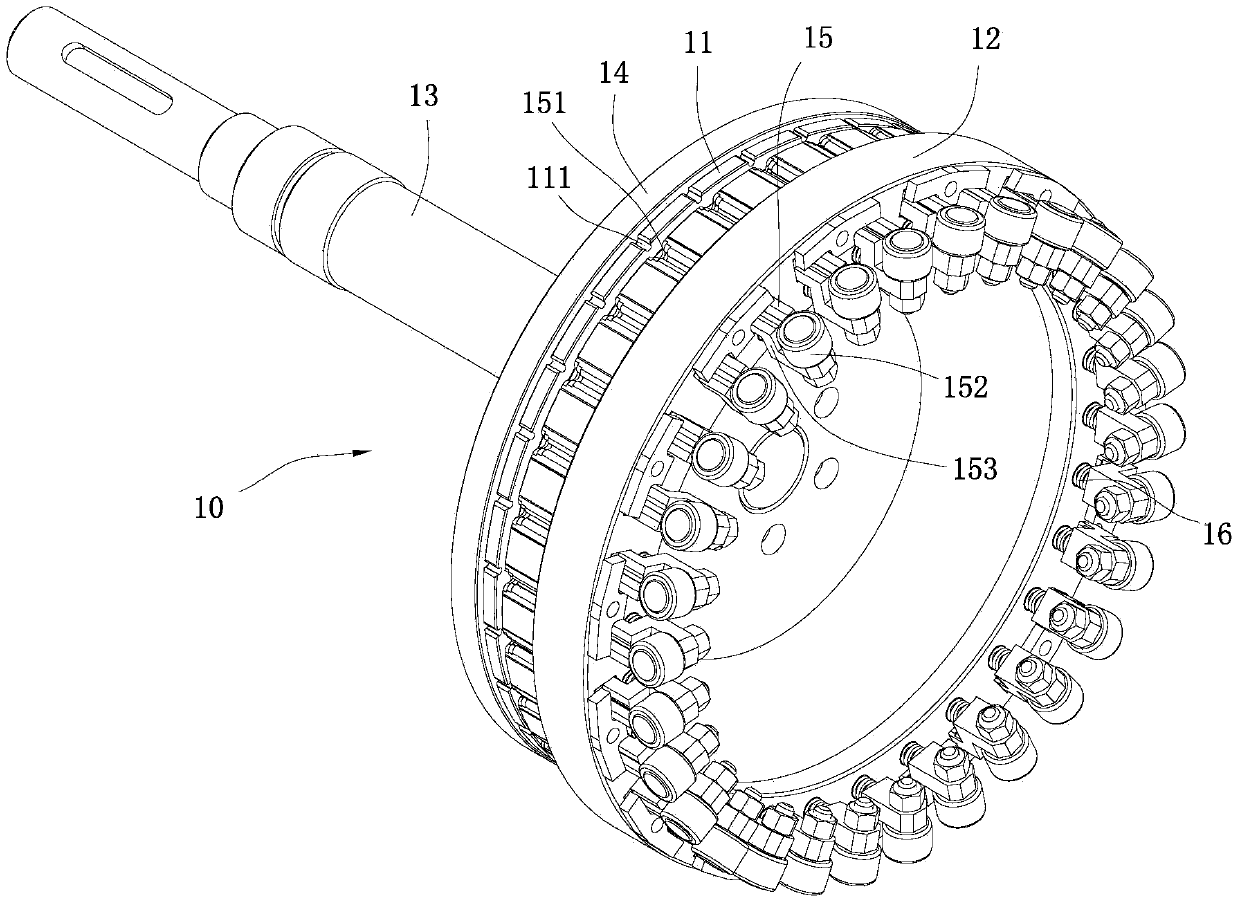

[0021] refer to Figure 1 to Figure 6 , an optical fiber ferrule high-speed automatic crimping machine of the present invention is used for crimping a metal tail handle 31 and a ceramic ferrule 32, comprising a support seat 40, a turntable body 10 horizontally arranged on the support seat 40, and a drive turntable body 10 The rotating driving device 70 and the feeding mechanism 60 are arranged at intervals along the circumferential direction on the outer circular end surface of the turntable body 10 with a plurality of accommodating grooves 111 for placing ceramic ferrules 32, and on the outer circular end surface of the turntable body 10 along the circumferential direction There are sliders 15 that are arranged side by side with each receiving groove 111 and can move axially along the turntable body 10 at intervals in the direction. At the end of each slider 15 facing the ceramic ferrule 32, there is a receiving notch 151 where the metal tail handle 31 can be placed. On the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com