Portable on-site buckling device and buckling method

A portable and on-site technology, applied in hand-held appliances, other household appliances, household appliances, etc., can solve the problems of increasing pipe costs, high requirements for joint material consistency, and increasing energy consumption, so as to improve application reliability and crimping Insufficient process, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

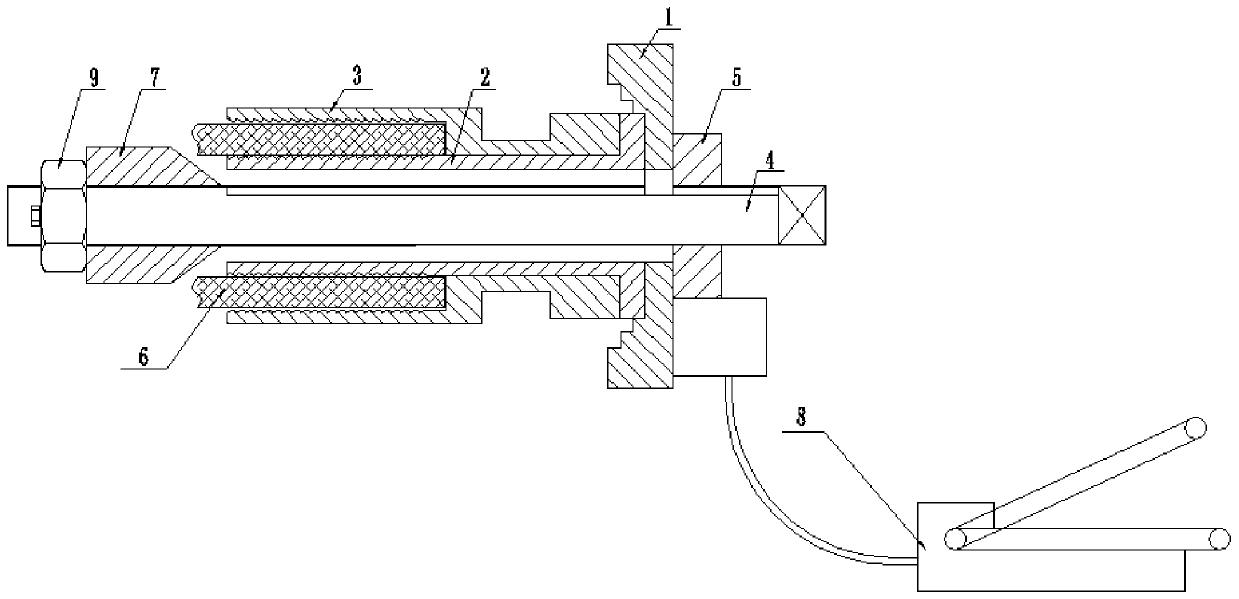

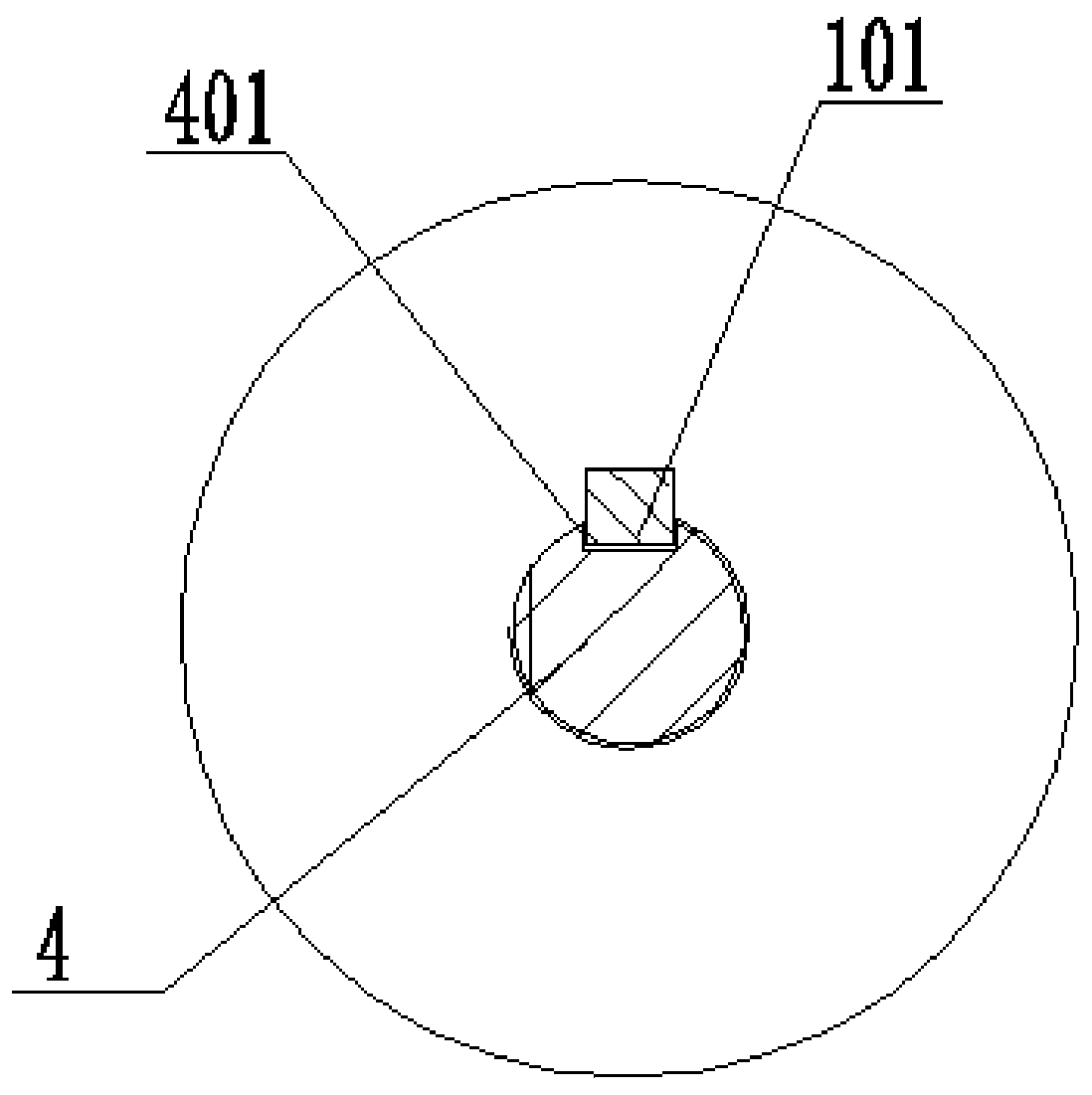

[0035] Such as figure 1 A portable on-site crimping device is shown, including a support connecting plate 1, a rotating mechanism 5 fixedly connected to one side of the supporting connecting plate 1, a connecting rod 4 is movably connected to the rotating mechanism 5, and the rotating mechanism 5 drives the connecting rod 4 to move, the end of the connecting rod 4 passes through the support connecting plate 1 and is fixedly connected with the internal expansion head 7 on one side of the supporting connecting plate 1; the supporting connecting plate 1 is used as the basis of the whole device and supports The shape of the connecting plate 1 is not limited in detail, and the supporting connecting plate 1 can be fixedly connected to the bracket for use according to the environment used on site. A central hole penetrating the supporting connecting plate 1 is provided on the supporting connecting plate 1 to ensure The connecting rod 4 can be driven by the rotating mechanism 5 to fre...

Embodiment 2

[0044] On the basis of Example 1, when fastening the wire-tip core tube assembly 2 and the sleeve 3 to the supporting connecting plate 1, it is necessary to carry out the fastening stably, and at the same time, it is convenient to disassemble it after the crimping is completed. For this reason Figure 5 The side of the supporting connecting plate 1 is provided with a clamping device 9 for clamping the casing 3 and the thread core tube assembly 2 . The clamping device 9 can conveniently clamp the sleeve pipe 3 and the threaded core tube assembly 2, specifically, it is convenient to clamp the threaded core tube assembly 2 on the support connecting plate 1, and combine the threaded core tube After the fastening of the body 2 is completed, the matching sleeve is set on the wire head core tube assembly 2 to complete the fastening;

[0045] Specifically, when crimping the pipeline, there are several standards for the pipe diameter of the wire end core tube assembly 2. In order to e...

Embodiment 3

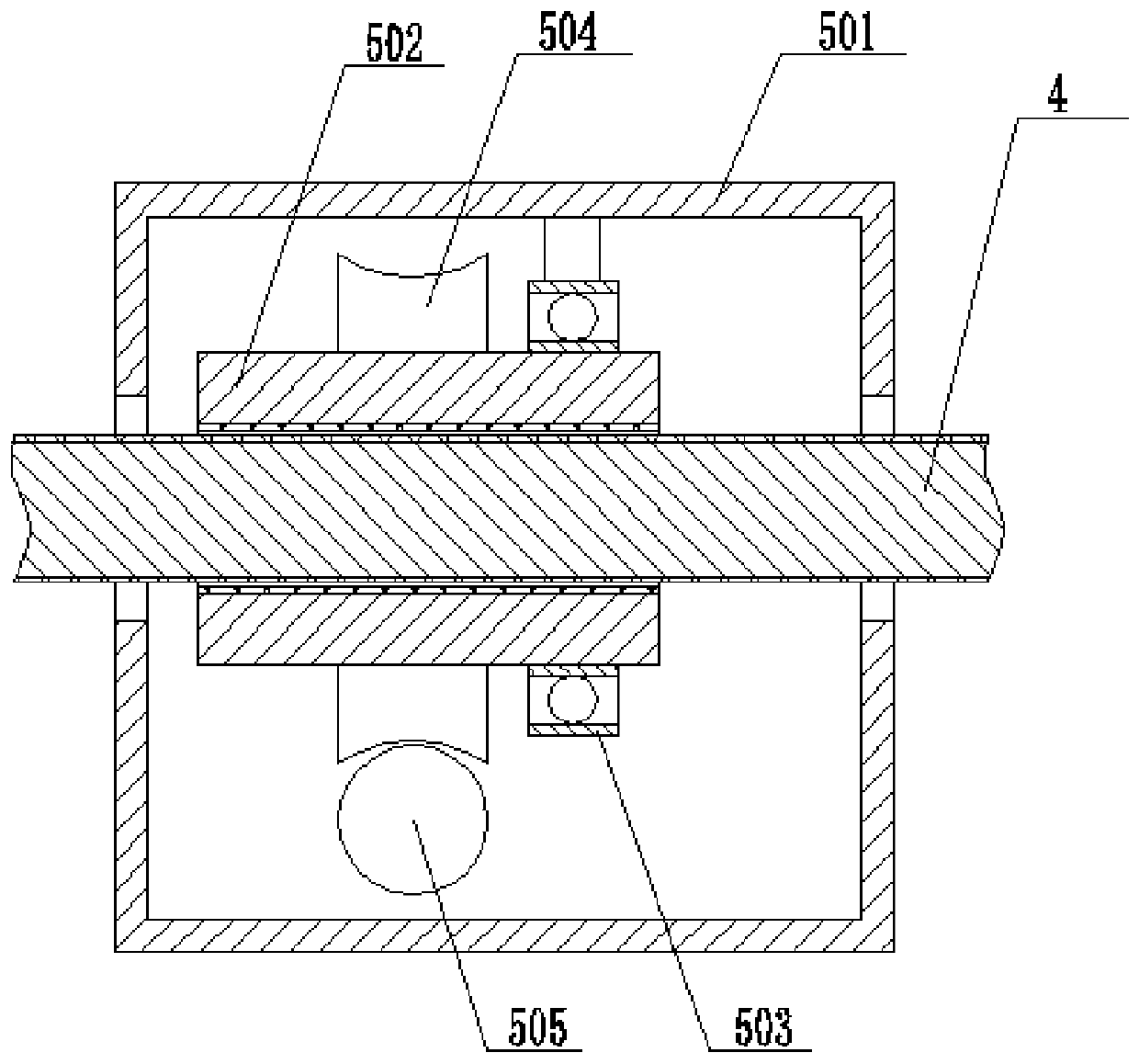

[0047] On the basis of Embodiment 1, the rotating mechanism 5 needs to drive the connecting rod 4 to move laterally, so as to ensure that the internal expansion head on the pull rod can be driven to perform internal expansion work, such as image 3 and Figure 4 The rotating mechanism 5 includes a rotating body 501 fixedly connected to the supporting connecting plate 1, a driving screw nut 502 arranged in the rotating body 501, and the driving screw nut 502 is threadedly connected with the connecting rod 4, and the driving wire The lever nut 502 is movably connected to the rotating body 501 through a bearing 503. A worm gear 504 is fixedly sleeved on the driving screw nut 502. The worm gear 504 is meshed with a worm 505, and the end of the worm 505 is fixedly connected with a driving device 506. ; The driving device 506 is a driving motor.

[0048] The power consumption of the drive motor can be based on the situation on site, using municipal power, and can also provide power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com