Hydraulic crimping method of strain clamp of bus in power substation

A tension wire clamp and substation technology, applied in the field of hydraulic crimping, can solve the problems of reduced tensile force affecting the conductive effect of the wire, scattered wires, and delayed progress, etc., to improve the aesthetics, save waste, and improve crimping. The effect of quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

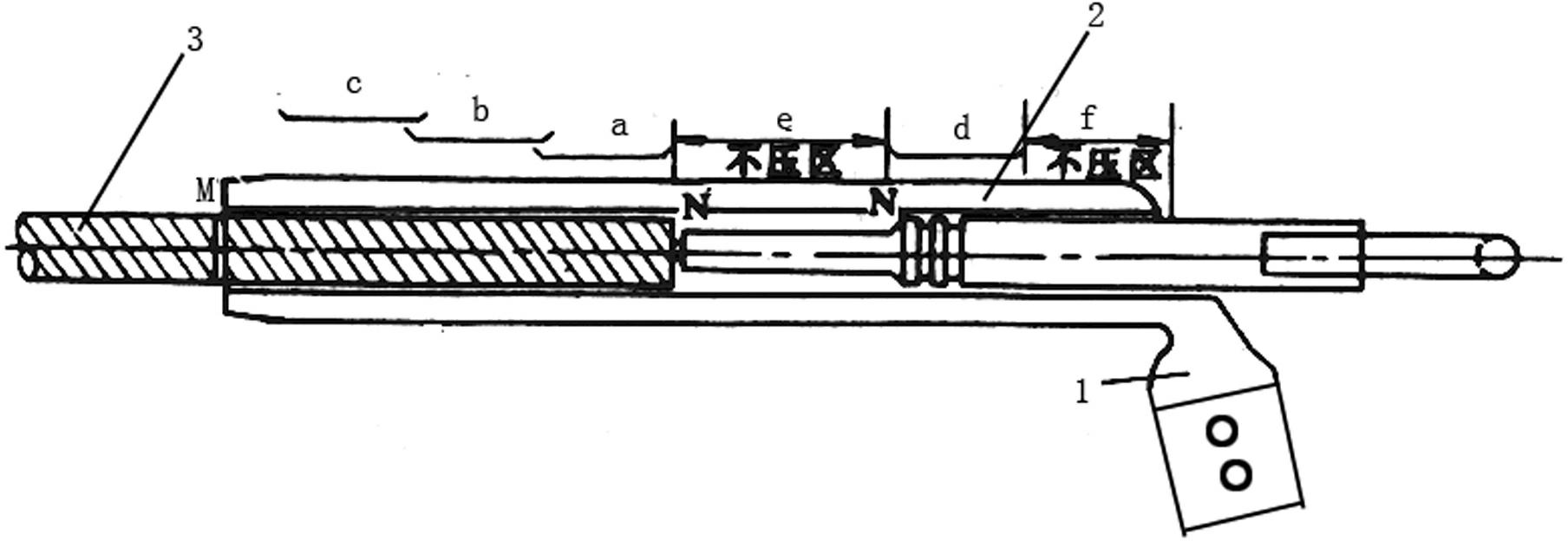

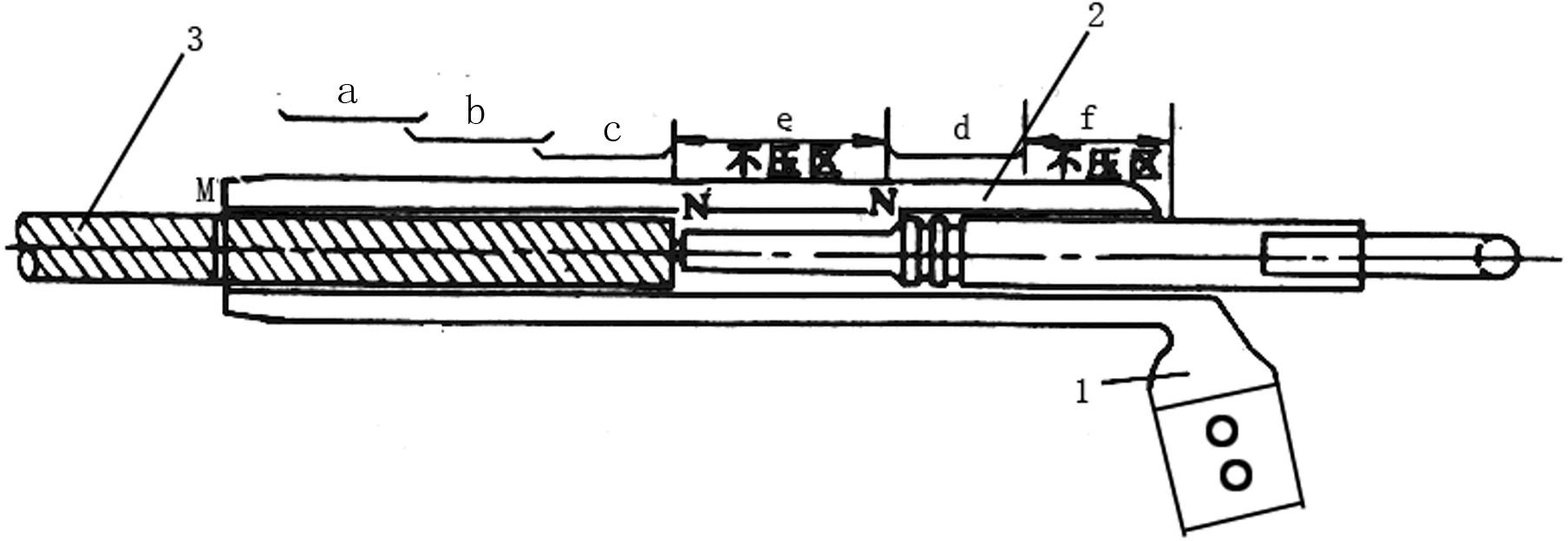

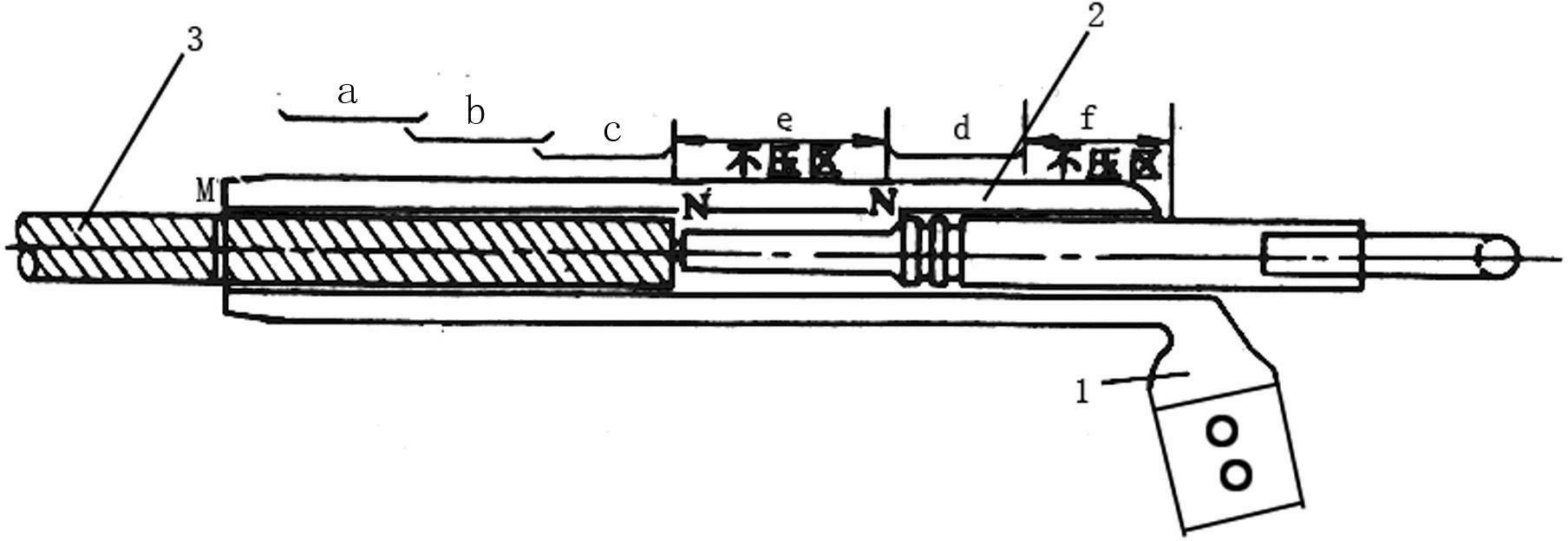

[0011] The hydraulic crimping method of the tension clamp of the busbar in the substation according to the present invention is based on the crimping process of the strain clamp in the original "Technical Regulations for Hydraulic Construction of Overhead Power Transmission Line Conductors and Lightning Lines SDJ 226-87 (Trial)" On the basis of the method, the crimping construction is not carried out in the order required by the process regulations, but in the opposite direction.

[0012] Such as figure 2 The hydraulic position and operation sequence of the steel anchor shown: the first mold a crimping: first insert the aluminum wire 3 into the steel anchor 2 of the hydraulic tension clamp, and carry out the first Crimping of mold a; crimping of second mold b: on the basis of crimping of the first mold, the second mold is crimped outward along the first mold. When crimping, it is necessary to cover the part of the crimping of the first mold, so as to play the role of reliabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com