Ground wire crimping correction and pressure detection control device

A detection control, crimping device technology, applied in the direction of connection, line/collector parts, electrical components, etc., can solve the problems of repeated crimping correction, long construction time, etc., to improve crimping quality, improve transmission efficiency, The effect of reducing working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

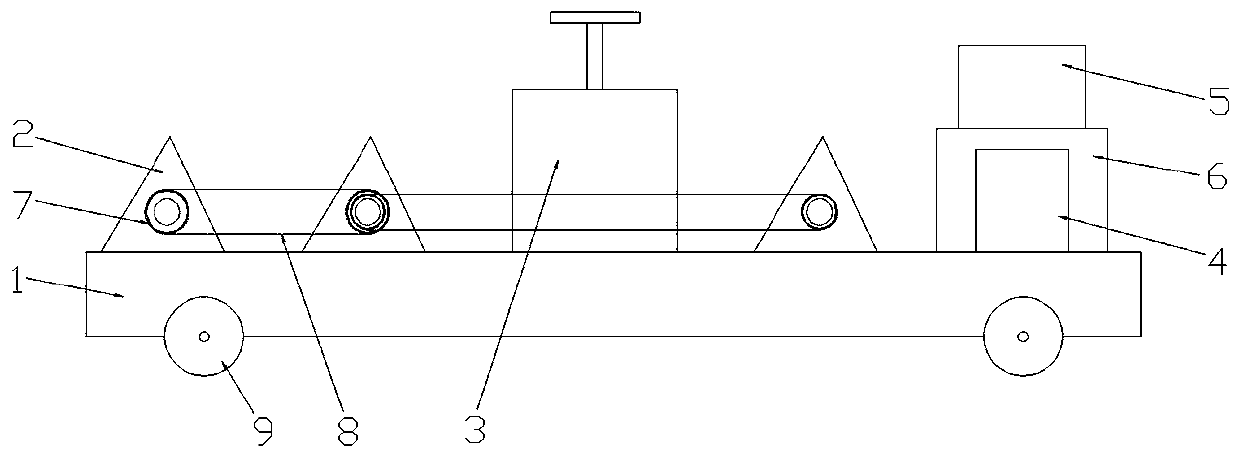

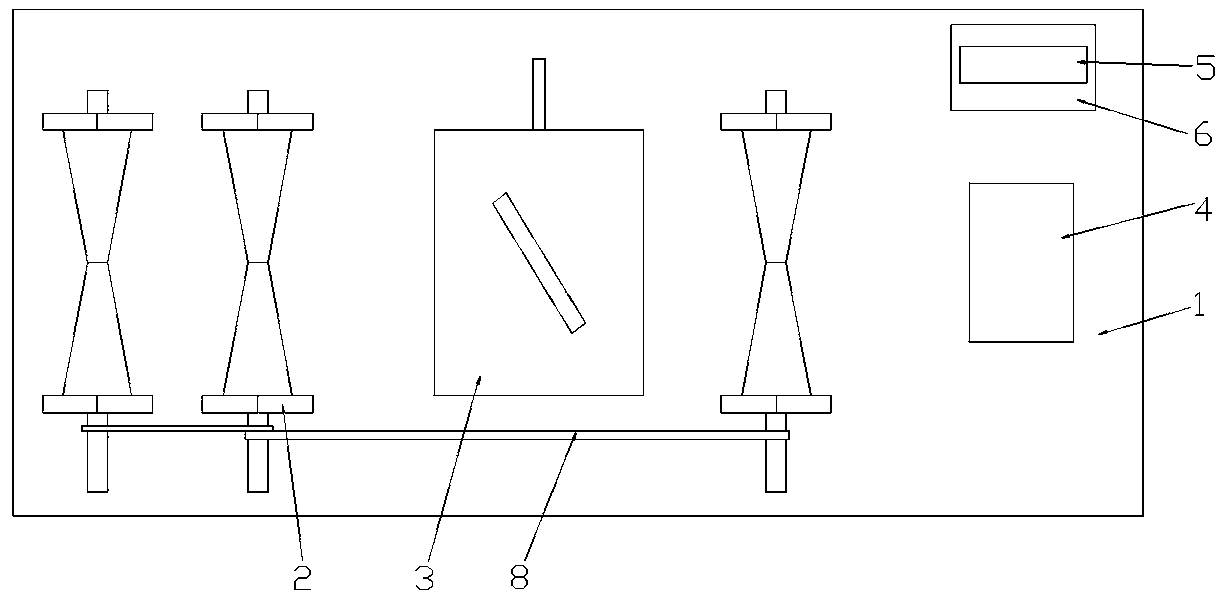

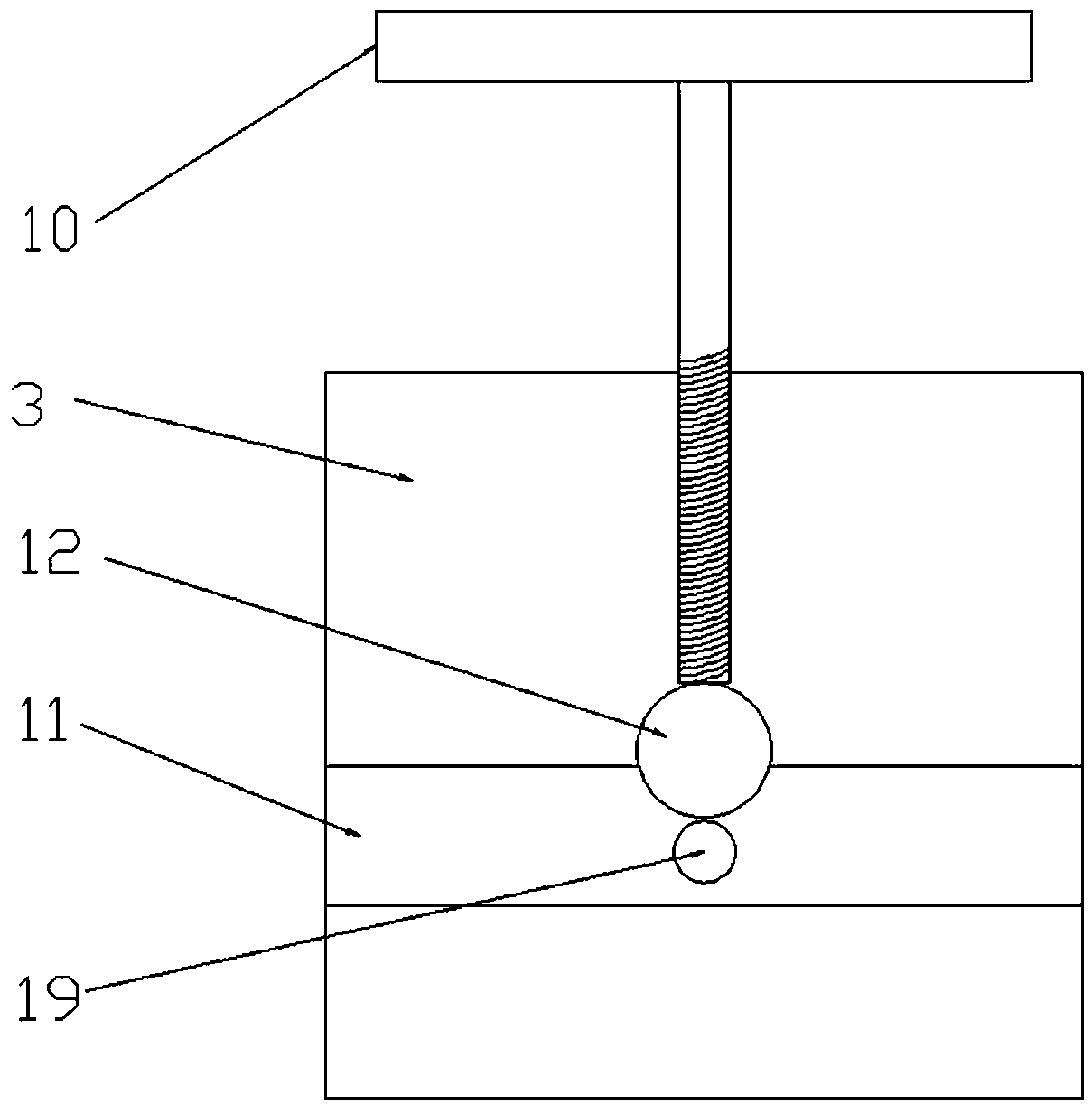

[0029] Such as Figure 1-4 As shown, a ground wire crimping correction and pressure detection control device includes a crimping platform 1, and a transmission wheel 2, a positioning device 3, a crimping device 4, and a pressure monitoring and alarming device are fixedly installed on the crimping platform 1 , the transmission wheel 2, the positioning device 3 and the crimping device 4 are arranged horizontally in sequence to facilitate the crimping correction of the ground wire. The pressure monitoring and alarm device includes a pressure sensor, a control device, a display screen 5 and an alarm device 6, the crimping device 4 is a hydraulic press, the alarm device 6 is a sounder, and the crimping device 4 is connected to the pressure sensor , the pressure sensor is connected with the control device, and the control device is connected with the display screen 5 and the alarm device 6 respectively. When in use, after the wire is crimped, the pressure sensor senses its pressure...

Embodiment 2

[0034] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a gear 7 is provided on one side of the transmission wheel 2, a chain 8 is provided on the gear 7, and a chain 8 passes between the transmission wheels 2. Transmission, the chain 8 is connected with a driving motor. When in use, the driving motor drives the chain to rotate the gear, thereby rotating the transmission wheel, improving the transmission efficiency of the wire, improving the working efficiency and reducing the working time.

Embodiment 3

[0036] Such as Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: the bottom of the crimping platform 1 is provided with a lifting device, and the lifting device is composed of a plurality of cross pieces 14, and the cross pieces 14 A cross bar 15 is connected between them, and there are two cross bars 15, and through holes 4 are provided on the cross bars 15, and a screw rod 16 is connected between the through holes 4, and one end of the screw rod 16 is provided with Rocking bar 17, the other end of described screw rod 16 is connected with through hole 4 by screw thread. The bottom of the lifting device is provided with fixed wheels 9 . When in use, the screw rod is rotated by rotating the rocker, the distance between the cross bars is adjusted, the lifting device is raised or lowered, and the height of the crimping platform is conveniently controlled, and the operation is simple and easy to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com