Pneumatically-driven double-end automatic crimping device

A technology of pneumatic drive and crimping device, which is applied in the direction of connection, electrical components, circuits, etc., can solve the problems of high labor intensity, affect the appearance, and slow speed, and achieve the effect of improving crimping efficiency, simple structure, and solving interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

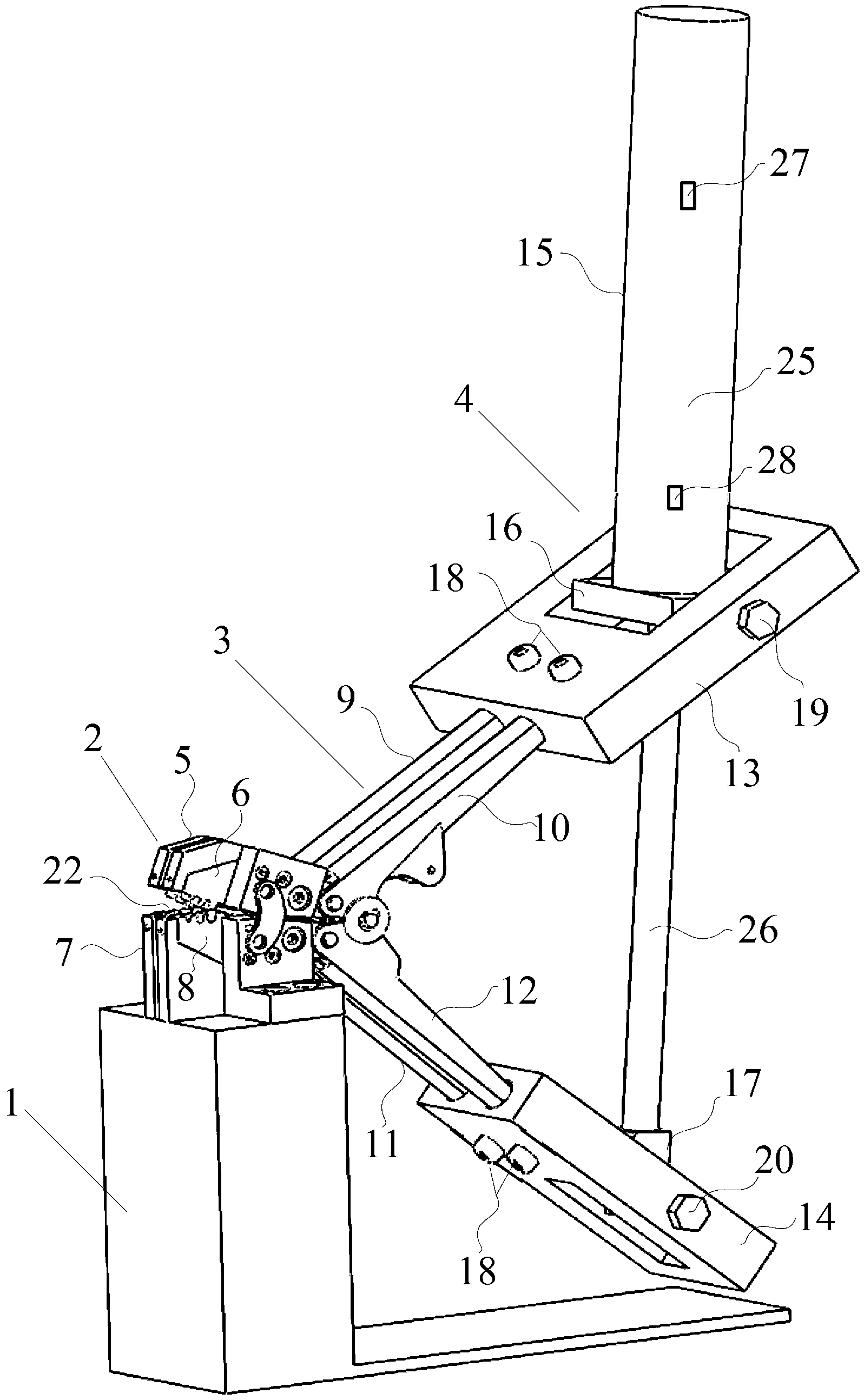

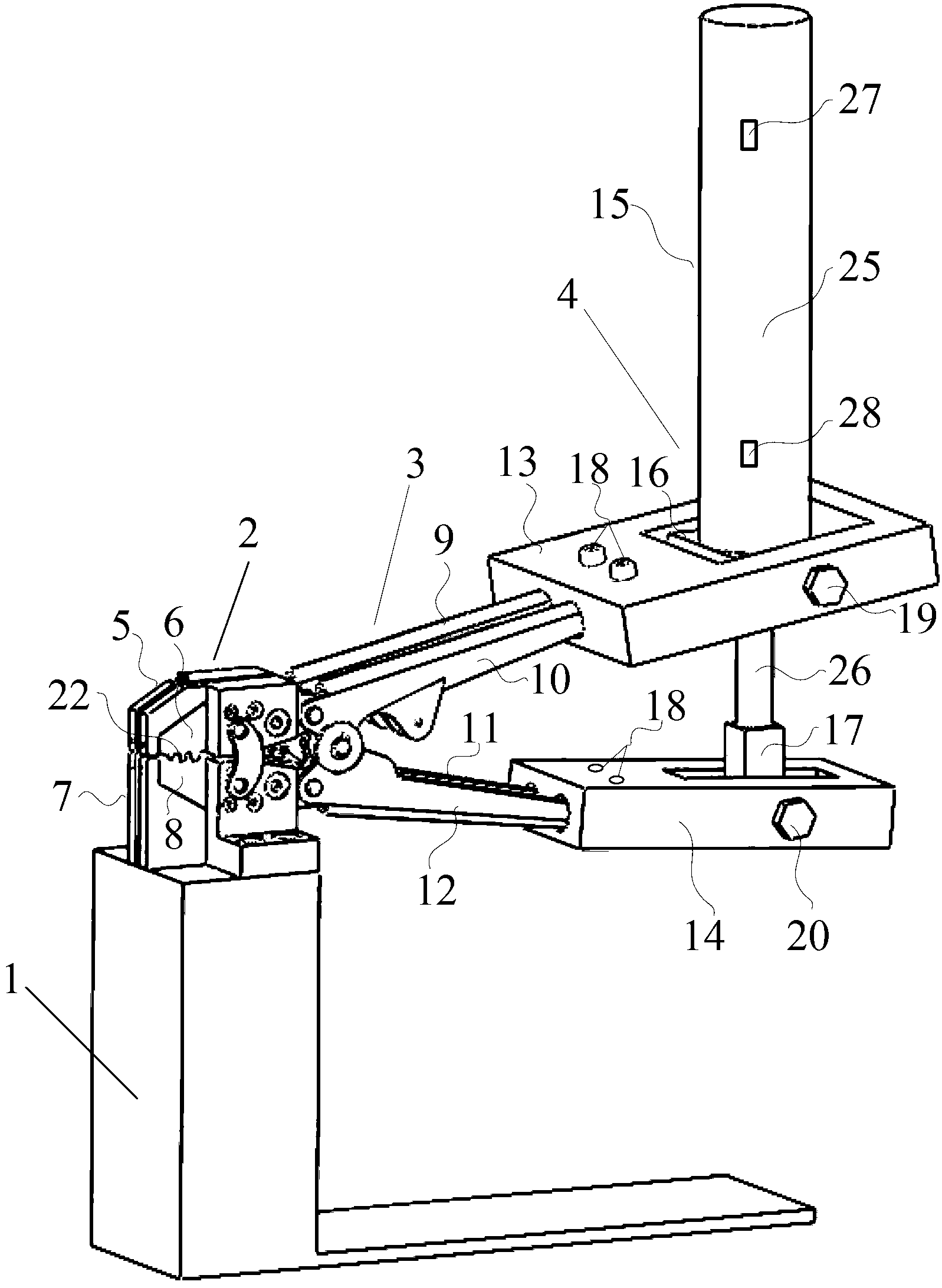

[0017] The process of double-ended terminal crimping is simply to put the two ends of the double-ended terminal through the wires for crimping. Such as figure 1 As shown, the device of the present invention includes a base 1, a clamp assembly 2, a clamp arm assembly 3 and a pneumatic device 4; the clamp assembly 2 is fixed on the base 1, its rear end is connected with the clamp arm assembly 3, and the pneumatic device 4 is installed on the clamp After the arm assembly 3, it exerts force on the pliers arm assembly 3 to realize automatic crimping.

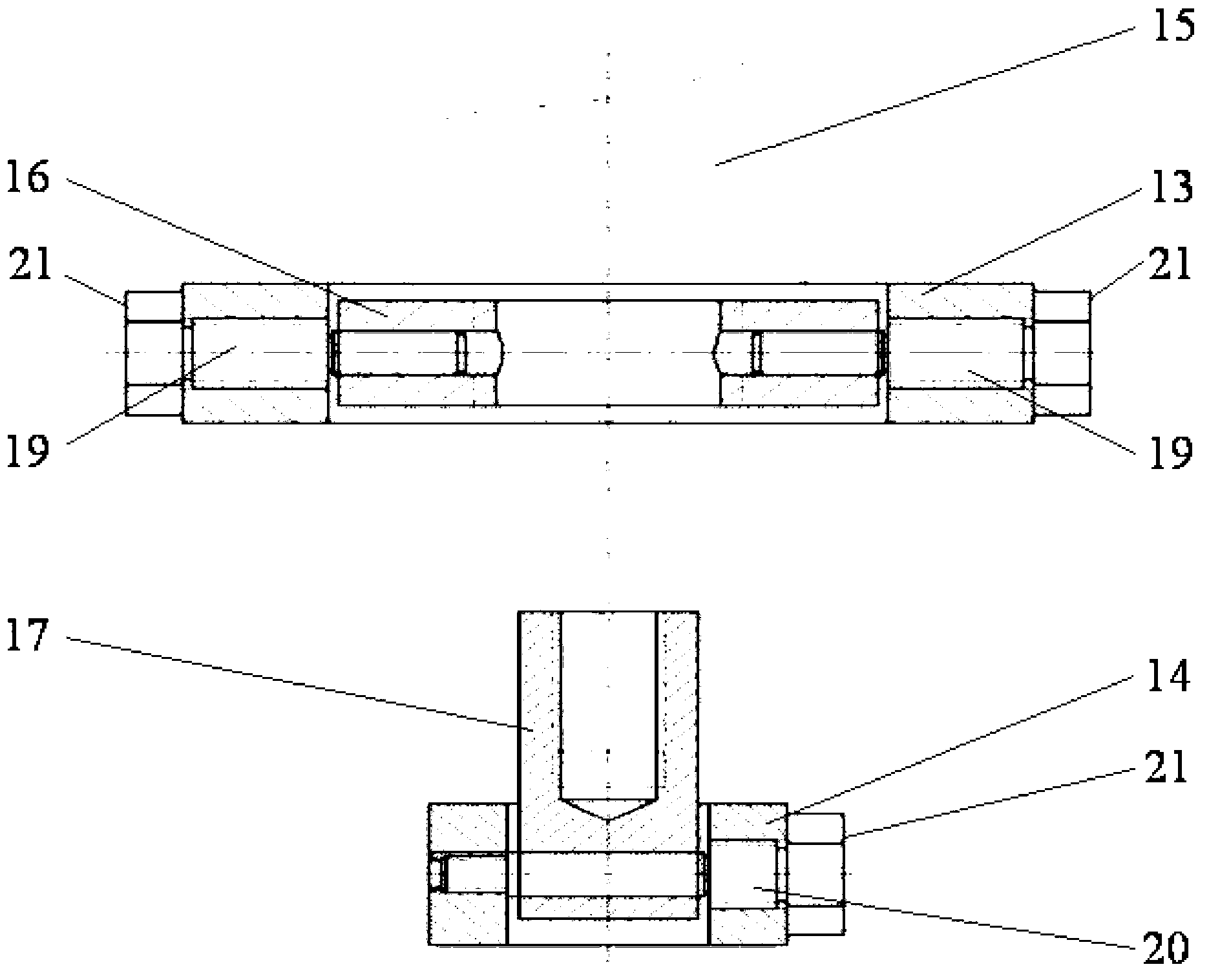

[0018] The initial state of the double-ended automatic crimping device is as follows figure 1 Shown, this moment press clamp jaw 22 opens fully, at first, will Figure 4 The butt joint terminal shown is placed on the jaws 22 of the pliers, and the wires are respectively penetrated to both ends of the butt terminal; after the threading is in place, the crimping action is performed: the cylinder 15 is driven to retract the piston rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com