Patents

Literature

569results about How to "Ensure job safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-magnesium hard water anti-magnesium corrosion environmentally-friendly water soluble cutting solution

ActiveCN101560433APrevent corrosion and discolorationExcellent anti-magnesium hard water performanceLubricant compositionDisinfectantDefoaming Agents

The invention discloses an anti-magnesium hard water anti-magnesium corrosion environmentally-friendly water soluble cutting solution, which is composed of organic acid, organic amine, corrosion inhibitor, base oil, synthetic ester, surfactant, water and other additives. The invention employs particular surfactant to improve the anti-magnesium hard water performance of the product, employs special compound corrosion inhibitor to enhance the anticorrosion performance of the product, and compounds a plurality of rust inhibitors, lubricants, disinfectants and defoaming agents, the product has excellent anti-magnesium hard water performance, anti-magnesium corrosion performance and operating safety performance, and can heighten the service performance and processing performance of the product greatly. Meanwhile, the product, which is good for environmental protection, is an environmentally-friendly magnesium alloy cutting solution with excellent performances.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD +1

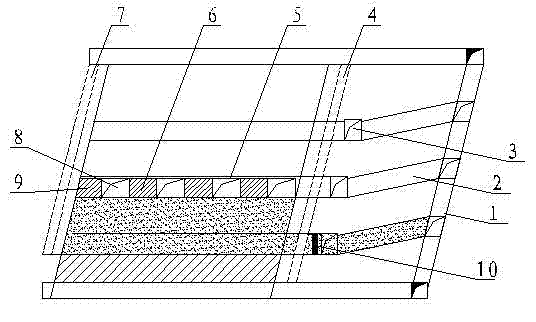

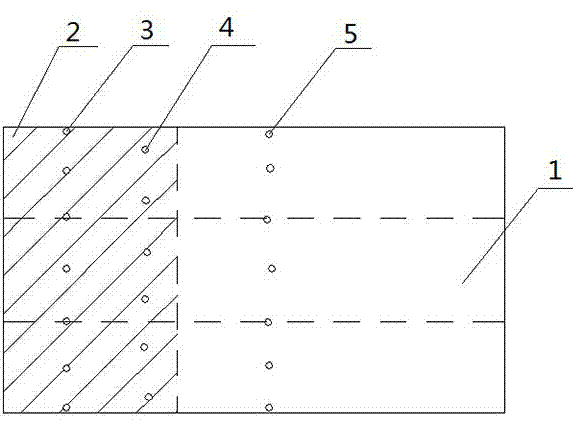

Upward cut-and-fill mining method for in-vein slope ramp of gentle dip thin vein

ActiveCN104060991AEnsure safetyImprove recovery efficiencyUnderground miningSurface miningVeinCut and fill

The invention discloses an upward cut-and-fill mining method for an in-vein slope ramp of a gentle dip thin vein. The method comprises the following steps: stoping layers of an ore body, tunneling a cross gateway from a bottom middle haulage drift to the ore body, tunneling a diagonal slope ramp along the vein to rise for certain height, and tunneling a slice drift, a reversing chamber and a sectional ore removal draw shaft forwards along the vein, wherein the reversing chamber and the sectional ore removal draw shaft are perpendicular to the slice drift; reversely tunneling the diagonal slope ramp along the vein from one side of the slice drift to rise for the certain height, and tunneling the slice drift, the reversing chamber and the sectional ore removal draw shaft along the vein; dividing a stope by using the diagonal slope ramp as the boundary, continuously propelling from one end of the vein to the other end of the vein, reaching all the layers of the ore body by virtue of the diagonal slope ramp which is tunneled in the vein, and sequentially stoping and filling from bottom to top by virtue of each layer stoping unit in the stope. The upward cut-and-fill mining method for the in-vein slope ramp of the gentle dip thin vein is high in mechanization degree, small in out-vein stope preparation engineering amount, low in labor intensity, low in ore dilution loss, safe to operate and high in efficiency.

Owner:河南发恩德矿业有限公司

Preparation and use method of downhole intelligent plug

ActiveCN103160261AEnsure job safetyAffect production capacityDrilling compositionSealing/packingCross-linkOperation safety

The invention discloses a preparation and use method of a downhole intelligent plug. The preparation method is as below: using acrylamide and sodium acrylate as raw materials, adding an initiator sodium sulphite to synthesize a jelly, preparing a base fluid, and crosslinking with a cross-linking agent to form a stable plug capable of automatically breaking at a set time. The downhole intelligent plug provided by the invention is in a liquid shape before gelatinization, and is pumped to a preset position of the wellhole by a ground pump; after gelatinization, the rubber plug can seal the wellhole and prevent up transportation of stratum oil gas, so as to ensure wellhole operation safety; meanwhile the rubber plug can avoid entering of killing fluid into the stratum to cause reservoir damage affecting well productivity, and the rubber plug can automatically degrade after operation, thereby ensuring smoothness of the wellhole.

Owner:PETROCHINA CO LTD

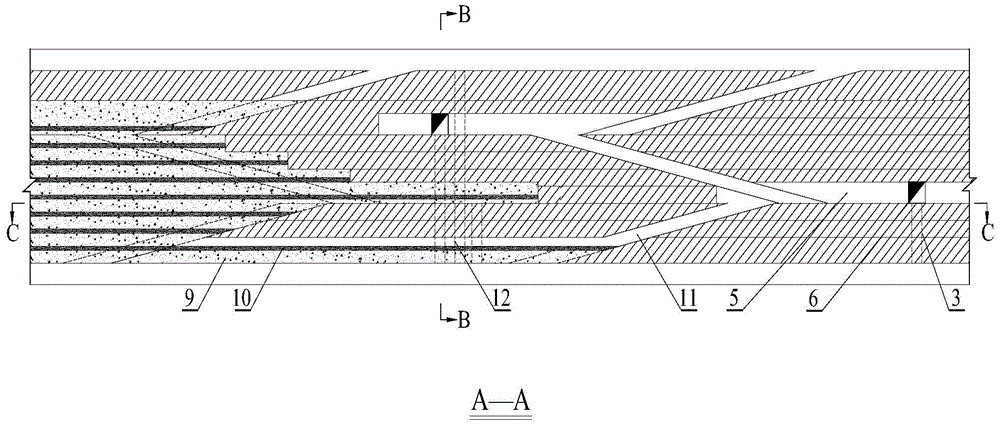

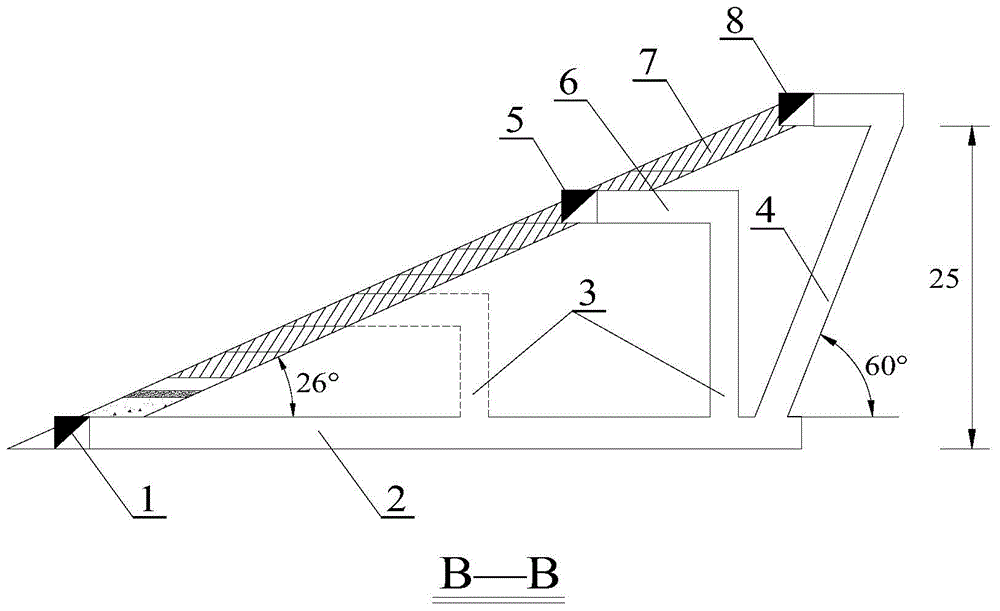

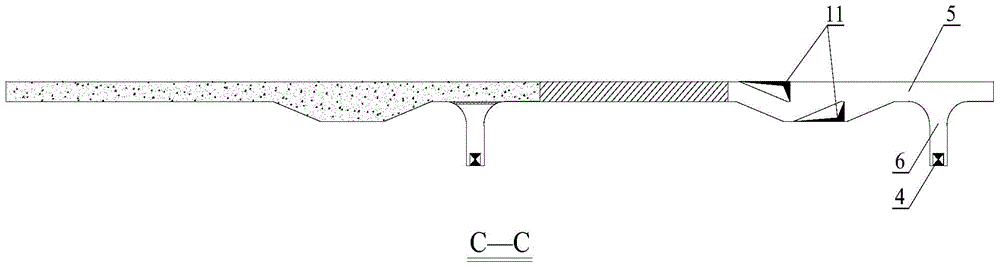

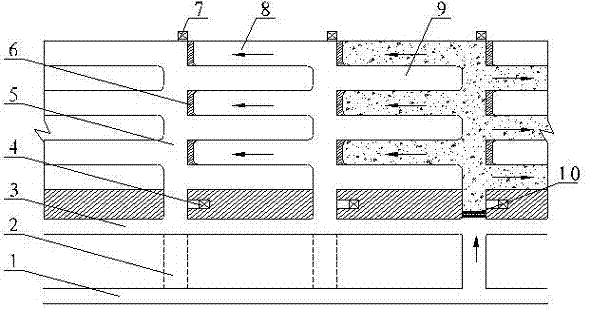

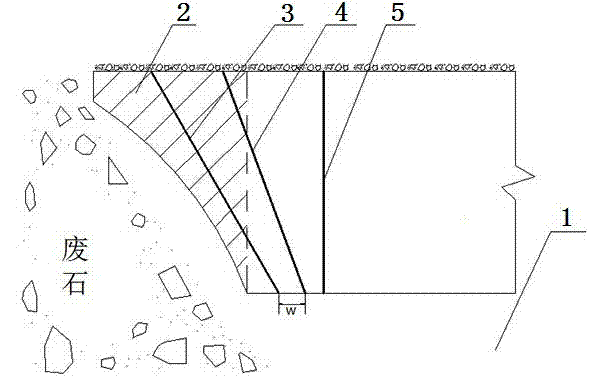

Stope route arrangement mode and method beneficial to roof-contacted filling

ActiveCN103615285ASimple process and construction managementReduce support costsMaterial fill-upFilling materialsEngineering

The invention provides a stope route arrangement mode and method beneficial to roof-contacted filling. The roof-contacted filling rate can reach above 90%, filling cost is low, and the process is simple. According to the stope route arrangement mode, a mining cutting roadway is arranged perpendicular to the moving direction of an ore body, extracting drifts at two wings of the mining cutting roadway are arranged in the moving direction of the ore body in a staggered mode, a chute is arranged in a surrounding rock section of the footwall of the mining cutting roadway, the height of the extracting drifts is 3m, the length of the first extracting drift is 14-18m, the length of the second extracting drift is 16-20m, and the height of the mining cutting roadway is 4.5m. According to the stope route arrangement method, a slope ramp linking way, a footwall stope layering linking roadway and the mining cutting roadway are constructed sequentially, and the chute and a return air filling shaft are communicated; the second extracting drift is constructed after the first extracting drift is finished; brushing extraction is carried out on a temporary jamb, the width of a central mining cutting roadway is 4.5-5m, and a top plate is shaped like an arch; waste stones are dumped into the second extracting drift, the height of a smooth chute is increased by 3.5m, a filling blocking wall is erected, and filling operation is finished when the liquid level of filling material slurry is higher than the top plate of the extracting drifts by 20-30cm.

Owner:南京银茂铅锌矿业有限公司

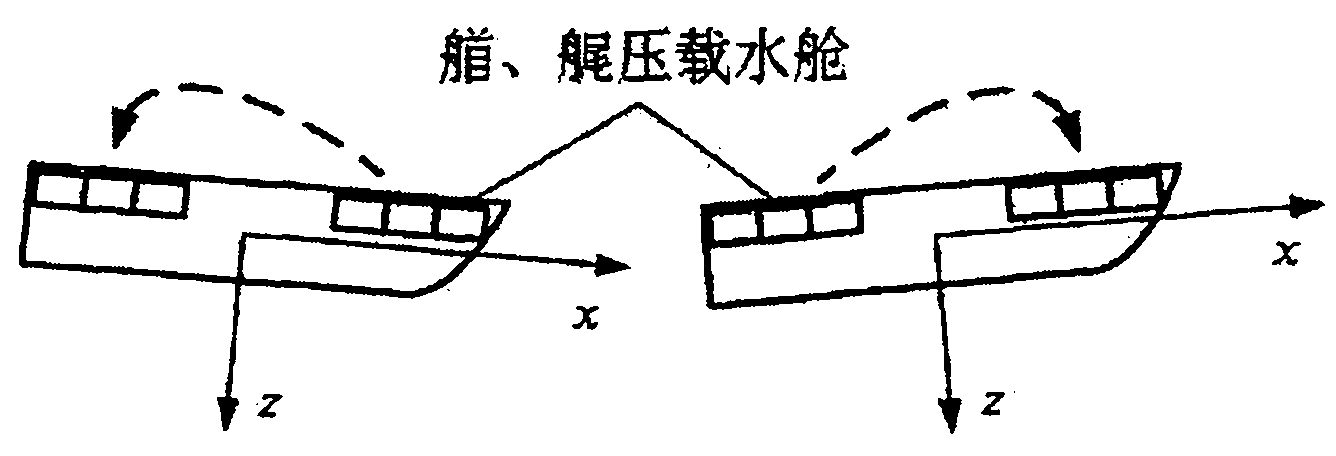

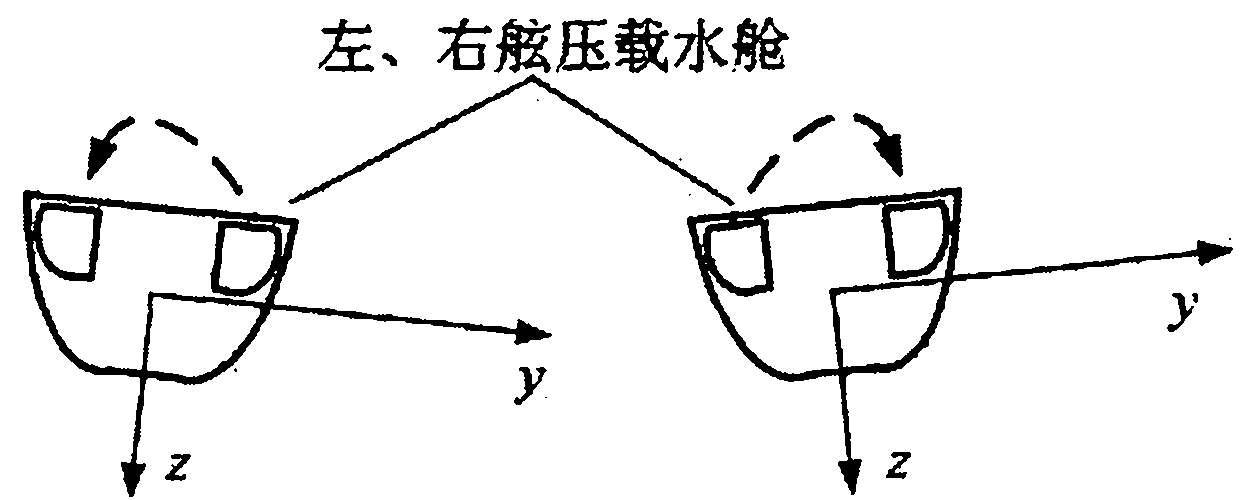

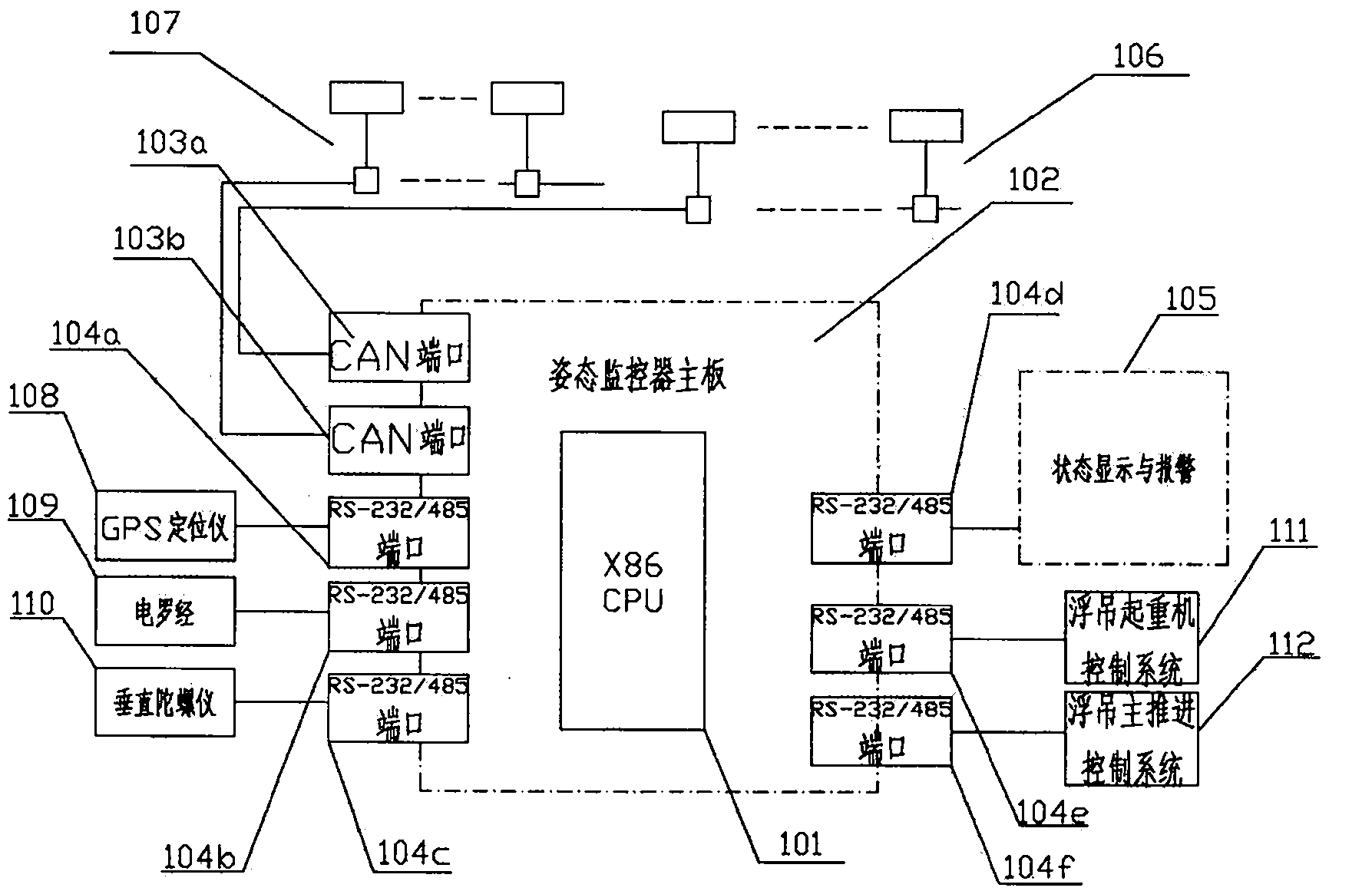

Method for monitoring work attitude and safety of hoisting operation of floating crane

InactiveCN101780921AWorking posture monitoringGuarantee quality and safetyCranesLoad-engaging elementsSimulationMonitoring methods

The invention discloses a method for monitoring the work attitude and safety of hoisting operation of a floating crane, comprising the following steps: acquiring initial data of floating crane attitude relative to a vertical reference coordinate system in real time; judging the hoisting operation work attitude of the floating crane; performing azimuth shift control on the floating crane; performing trim control on the floating crane; and performing heeling control on the floating crane. Real-time and accurate monitoring on the work attitude of the floating crane can be realized via the method for monitoring the hoisting operation work attitude of the floating crane obtained from the technical scheme, and simultaneously corresponding devices are controlled to perform corresponding adjustment on the floating crane so as to ensure the hoisting construction operation quality and safety of the floating crane.

Owner:SHANGHAI MARITIME UNIVERSITY

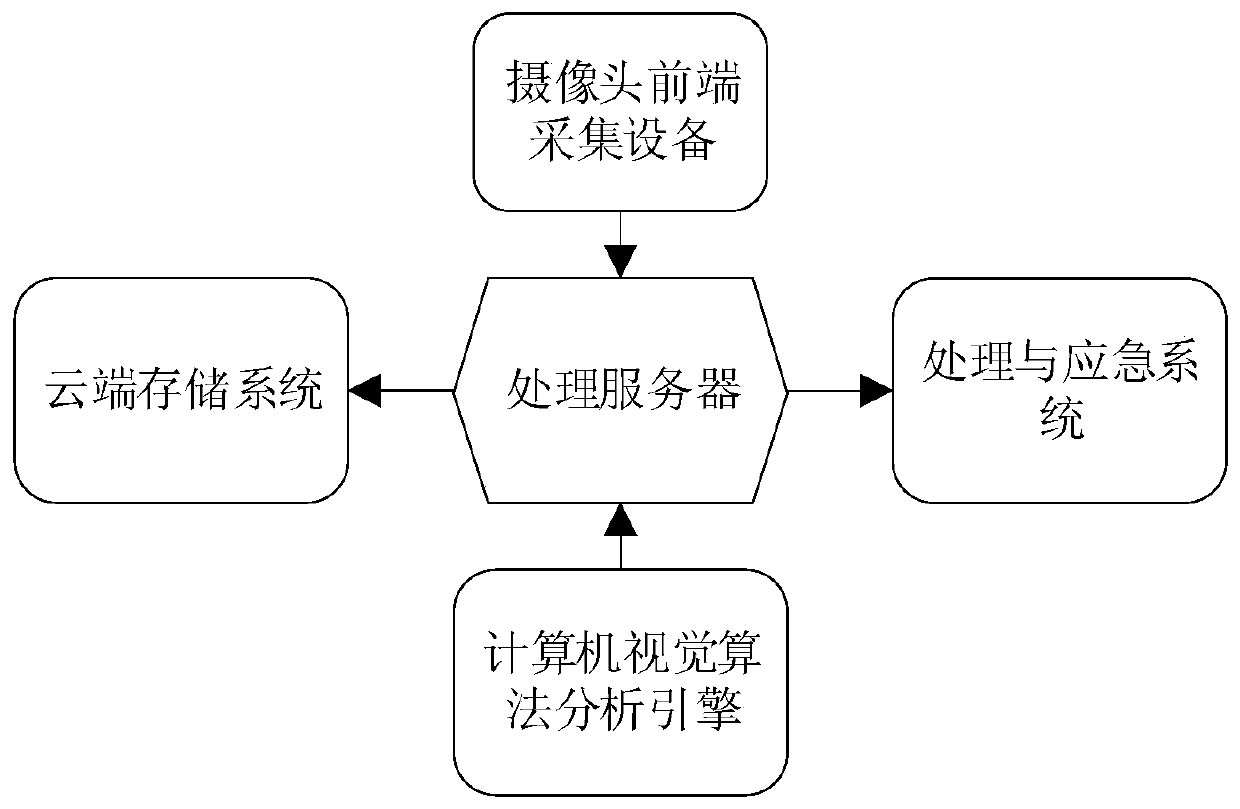

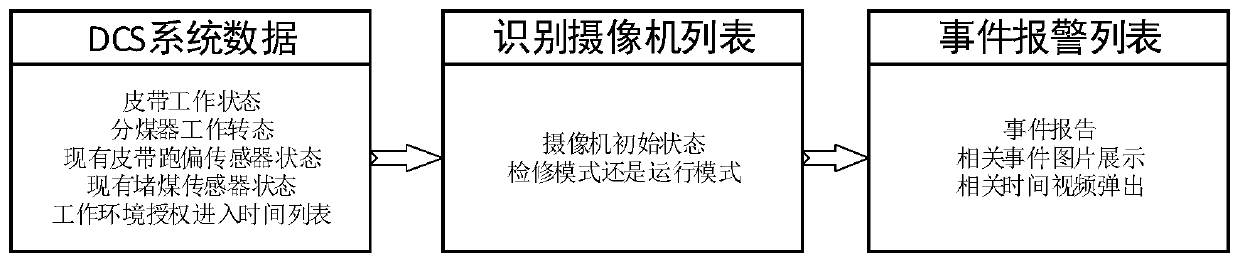

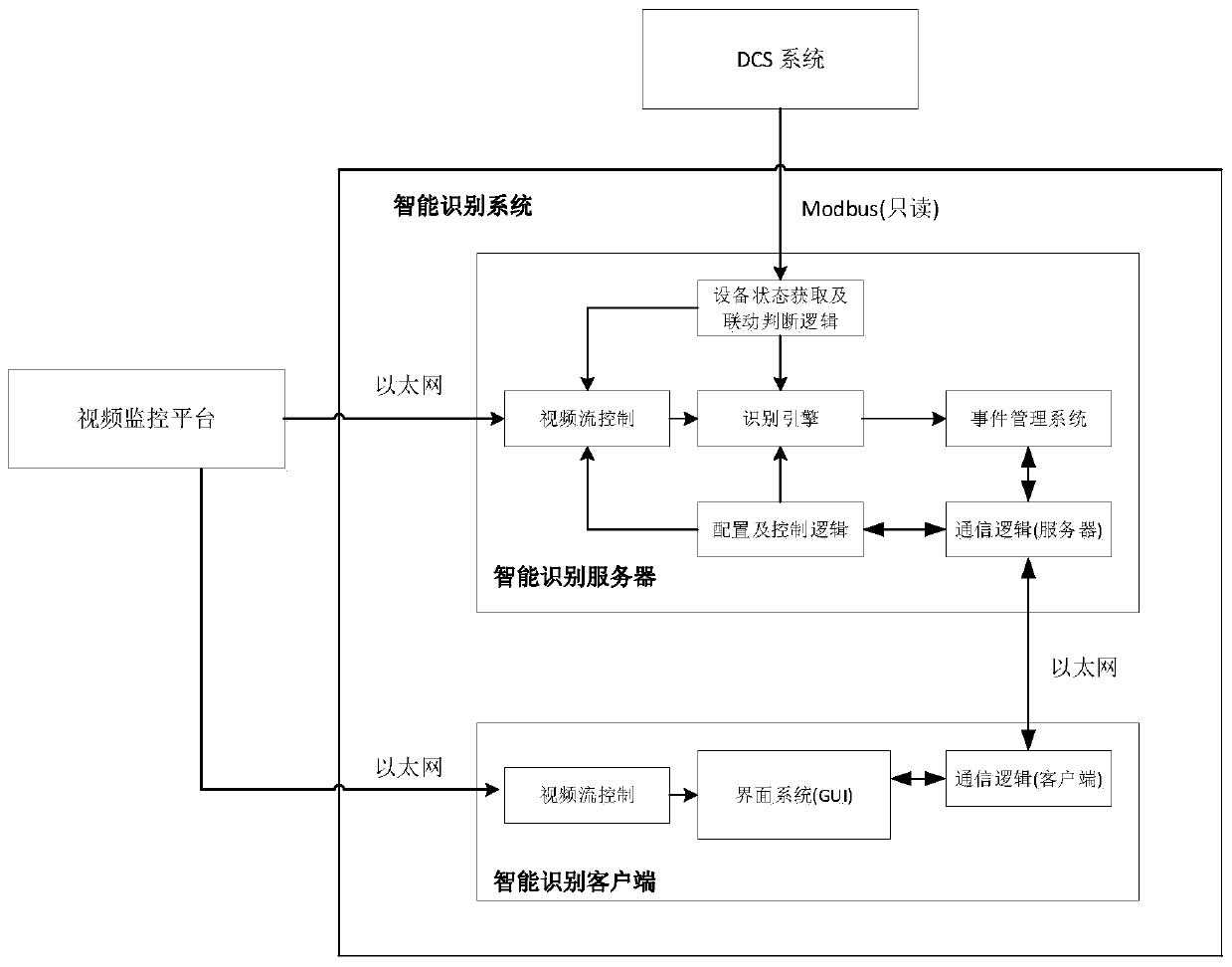

Intelligent coal conveying belt inspection system and method based on computer vision

InactiveCN111432179AUniversalQuickly grasp the actual situation on siteChecking time patrolsClosed circuit television systemsControl engineeringOperation safety

One technical scheme of the invention is to provide an intelligent coal conveying belt inspection system based on computer vision. Another technical scheme of the invention is to provide an intelligent coal conveying belt inspection method based on computer vision. In the belt running process, the running state of the belt can be detected in real time, abnormal conditions are found in time, and analarm is given. The system provided by the invention has universality, is suitable for various belt transportation scenes, helps operation and maintenance personnel to master the actual situation ofthe scene more quickly, reduces the fixed-time operation of the existing detection sensor by manpower, prevents the further expansion of accidents caused by equipment faults so as to ensure the operation safety, and reduces the waste of manpower and time at the same time.

Owner:SHANGHAI POWER EQUIP RES INST

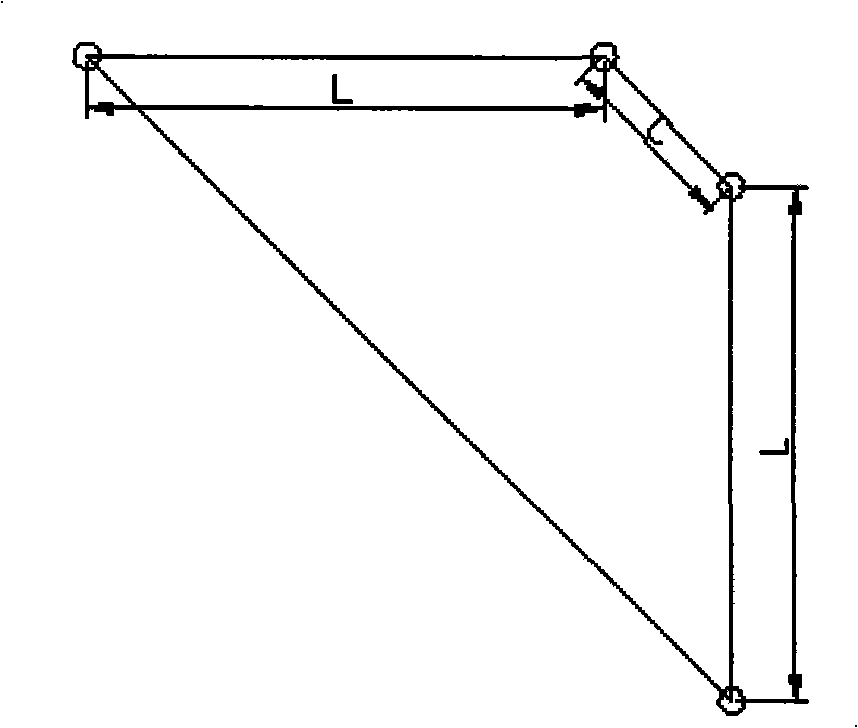

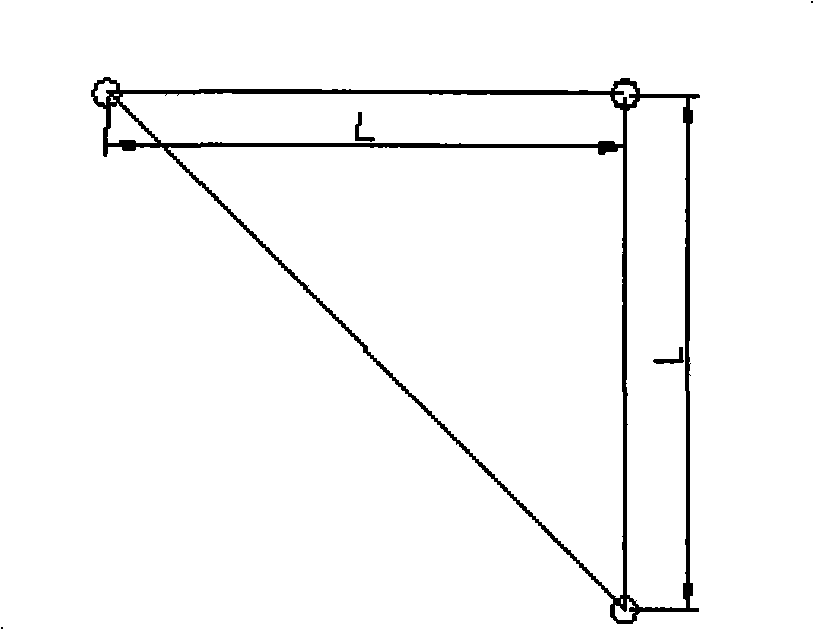

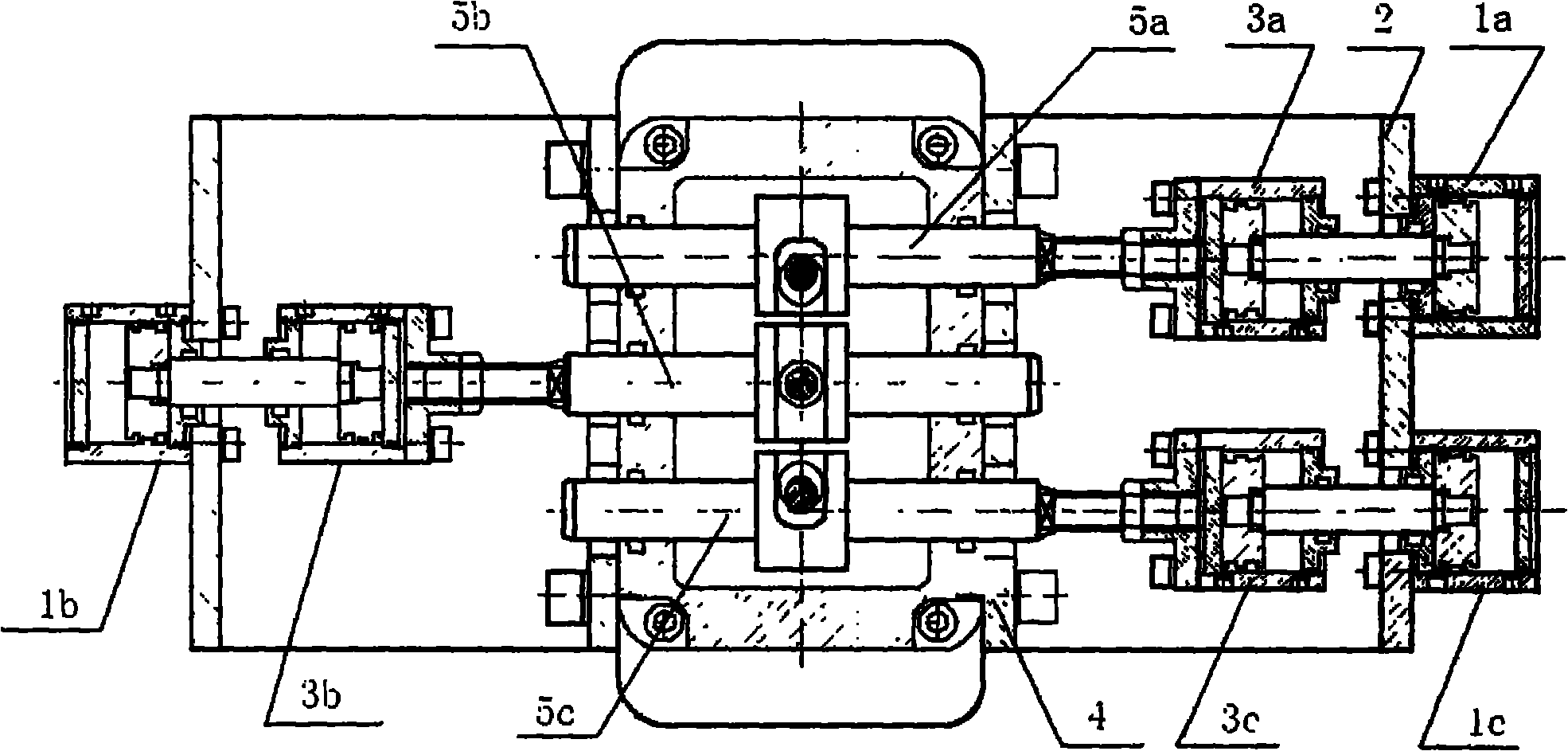

Hydraulic control system and apparatus for split positioning of ship body

ActiveCN101318538AIncrease collapse speedReduce time spentVessel partsMultiple deviceMarine engineering

The invention discloses a hydraulic control system and a device used for the location of a ship body by sections. Three hydraulic cylinders that are mutually orthogonal are adopted; wherein, the piston rod of a hydraulic cylinder with a displacement sensor moves up and down; the other two hydraulic cylinders push the hydraulic cylinder to move front and back as well as left and right on a horizontal plane. The moving displacement on the horizontal plane of the hydraulic cylinder the piston rod of which moves up and down is monitored and recorded by a displacement sensor; the recorded data is input into a PCL control circuit, thereby further controlling the expansion amount of the other two hydraulic cylinders to be capable of ensuring the hydraulic cylinder the piston rod of which moves up and down to make translational motion on the horizontal plane. The system and the device of the invention can adjust and control the precise positions of up and down, front and back as well as left and right of the substances arranged at the hydraulic cylinder the piston rod of which moves up and down. Location with high precision can be carried out on the ship body by sections according to the free combinations of three or multiple devices.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

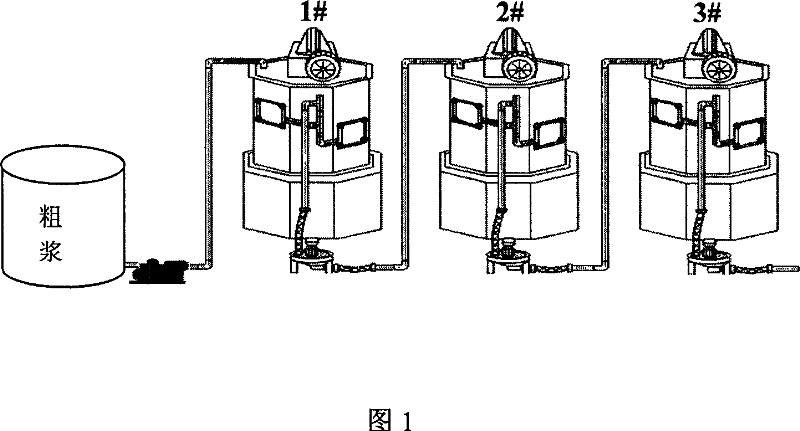

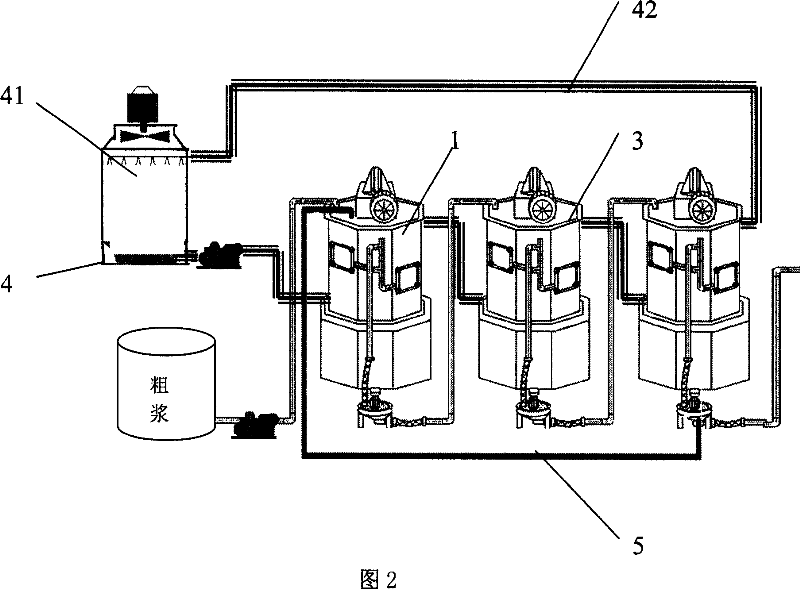

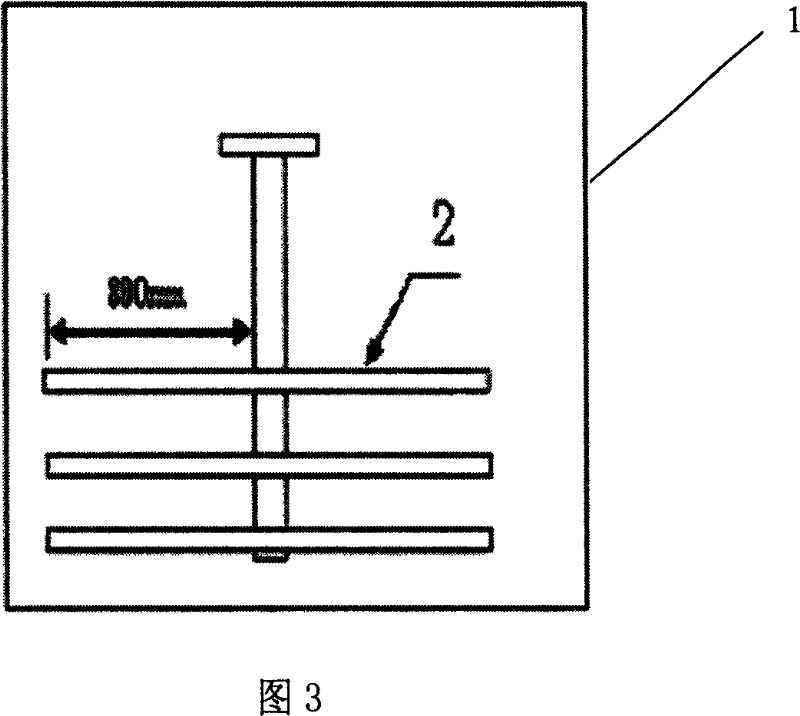

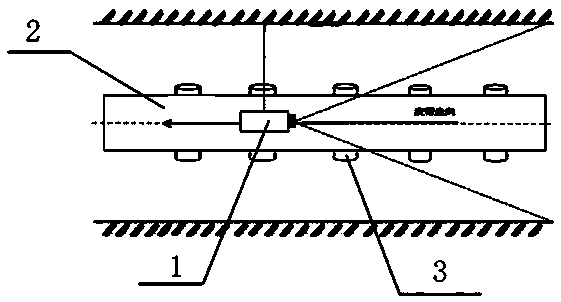

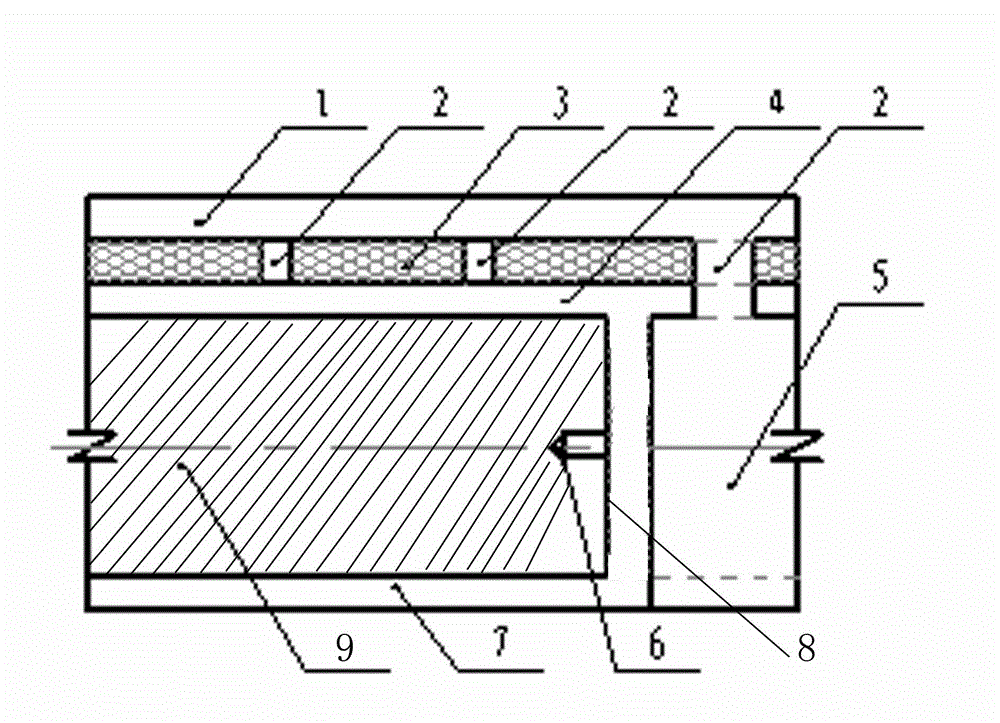

Preparation method of heavy calcium carbonate and special sharpener

InactiveCN101037213AEmission reductionEnsure job safetyCalcium/strontium/barium carbonatesGrain treatmentsMetallurgySlurry

The present invention discloses a preparation method of large calcium carbonate and a special grinding equipment thereof. The preparation method comprises the steps of that: the large calcium carbonate powder is prepared into serum and then is send to the wet grinding equipment to be grinded by a plurality of stages; the defective products generated in the grinding process is returned, by a circulating system, to the feeding system to be regrinded; when the surface temperature of the wet grinding equipment rises up to a certain temperature, the cooling system is started to drop in temperature; the acceptable products are obtained after multistage grinding. The special grinding equipment comprises a grinding chamber, an agitator arranged inside of the grinding chamber and a cooling jacket arranged outside of the grinding chamber, wherein the cooling water from the cooling system flows across the cooling jacket and then returns to the cooling system. The heat generated in the grinding process can be taken away by the cooling water in the cooling jacket, so that the ambient temperature can be efficiently improved, the number of defective product is reduced, the raw material is saved and the cost is reduced.

Owner:GOLD EAST PAPER JIANGSU

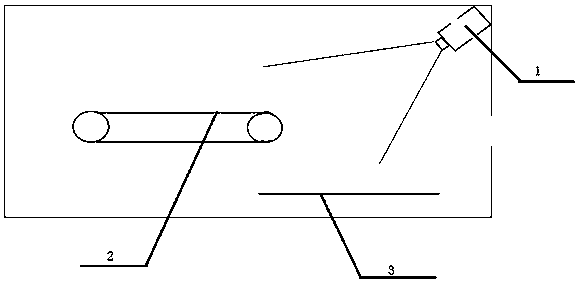

Monitoring method capable of identifying belt deviation through artificial intelligent video

ActiveCN110040470ASolve running detection problemsReduced timeliness for operationsConveyorsControl devices for conveyorsHigh definitionOperation safety

The invention discloses a monitoring method capable of identifying belt deviation through an artificial intelligent video. The monitoring method comprises the following steps of selecting not less than two support rollers on two side frames of a belt as two or more tracking objects, acquiring a tracking object video in real time through a mineral high-definition anti-explosion video camera, transmitting the tracking object video to a server in real time through a network by the mineral high-definition anti-explosion video camera, analyzing the tracking target video by the server through an artificial intelligent video identifying module, detecting whether the belt shields a tracking target or not when the tracking target is shielded, determining that the belt deviates if the detected result is that shielding is caused by the belt, and judging that the belt does not deviate if the detected result is that shielding is not caused by the belt. The invention aims to solve the belt operationdetecting problem through an artificial intelligent technology. The monitoring method achieves timely finding and alarming while a belt deviation phenomenon appears in a belt operation process, is suitable for various belt transportation scenes, and reduces manual timed correcting operation of an existing detecting sensor, so that coal mine operation safety is ensured, and waste of labor power and time is reduced.

Owner:JINGYING SHUZHI TECH HLDG CO LTD

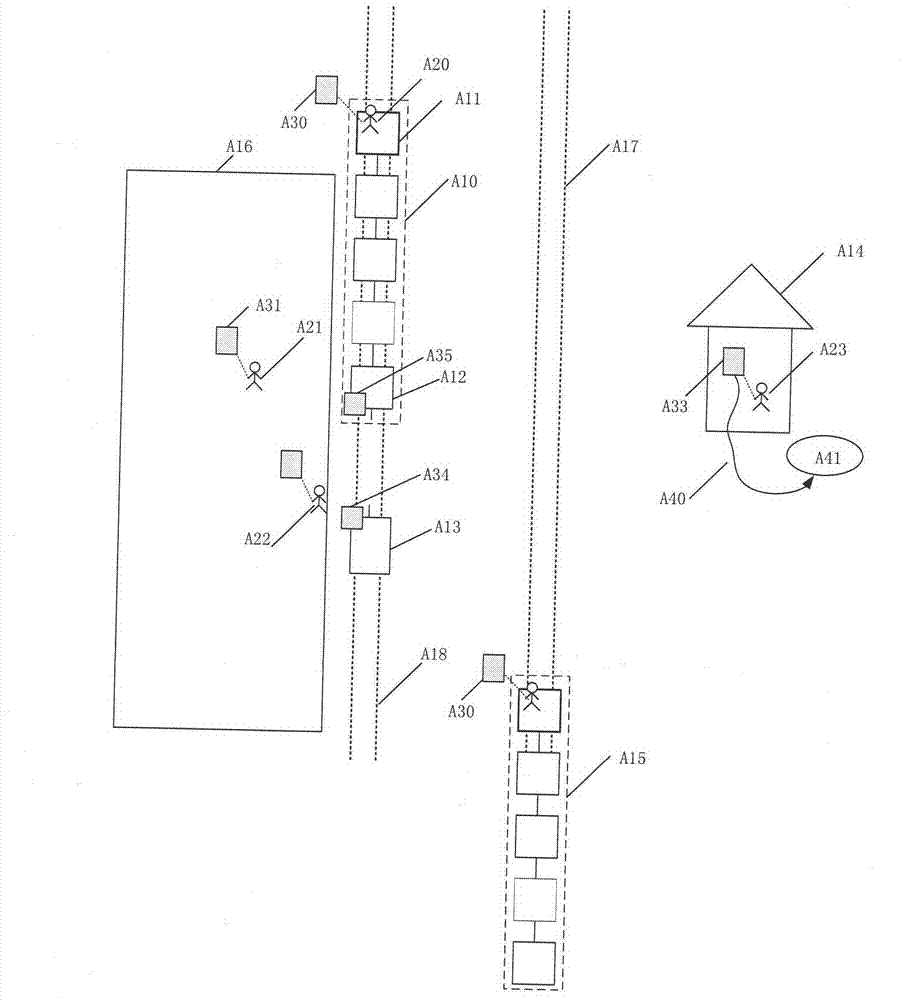

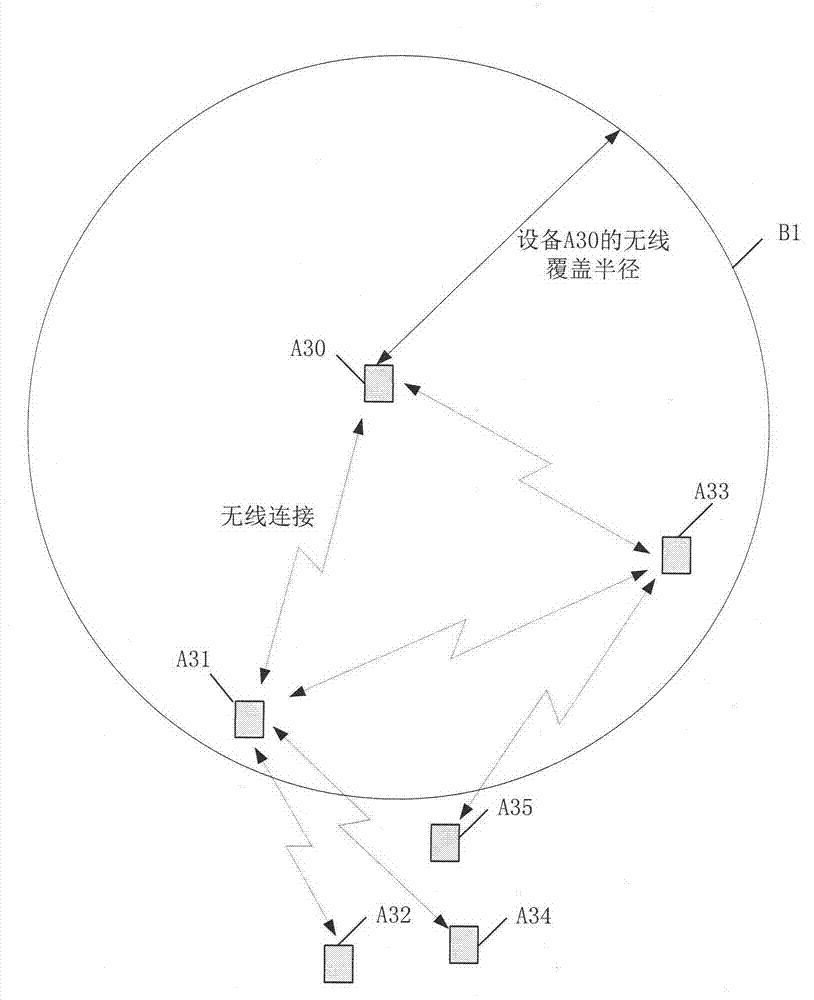

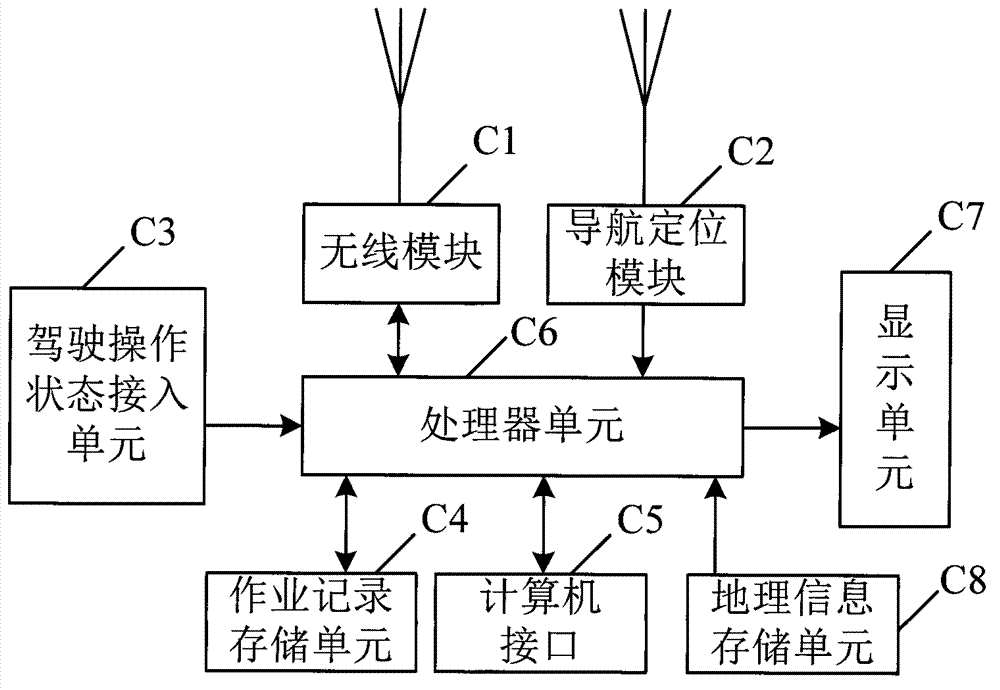

Safety warning method and system for railway operation

The invention discloses a warning method and a warning system for guaranteeing the safety of railway operation. The warning method for guaranteeing the safety of railway operation comprises the following steps: train driver operation equipment, non-train-driver worker handheld equipment, compartment positioning equipment and dispatching room equipment form a wireless network; the train driver operation equipment, the non-train-driver worker handheld equipment and the compartment positioning equipment acquire the own position through a satellite navigation and positioning system and broadcast the own position to other equipment continuously through the wireless network; the non-train-driver worker handheld equipment broadcasts the own operation state to other equipment continuously; and the train driver operation equipment collets other node positions and displays the positions of all the workers involved in the operation by combining a geographic information system. The warning system for guaranteeing the safety of railway operation comprises the train driver operation equipment, the non-train-driver worker handheld equipment, the compartment positioning equipment and the dispatching room equipment and realizes the method. The method and the system have the benefits of providing objective warning for guaranteeing the safety of railway operation and eliminating man-made hazards so as to guarantee the safety of railway operation.

Owner:陈波

Steel bar strapping machine

The invention discloses a steel bar strapping machine which comprises a machine head, a casing, a transmission system, a wire feeding system fixed inside the casing, a wire cutting system and a stranding system. The stranding system comprises a stranding shaft, wherein the stranding shaft is of a segmented structure and comprises a driving shaft and a driven shaft at least. The stranding system further comprises a slipping device for being connected with the driving shaft and the driven shaft. When transfer torque between the driving shaft and the driven shaft exceeds slipping torque of the slipping device, the driving shaft breaks away from the driven shaft in a transmission mode. The stranding shaft of the steel bar strapping machine is designed to be of the structure provided with at least two segments, and the slipping device is added and enables the driving shaft and the driven shaft to be connected. When the transfer torque between the driving shaft and the driven shaft exceeds the preset slipping torque of the slipping device, the slipping device slips and accordingly enables the driven shaft to stop rotating and suspending stranding process, the torque control effect is achieved, iron wires are prevented from being twisted off, the labor amount of workers is reduced, the operation efficiency is improved, and the operation safety is ensured.

Owner:SUZHOU BIAOTU SENIOR SEAT CO LTD

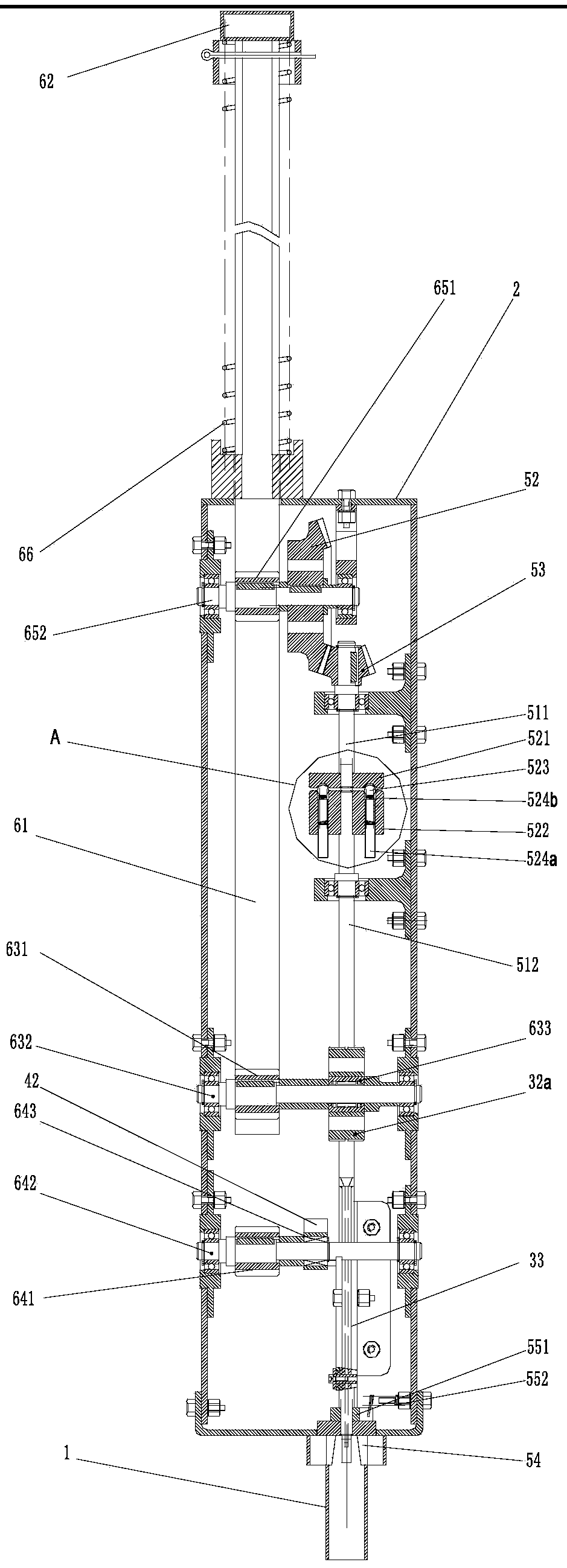

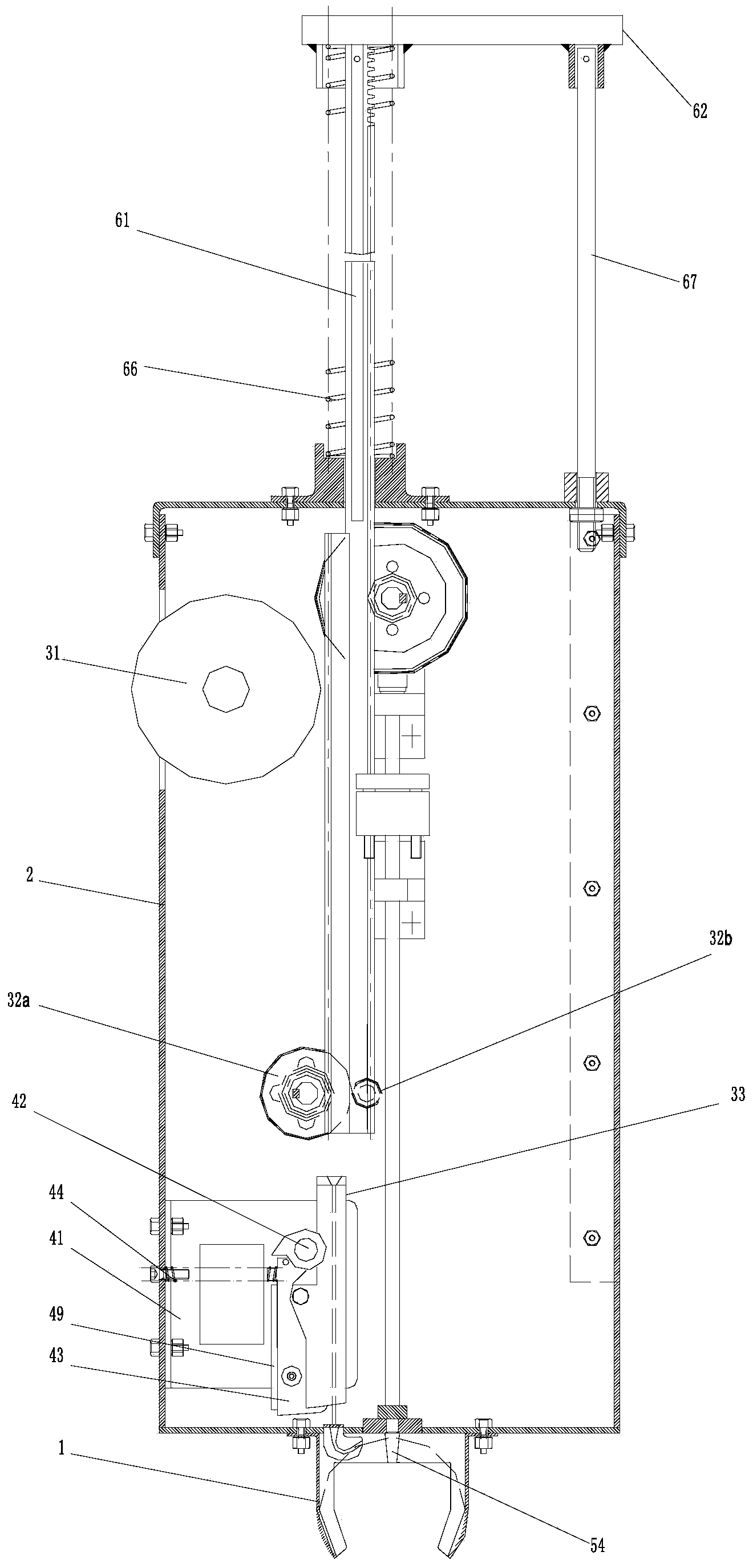

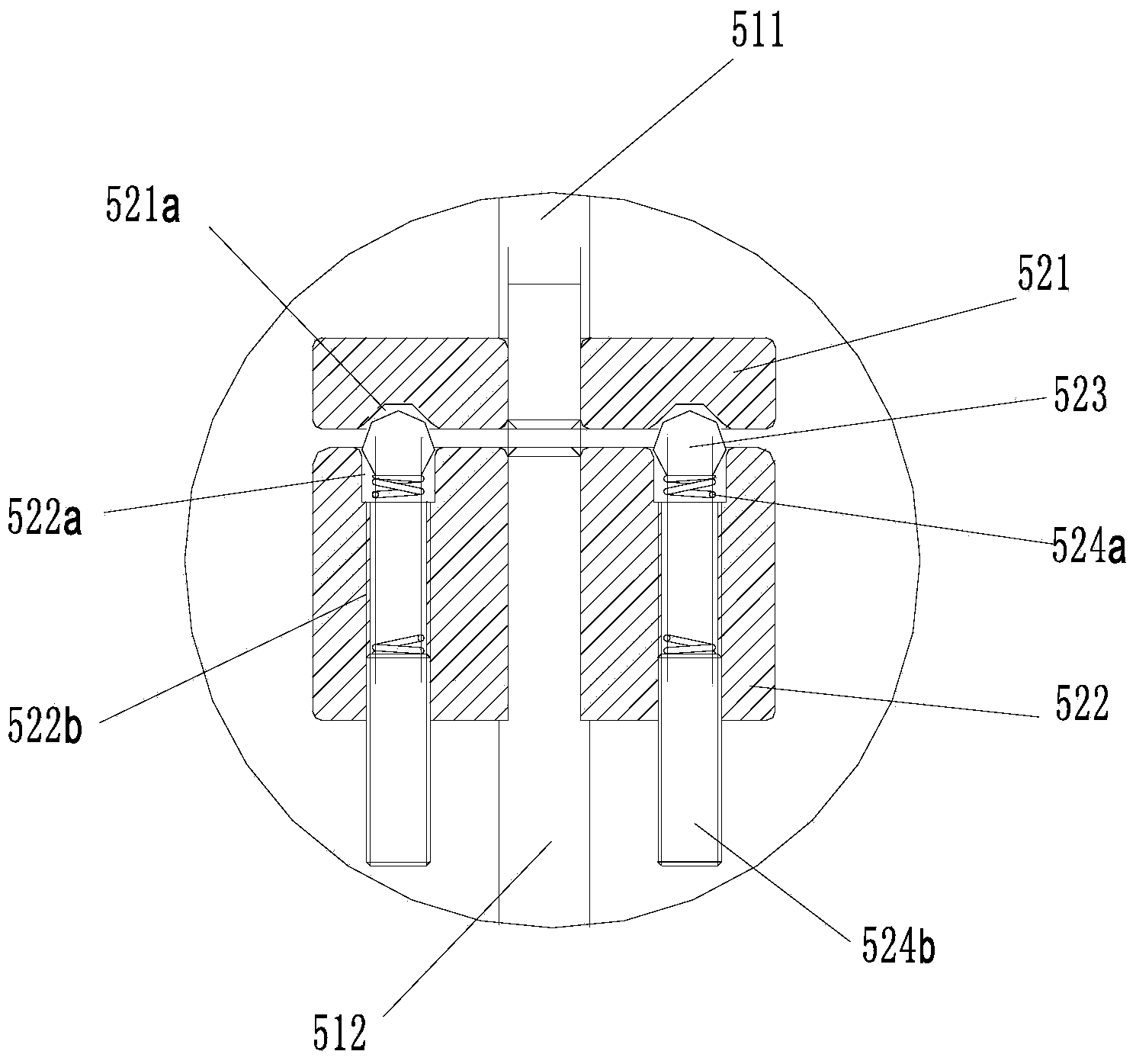

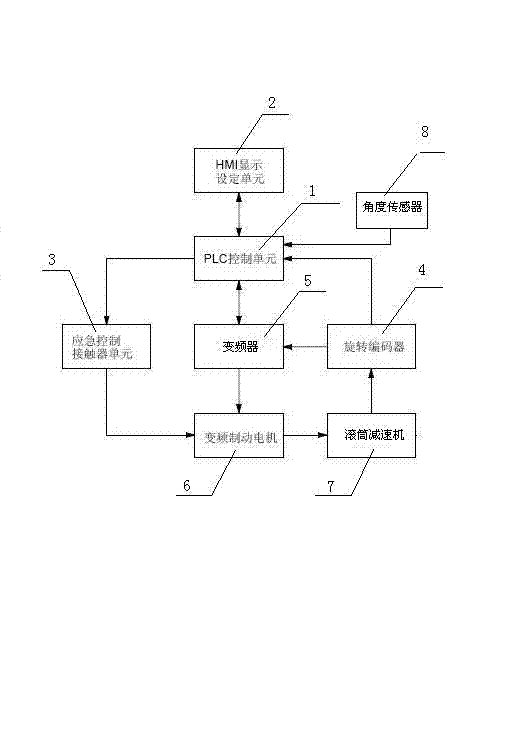

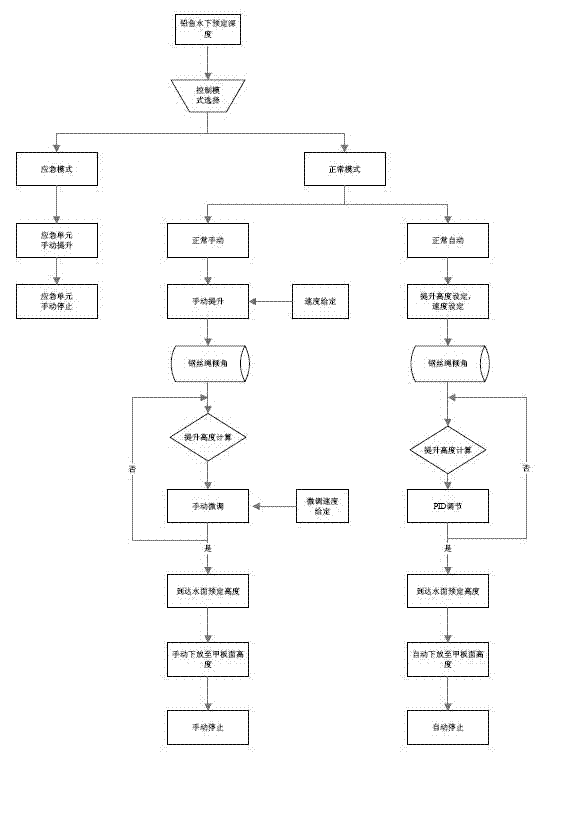

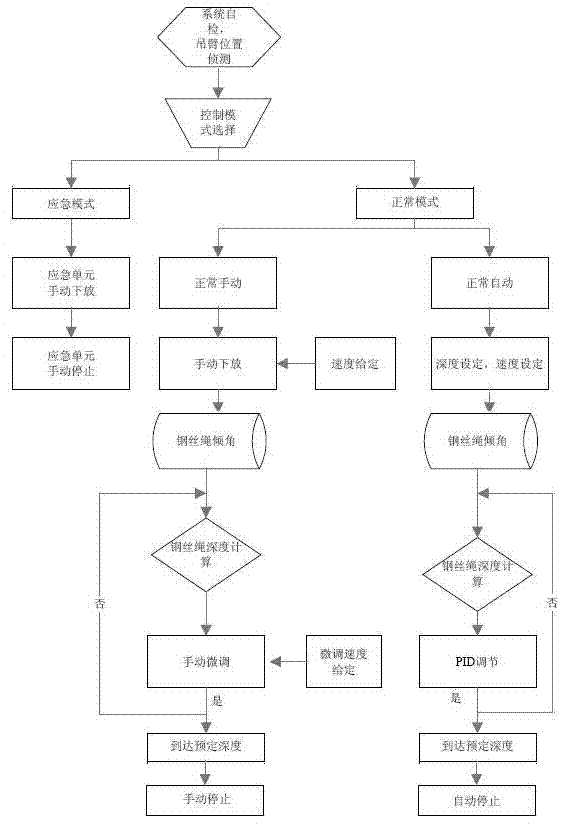

System and method for controlling hydrological winch

InactiveCN103043553AEnsure job safetyConvenient surveying and mappingWinding mechanismsFrequency changerHuman–machine interface

The invention discloses a system and method for controlling hydrological winch. The system comprises a programmable logic controller (PLC) control unit, a human machine interface (HMI) display setting unit, an emergency control contact unit, a rotary encoder, a frequency converter, a frequency conversion brake motor, a rotary drum speed reducer and an angle sensor. The HMI display setting unit is connected with the PLC control unit, the PLC control unit controls the emergency control contact unit and the frequency converter, the emergency control contact unit and the frequency converter are connected with the frequency conversion brake motor, the frequency conversion brake motor is connected with the speed reducer to drive the speed reducer to drive a rotary drum to work, the rotary encoder detects a state signal of the rotary drum speed reducer and transfers the state signal to the PLC control unit and the frequency converter, and the angle sensor transfers an angle signal to the PLC control unit. The system can accurately measure and calculate the length, the speed and relative water depth of a winding and releasing steel wire rope and accurately and stably delivers a device to a designated position to finish surveying and mapping operation.

Owner:镇江赛尔尼柯自动化股份有限公司

Fast maintenance method for furnace lining of deslagging surface of converter

InactiveCN108660282AImproves washout propertiesEasy dischargeManufacturing convertersProcess efficiency improvementSmelting processTemperature difference

The invention provides a fast maintenance method for a furnace lining of a deslagging surface of a converter. The fast maintenance method for the furnace lining of the deslagging surface of the converter is applied to the technical field of iron and steel smelting processes, and comprises the maintenance steps of deslagging the converter, and remaining high-temperature residual furnace slags in the converter; adding bar steel scraps having temperature difference with the residual furnace slags into the converter, precipitating and condensing high-melting-point mineral substances in the furnaceslags under the action of the temperature difference of the bar steel scraps and the residual furnace slags, and adhering to the deslagging surface of the converter so as to replace a fettling material; and statically cooling the converter, and after finishing cooling, accomplishing the fast maintenance operation for the furnace lining of the deslagging surface of the converter. According to thefast maintenance method for the furnace lining of the deslagging surface of the converter provided by the invention, no cost input of the fettling material is required, the problems of the adverse effect on fettling and the environment pollution due to too long or too short sintering time are avoided, the molten steel end point components are ensured, the fettling time is effectively shortened, the converter operability is improved, and meanwhile, the fast maintenance method for the furnace lining of the deslagging surface of the converter has the characteristics of fast maintenance speed, good fettling effect, low fettling cost, safety, environment protection and the like.

Owner:MAANSHAN IRON & STEEL CO LTD

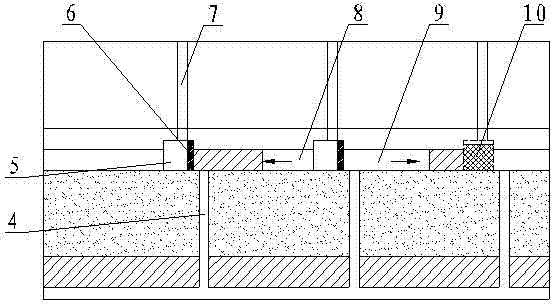

Under-building, under-railway and under-water mining filling process

ActiveCN102865099AImprove recovery rateReasonable utilization of gangueTunnel/mines ventillationMaterial fill-upCoal wasteCoal pillar

The invention relates to a coal mining process, in particular to an under-building, under-railway and under-water mining filling process, and solves the technical problems that the recovery ratio is low and a god cannot be filled effectively in the conventional coal mining technology. The under-building, under-railway and under-water mining filling process comprises the following steps of: (a) respectively tunneling a belt air return lane and a railway air inlet lane on the two sides parallel to a coal seam to be mined; (b) tunneling a waste rock transportation and air return lane along one side of the belt air return lane; (c) performing recovery on the coal seam (9) to be mined, and simultaneously, digging a contact channel perpendicular to the waste rock transportation lane on a coal pillar between the waste rock transportation and air return lane and the belt air return lane; (d) performing coal waste rock filling operation on the gob to finish a work cycle; and (e) repeating the work cycle continuously until all gobs are filled. The under-building, under-railway and under-water mining filling process is suitable for comprehensive mechanized coal mining of large and medium-sized coal mines and high in recovery rate; waste rock is utilized reasonably; and the harmony of ecology and production in a mine area is realized.

Owner:晋能控股装备制造集团金鼎山西煤机有限责任公司

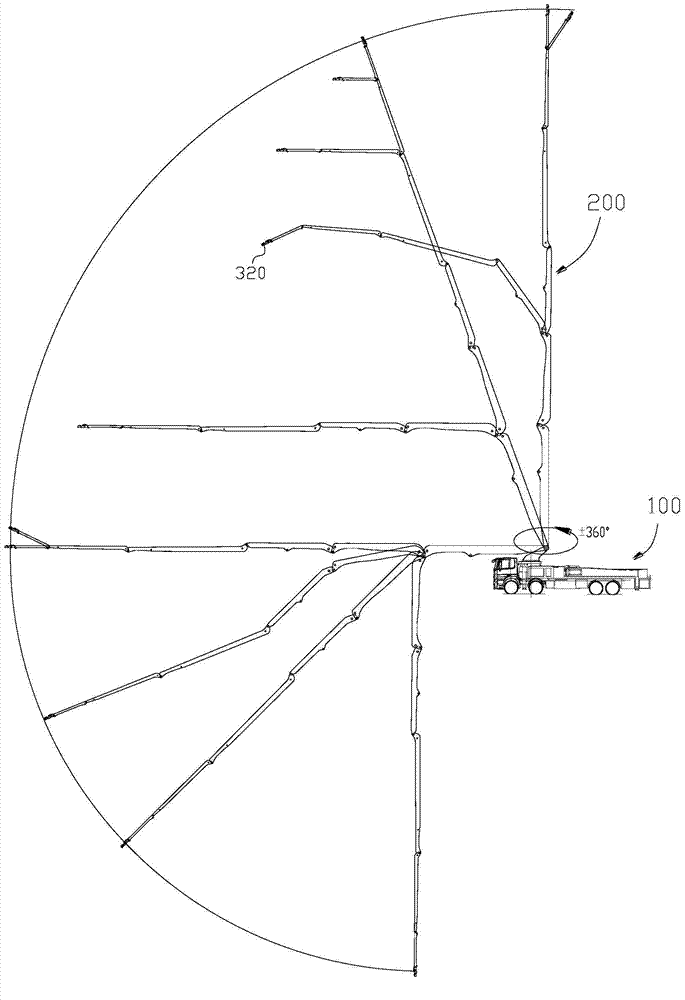

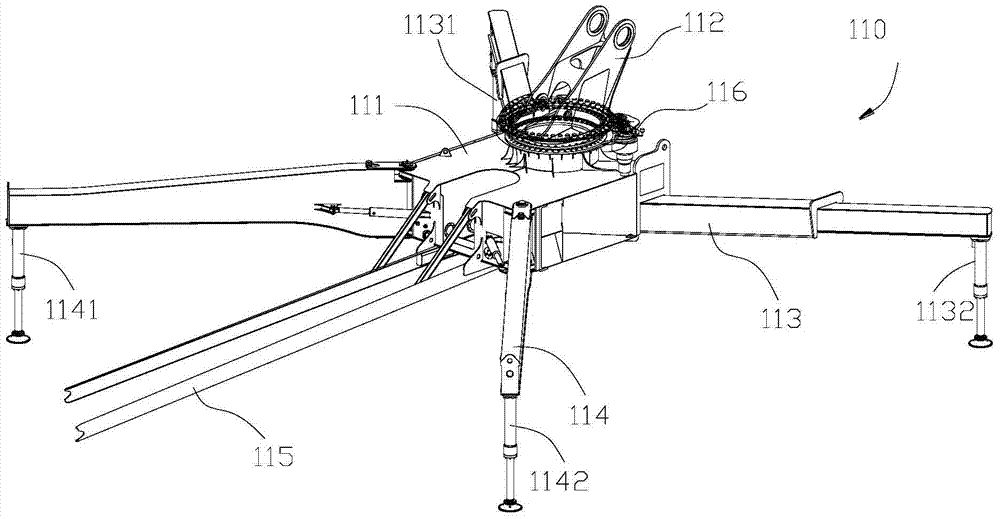

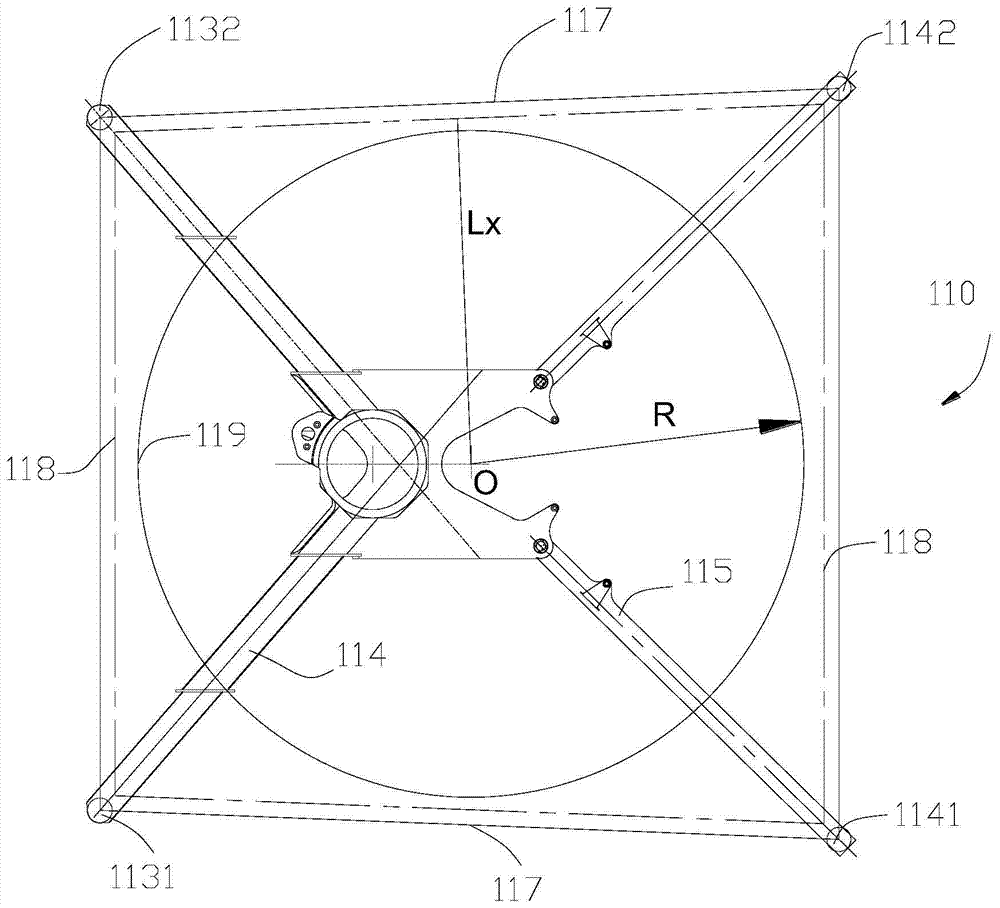

Fire fighting truck

The invention provides a fire fighting truck which comprises a chassis, a boom system, a spraying system, a hydraulic system and an electrical control system. The boom system, the spraying system, the hydraulic system and the electrical control system are arranged on the chassis, the chassis comprises a supporting device, a power system and a running unit. The boom system comprises multiple folding arms which are sequentially hinged, the first arm of the multiple folding arms is connected with the supporting device, the spraying system comprises a delivery pipe extending from the multiple folding arms, an ejector arranged at the tail end of the multiple folding arms and a medium pump for pumping a medium towards the ejector. The hydraulic system comprises a hydraulic pump for driving the multiple folding arms to perform amplitude variation, the electrical control system is connected with the power system and the hydraulic system, and the power system can selectively provide power for at least one of the running unit, the medium pump and the hydraulic pump. The fire fighting truck can achieve full-level work or even work at the position lower than the fire fighting truck through a whole folding boom and the boom system and is large in boom working amplitude, flexible in action and capable of striding over an obstacle to perform extinguishment.

Owner:SANY AUTOMOBILE MFG CO LTD

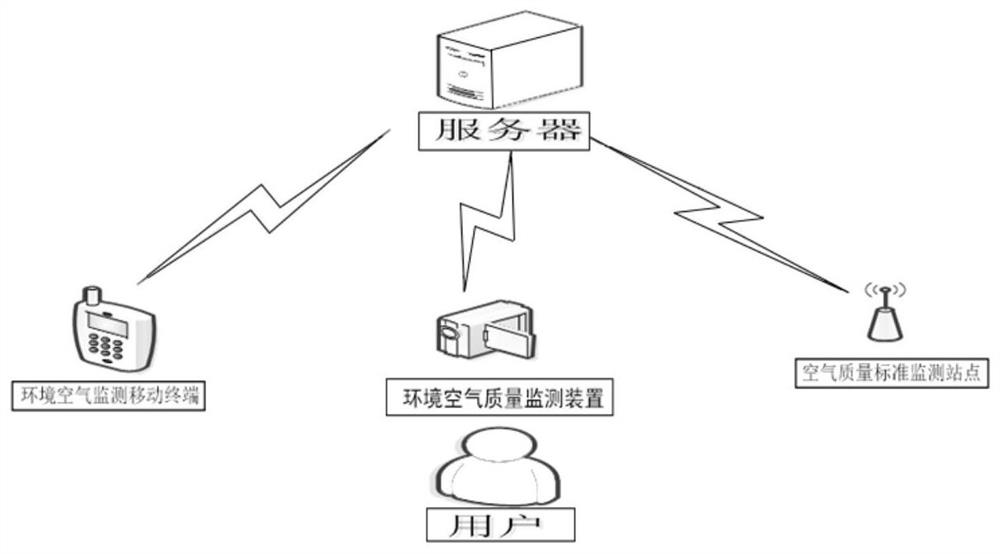

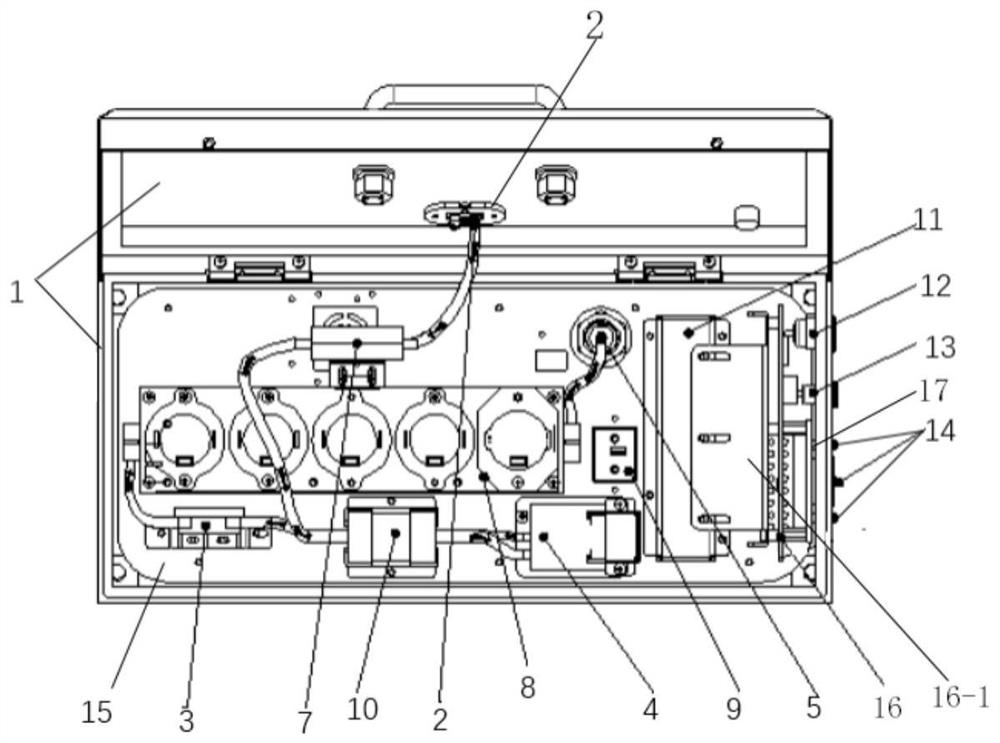

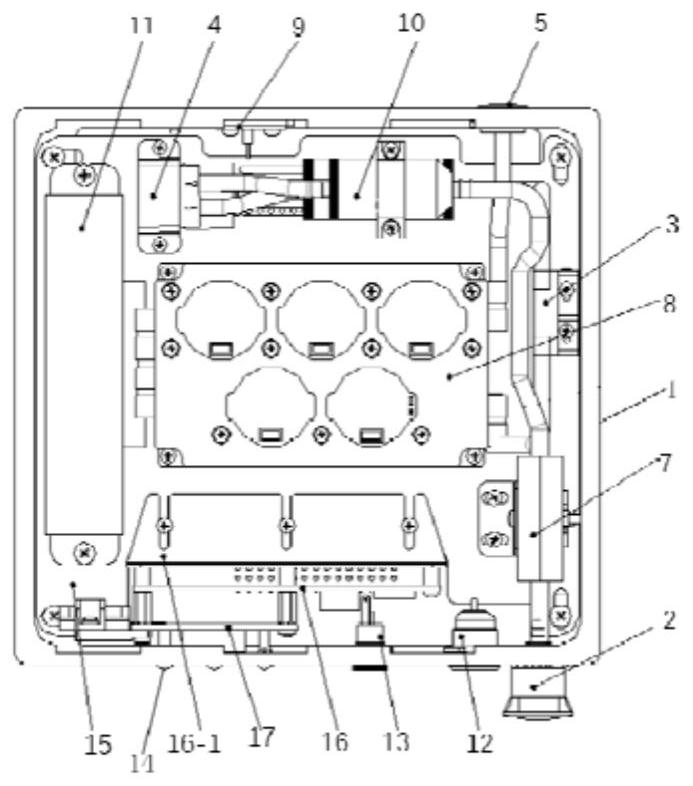

Ambient air monitoring sensor remote calibration method and ambient air quality monitoring device

ActiveCN112147280AImprove calibration efficiencyAvoid the needFlow control using electric meansSatellite radio beaconingAir monitoringComputer science

The invention provides an ambient air monitoring sensor remote calibration method. The sensor remote calibration method is characterized in that a server, an ambient air monitoring mobile terminal andan air quality standard monitoring station are adopted to carry out remote calibration on a sensor of an ambient air quality monitoring device. The invention also provides the ambient air quality monitoring device for ambient air monitoring. The ambient air quality monitoring device comprises a shell and an air quality monitoring system located in the shell, wherein the air quality monitoring system is internally provided with the sensor, and the ambient air quality monitoring device is applied to the sensor remote calibration method to carry out remote calibration on the sensor. The sensor remote calibration method can solve problems of complex sensor calibration process, low efficiency and high cost of the existing ambient air quality monitoring device; and the ambient air quality monitoring device has the advantages of convenient carrying, easy calibration, accurate detection result and low cost, and can carry out remote calibration on the sensor through the sensor remote calibration method, thereby reducing the calibration cost.

Owner:BEIJING INSIGHTS VALUE TECHNOLOGY CO LTD

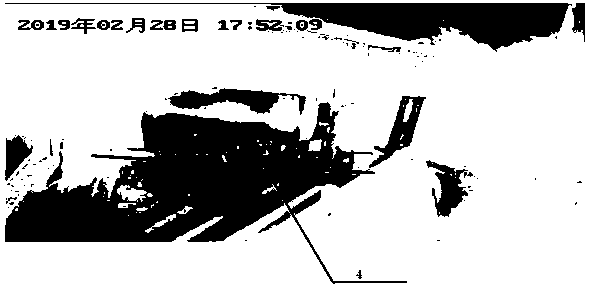

Monitoring method for identifying belt coal piling through artificial intelligent video

ActiveCN110053943AReduced timeliness for operationsEnsure job safetyConveyorsControl devices for conveyorsSmart technologyMonitoring methods

The invention discloses a monitoring method for identifying belt coal piling through an artificial intelligent video. The monitoring method comprises the following steps: arranging a warning line among a belt coal drop and a transferring point, and a belt; then acquiring a warning line video in real time through a mineral high-definition and explosion-proof camera; transmitting the warning line video to a server in real time by the mineral high-definition and explosion-proof camera through a network; analyzing the warning line video by the server through an artificial intelligent video identification model; when the warning line is shielded, detecting whether a target is shielded by coal piling or not; determining the belt coal piling when a detection result is that the shielding is causedby the coal piling; and judging that the belt coal piling is not caused when the detection result is that the shielding is not caused by the coal piling. The monitoring method disclosed by the invention aims at solving the problem of belt operation detection by utilizing an artificial intelligent technology; a belt coal piling phenomenon in a belt operation process is found and alarmed in time; the monitoring method is applicable to various belt conveying scenes and fixed-time correction operation of manpower on an existing detection sensor is reduced; and meanwhile, wastes of manpower and time are reduced.

Owner:JINGYING SHUZHI TECH HLDG CO LTD

Multi-purpose 10 kV drainage wire insulation fixer and work method with same

ActiveCN104143786AAvoid groundingAvoid short circuit failureApparatus for overhead lines/cablesEpoxyFiber

The invention relates to a multi-purpose 10 kV drainage wire insulation fixer and a work method with the multi-purpose 10 kV drainage wire insulation fixer. The multi-purpose 10 kV drainage wire insulation fixer comprises a forceps holder, an insulation outer cylinder, a forceps clamp transmission mechanism, a fixing and locking mechanism and an insulation crank. The insulation material of the body of the multi-purpose 10 kV drainage wire insulation fixer is formed by compositely pressurizing epoxy resin and alkali-free glass fibers in an integral surrounding mode. The forceps clamp is in a stretched state under the normal state. The multi-purpose 10 kV drainage wire insulation fixer and the work method with the multi-purpose 10 kV drainage wire insulation fixer are characterized in that an insulation rod work method and an insulation glove work method are adopted in the multi-purpose 10 kV drainage wire insulation fixer, and an operator can climb a pole or take an insulation bucket arm vehicle to conduct 10 kV overhead line electrified lead breaking and connecting work. The multi-purpose 10 kV drainage wire insulation fixer and the work method with the multi-purpose 10 kV drainage wire insulation fixer have the advantages that the insulation performance is high, and strength is large. The forceps clamp can stably control wires of different types, the operator can firmly control drainage wires to prevent grounding or short circuit faults caused by swinging of the drainage wires and ensure work safety, the safety in the electrified lead breaking and connecting process is greatly improved, the application range is wide, and the distinct practicability characteristic is achieved.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

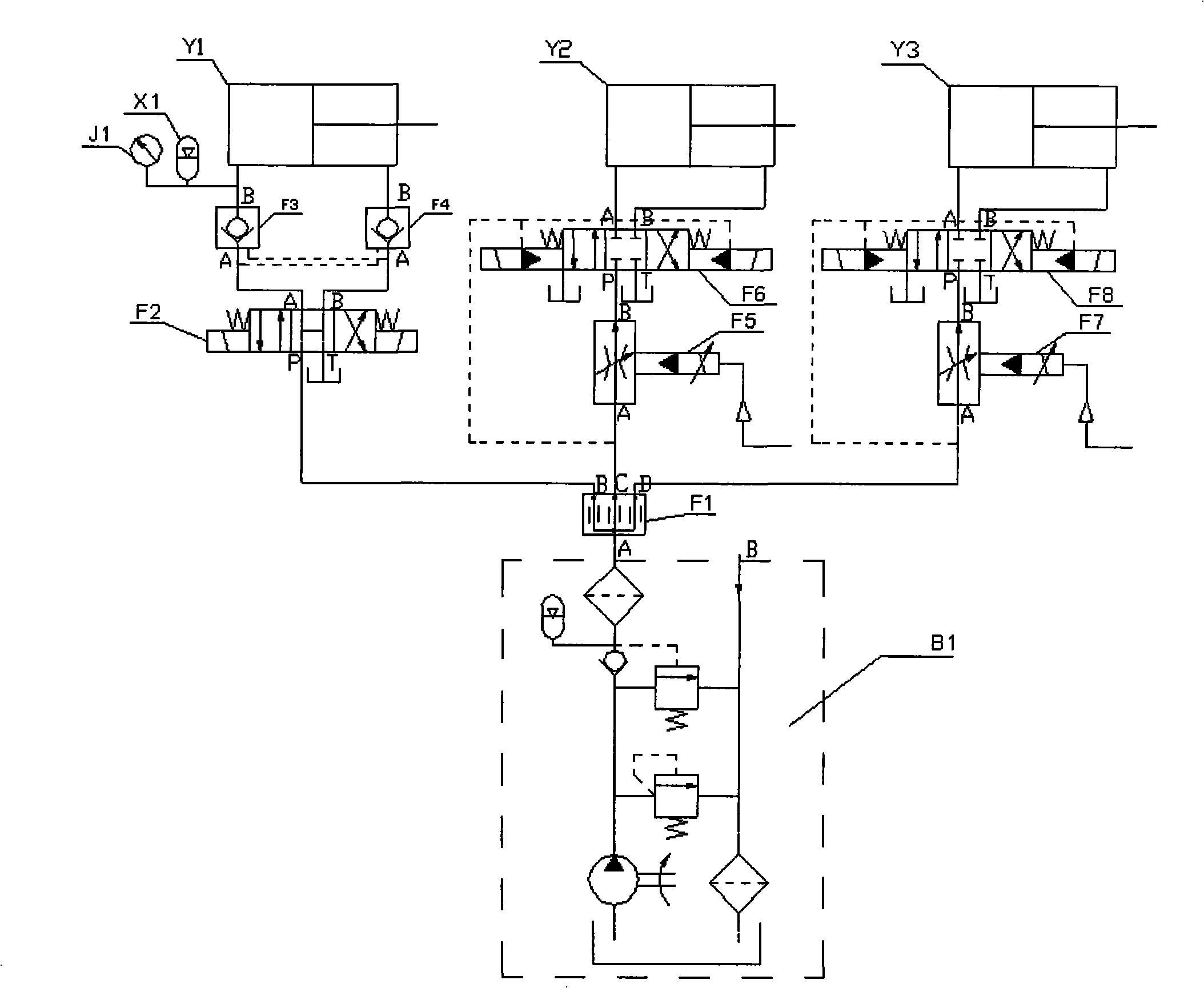

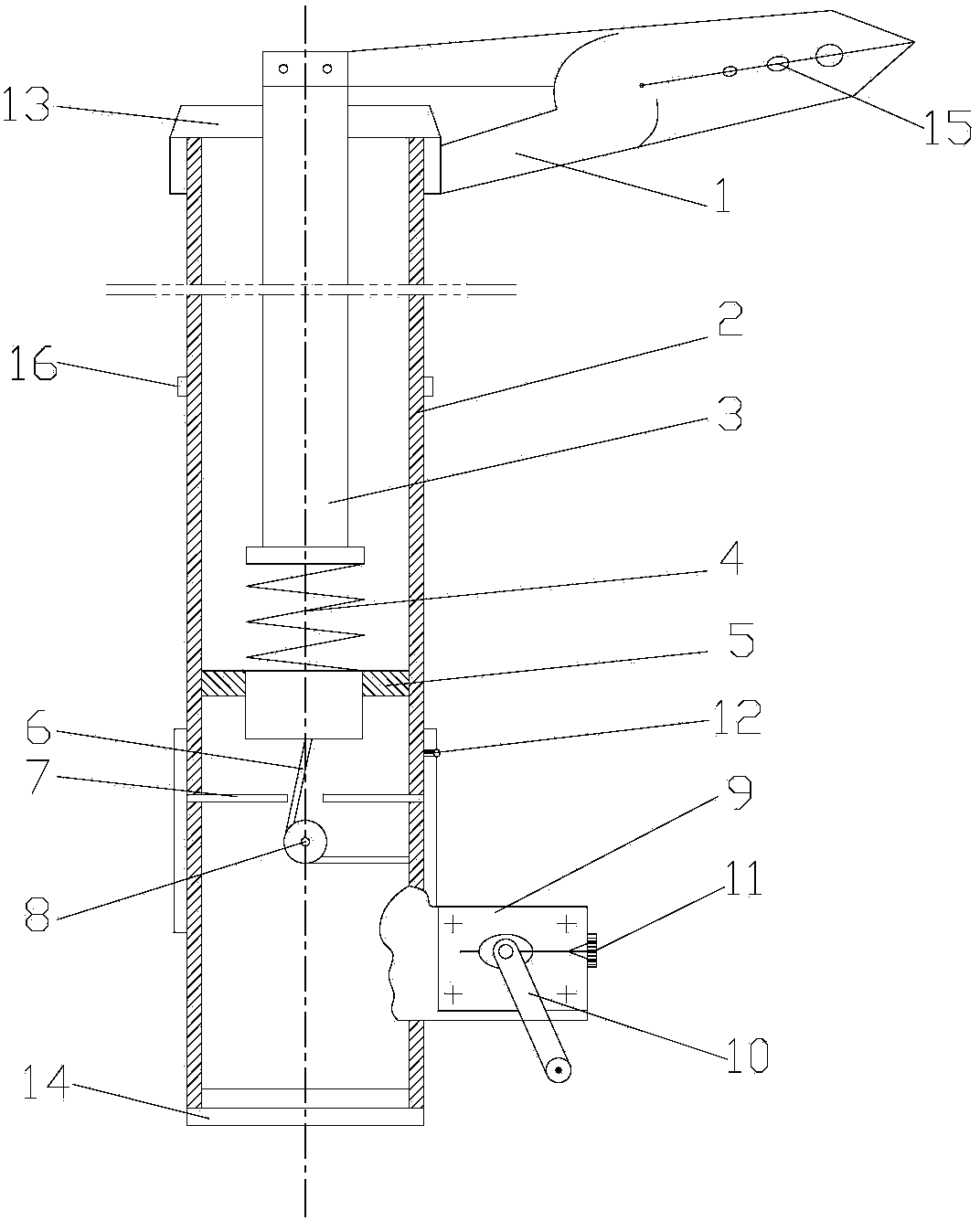

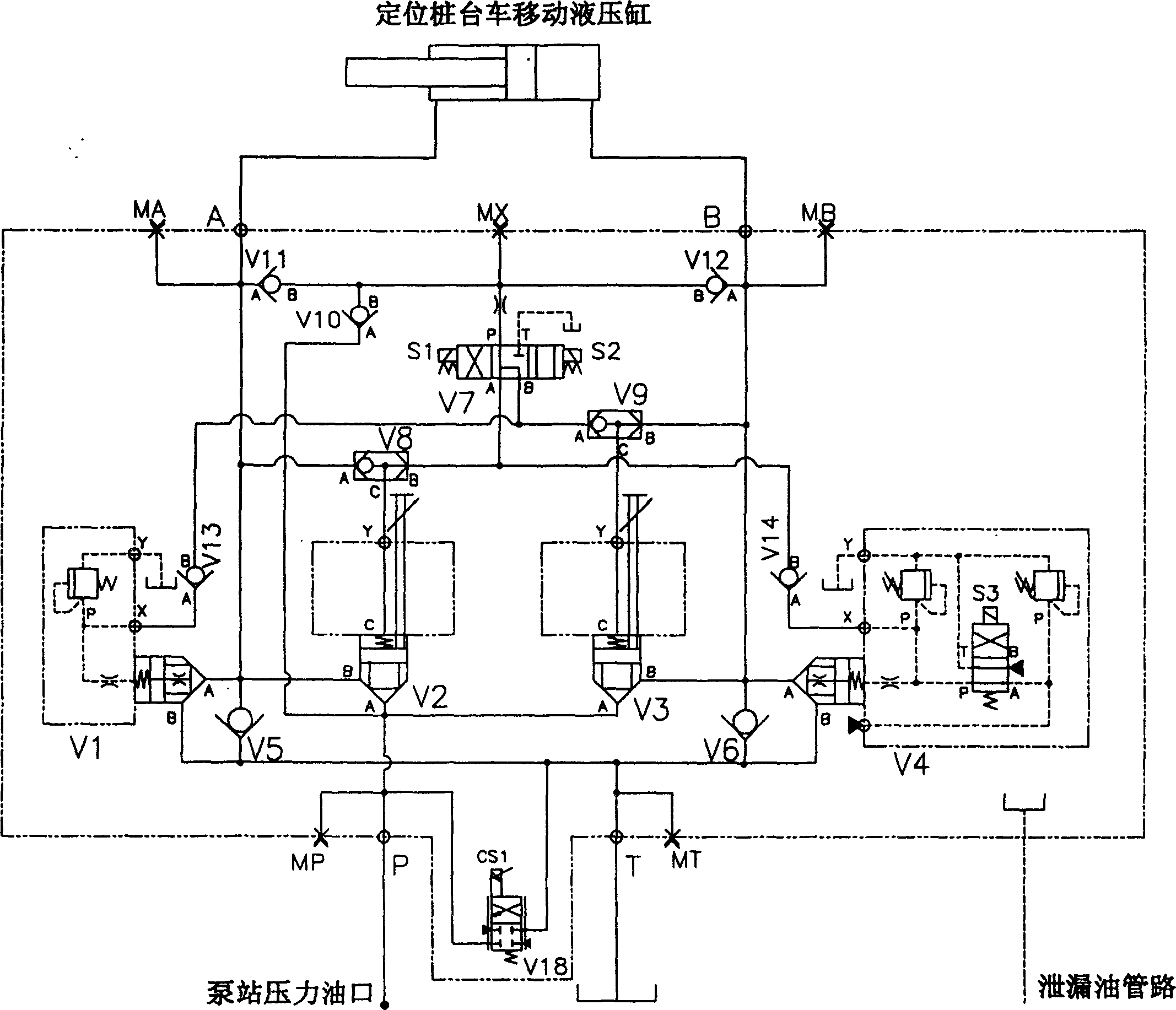

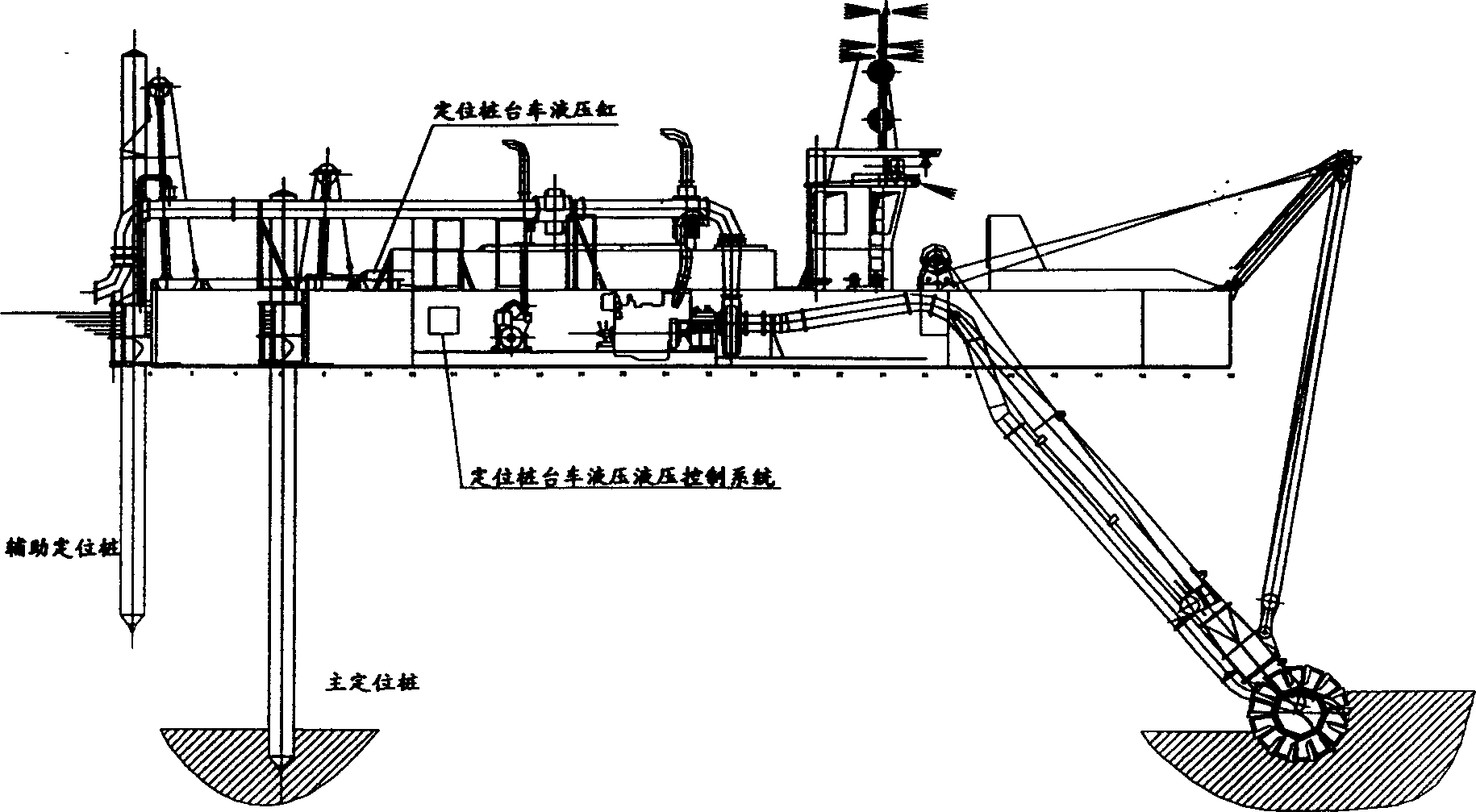

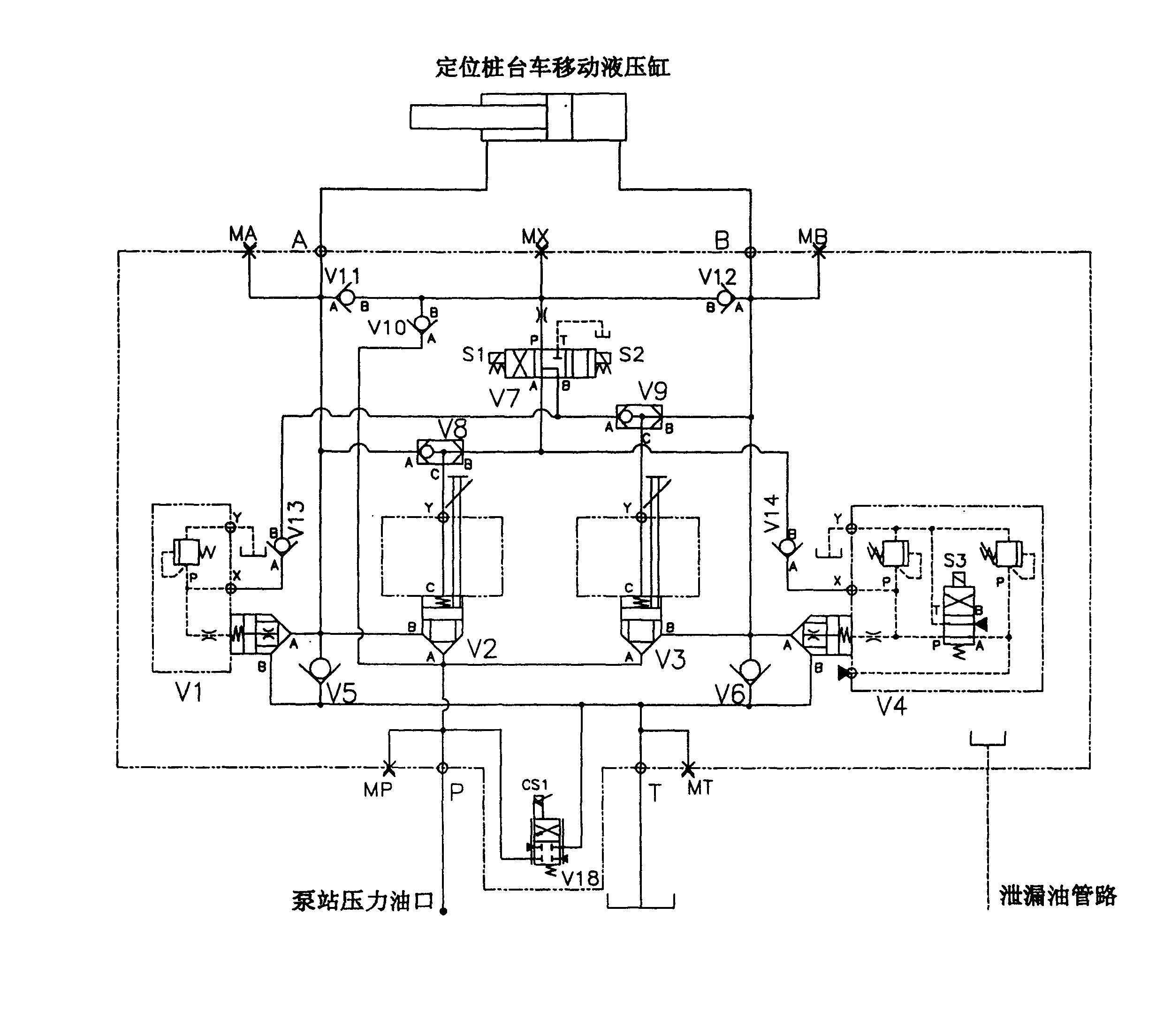

Trolley hydraulic control system of dredge boat positioning pile

InactiveCN1456819ACompact structureHighly integratedAuxillariesServomotor componentsHydraulic cylinderControl system

A hydraulic control system for the locating unit of dredger is composed of two one-way valves, two shuttle valves, two overflow valves, electromagnetic diverter valve, two locking one-way valves, proportional throttle valve, and five logic one-way valves. It can control the hydraulic cylinder of locating pile to realize accurate location of dredger and adjustable moving speed, and can also protect the dredge when external force is too great.

Owner:ZHEJIANG UNIV

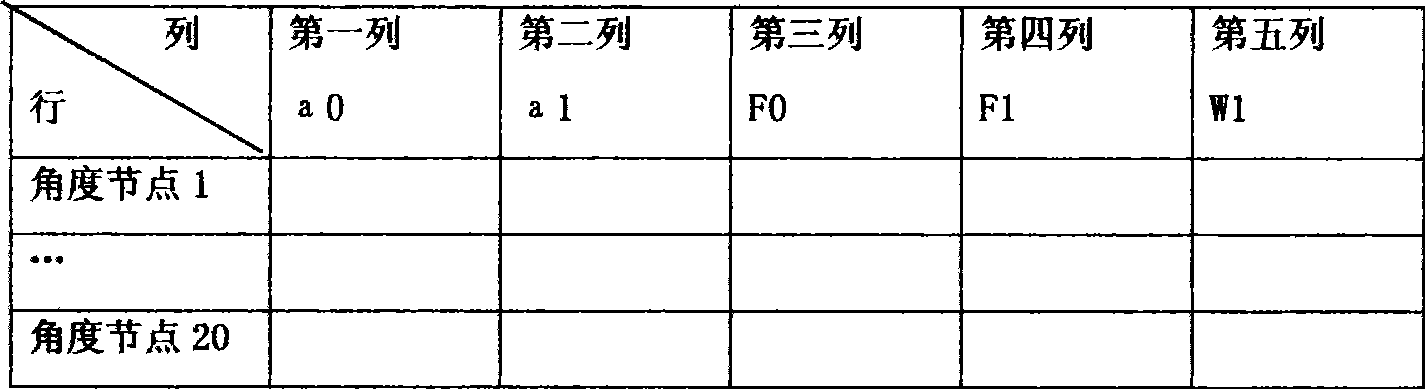

Load moment limiting device self-adaption accuracy calibrating method based on artificial neural network algorithm

A precision calibration method of a load moment limiter which timely measures and displays crane working condition parameters as the weight, the amplitude, the length, the angles and the like. The method comprises the following steps: adopting the self-adapting calibration technology based on artificial neural net algorithm; through transforming a circuit, a single chip microcomputer and a memoryto automatically collect and store the working condition parameters in different motion states (upward and downward or stillness) and timely operating and treating data, obtaining precision value of the weight and the amplitude of the crane in the working condition; having no need for operating and treating data additionally; effectively excluding the errors due to man-made interference; and greatly improving the efficiency and the precision of the load moment limiter. The method can cause the load moment limiter to precisely calibrate according to the practical use condition, improve the precision and the debugging efficiency of the load moment limiter, effectively guarantee the operating safety of the crane, and is widely applicable to the precision calibration of load moment limiters of mobile cranes (an automobile crane, a crawler crane and a tyre crane) and non-mobile cranes.

Owner:北京华芯数据科技股份有限公司 +1

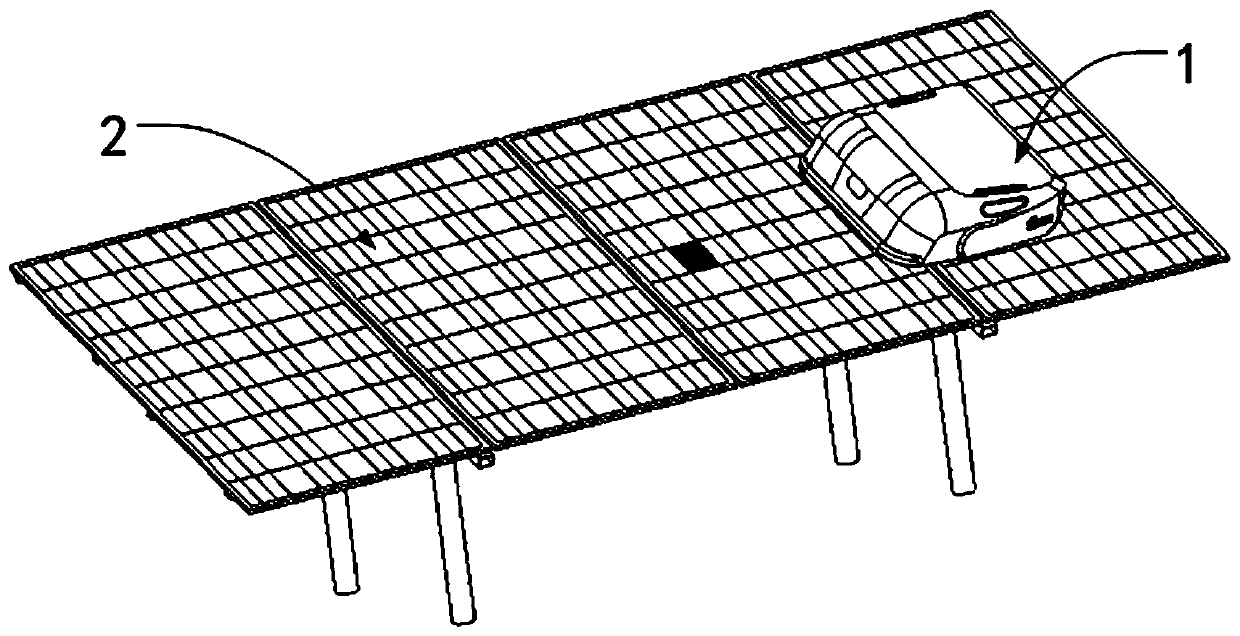

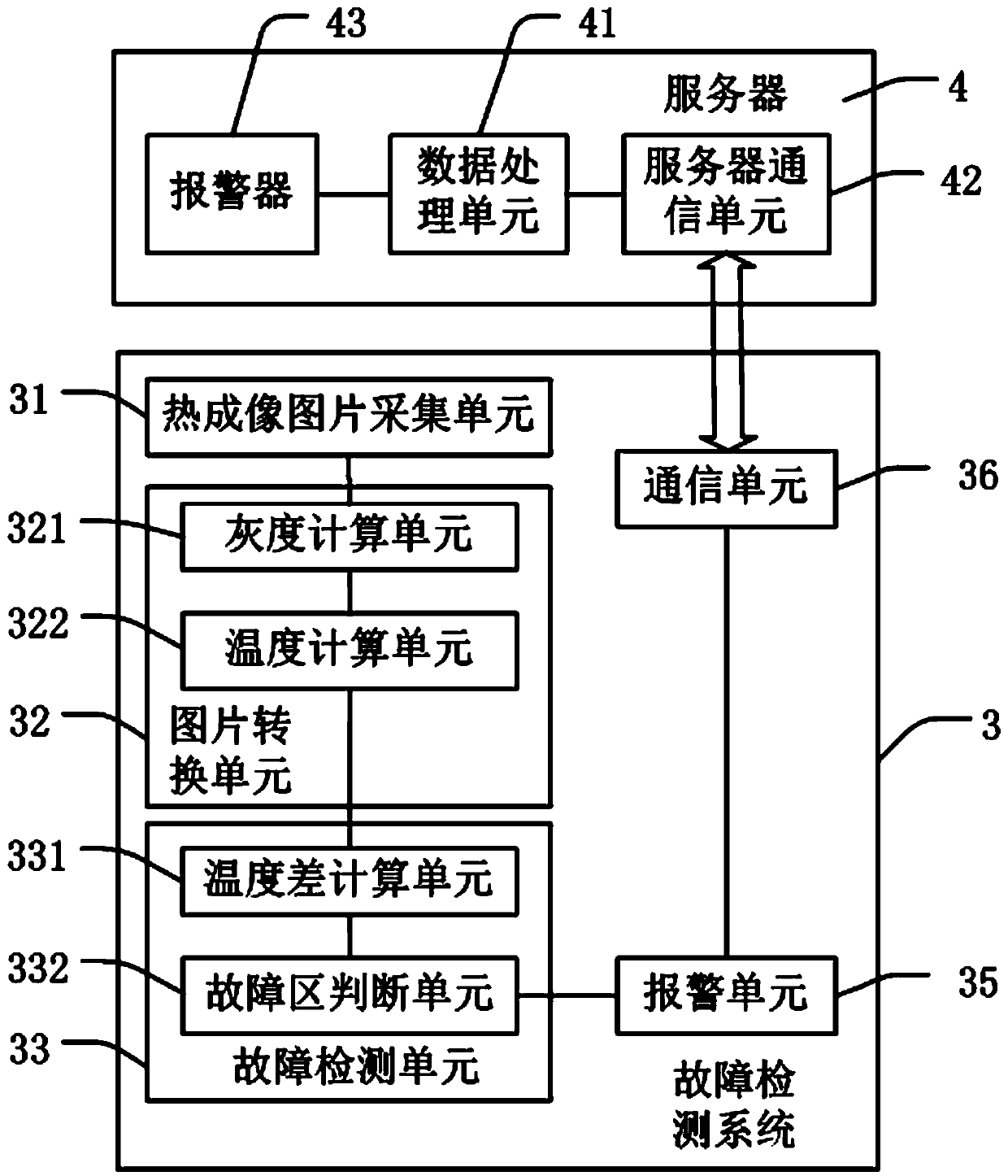

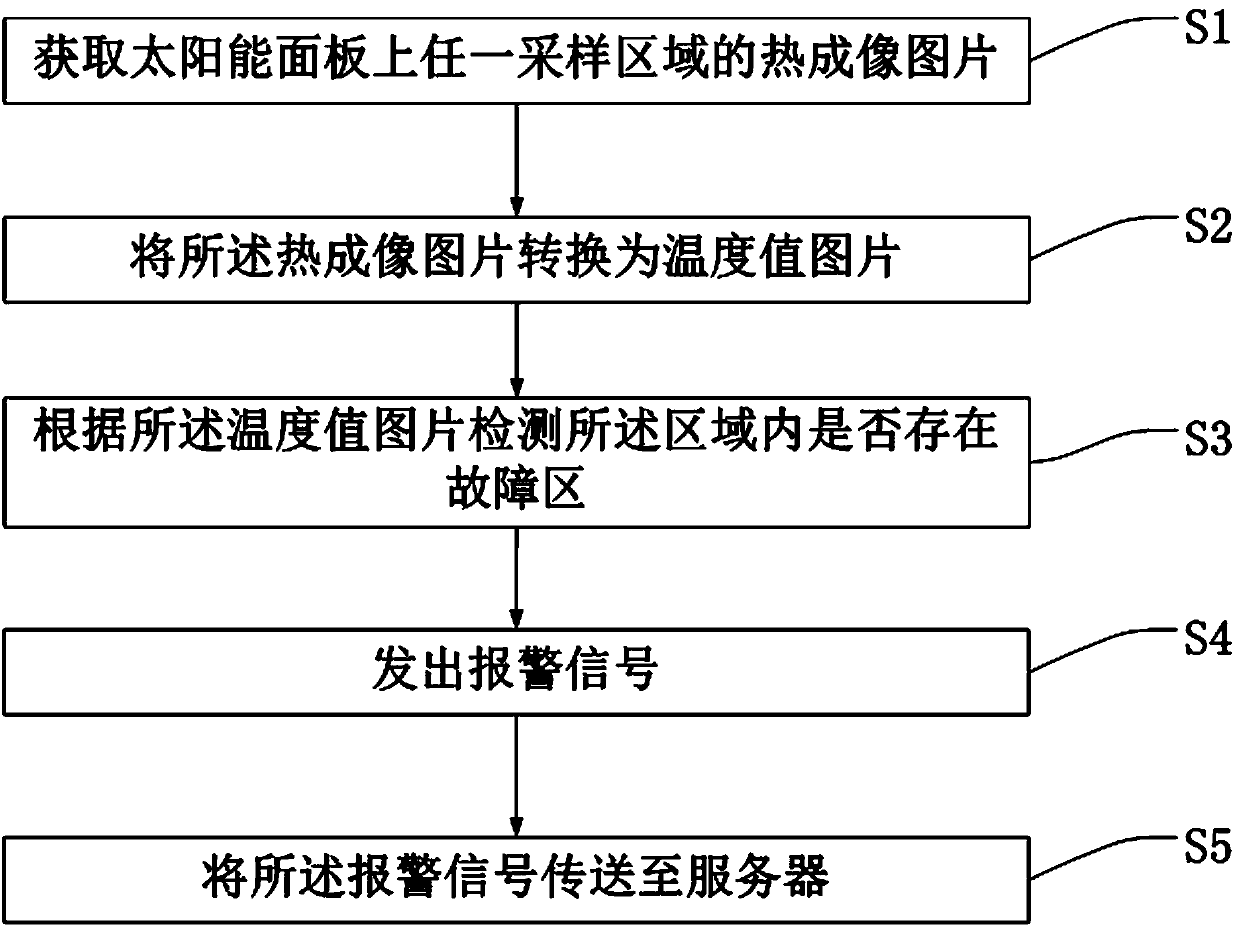

Solar panel Fault detection method and system and robot

ActiveCN107612503AEnsure job safetyAvoid elevationPhotovoltaic monitoringPyrometry using electric radation detectorsEngineeringAtmospheric sciences

The invention discloses a solar panel fault detection method and system and a robot. The method comprises the following steps that 1, a thermal imaging picture of any sampling area on the solar panelis acquired; 2, the thermal imaging picture is converted into a temperature value picture; 3, according to the temperature value picture, whether or not a fault area exists in the area is detected. Byadopting a thermal imaging technology, the temperature conditions of the solar panel on all areas are detected when the sweeping robot walks, an area with extremely high temperature is judged into the fault area, the system gives an alarm to a background server in time and informs maintenance, so that the operation safety of the solar panel is guaranteed, and the fault area of the solar panel isprevented from being further enlarged.

Owner:SUZHOU RADIANT PHOTOVOLTAIC TECH

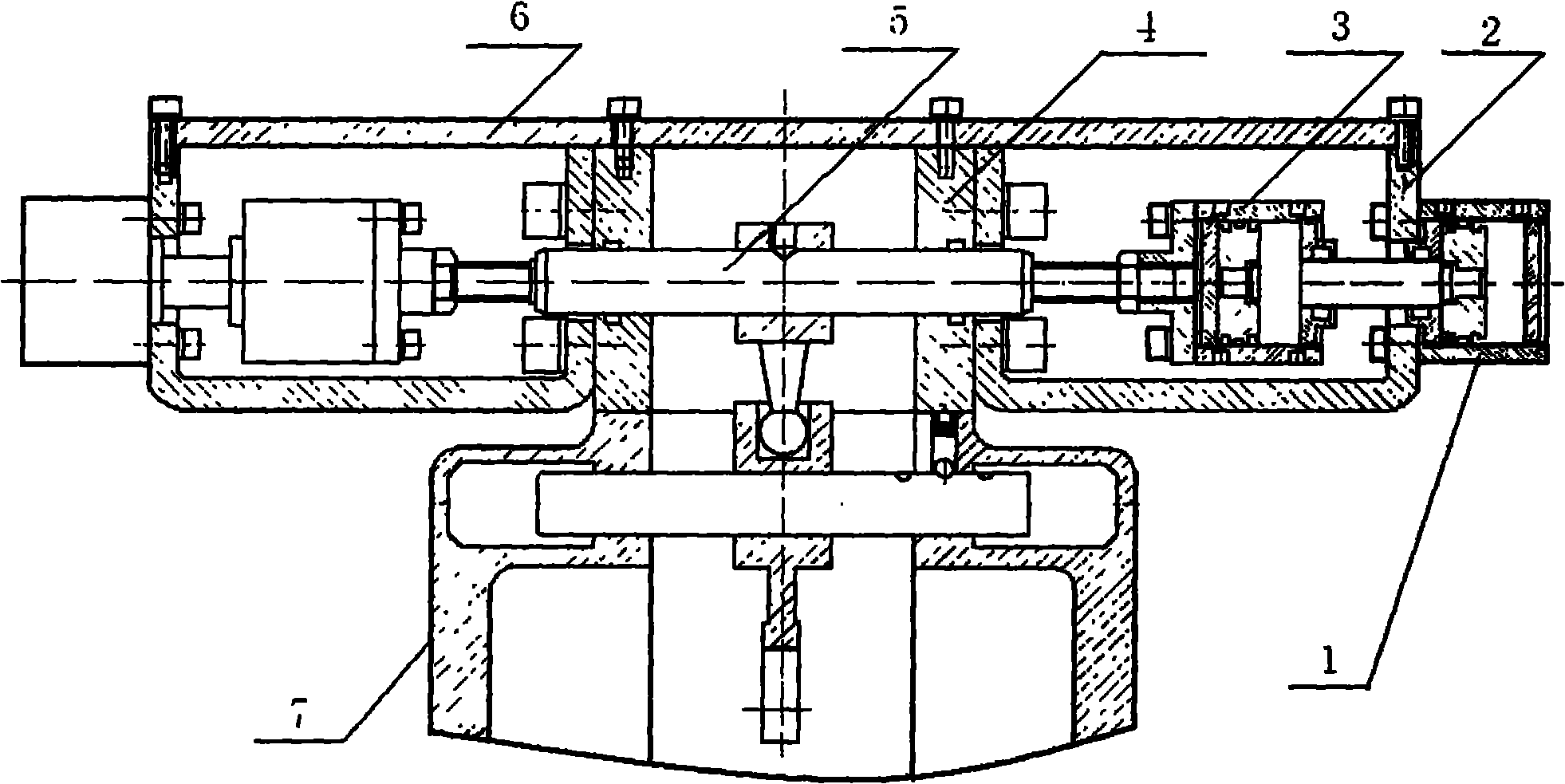

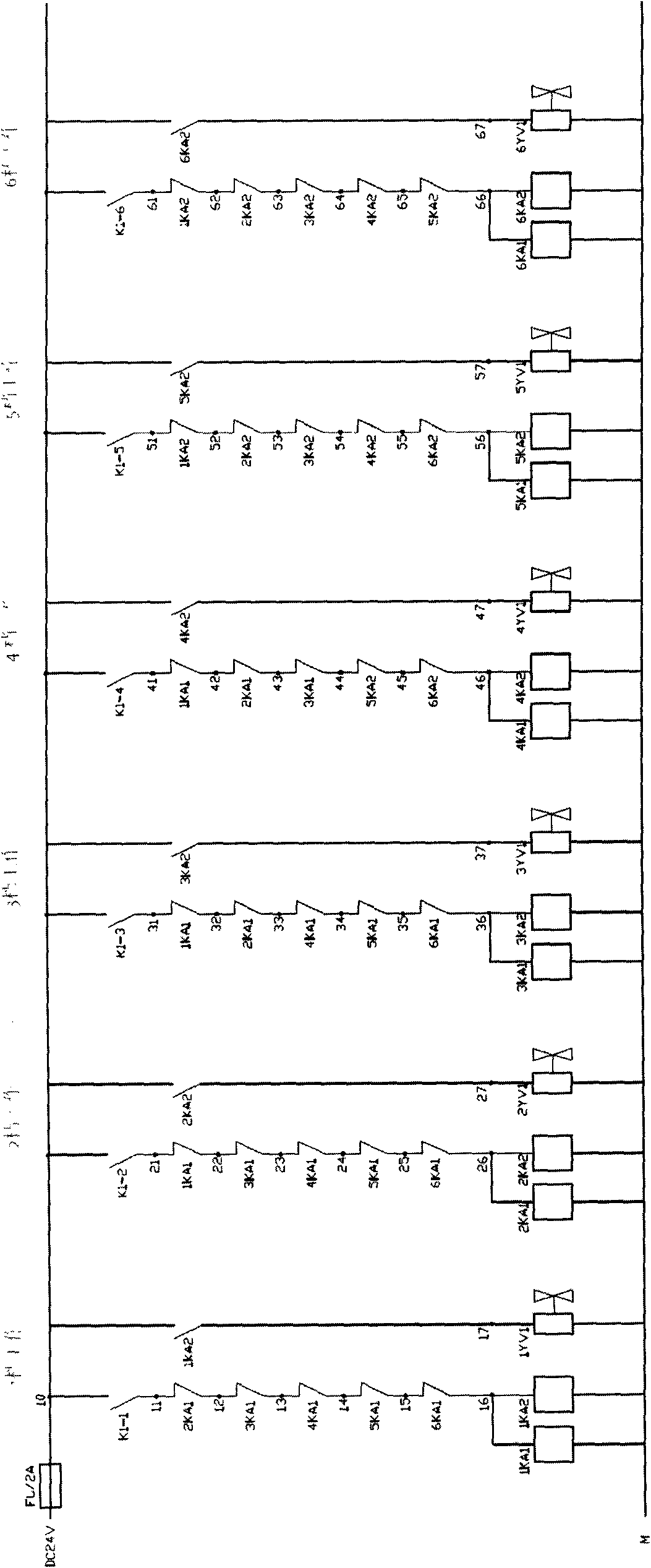

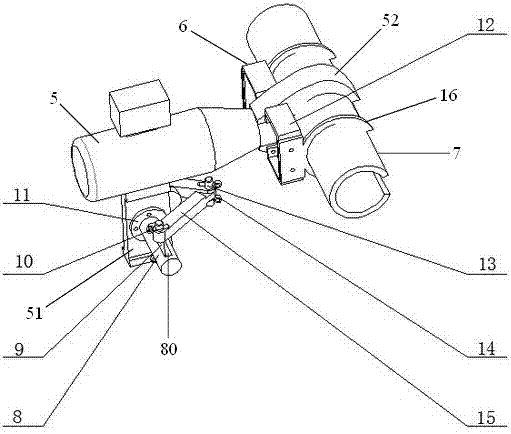

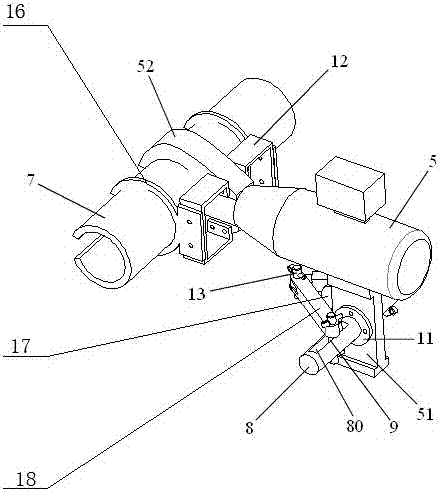

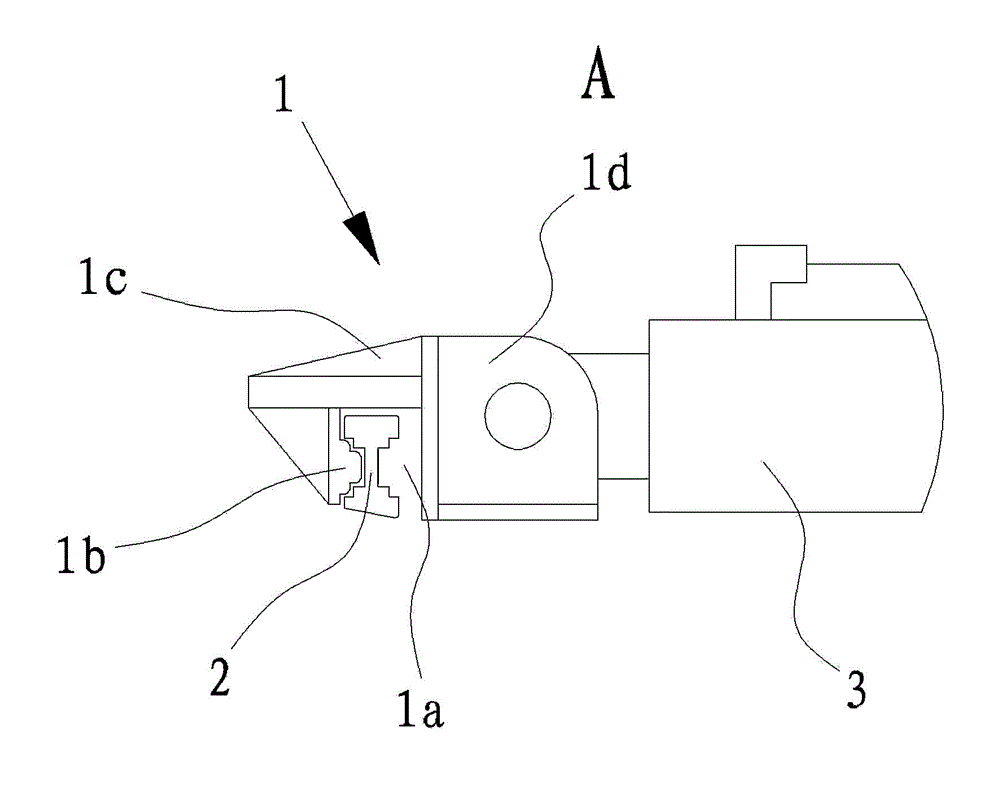

Electronic control pneumatic gear shift device of beam transportation vehicle

InactiveCN102207196AEnsure job safetySimple structureGearing controlControl devicesRemote controlControl circuit

The invention relates to a gear shift device for a motor vehicle, and in particular relates to an electronic control pneumatic gear shift device of a beam transportation vehicle. The gear shift device comprises a manual transmission gear and at least two gear shift rods; at least one end of each gear shift rod is connected with a piston rod of a double-acting air cylinder; the double-acting air cylinder is fixed on an air cylinder frame at the outer part of the manual transmission gear; a front air opening and a rear air opening of each double-acting air cylinder is connected with an air source through a gas pipe and an electromagnetic valve; the electromagnetic valve is connected with a gear shift control circuit; a gear shift handle controls the electromagnetic valve to supply air to the corresponding double-acting air cylinder respectively through the gear shift control circuit, thus the corresponding gear shift rod is driven to move back and forth to finish the gear shift actions. The gear shift device provided by the invention has the advantages of simple structure and reliable actions, and is simple, convenient and visual to operate, remote control gear shift can be realized on an auxiliary car, the phenomenon of fault gear engaging is avoided, and the safe operation of the beam transportation vehicle is ensured.

Owner:HEFEI ZHENGHAO MECHANICAL TECH

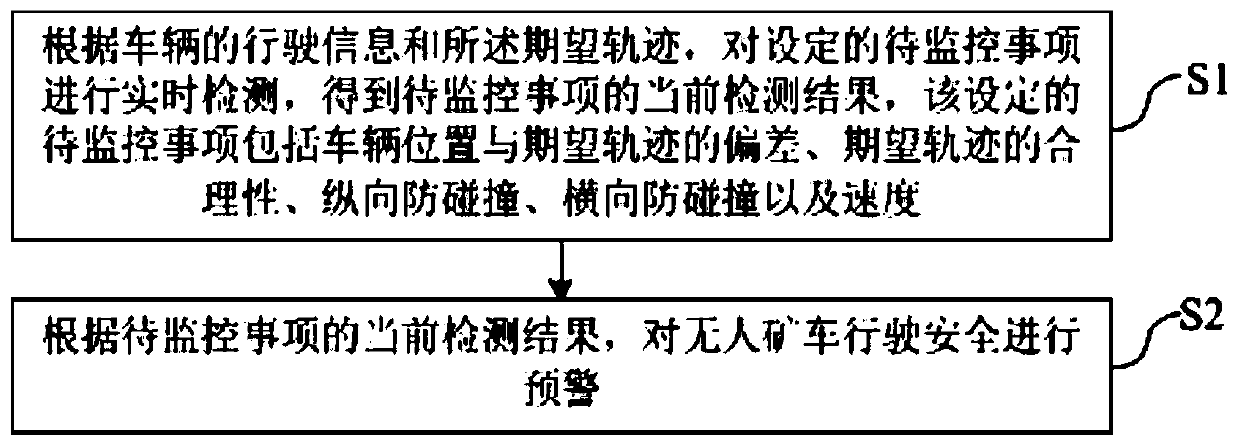

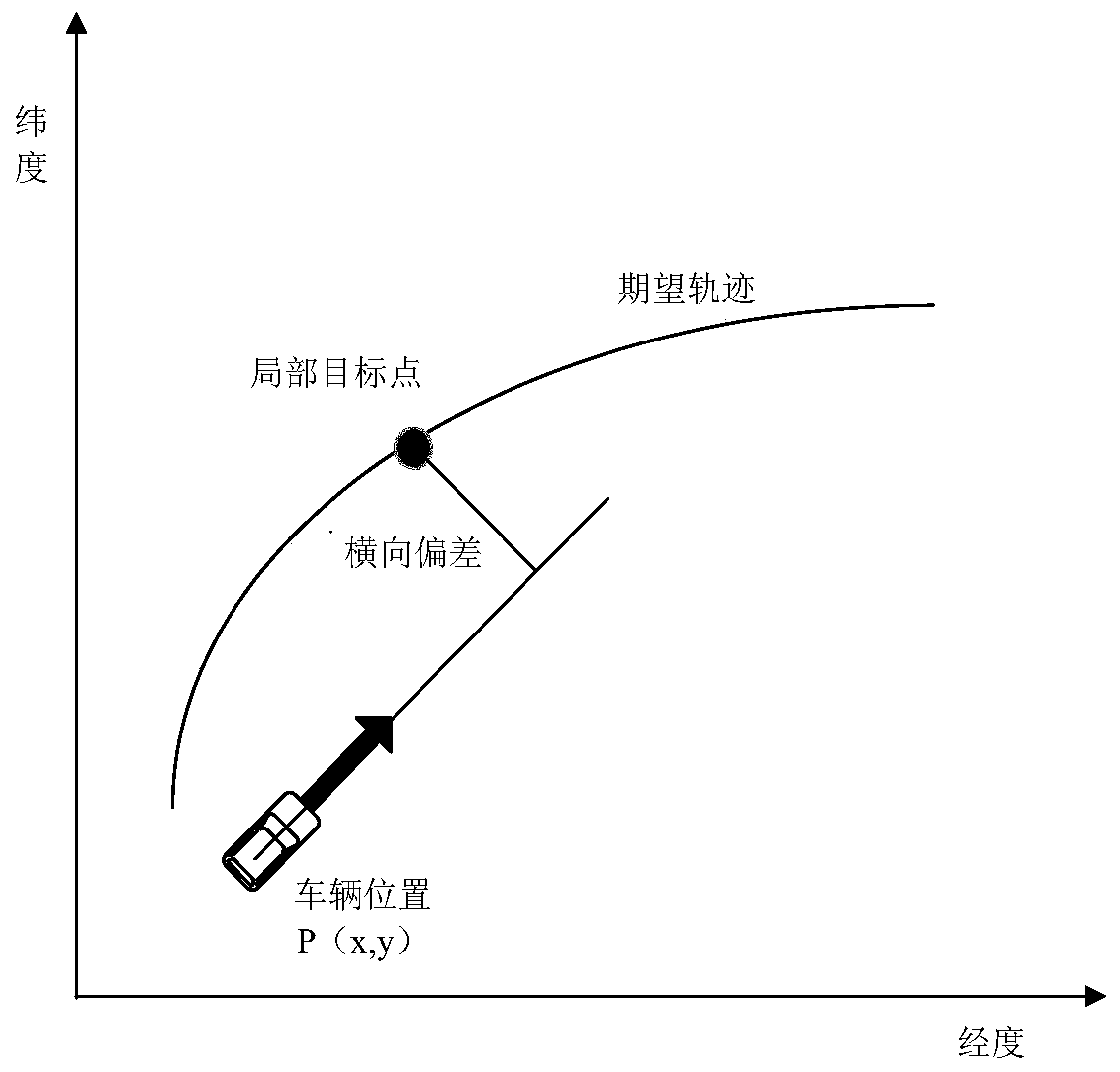

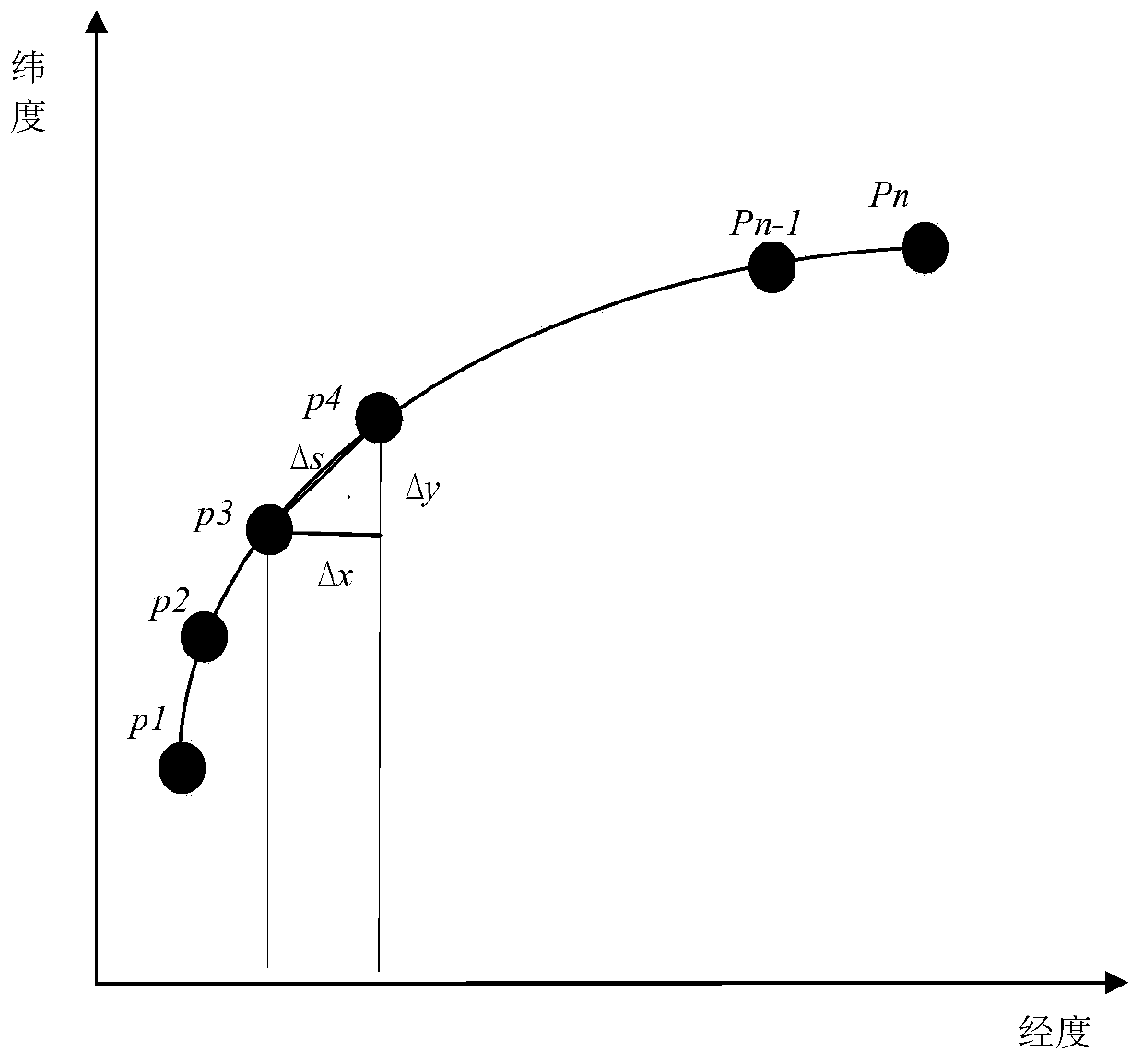

Unmanned mine car safety monitoring method and system

ActiveCN111003027AEnsure driving safety performanceEnsure job safetyRailway signalling and safetySecurity monitoringOperation safety

The invention discloses an unmanned mine car safety monitoring method and system, and belongs to the technical field of unmanned driving. The method comprises the steps that according to driving information of a vehicle and an expected track, a set to-be-monitored item is detected in real time, the current detection result of the to-be-monitored item is obtained, and the set to-be-monitored item comprises deviation between the position of the vehicle and the expected track, reasonability of the expected track, longitudinal collision prevention, transverse collision prevention and speed; and early warning is performed on the driving safety of the unmanned mine car according to the current detection result of the to-be-monitored item. The safety risk level of the environment where the unmanned mine car is located can be comprehensively evaluated, and driving and operation safety of the unmanned mine car is ensured.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

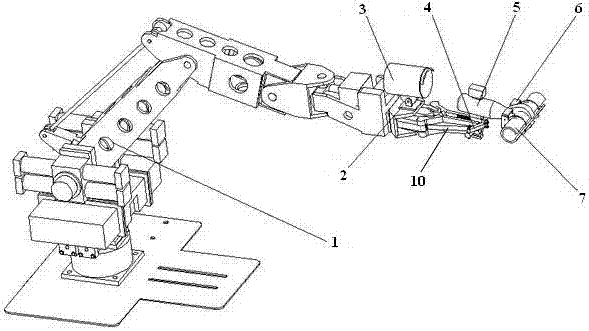

Wire crimping repair device and method of substation

ActiveCN106953274AHigh degree of automationEnsure job safetyApparatus for joining/termination cablesOperation modeEngineering

The invention provides a wire crimping repair device and method of a substation. The wire crimping repair device of the substation comprises a wire repair tube, hydraulic crimping pliers, a clamping execution unit and a mechanical arm, wherein the hydraulic crimping pliers comprise a handle of a crimping switch and a crimping part, the clamping execution unit comprises a clamping shaft, a left clamping support arm and a right clamping support arm, the clamping shaft penetrates through the handle and is fixed at two sides of the handle, one end of the left clamping support arm and one end of the right clamping support arm are connected by a support arm connection shaft, the other ends of the left clamping support arm and the right clamping support arm are connected with a clamping adjustment shaft arranged in a groove, and the mechanical arm is used for moving the hydraulic crimping pliers to a wire position to be repaired and controlling the clamping adjustment shaft to move in the groove so that the support arm connection shaft is driven to move towards the crimping switch and trigger the crimping switch. By the wire crimping repair device, the requirement of wire crimping in the substation is met, the operation safety of an operator is ensured, the working strength of manual operation can be effectively reduced, the crimping efficiency and the automatic level are improved, and a positive change effect is generated for a wire crimping repair operation mode of the substation in China.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

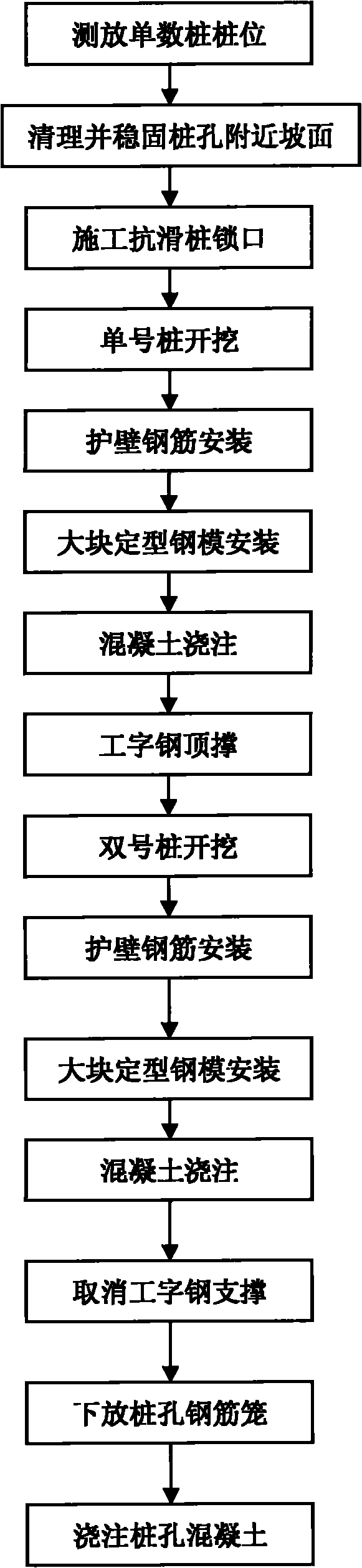

Longhole rectangular terraced antiskid pile jump-preventing excavating construction

InactiveCN101994314AEnsure job safetyExcavationsIn situ soil foundationEmergency rescueQuality control

The invention relates to longhole rectangular terraced antiskid pile jump-preventing excavating construction. The pile jump-preventing artificial excavation has the main characteristics of improving the construction efficiency to a maximum degree and providing necessary guarantee for emergency rescue and smoothness, along with less disturbance of mountains, safety, reliability, simplicity of constructional operation, multiple working surfaces and short construction period. A locking notch of an antiskid pile is reinforced necessarily on the premise of establishing the strict quality control and guarantee measures, monitoring points are distributed on a slip mass to monitor the variation condition of water pressure and soil pressure and multipoint displacement condition of the slip mass. The detailed construction scheme is formulated to organize construction, a rectangular orifice is subjected to lofting, the lofting of a five-point perpendicular line is controlled strictly, the delimitation in a hole is checked after each section of artificial excavating is finished, and the size and perpendicularity of the pile are controlled strictly. The quality of concrete strength of retaining walls is ensured. The terraced operation is performed in a mode of terraced excavation and the vertical displacement excavation, so that the operation depths of excavating piles are in accordance with a concave-convex mode, and the disturbance to unstable soil mass due to oversized excavating is avoided and the effect of expected construction is achieved.

Owner:安通建设有限公司 +2

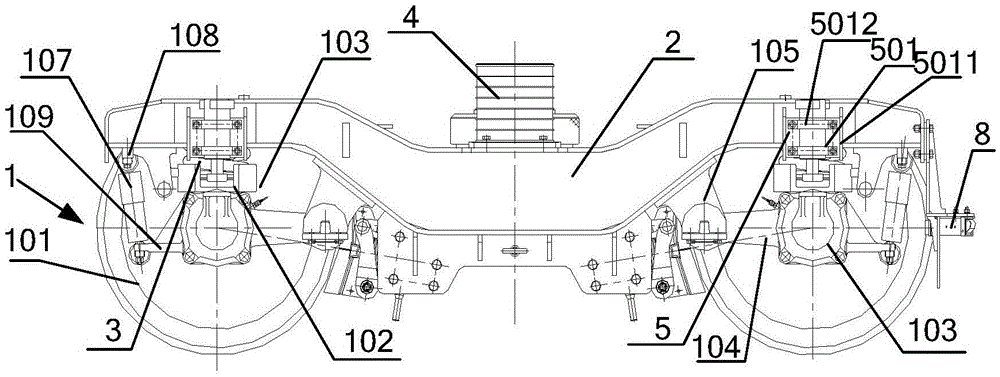

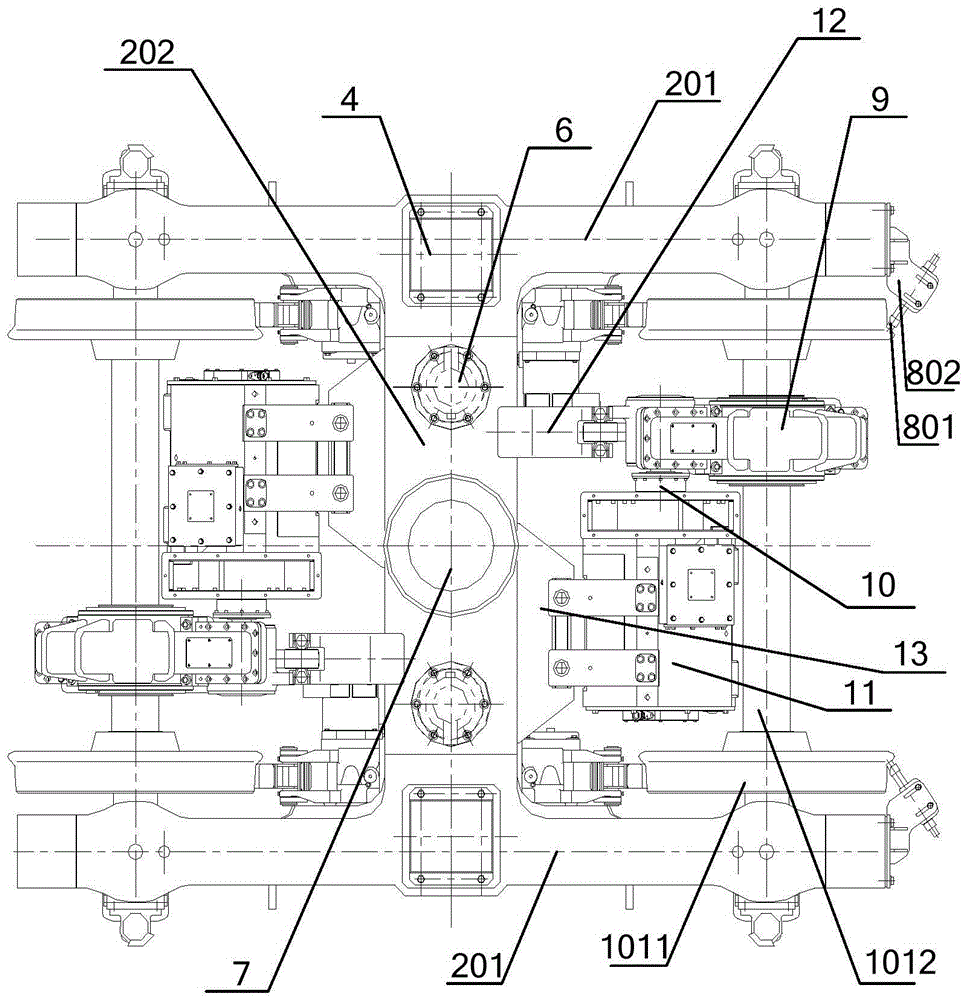

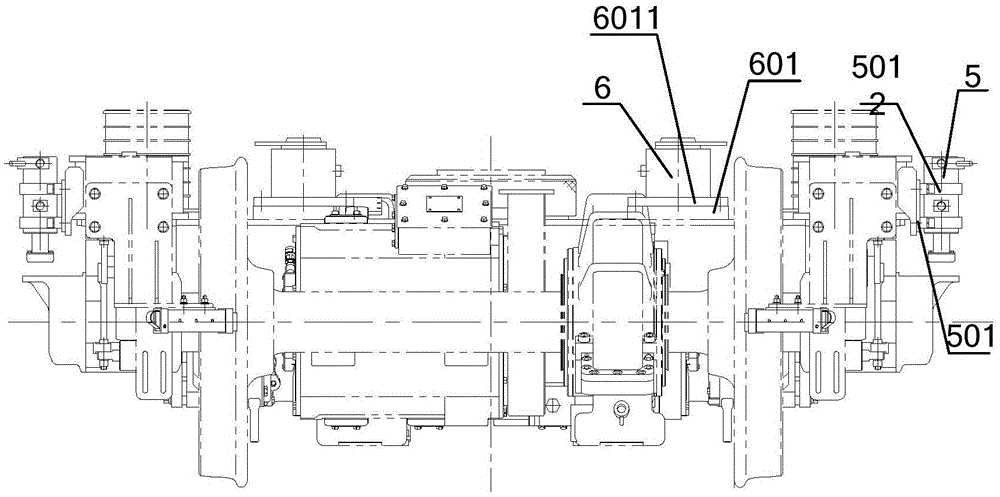

Rail engineering vehicle bogie and rail engineering vehicle

InactiveCN105460039AReliable rigid supportGuaranteed working accuracyBogie-underframe connectionsAxle-boxes mountingBogieCylinder block

The invention discloses a rail engineering vehicle bogie and a rail engineering vehicle. The rail engineering vehicle bogie comprises wheel set axle box devices and a framework arranged on the wheel set axle box devices and used for supporting a vehicle body. The framework is elastically connected with the wheel set axle box devices through first elastic parts, and the framework is provided with second elastic parts used for elastically supporting the vehicle body. The framework is further provided with first supporting oil cylinders and second supporting oil cylinders, a cylinder body of each first supporting oil cylinder is fixedly connected with the framework, and a piston rod of each first supporting oil cylinder is used for abutting against the corresponding wheel set axle box device; a cylinder body of each second supporting oil cylinder is fixedly connected with the framework, and a piston rod of each second supporting oil cylinder is used for abutting against the bottom of the vehicle body. According to the rail engineering vehicle bogie and the rail engineering vehicle, operation precision and operation safety of the rail engineering vehicle can be guaranteed.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

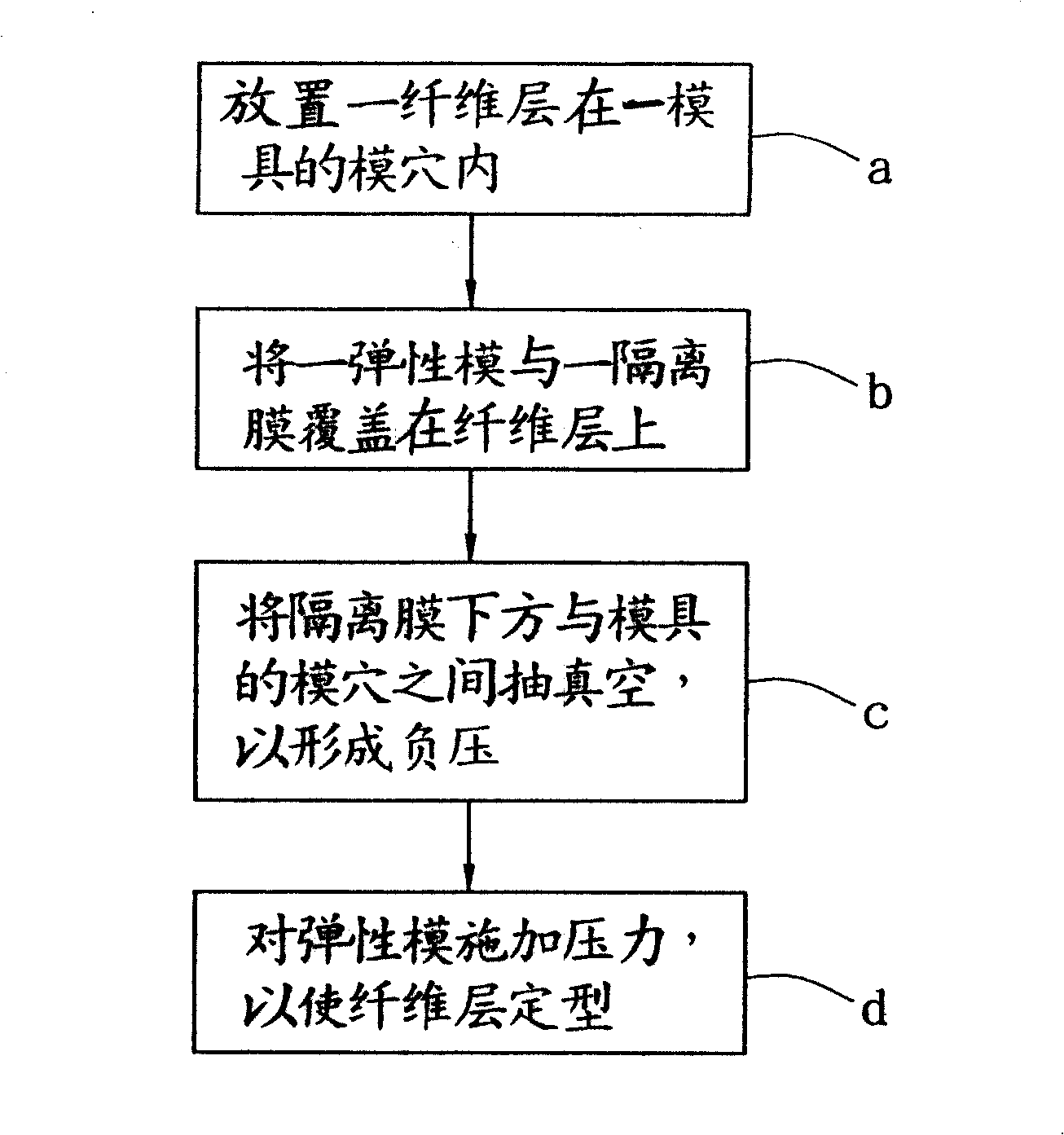

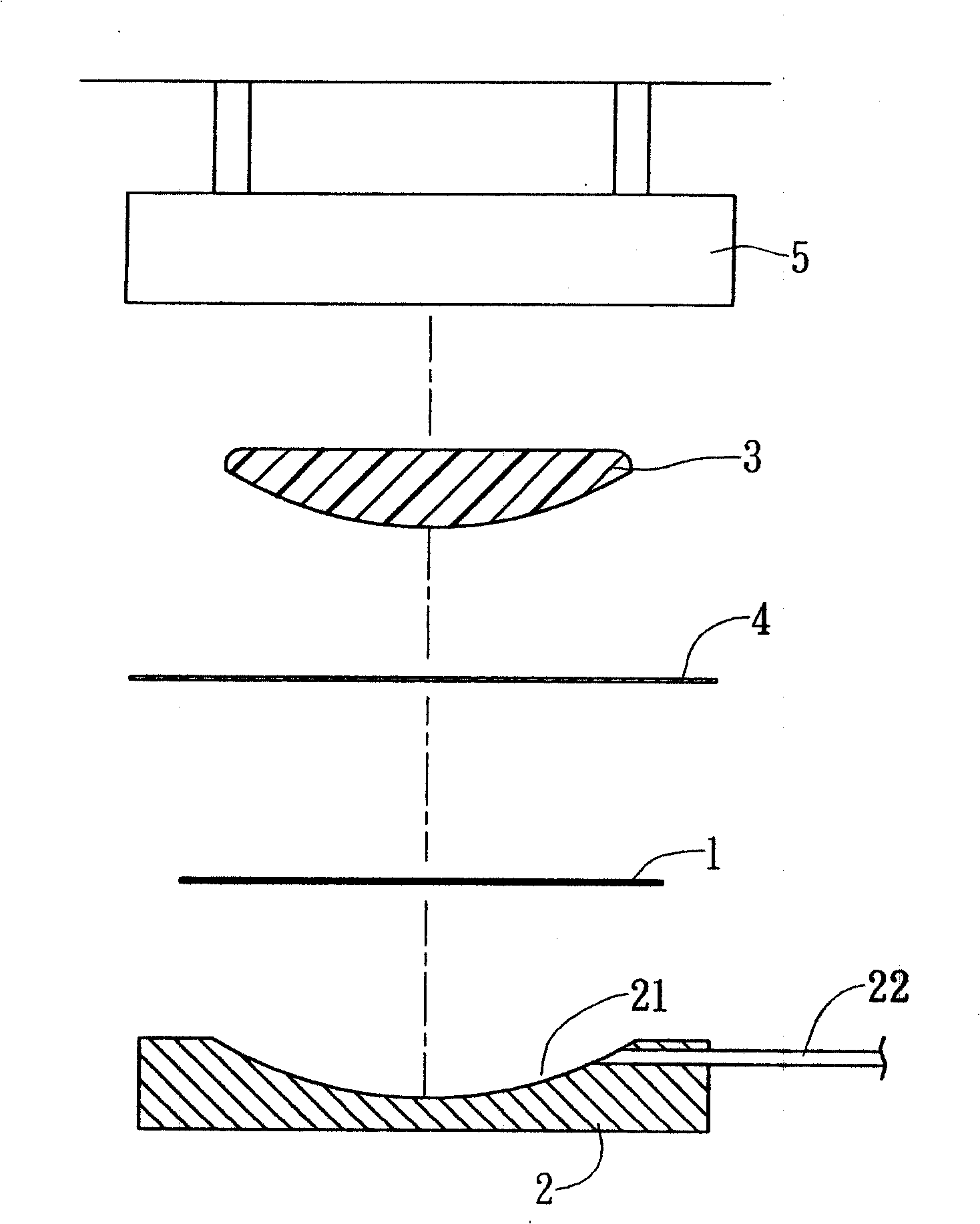

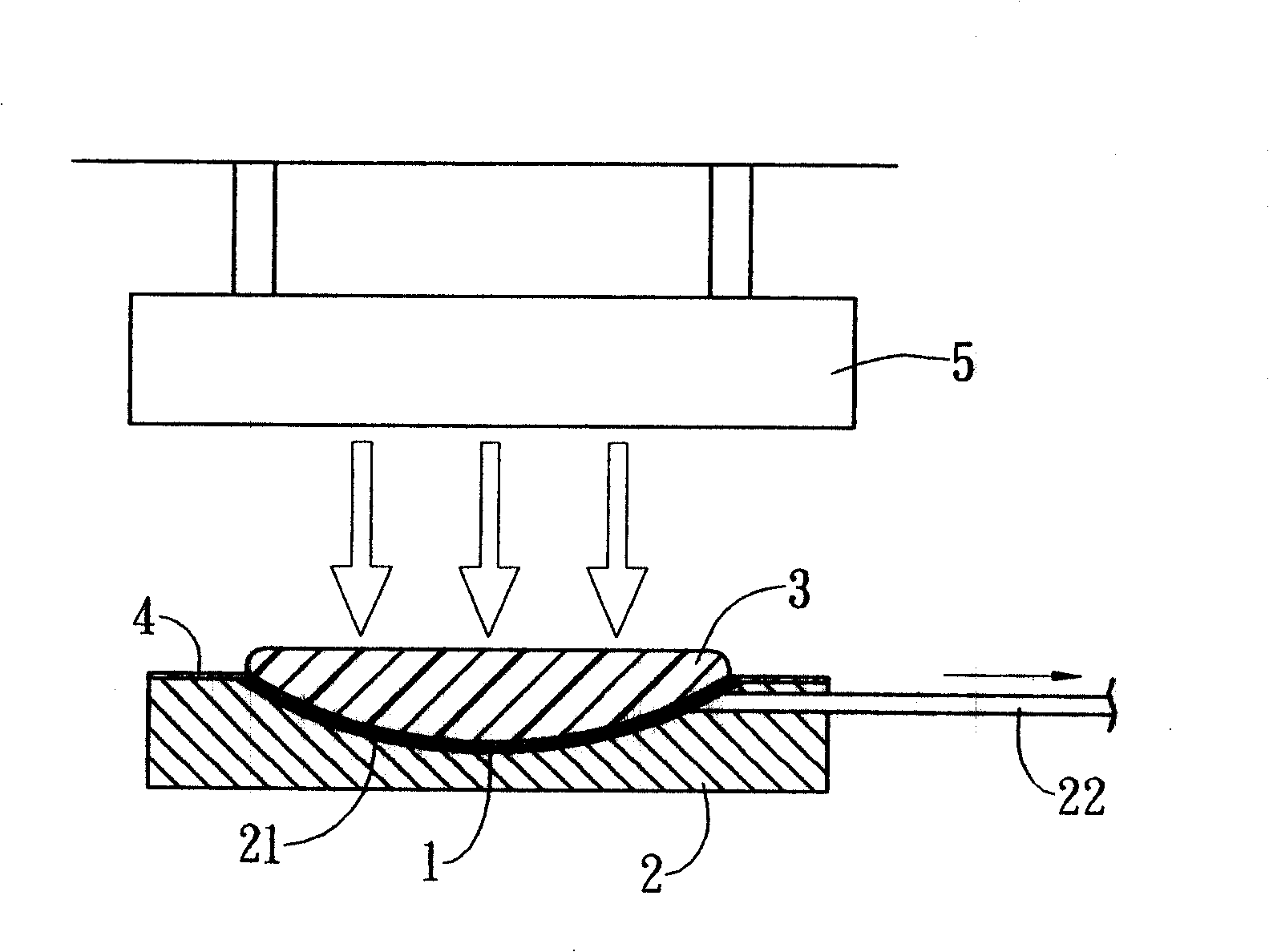

Composite material forming method

The invention relates to a method for forming a composite material; a fibrous layer is first placed in the die cavity of a mold; an elastic membrane and an isolating film are covered on the fibrous layer. Then, evacuation is carried out between the lower space of the the isolating film and the die cavity of the mold so as to form the negative pressure and simultaneously apply a mechanical pressure to the elastic membrane to cause the fibrous membrane to be formed, thus eliminating air holes possibly generated on the surface of the formed fibrous layer and increasing the excellent rate of the product. Furthermore, the mold can be preheated before pressurization; after the fibrous layer is formed through pressurization, the mechanical pressure is removed to separate the steps of pressurizing, heating and cooling, so as to accelerate the production and reduce the cost.

Owner:HOCHENG CORPORATION

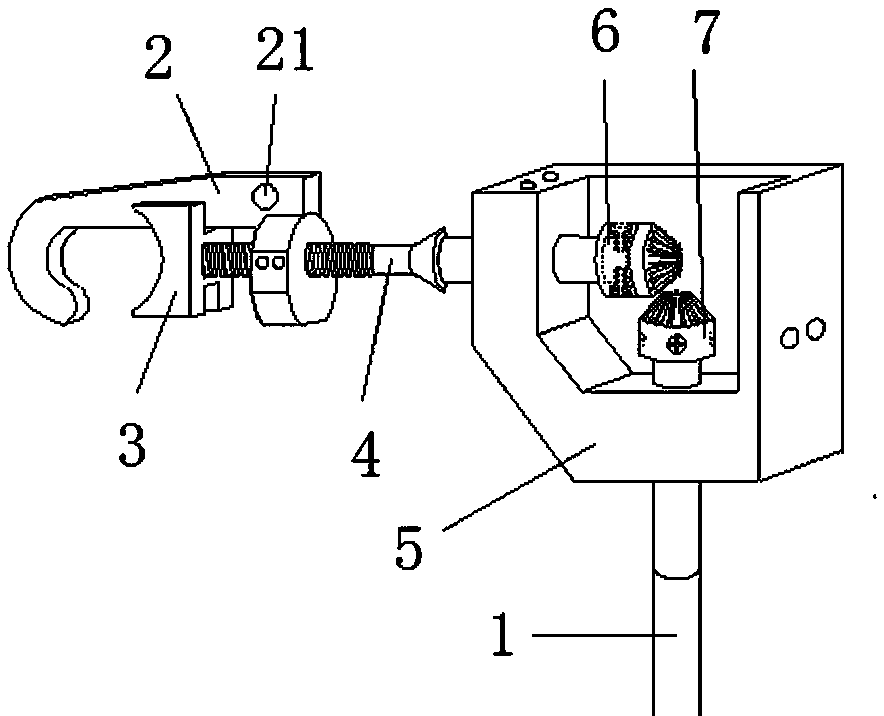

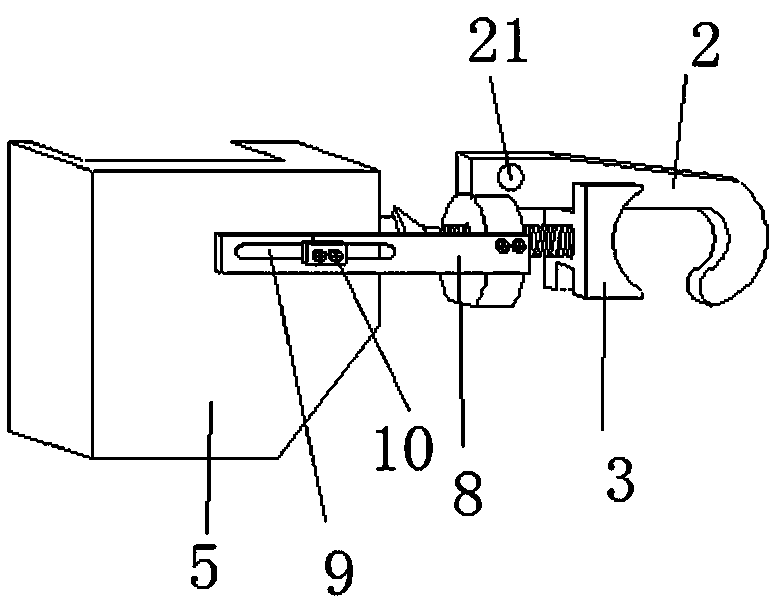

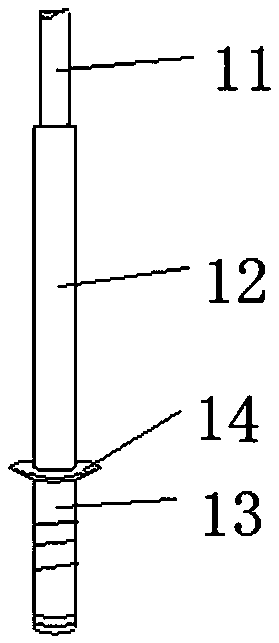

Novel ground wire clamp

PendingCN107658768AEasy to GrindReliable groundingClip conductor connectionSwitchgearEngineeringElectrical and Electronics engineering

The invention belongs to the technical field of power detection and particularly relates to a novel ground wire clamp which comprises a clamping part, a connecting part and an operating rod. The clamping part is connected to the operating rod through the connecting part to form an L-shaped structure. A limit mechanism is arranged between the connecting part and the clamping part. The clamping partis provided with a hook clamp and a pushing clamp. The hook clamp is provided with a wiring hole and is slidingly connected to the pushing clamp. One end of the pushing clamping is movably connectedto the connecting part. The other end of the pushing clamp is slidingly connected to the hook. One end of the limit mechanism is fixedly connected to the hook, and the other end of the limit mechanismis movably connected to the connecting part. The connecting part is movably connected to the operating rod. According to the novel ground wire clamp, through the principle of a rotating shaft of a helical gear, a wiring clamp and a manual rotation operation rod are separated to form a core component which is an L-shaped operation mechanism, and a convenient grounding mode of a lead conductor in avertical direction is realized.

Owner:HUIZHOU POWER SUPPLY BUREAU OF GUANGDONG POWER GRID CO LTD

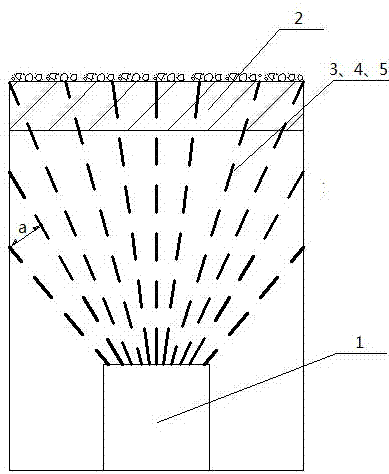

Method for treating hanging arch through medium-length hole blasting

InactiveCN104847350AReach normal mining conditionsImprove mining recoveryUnderground miningSurface miningDetonatorTEX-explosive

The invention belongs to the technical field of mining, and particularly relates to a method for treating a hanging arch through medium-length hole blasting. The method comprises the following steps: forming a first row, a second row and a third row of medium-length holes in sequence in the top rock stratum of a mining roadway from a hanging arch area into the mining roadway, wherein each row of medium-length holes is distributed in a sector form, thereby forming sector-shaped medium-length holes; the distribution surface angle of the first row of medium-length holes is 60 degrees; the distribution surface angle of the second row of medium-length holes is 70 degrees; the distribution surface angle of the third row of medium-length holes is 90 degrees; and the first row and second row of medium-length holes extend to the hanging arch area; filling explosives and millisecond delay detonator tubes into the medium-length holes, and detonating the explosives to break the hanging arch. Compared with the conventional method, the method has the advantages that the ore loss rate is lowered from 60 to 70 percent to 6 to 9 percent, the mining recovery rate is increased greatly from 30 to 40 percent to 91 to 94 percent, and the operation safety is ensured.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

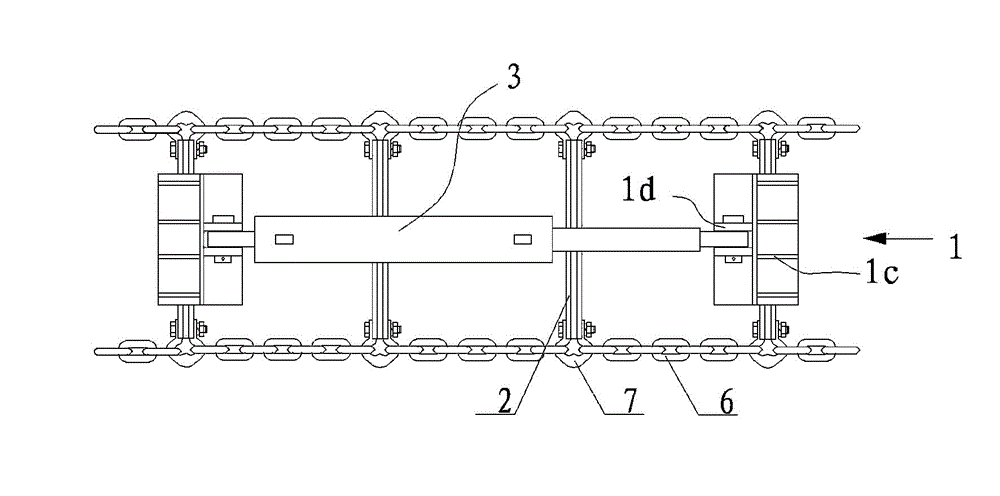

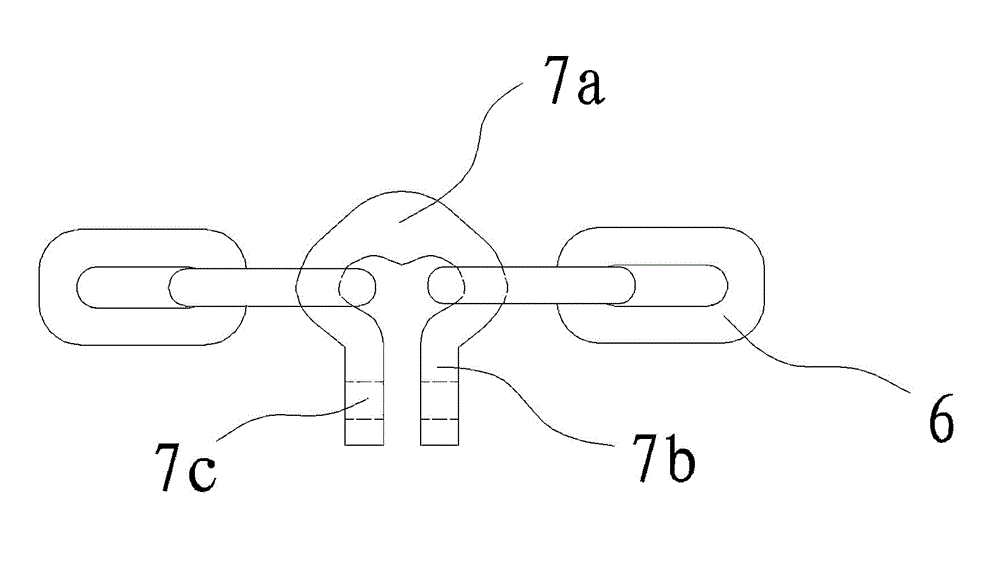

Hydraulic chain tightening device for mining edge double chain plate machine

The invention relates to a hydraulic chain tightening device for a mining edge double chain plate machine, which is characterized by comprising a group of scraping plates (2), wherein cross sections of the scraping plates (2) are in stepped I-shaped structures; the two ends of each scraping plate (2) are connected with chains (6) by connecting rings (7); two of the scraping plates (2) are connected with clamping blocks (1) in an upper matching manner respectively; at least one scraping plate (2) is arranged between the two clamping blocks (1) at an interval; a hydraulic pump (3) is articulated between the two clamping blocks (1), and connected with a hydraulic lock (4) by a hose (8); and the hydraulic lock (4) is connected with a head-tail valve (5) by the hose (8). The device has the advantages that chain scission or combination working of the chain plate machine is accomplished by long-distance fluid feed and the extension of the hydraulic pump, so that a process of the device is concise and efficient; the working safety is improved; the labor difficulty and the risk are reduced; and the operation safety of staff is guaranteed.

Owner:赵明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com