Upward cut-and-fill mining method for in-vein slope ramp of gentle dip thin vein

A technology of filling mining method and ramp, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of technical and economic index decline, low mining efficiency, high production cost, etc., and achieve the effect of improving mining efficiency and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

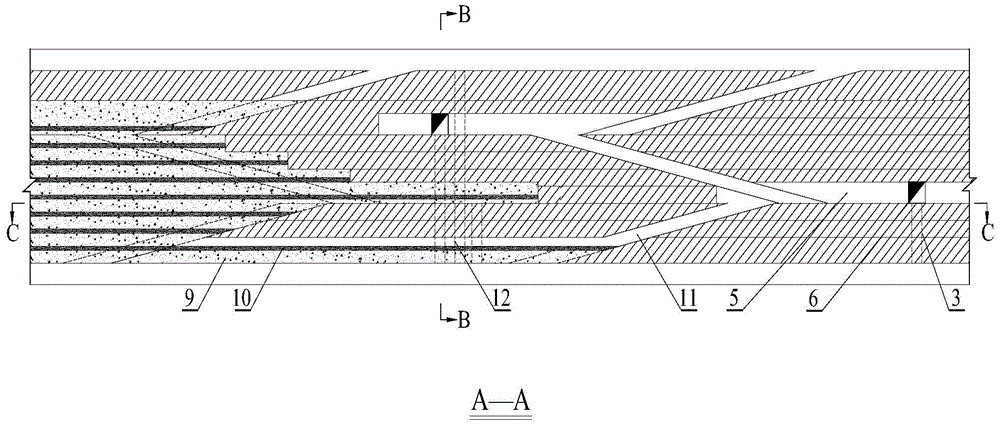

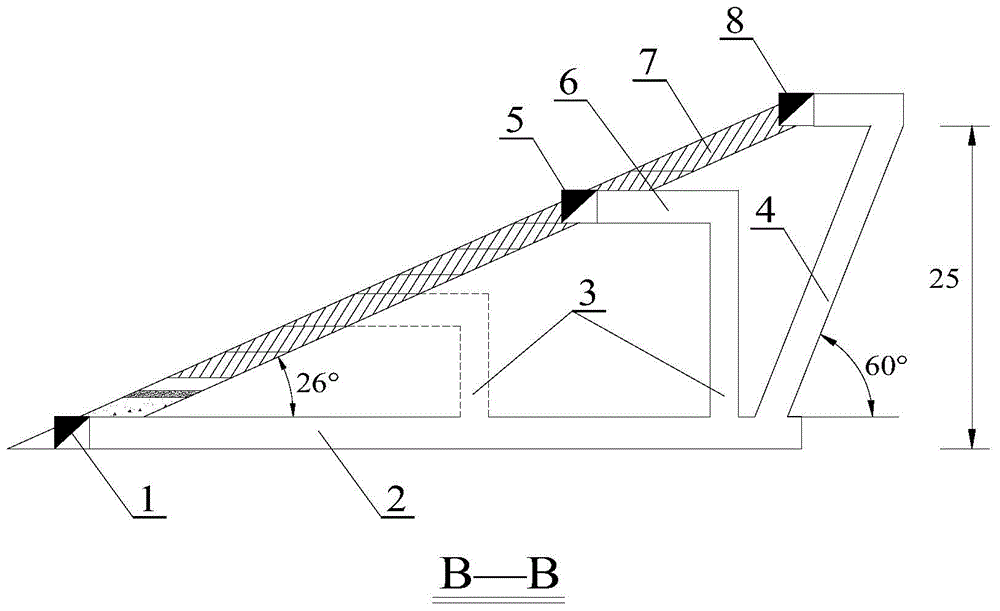

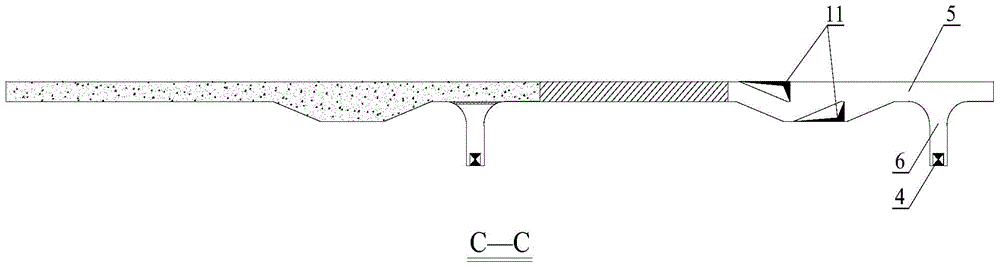

[0026] The present invention provides an upward layered filling mining method for inclined slopes in thin ore veins. The veins are divided into middle sections in the vertical height direction, and trackless equipment enters the stope by relying on the pseudo-inclined slopes excavated in the veins to realize gentle inclines. Mechanized mining of thin ore veins; pseudo-inclined ramps in the veins, excavation of the connecting road from the middle section of the bottom to the ore veins, and then digging along the pseudo-inclined ramps to a certain height, and then driving forward along the veins. The reverse tunnel and segmented ore exit shaft are excavated in the segmental entry, and the pseudo-inclined ramp along the vein is reversely excavated from the side of the segmental entry, and then a section of height is raised, and the segmented entry, reverse chamber and sub-section are excavated along the vein. Section ore exit shaft, and so on until the upper and middle section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com