Hydraulic chain tightening device for mining edge double chain plate machine

A technology of a chain tightening device and a chain plate machine is applied in the field of coal mining machinery, which can solve problems such as potential safety hazards, and achieve the effects of reducing difficulty and danger, ensuring operational safety, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

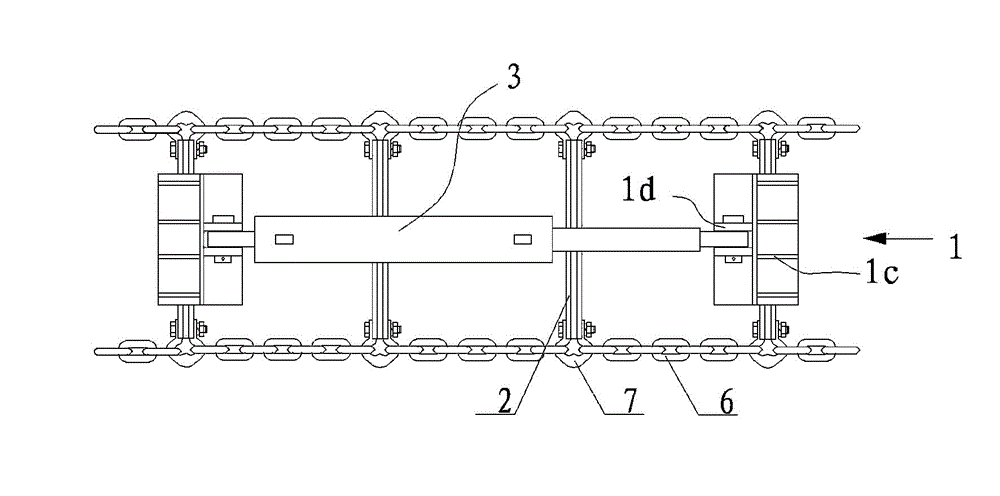

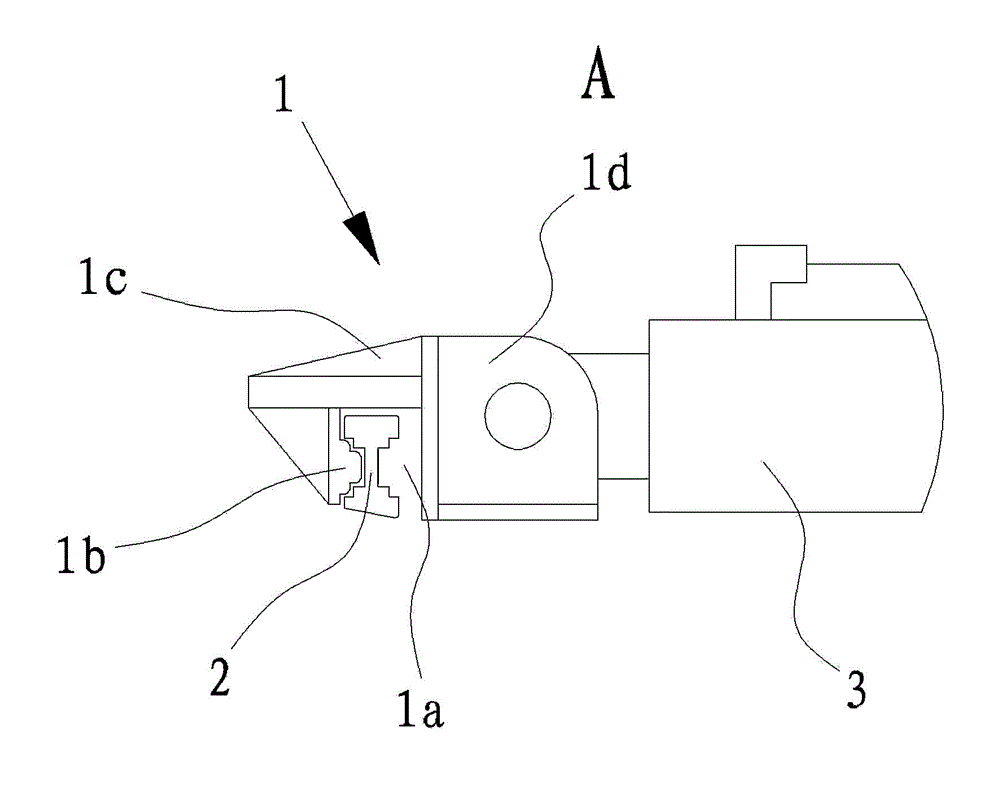

[0013] Such as figure 1 and figure 2 As shown, the hydraulic chain tightening device of the side double chain chain plate machine provided by the present invention is characterized in that it includes a set of scrapers 2, and the section of the scrapers 2 is an I-shaped structure with steps. The two ends of the two chains 6 are connected by connecting rings 7, and each connecting ring 7 connects two chains 6 together. One block 1 is clamped on two of the scrapers 2 respectively, and two scrapers 2 are spaced between the two blocks 1 . A hydraulic pump 3 is connected between the connecting seats 1d of the two blocks 1 through a connecting pin, the hydraulic pump 3 is connected to the hydraulic lock 4 through the hose 8, and the hydraulic lock 4 is connected to the head and tail valve 5 through the hose 8.

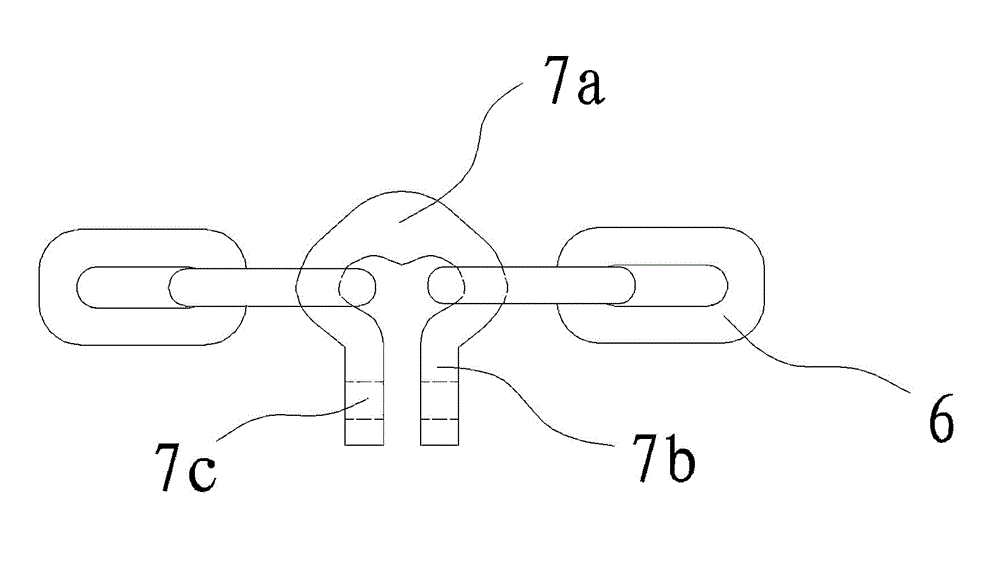

[0014] combine Figure 4 As shown, the front end of the connecting ring 7 is a split ring 7a matched with the chain 6, a symmetrical connecting plate 7b is provided at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com