Novel ground wire clamp

A grounding wire clamp, a new type of technology, is applied in the direction of winding connectors, clips connecting conductors, switching devices, etc. It can solve the problems of difficult grounding wires, difficult grounding, and poor grounding contact area, so as to ensure safe operation, Convenient grounding method and reliable grounding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

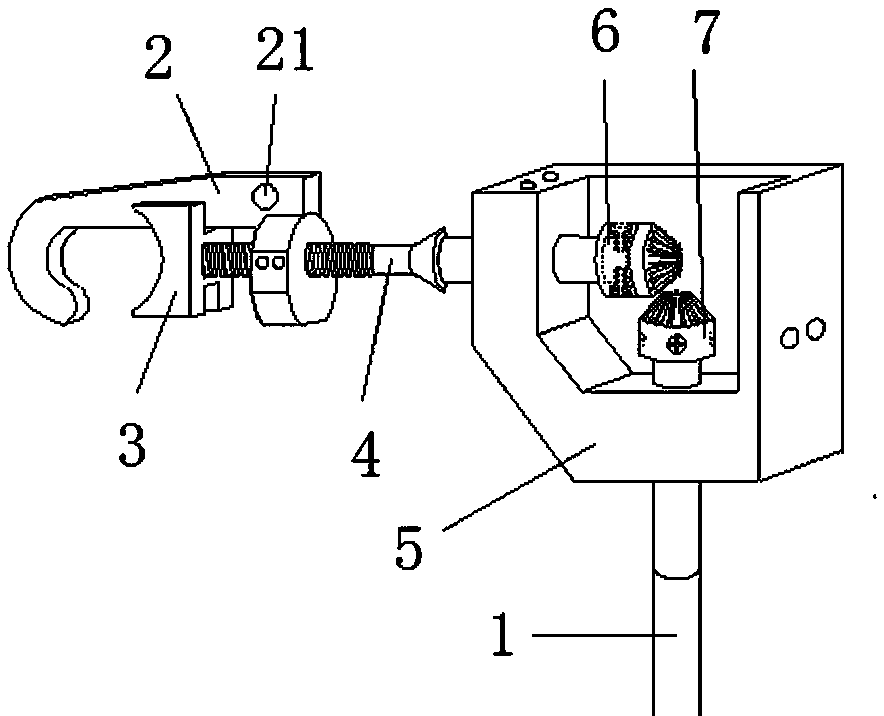

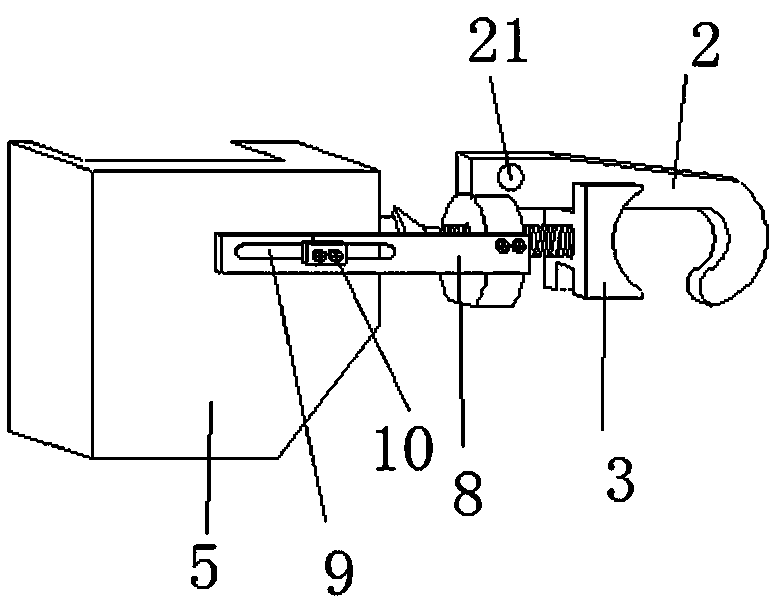

[0022] like figure 1 and figure 2 As shown, a new type of grounding wire clamp, wherein the grounding wire clamp includes a clamping part, a connecting part, and an operating rod 1. The clamping part is connected with the operating rod 1 through the connecting part to form an L-shaped structure. The connection between the connecting part and the clamping part The clamping part is provided with a hook clip 2 and a push clip, and the hook clip 2 is provided with a wiring hole 21. The hook clip 2 is slidably connected with the push clip, one end of the push clip is movably connected with the connection part, and the other end of the push clip One end is slidingly connected with the hook clip 2, one end of the limit mechanism is fixedly connected with the hook clip 2, the other end of the limit mechanism is movably connected with the connection part, and the connection part is movably connected with the operating rod 1.

[0023] Wherein, the hook clip 2 is a curved hook body str...

Embodiment 2

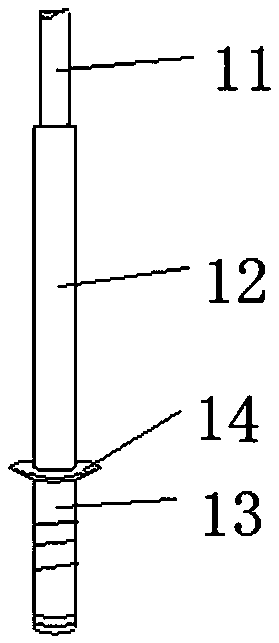

[0028] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that the operating rod 1 is provided with an insulating part 11 and a metal part 12, the metal part 12 is connected to the connecting part, and the metal part 11 is connected to the insulating part 12 through bolts. The insulating part 12 is provided with an operating handle 13 at the end away from the metal part, and the operating handle 13 is provided with a guard ring 14 and an anti-slip thread.

[0029] The insulating part 12 of the operating rod 1 is made of plastic material, which plays a main insulating role, and has a long length to ensure the safe operation of the operator; the operating handle 13 is convenient for the operator to rotate the operating rod 1 when using the grounding clamp for wiring; the protective ring 14 In order to prevent the operator from extending his hand to the connecting part when the operating lever 1 is rotated, thereby causing electric shock; the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com