Under-building, under-railway and under-water mining filling process

A process and goaf technology, which is applied to filling materials, mining equipment, earth cube drilling and mining, etc., can solve the problems of low recovery rate and inability to effectively fill the goaf, and achieve high recovery rate, reasonable use of gangue, and ecological protection. Harmony with society

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

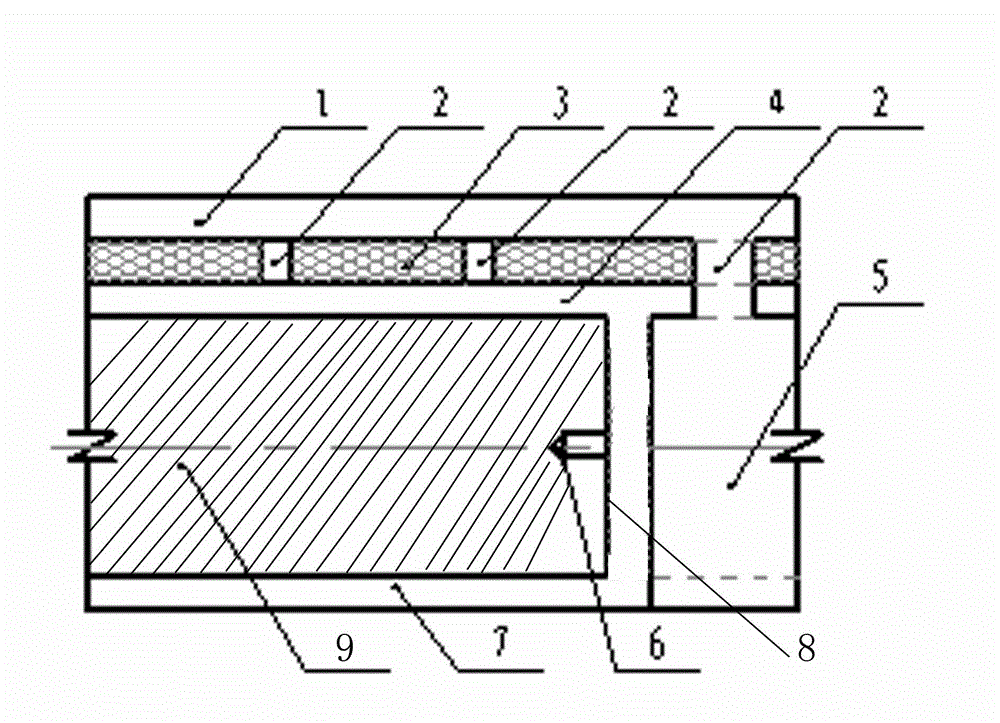

[0011] A "three-down" mining and filling process, comprising the following steps: (a) Excavating a belt return airway 4 and a track air inlet 7 on both sides parallel to the coal seam 9 to be mined; the belt return airway 4 The direction of the track air inlet lane 7 is parallel to the mining direction 6; (b) excavate a gangue return air lane parallel to the belt air return lane 4 along the side of the belt return air lane 4 that is not adjacent to the coal seam 9 to be mined 1. The coal seam between the gangue return airway 1 and the belt return airway 4 forms a coal wall; (c) mining the coal seam 9 to be mined, and at the same time between the gangue return airway 1 and the belt return airway 4 The coal wall in the middle is perpendicular to the gangue return airway 1, and the contact Hengchuan 2 connected with the goaf 5 formed after mining is excavated, and the gangue is transported to the excavated contact Hengchuan 2 through the gangue return airway 1 (d) Carry out coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com