Preparation and use method of downhole intelligent plug

A kind of rubber plug, intelligent technology, applied in the field of preparation of underground intelligent rubber plug, can solve the problems of obvious degradation and damage, poor adhesion, low strength, etc., to ensure the safety of operation, prevent upward migration, and ensure the effect of wellbore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

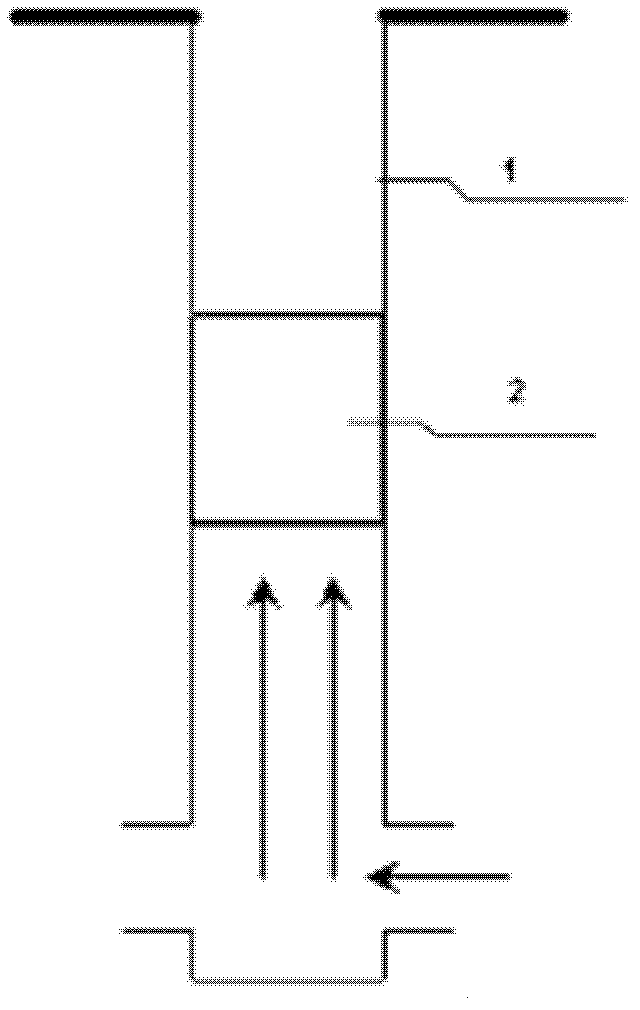

Image

Examples

Embodiment 1

[0016] The preparation method of downhole intelligent rubber plug of the present invention is as follows:

[0017] 1. Synthetic rubber stopper raw materials: 30% acrylamide and 3% sodium acrylate as raw materials, in deionized water medium, use 20% sodium hydroxide solution to adjust the pH value of the solution to 10-11, and nitrogen to remove oxygen , add 0.1% ammonium persulfate, 0.1% sodium nitrite and 0.2% disodium edetate, react at 30°C for 2 hours, then add 35% soluble starch solution, heat up to 55°C and react for 3h, Cool the discharge.

[0018] 2. Prepare the rubber stopper solution: prepare the synthesized gel into a 5% solution, add 0.5% nano-silica, and stir until completely dissolved. Add 0.3% chromium acetate to the solution, and cross-link at 80°C to form a stable gel for 15 days.

[0019] The added initiator is a mixture of potassium persulfate, sodium sulfite and sodium bisulfite, and the initiation system can generate free radicals at a relatively low temp...

Embodiment 2

[0030] Trial of Downhole Smart Rubber Plug in Ya 940 Well in Yumen Oilfield:

[0031] 1. First use the reaction furnace to synthesize the raw material of rubber stopper: use 12% acrylamide and 3% sodium acrylate as raw materials, in deionized water medium, adjust the pH value of the solution to 10-11 with 15% sodium hydroxide solution, Nitrogen was used to remove oxygen, 0.2% ammonium persulfate, 0.3% sodium nitrite and 0.2% disodium edetate were added, reacted at 30°C for 5 hours, then 16% soluble starch solution was added, and the temperature was raised to 55 °C for 3h, cooled and discharged.

[0032] 2. Prepare the rubber stopper solution: prepare the synthesized gel into a 5% solution, add 0.5% nano-silica, and stir until completely dissolved. Add 0.5% chromium acetate into the solution and inject it into the wellbore at the design position at 80°C. The construction requires a gel with stable cross-linking properties for 5 days.

[0033] Well Ya 940 had obvious oil and g...

Embodiment 3

[0035] Trial of Downhole Smart Rubber Plug in Well Ke 21-2 in Tuha Oilfield:

[0036] 1. First use the reaction furnace to synthesize the raw material of the rubber stopper: use 10% acrylamide and 5% sodium acrylate as raw materials, in deionized water medium, adjust the pH value of the solution to 6-8 with 15% sodium hydroxide solution, Nitrogen was used to remove oxygen, 0.3% ammonium persulfate, 0.4% sodium nitrite and 0.2% disodium edetate were added, reacted at 30°C for 2 hours, then 10% soluble starch solution was added, and the temperature was raised to 80 ℃ reaction 2h, cooling discharge.

[0037] 2. Prepare the rubber stopper solution: prepare the synthesized gel into a 5% solution, add 0.8% nano-silica, and stir until completely dissolved. Add 0.6% chromium acetate into the solution and inject it into the wellbore at the design position at 80°C. The construction requires cross-linking to form a stable gel for 4 days.

[0038] After the downhole smart rubber plug wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com